Automatic system for IML injection molding

An automated system and sheet technology, applied in the field of automated systems, can solve problems such as hidden safety hazards, low safety systems, and burrs on the cut surface of the plastic mouth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

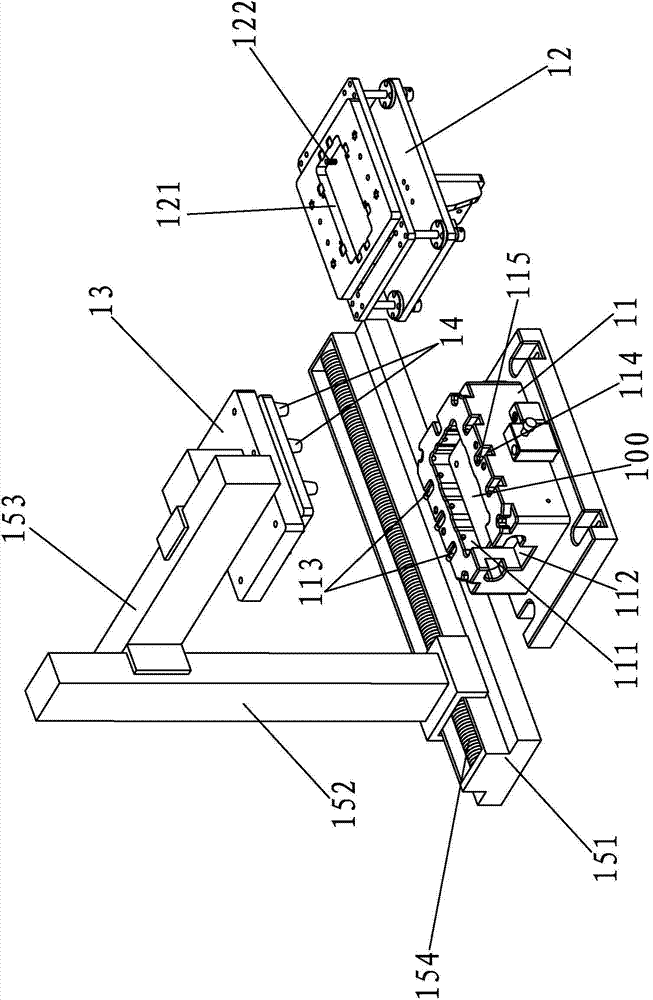

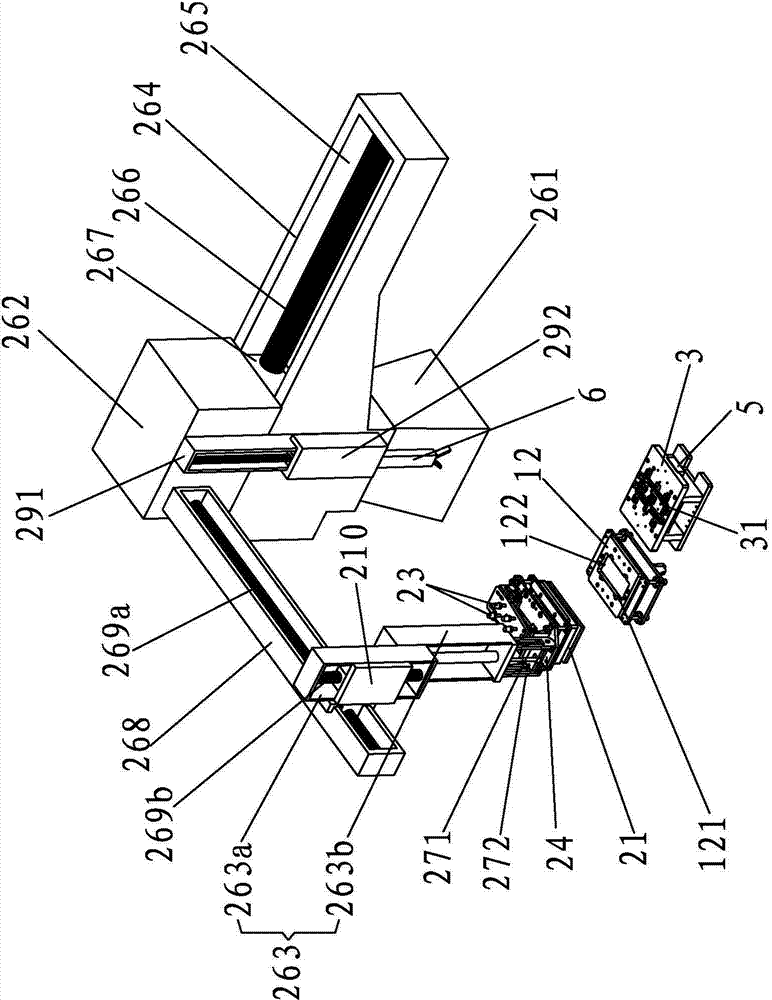

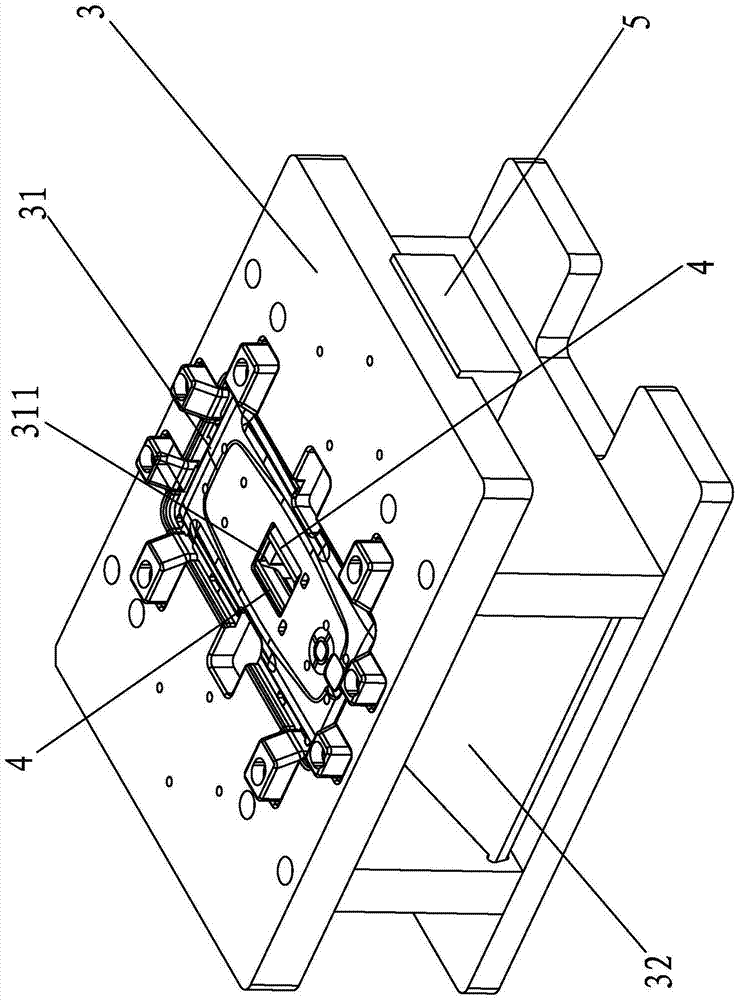

[0022] A kind of IML injection molding automation system of the present invention, as Figure 1-5 As shown, it includes a sheet storage mechanism, a sheet transfer mechanism and a cutting seat at the feed port; among them,

[0023] The sheet storage mechanism has a sheet access seat 11 for storing a stack of film sheets, and a sheet storage seat 12 behind the sheet access seat 11 for storing a film sheet. , and a sheet suction and release device that can take out a film sheet on the sheet access seat and place it on the sheet storage seat; the sheet access seat 11 is a square block, and the top of the sheet access seat 11 There is an accommodating cavity 111 for storing a stack of film sheets in the concave surface, and there is a lifting device (not shown in the figure) in the accommodating cavity 111 to lift up a stack of film sheets. The jacking device is a jacking cylinder, and the cylinder body of the jacking cylinder is fixed at the bottom of the accommodating cavity 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com