Auxiliary tool for reserving hole

An auxiliary tool and a technology of reserved holes, which are applied in the field preparation of formwork/formwork/work frame, building components, construction, etc. Cracking and other problems, to achieve good waterproof performance, prevent concrete cracking, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

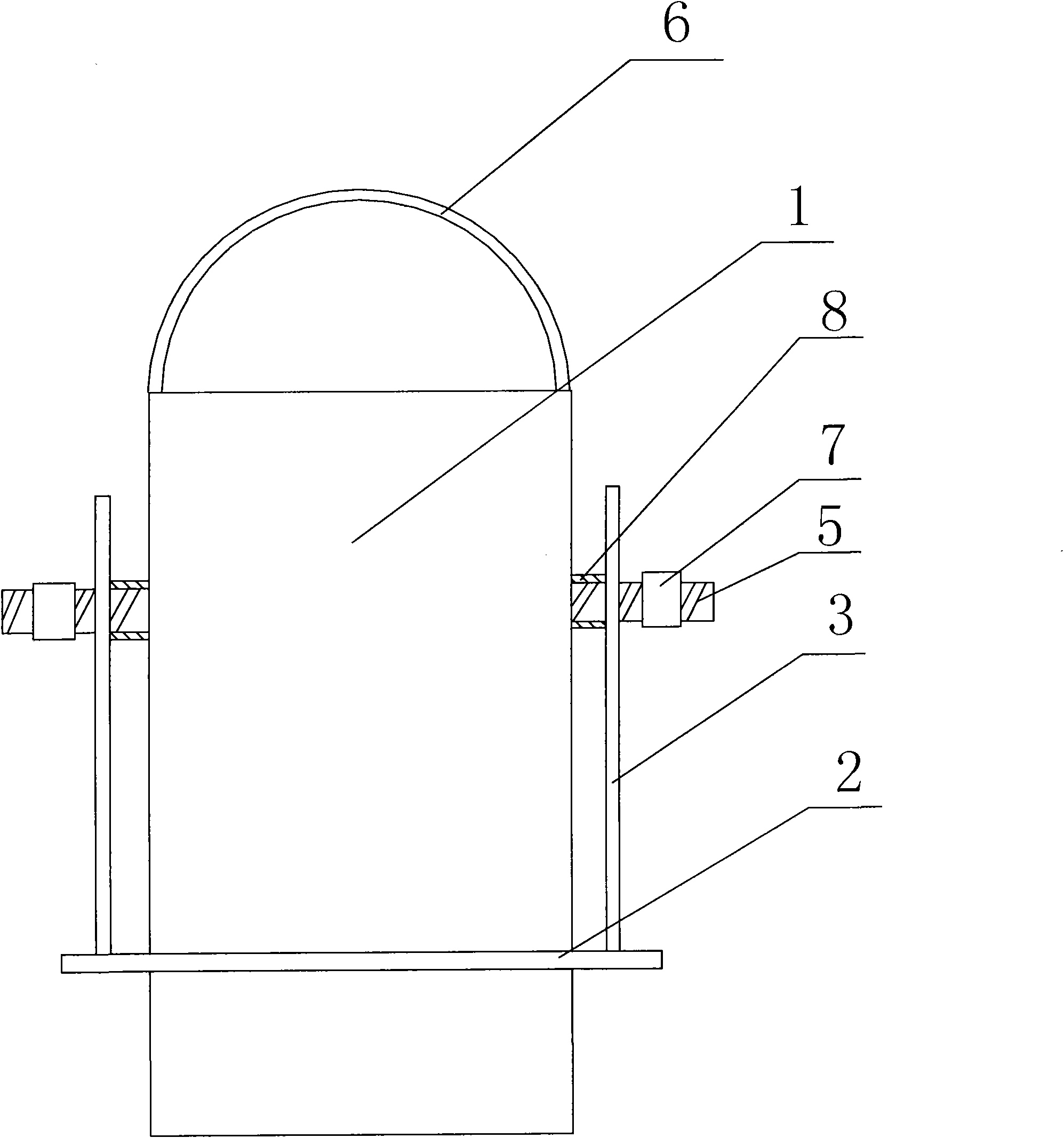

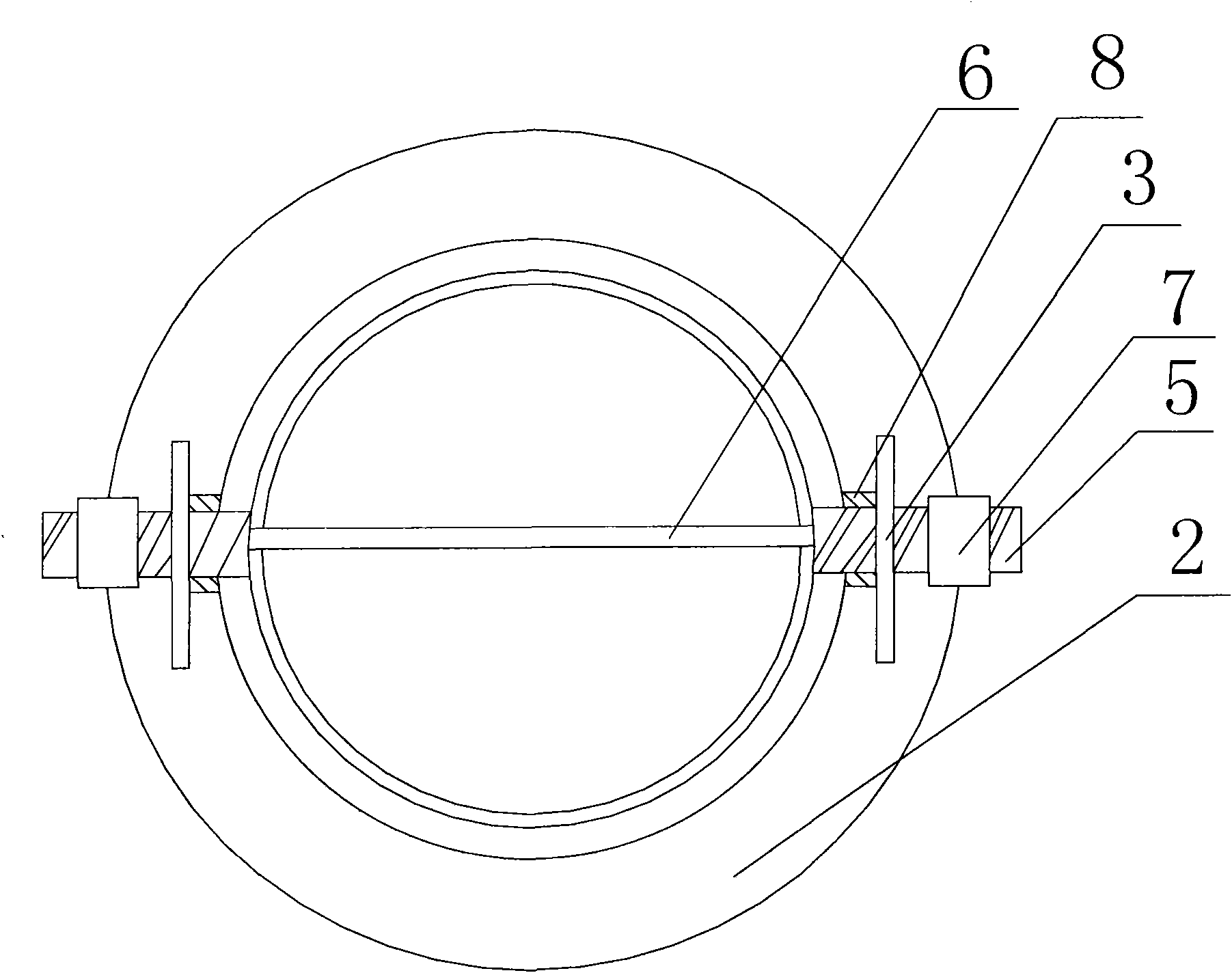

[0016] like Figure 1-3 As shown, the auxiliary tool for reserving holes includes a cylindrical cylinder body 1, a circular baffle plate 2 and two connecting plates 3 symmetrically arranged with respect to the cylinder body 1, and the baffle plate 2 is set on the cylinder body 1 according to the shape of the cylinder body 1. At the bottom of the cylinder body 1, one end of the connecting plate 3 is fixedly connected with the baffle plate 2 by welding, and the other end is fixed on the cylinder body 1 through the bolt 5 and the nut 7, and the connecting plate 3 is also provided with a baffle plate 2 to move up and down. track 4; in order to facilitate the operation, a handle 6 is also provided on the top of the cylinder body 1, after adjusting the height of the baffle plate 2, it is convenient to fix its height, and a gasket 8 is also provided between the connecting plate 3 and the cylinder body 1, The washer 8 is sleeved on the bolt 5. In order to be recyclable and cost-saving...

