Connecting joint construction

A technology for connecting joints and structures, applied in sleeve/socket connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as lock nut looseness, achieve loosening prevention, reliable connection, and improve workability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

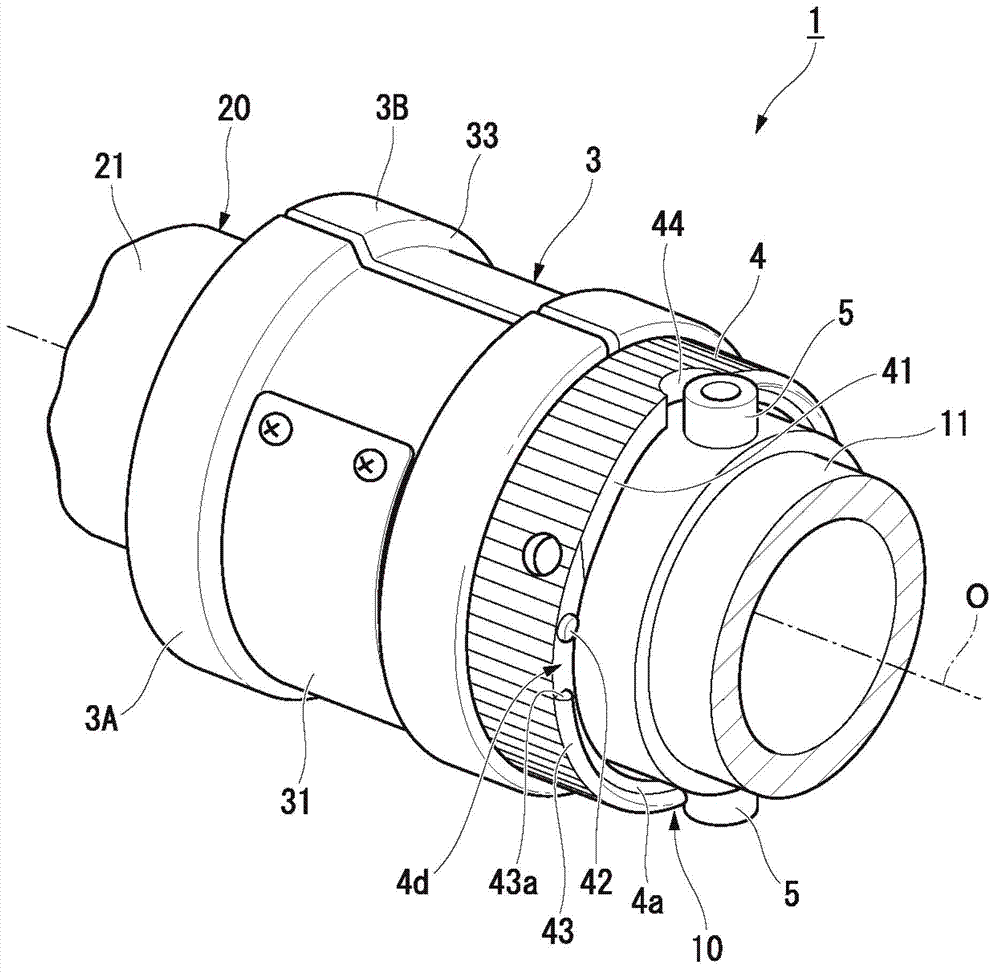

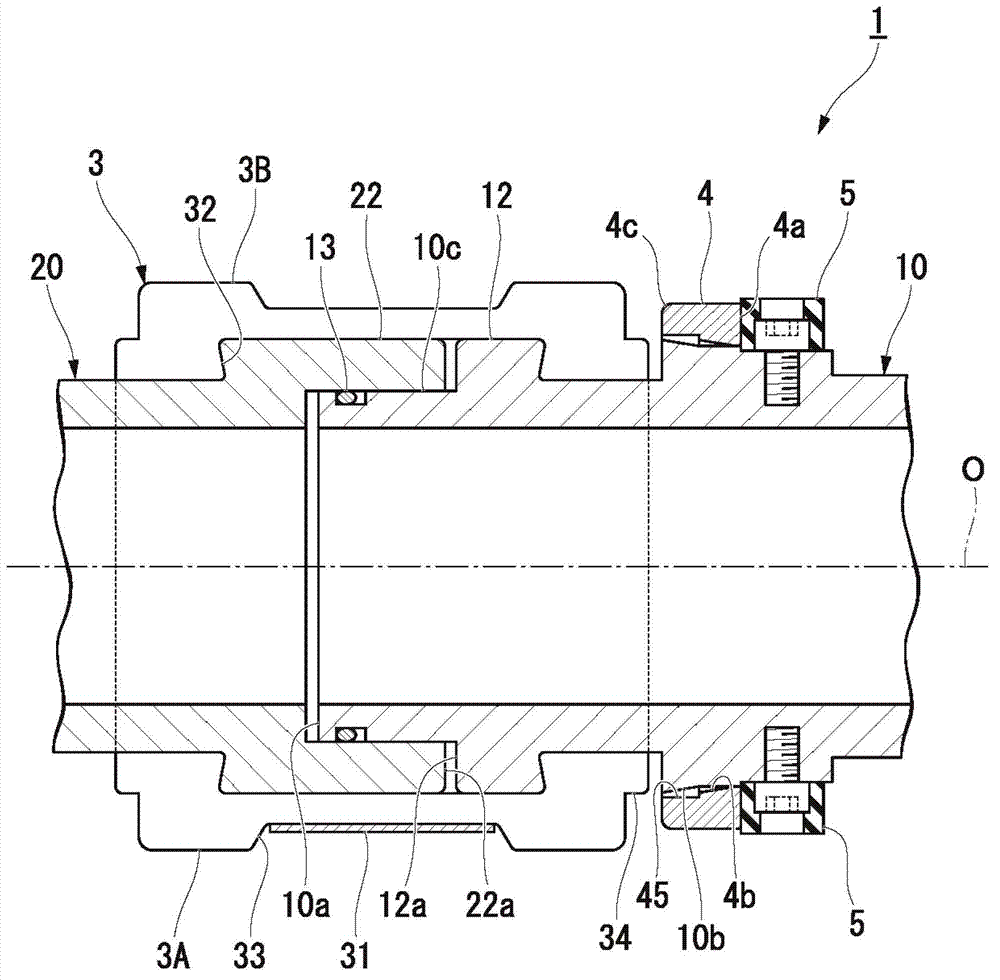

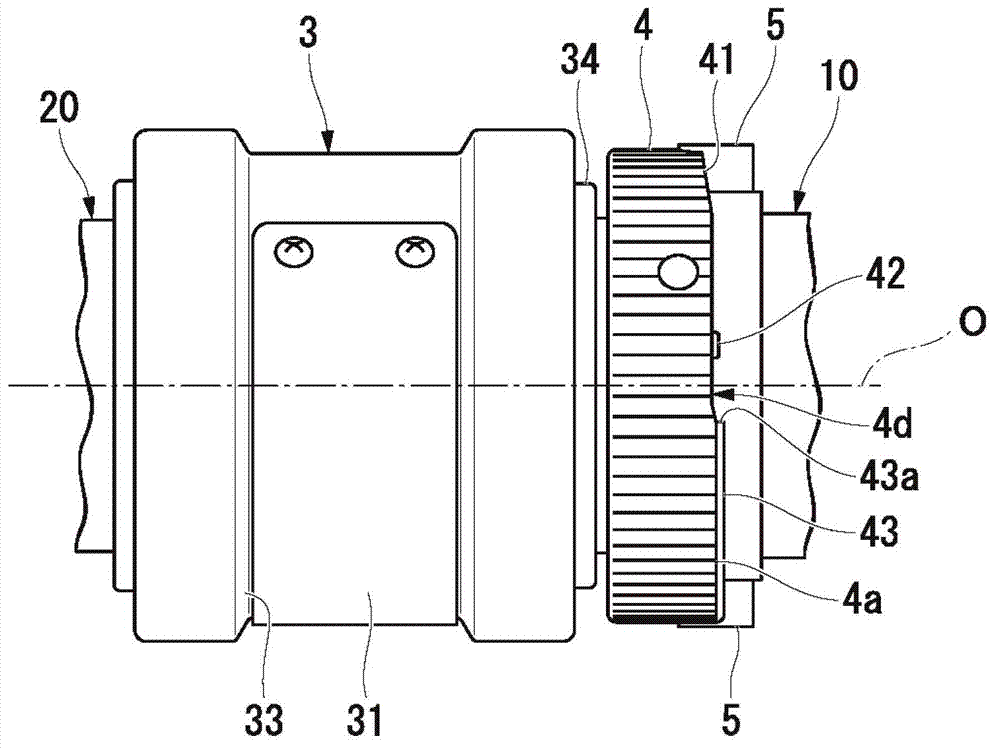

[0045] Such as figure 1 and figure 2 As shown, the connecting joint structure 1 of this embodiment is a structure for firmly connecting the male joint 10 (first joint) and the female joint 20, and the male joint 10 (first joint) is overlaid on the first hydraulic pipe 11 ( pipe body), the female joint 20 is overlaid on the end of the second oil pressure pipe 21 (pipe body).

[0046] In addition, the above-mentioned male joint 10 (first hydraulic pipe 11 ) and female joint 20 (second hydraulic pipe 21 ) are arranged such that their respective central axes are located on a common axis. In the present embodiment, the common axis is referred to as the piping axis O, the direction perpendicular to the piping axis O is referred to as the radial direction, and the direction around the piping axis O is referred to as the circumferential direction. In the male joint 10 and the female joint 20 , the connection side along the pipe axis O direction is referred to as the distal end side, ...

no. 2 Embodiment approach

[0074] Such as Figure 8 shown, replace figure 2 The structure of the above-mentioned first embodiment for connecting the male joint 10 and the female joint 20 is shown, and the connecting joint structure 1A of the second embodiment is suitable for connecting the nozzles and nozzles on the coaxial line by using the intermediate joint 6 (second joint). The structure between male joints 10A, 10B (first joints) connected by 14A, 14B.

[0075] The male joints 10A and 10B have the same structure as the male joint 10 in the first embodiment described above, and detailed description thereof will be omitted here.

[0076] The intermediate joint 6 includes: a main body 61 at the center in the direction of the pipe axis O; and female-side locking rings 62 provided on both sides of the main body 61 and capable of being inserted and fitted in the male joints 10A, 10B. In the outer peripheral edge portion 10c. Here, the male connector of reference numeral 10A (in Figure 8 The connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com