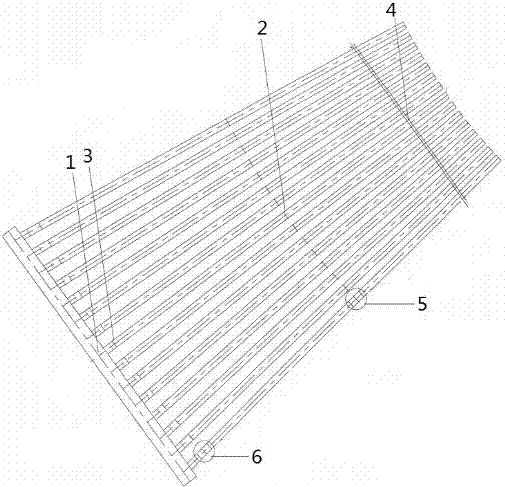

Isolation and protection structure of profile steel anchoring system of suspension bridge

A technology of protective structure and anchoring system, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as failure to perform sealing and waterproofing, cracking of anti-corrosion coating of anchor rods, affecting service life, etc., to avoid concrete cracking, excellent Sealing effect, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

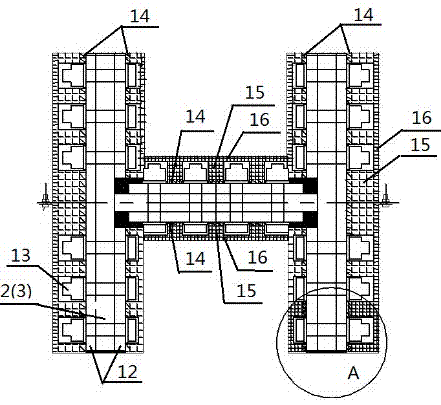

[0041] Embodiment 1: The construction process of the isolation protective coating of the steel anchorage system of the suspension bridge is as follows:

[0042] ⑴Isolate and protect the front and rear bolts in the factory: first, clean the outer surface of the bolt so that the anti-corrosion coating of the bolt should be free of oil, water, dirt, rust and other soluble salts; then Apply vulcanized rubber sealant on the outer surface of the anchor rod (except the friction surface). The mold area can be used, and the sealant is scraped to a thickness of 1mm at a time, and the dry film thickness is 1mm; after the sealant coating is dry, it will be cut The polyethylene foam material is gently pasted on the sealant coating, and the pasting operation time is controlled within 30 minutes. The thickness of the polyethylene foam material is 4 mm; finally, 4 μm polypropylene pressure-sensitive adhesive is pasted before pouring concrete. bring.

[0043] ⑵Isolate and protect the joints o...

Embodiment 2

[0047] Embodiment 2: The construction process of the isolation protective coating of the steel anchorage system of the suspension bridge is as follows:

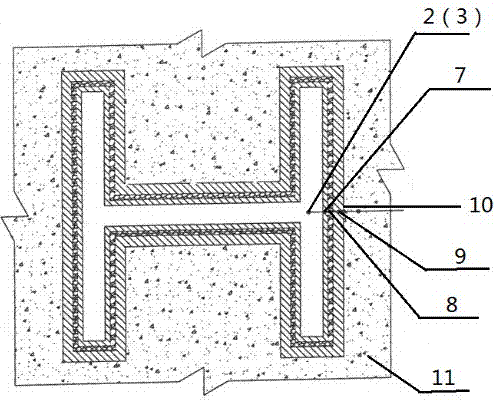

[0048] ⑴Isolate and protect the front and rear bolts in the factory: if figure 2 As shown, first clean the outer surface of the bolt so that the degree of purification of the anti-corrosion coating of the bolt should be free of oil, water, dirt, rust and other soluble salts; then clean the outer surface of the bolt (except the friction surface) Outside) apply silane-modified polyether sealant, you can use the mold area, scrape 1mm thick sealant at a time, the dry film thickness is 5mm; Paste lightly on the sealant coating, the pasting operation time is controlled within 30min, the thickness of the polyethylene foam material is 8mm; finally, a 6μm thick polypropylene pressure-sensitive adhesive tape is pasted before pouring concrete, the pressure-sensitive adhesive The adhesive tape can be a plastic film.

[0049] ⑵Isolate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com