Method for detecting cross-section profile by utilizing two-dimensional measuring machine

A two-dimensional measurement and cross-sectional profile technology, applied in the field of mechanical processing, can solve the problems of long detection time, high detection cost, and abnormal processing, etc., and achieve the effect of short detection time and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

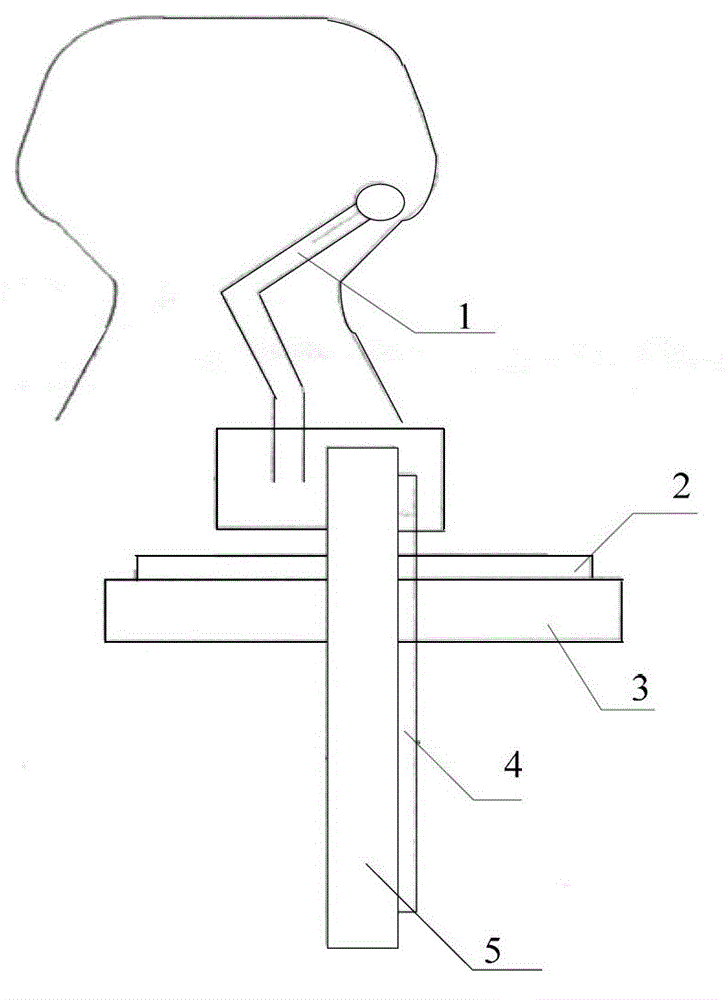

[0025] A method for detecting the profile degree of a section using a two-dimensional measuring machine, such as figure 1 As shown, the method adopts a two-dimensional measuring machine, and a horizontal grating ruler 2 is arranged on the transverse guide rail 3 of the two-dimensional measuring machine, a longitudinal grating ruler 4 is arranged on the longitudinal guide rail 5, and the spherical measuring head 1 contacts the measured Section, and the position information of the spherical probe is collected through the grating ruler. In the embodiment of the present invention, the model of the two-dimensional measuring machine is SCM_0001, and the grating ruler is an open grating ruler of the HEIDENHAIN brand.

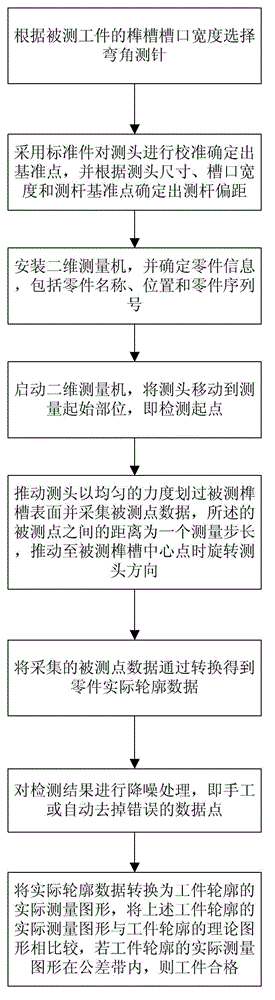

[0026] Specific steps such as figure 2 shown, including:

[0027] Step 1. Select the angled stylus according to the width of the tongue a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com