Embodiment 2

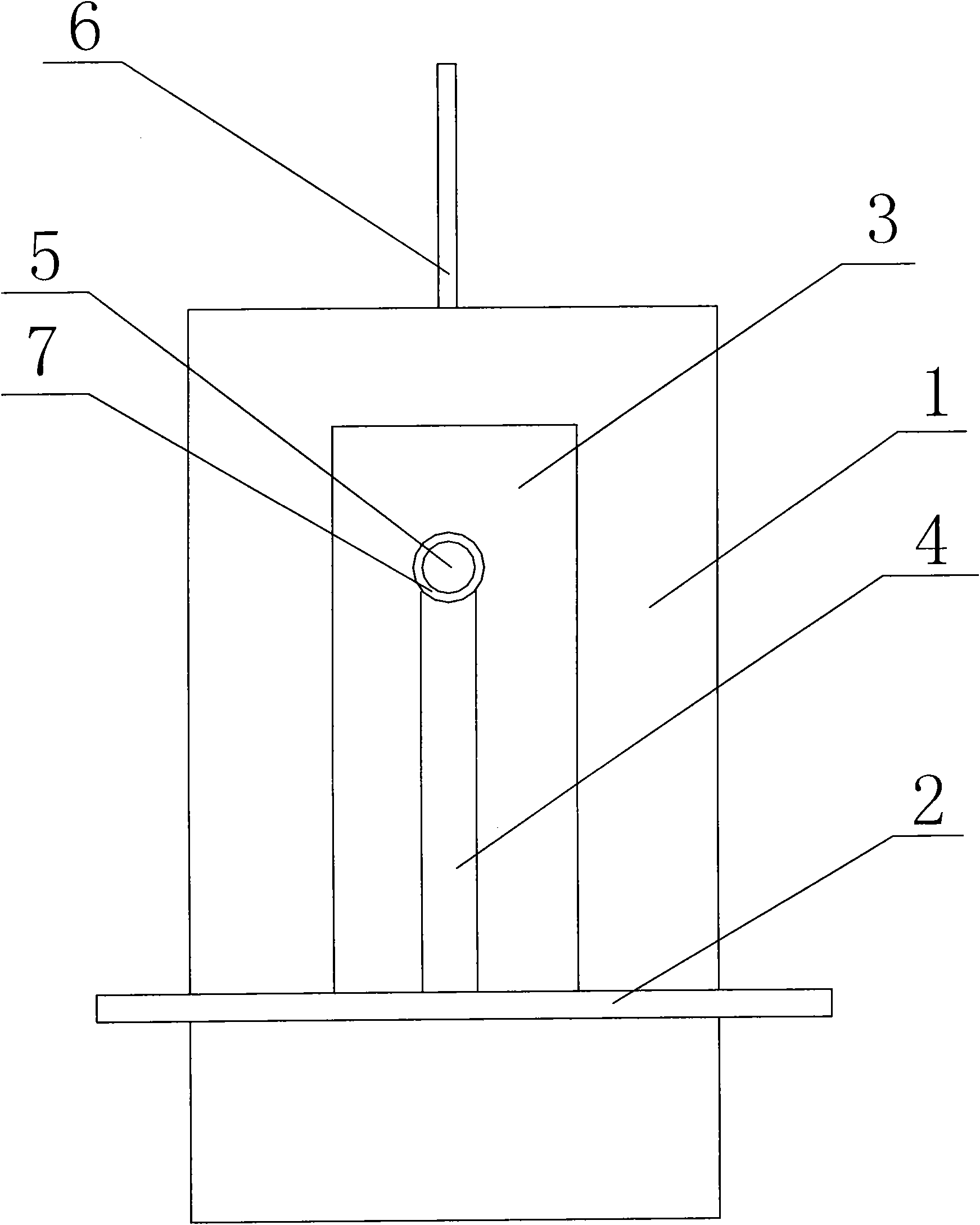

[0019] like Figure 4 As shown, the cylinder body 1 and the baffle plate 2 of the auxiliary tool with reserved holes can also be of square structure. The other structures of this embodiment, the relationship between each structure and the beneficial effects achieved are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com