Sliding connecting piece between steel member and concrete

A sliding connector and concrete technology, applied in the direction of building structure, construction, etc., can solve the problems of reducing the sliding capacity and working reliability of the connector, and achieve the effect of avoiding concrete cracking, avoiding damage and deformation, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

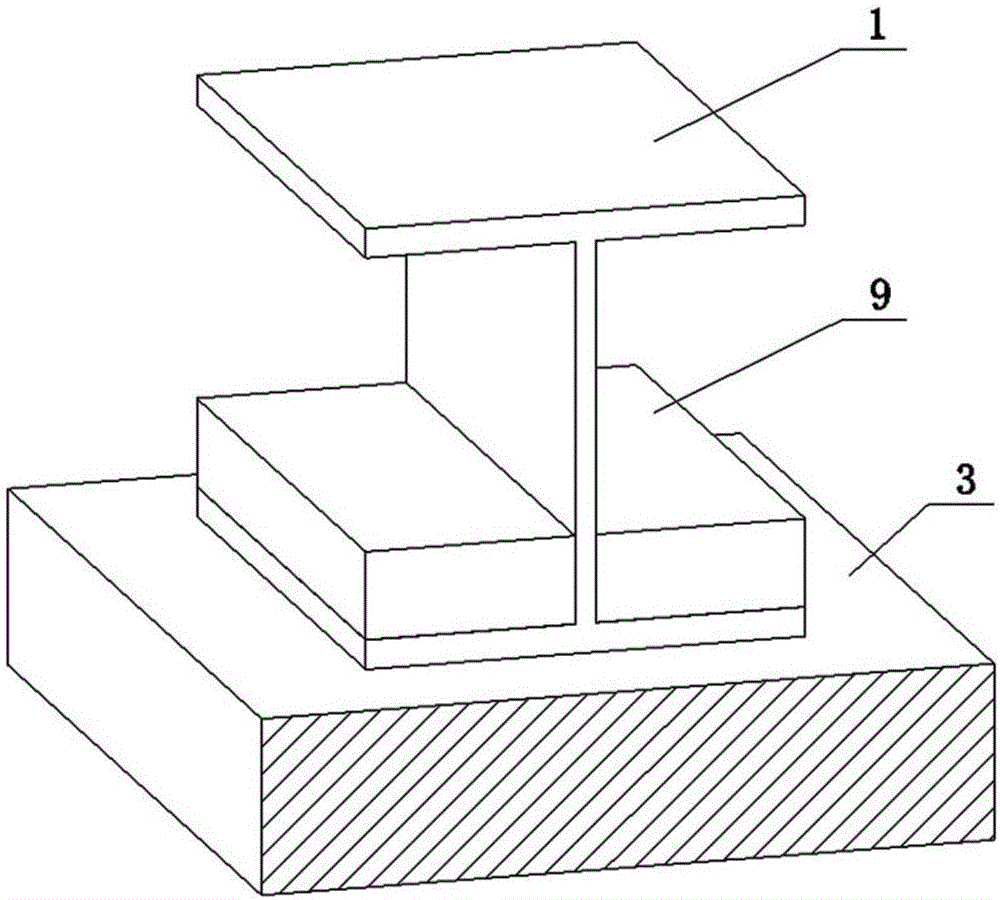

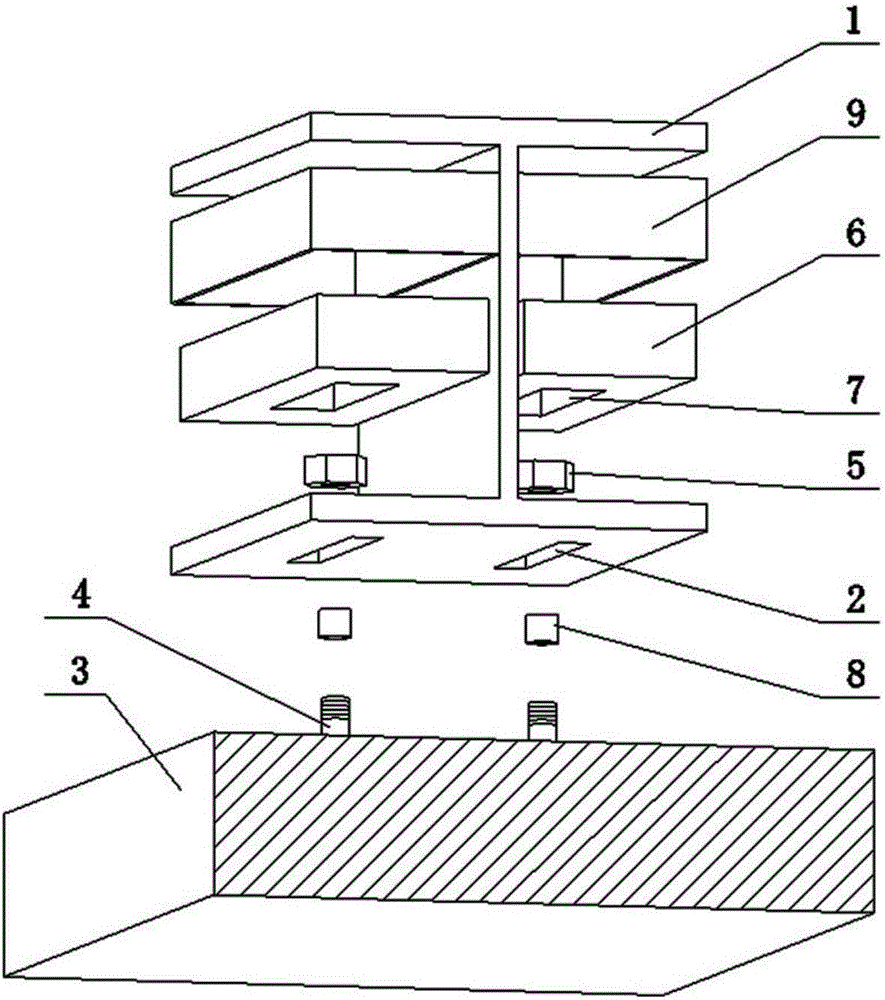

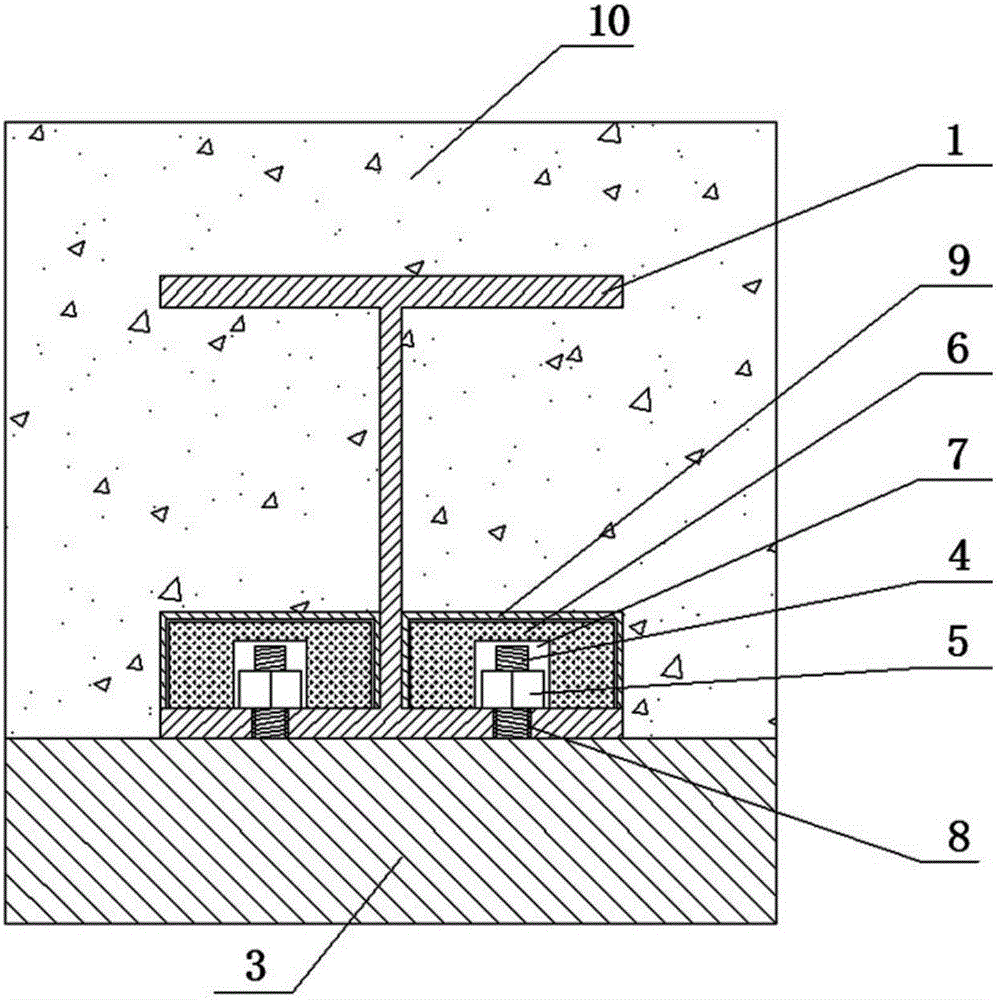

[0019] as attached figure 1 and figure 2 As shown, a sliding connection between a steel member and concrete includes an anchor 1 fixed in a concrete body 10, and at least one strip-shaped hole 2 is provided on the base of the anchor 1. In this embodiment, The anchor 1 is an I-shaped structure, and one strip-shaped hole 2 is provided on both sides of its base. Each of the strip-shaped holes 2 is provided with a bolt 4 fixed on the steel member 3 by welding or other means and a nut 5 matched with the bolt 4, and each of the bolts 4 is provided with a nut limit sleeve 8. Avoid the problem of losing the sliding connection function due to the nut 5 being pressed too tightly on the base of the anchor 1. At the same time, the nut 5 can be tightened on the nut limit sleeve 8 to avoid the separation of the steel member 3 and the concrete due to the loosening of the nut 5 qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com