Connecting structure of asynchronous cantilever construction steel-concrete joint part and construction method thereof

A joint and cantilever technology, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve problems such as cracks in the concrete roof, and achieve the effect of avoiding concrete cracking, ensuring project quality, and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples of implementation.

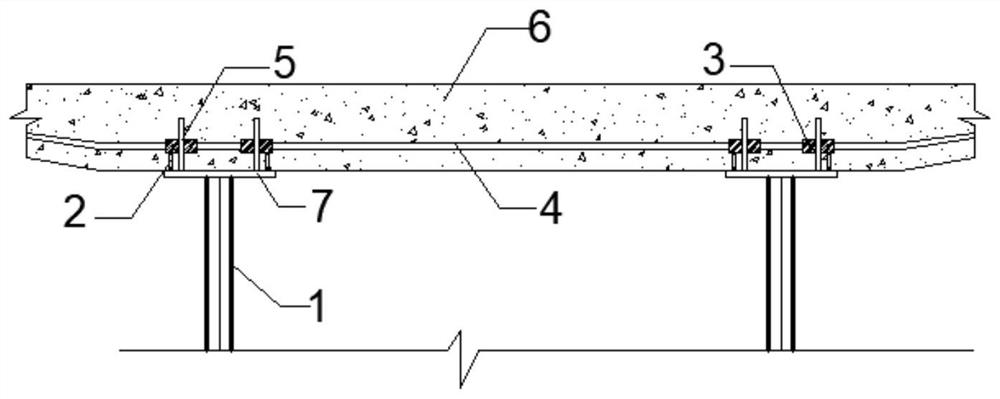

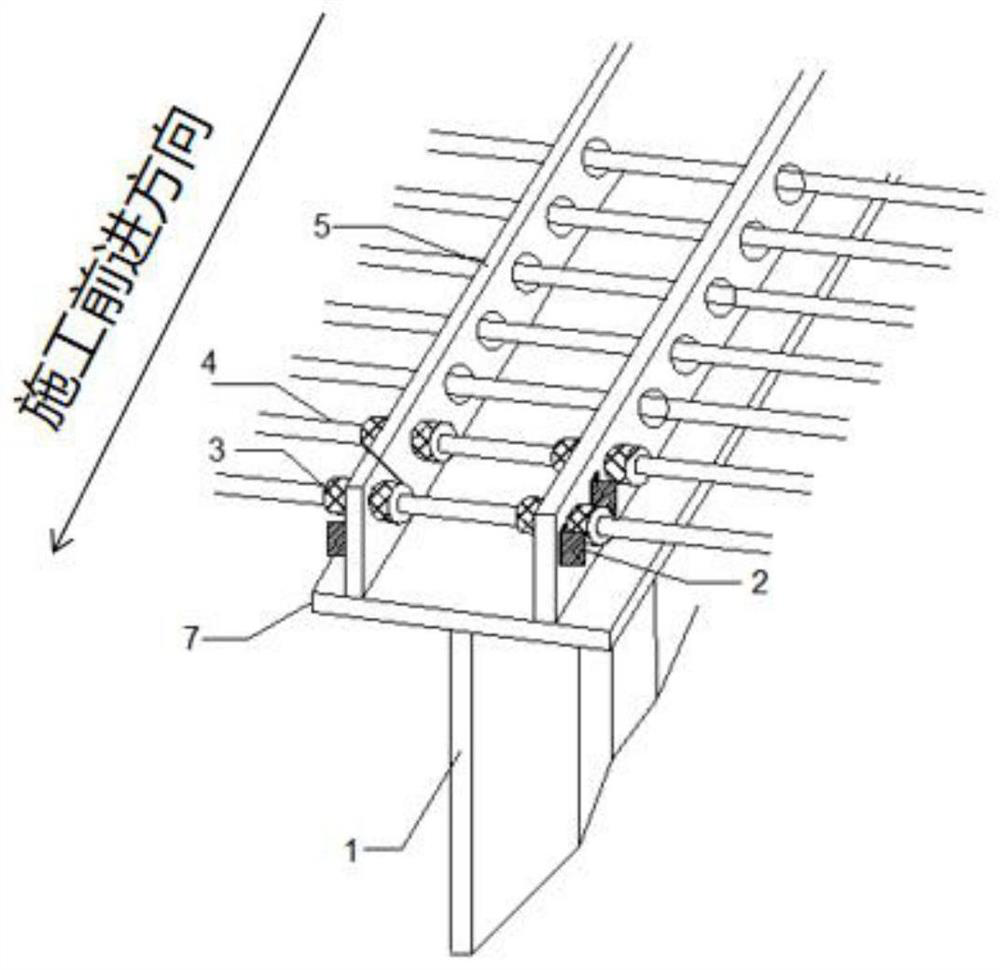

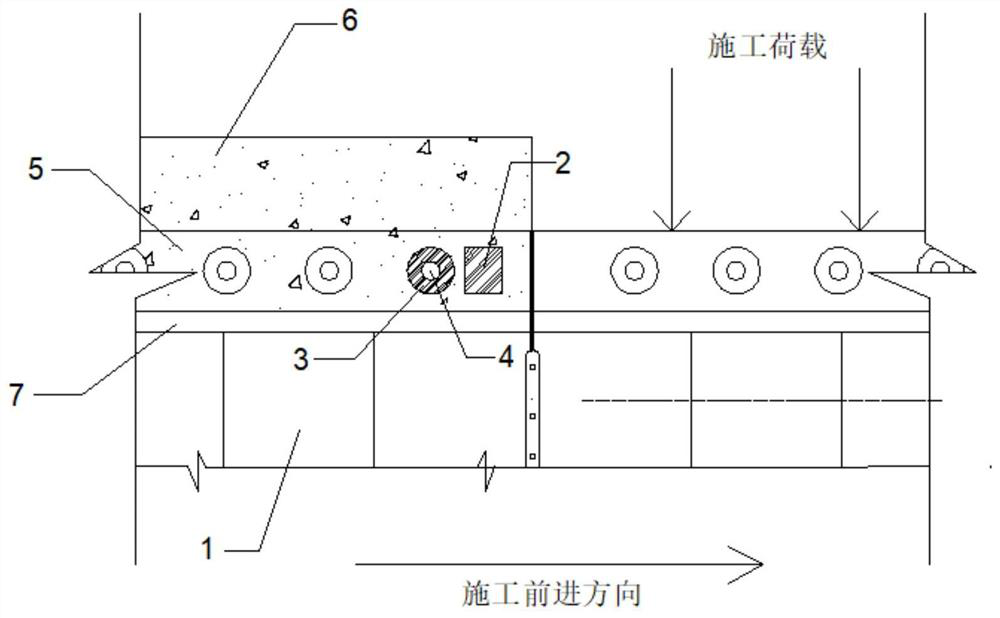

[0024] Such as figure 1 , figure 2 , as shown, a connection structure of steel-concrete junction of asynchronous cantilever construction, including 1 corrugated steel plate, 2L-shaped steel, 3 rubber sleeves, 4 through steel bars, 5. perforated ribs, 6. concrete roof, 7 flange plates.

[0025] The corrugated steel plate 1 is welded on the bottom of the upper flange plate 7, the flange plate 7 is evenly divided by the lower corrugated steel plate 1, the perforated rib plate 5 is symmetrically welded on the surface of the flange plate 7, the The penetrating steel bars 4 pass through the perforated ribs 5, the rubber sleeve 3 wraps the penetrating steel bars 4, the L-shaped steel 2 is symmetrically welded on the outside of the perforated ribs 5, and the concrete roof 6 wraps all the above st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com