Container and cover

A container and container body technology, applied in transportation, packaging, closing, packaging, etc., can solve problems such as large errors, troublesome volume precision measurement operations, and problems that are easily overlooked by people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

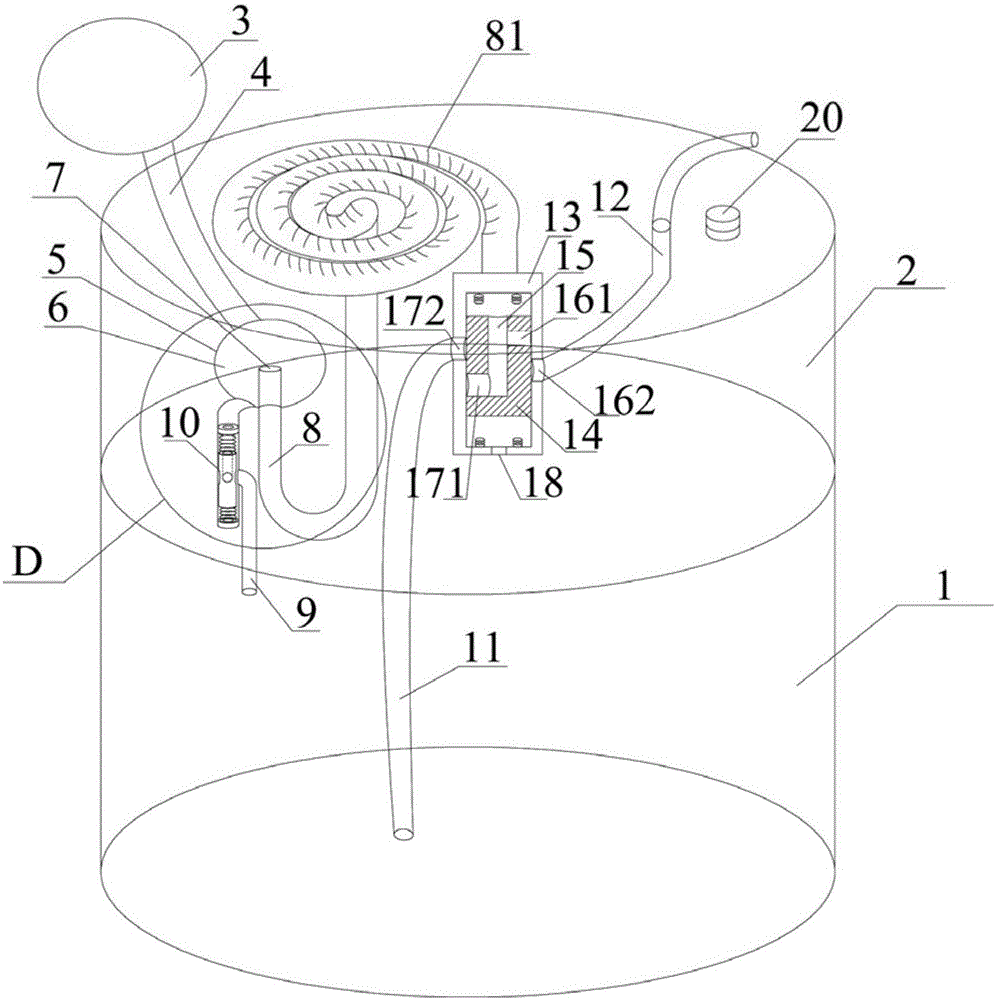

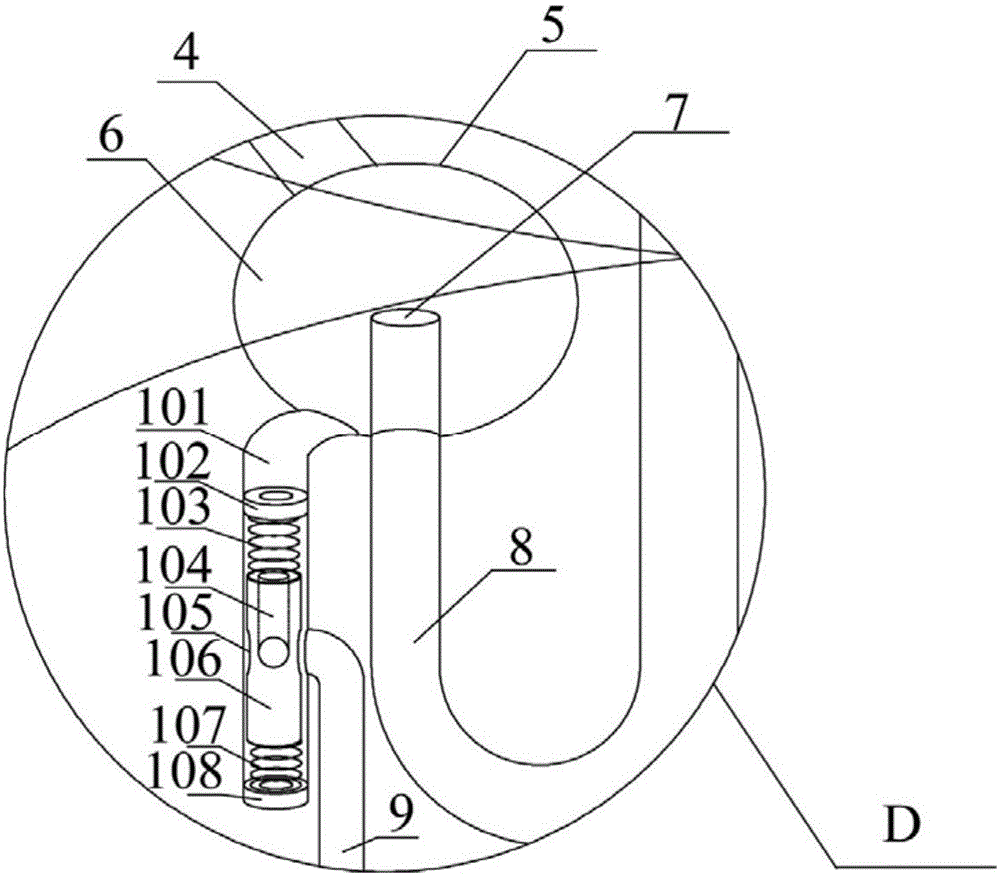

[0045] Such as figure 1 with figure 2 Shown is a container using the initial positioning system of the present invention according to Embodiment 1. The container as a whole includes a container body 1 and a top cover 2, and the upper part of the container body 1 is the top cover 2. The container body 1 contains most of the contents. Other components including variable pressure components, initial positioning device, metering channel 8, liquid taking channel 11, outflow channel 12 valves, etc. are all installed and fixed on the top cover 2. The top cover 2 also has a check valve 20 which only allows liquid and gas to enter the container body 1.

[0046] The pressure-changing component is a component that can pressurize and depressurize the reflux cavity 6, and includes an air bag 3 and a pressure-changing channel 4. The airbag 3 is located above the top cover 2 and is fixed on the top cover 2 through the pressure-changing channel 4. The initial positioning device includes a re...

