Device for wrapping groups of filter segments with a wrapping material for producing multi-segment filters of the tobacco industry and multi-segment filter production device

A technology for encapsulating materials and production devices, which is applied in the manufacture of cigarettes, tobacco, and applications, and can solve problems such as diameter changes, filter segment damage, and disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the following description of the drawings, part of the same components are denoted by the same symbols, and thus repeated descriptions are omitted.

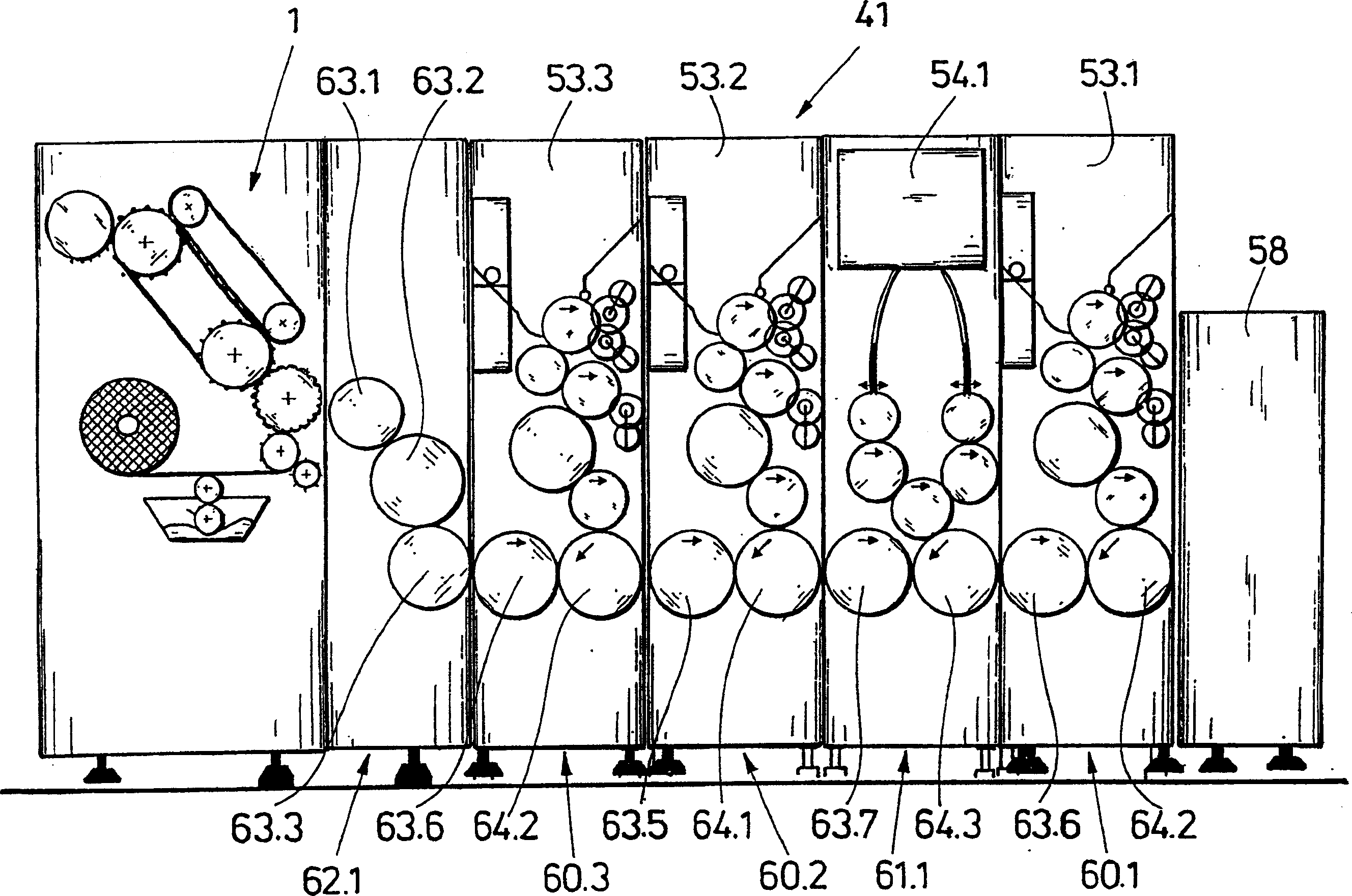

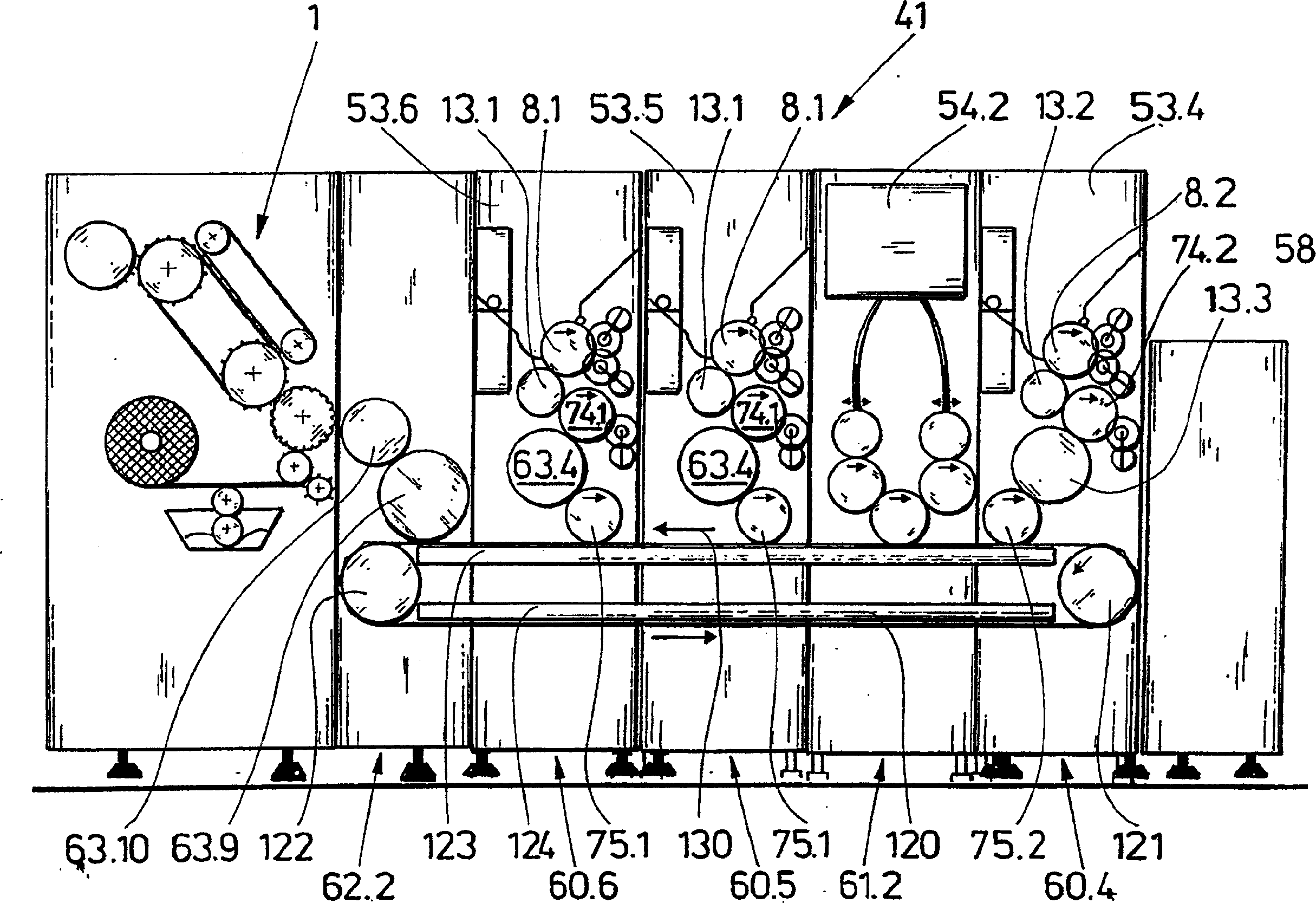

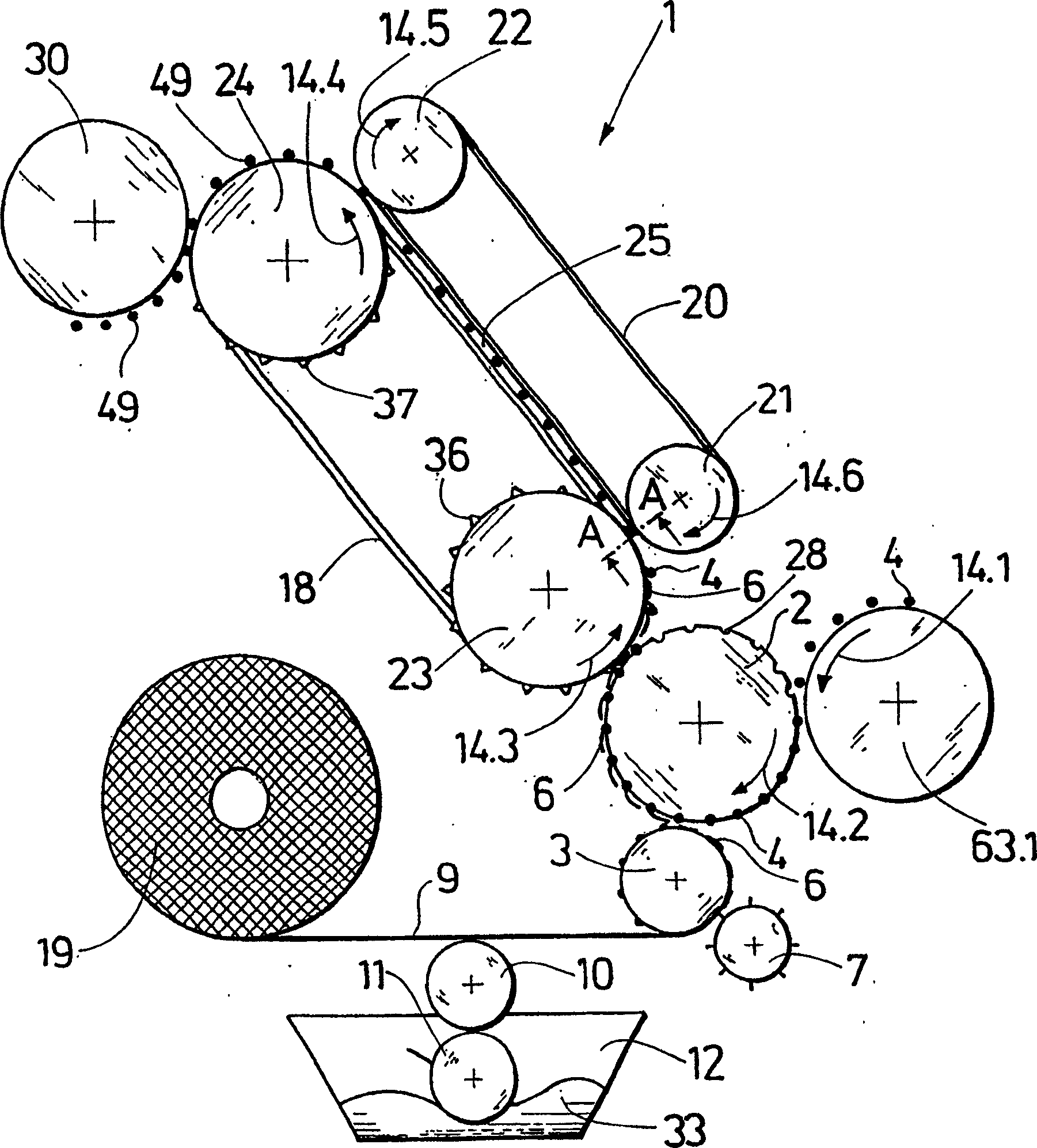

[0043] exist figure 1 The multi-segment filter production apparatus of the present invention is shown in , which has a combining mechanism for combining groups of filter segments to produce multi-segment filters. It can be a grouping mechanism 41 , but here the separate functional units 60.1-60.3, 61.1 are used. Functional units 60.2, 60.3 are software units by means of which two separate filter segments are conveyed (FIG. 5a), wherein functional unit 60.1 is a software unit by which a single filter segment is conveyed. Filter plugs or single filter segments with twice the service length. Functional unit 61.1 is a hardware unit. Storage containers 53.1-53.3 and 54.1 are respectively provided in these functional units, and of course, software storage containers 53.1-53.3 are provided in software units 60.1-60.3, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com