Molding equipment for gum soft board

A molding equipment and soft board technology, applied in the field of rubber soft board molding equipment, can solve the problems of slow production speed and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

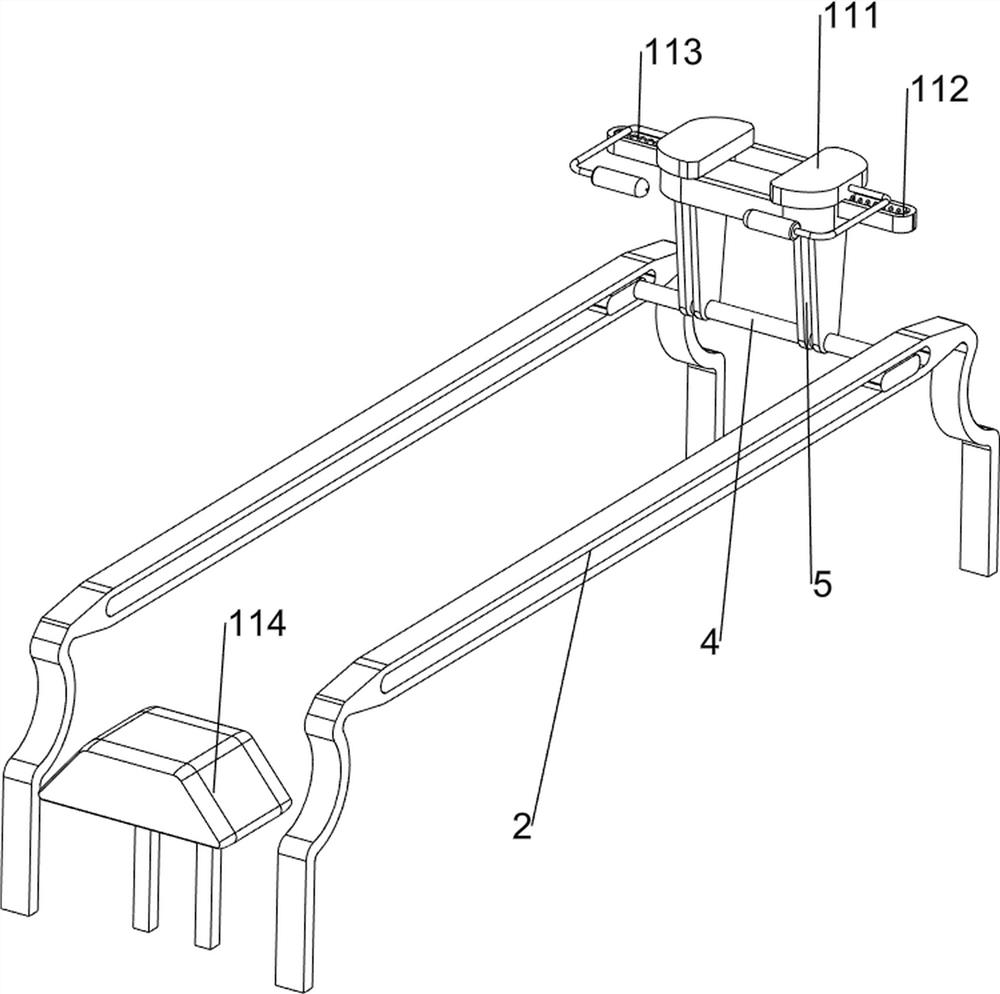

[0029] A kind of gum soft board forming equipment, such as Figure 1-2 As shown, it includes a base plate 1, a first slide rail 2, a slider 3, a first rotating shaft 4, a mold 5, a moving mechanism 6 and a blanking mechanism 7, and the upper part of the base plate 1 is symmetrically provided with the first slide rail 2, and the second Slide rails 2 are provided with sliders 3 for sliding, and a first shaft 4 is provided for rotation between the sliders 3. A mold 5 is provided on the first shaft 4. A moving mechanism 6 is provided on the upper part of the base plate 1. The upper part of the base plate 1 A blanking mechanism 7 is provided in the middle.

