Method for pulling out embedded bushing

The technology of a bushing and an upper sleeve is applied in the field of the electric pull-out hole containing the workpiece, which can solve the problems of deformation of the bushing and the workpiece, and achieve the effects of avoiding deformation or damage, good effect and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

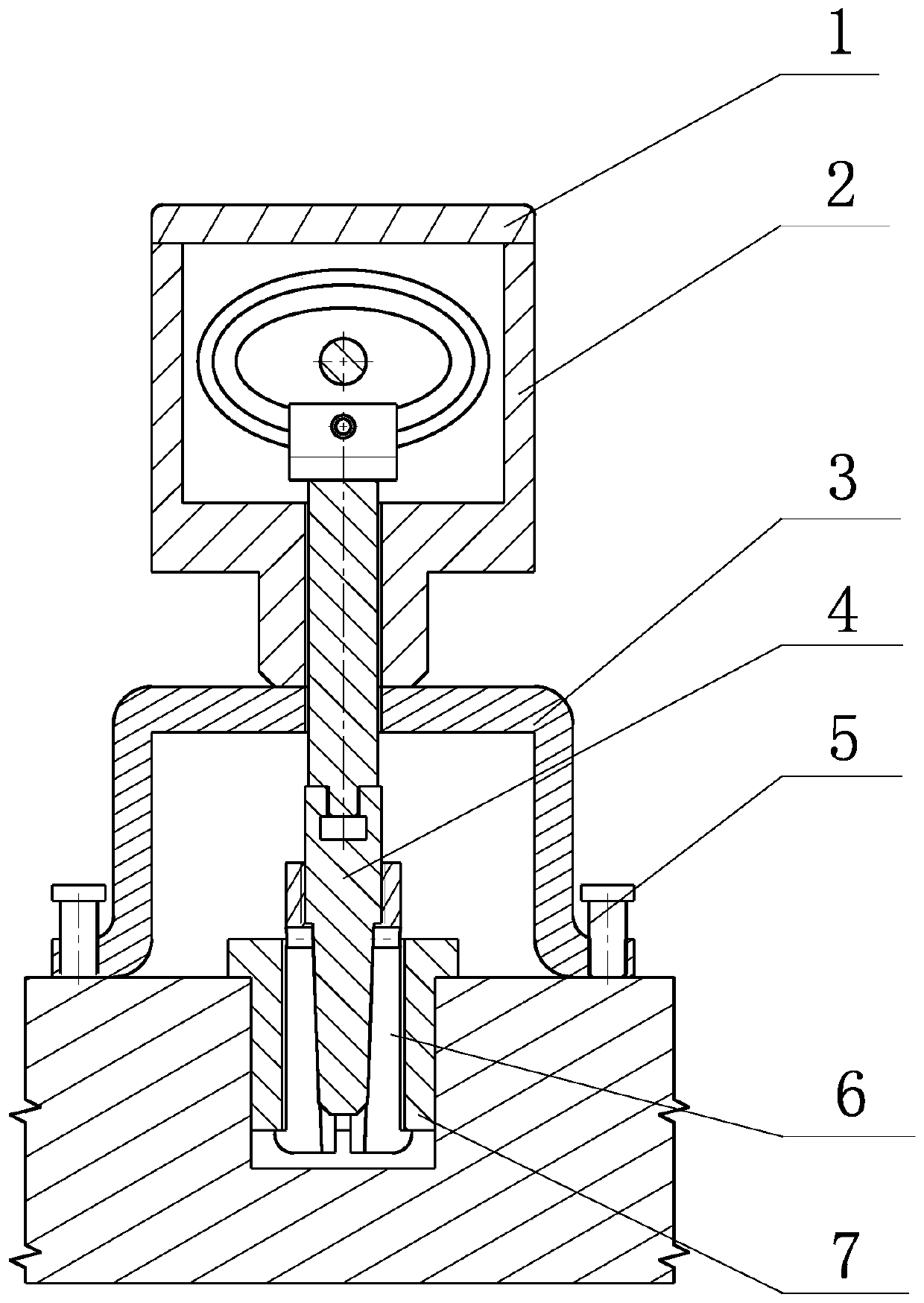

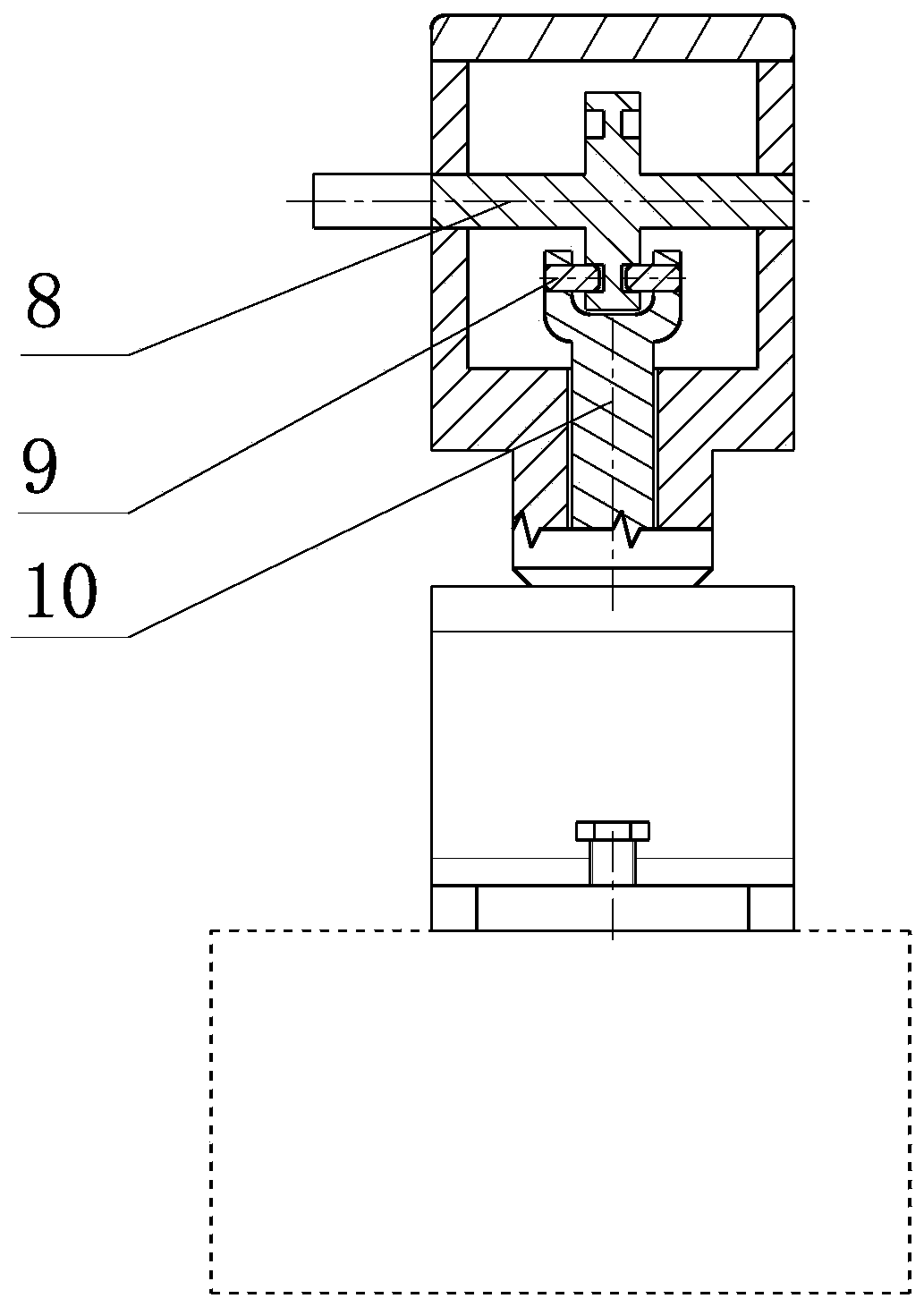

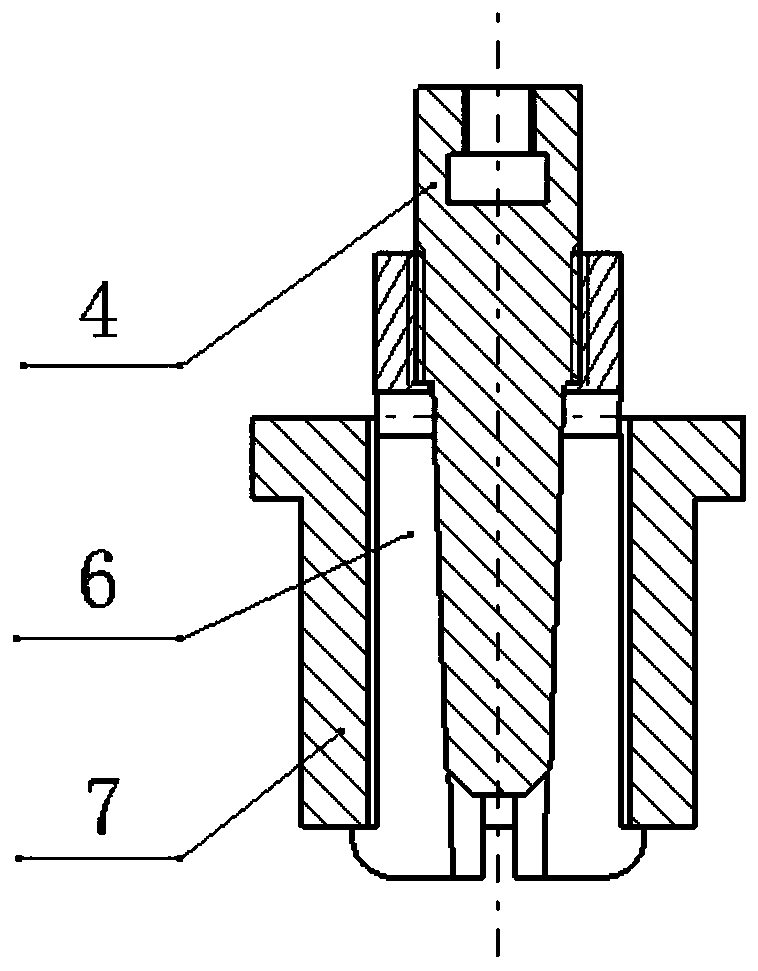

[0019] refer to Figure 1-Figure 5. According to the present invention, one prepares a pulling rod 10 that is inserted into the lower end step cylinder of the upper cover power cabin 2, the brim opening pressure seat 3 that can be fixed on the working surface of the workpiece bushing 7 and can be fixed along the inner wall of the workpiece bushing 7 It is inserted into the bottom end face of the workpiece hole, and is formed with an elastic expansion sleeve 6 with symmetrical opening grooves and end-bottom shackles, and a cam rotation shaft 8 assembled transversely through the cavity of the power cabin 2 of the upper cover. There is an opening groove connecting the short axis of the elliptical ring 11, and the other end is formed with a step buckle connecting the conical guide opening rod 4 gap groove; the elastic expansion sleeve 6 is radially contracted and inserted into the inner diameter of the workpiece bushing 7, and the rod 10 is pulled out Connect the conical guide op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com