Embodiment 2

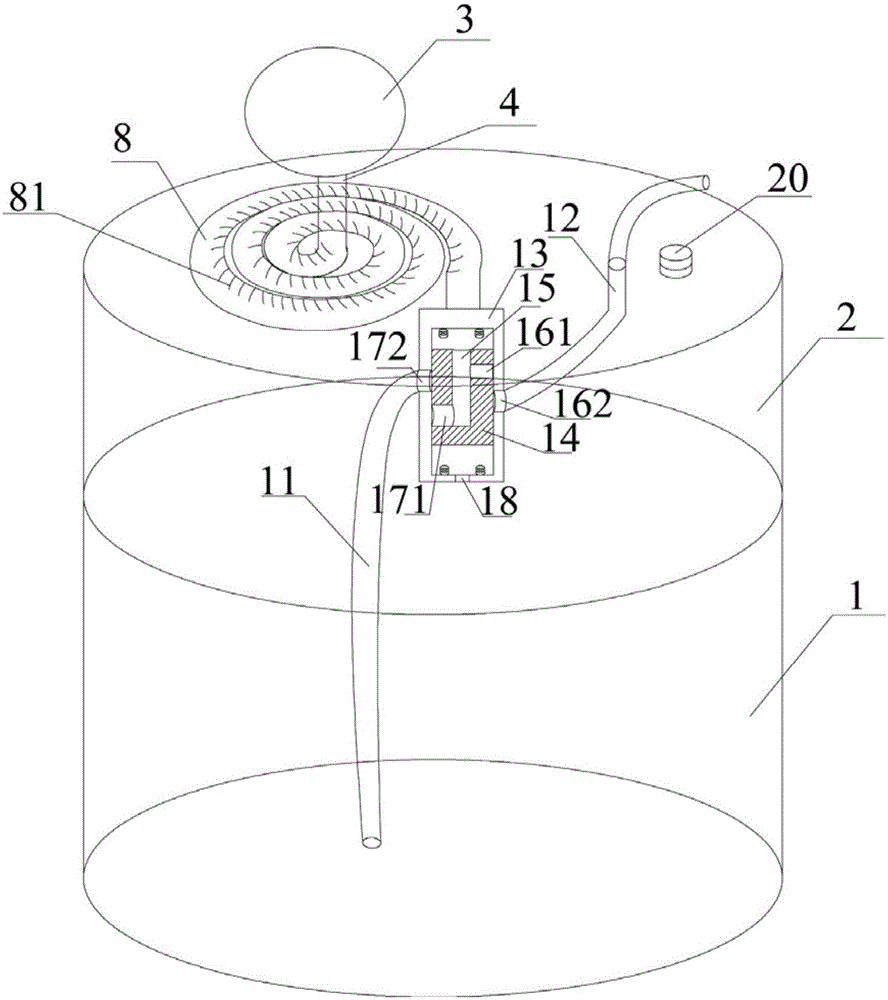

[0062] Such as image 3 Shown is a container according to the second embodiment. Compared with Embodiment 1, the container does not use the initial positioning device, and the pressure-changing channel 4 of the pressure-changing component is directly connected with the metering channel 8. The container also includes a container body 1 and a top cover 2 as a whole, and the upper part of the container body 1 is the top cover 2. Other components including variable pressure components, metering channel 8, liquid taking channel 11, outflow channel 12 valves, etc. are all installed and fixed on the top cover 2. The top cover 2 also has a check valve 20.

[0063] The initial section of the metering channel 8 communicates with the variable pressure channel 4, the middle section is a metering section with a metering scale 81, and the end is connected to a control valve composed of a valve body 13 and a spool 14 and communicates with the middle channel 15 in the spool 14. The valve body ...

Embodiment 3

[0068] Such as Figure 4 , Figure 5 Shown is a container using the initial positioning system of the present invention according to Embodiment 3. The container as a whole includes a container body 1 and a top cover 2, and the upper part of the container body 1 is the top cover 2. The container body 1 contains most of the contents. Other components including variable pressure components, initial positioning device, metering channel 8, liquid taking channel 11, outflow channel 12 valves, etc. are all installed on the top cover 2. The top cover 2 also has a check valve 20 which only allows liquid and gas to enter the container body 1.

[0069] The pressure-changing component is a component that can pressurize and depressurize the reflux cavity 6, and includes an air bag 3 and a pressure-changing channel 4. The airbag 3 is located above the top cover 2 and is fixed on the top cover 2 through the pressure-changing channel 4. The initial positioning device includes a return cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com