[0030] When the user needs to make and shape the rubber material, he can use this equipment. Firstly, the rubber material is placed in the unloading mechanism 7, and the moving mechanism 6 drives the slider 3, the first rotating shaft 4 and the mold 5 to move to the left and close to the bottom. The position of the feeding mec...

Embodiment 2

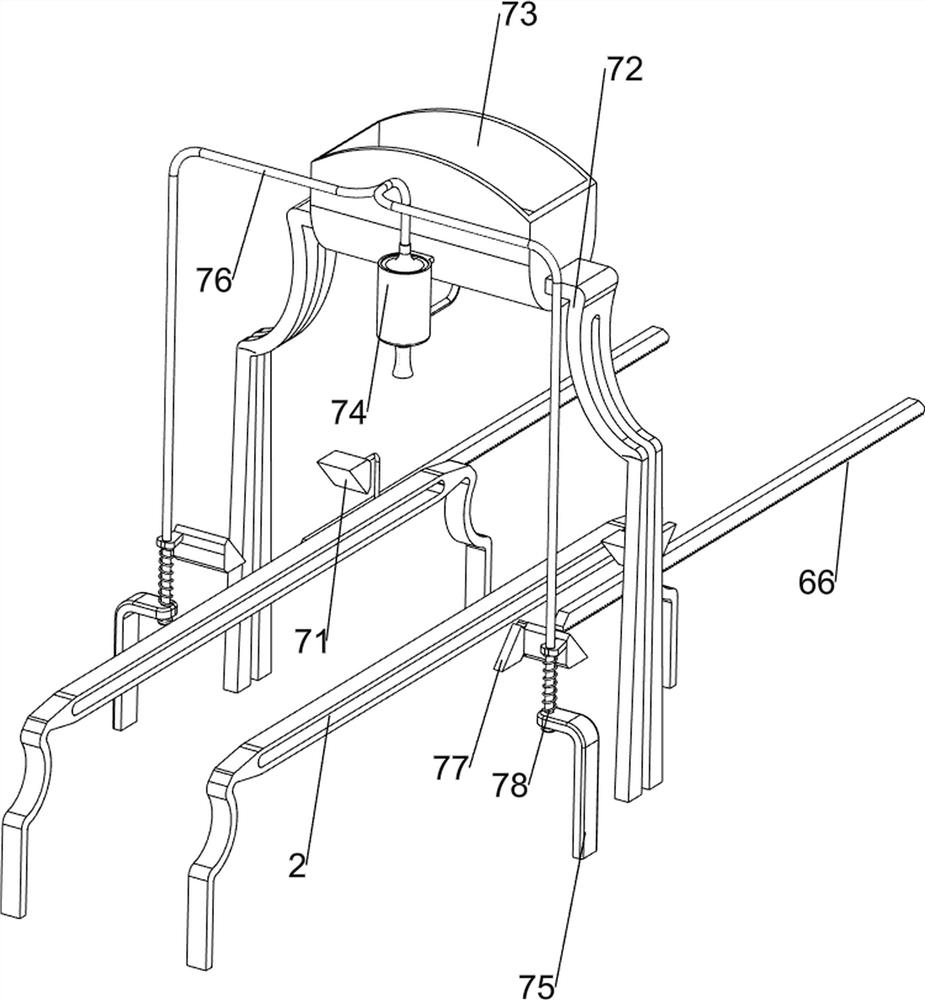

[0032] On the basis of Example 1, such as Figure 3-4 As shown, the moving mechanism 6 includes a motor 61, a first bracket 62, a second rotating shaft 63, a first full gear 64, a first belt 65 and a first rack 66, and the middle of the upper front side of the base plate 1 is provided with a motor 61, and the base plate 1 Two first brackets 62 are arranged on the front side of the upper part, and a second rotating shaft 63 is arranged in rotation between the first brackets 62, and a first full gear 64 is arranged on the second rotating shaft 63, and the output of the second rotating shaft 63 and the motor 61 A first belt 65 is connected between the shafts, and a first rack 66 is connected to the slider 3 , and the first rack 66 meshes with the first full gear 64 .

[0033] Start the motor 61, the motor 61 drives the first full gear 64 to mesh, and the first rack 66 meshes with the first full gear 64, so that the first rack 66 drives the slider 3 and the mold 5 to move to the l...

Embodiment 3

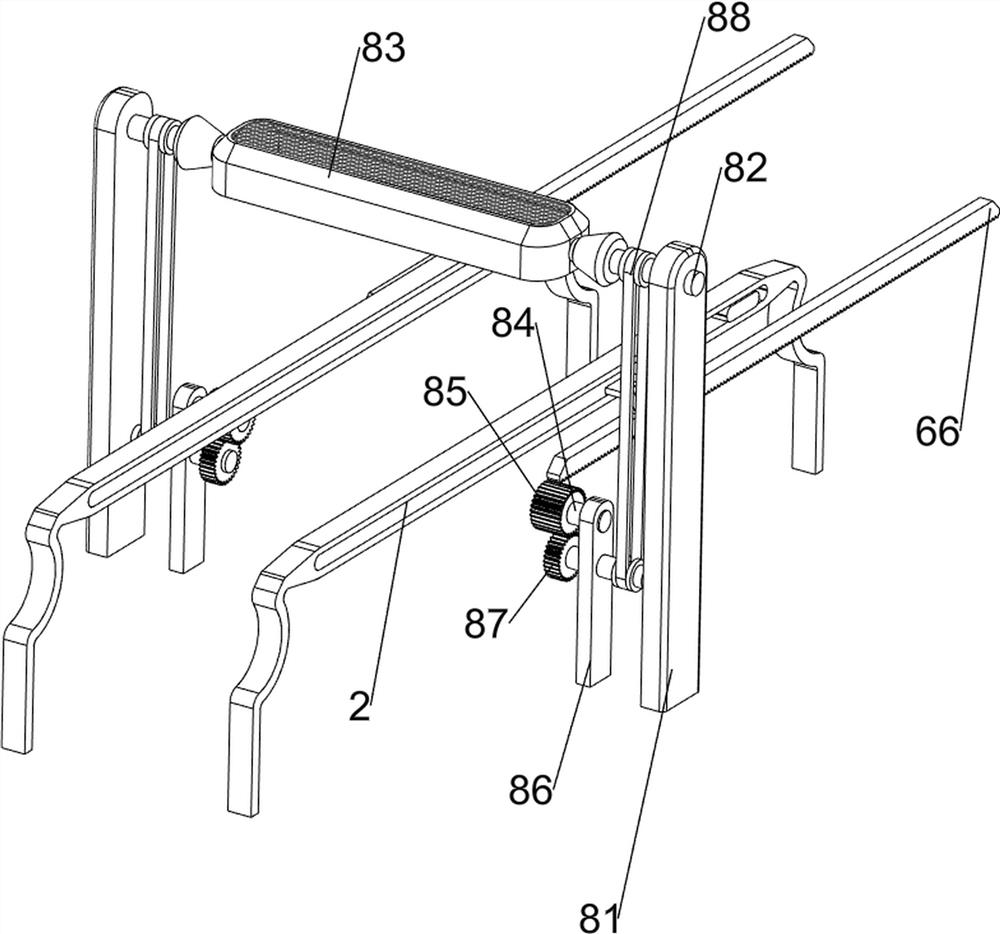

[0037] On the basis of Example 2, such as Figure 5-8As shown, a drying mechanism 8 is also included, and the drying mechanism 8 includes a second support frame 81, a third rotating shaft 82, a heater 83, a fourth rotating shaft 84, a second full gear 85, a third bracket 86, a third All gears 87 and the second belt 88, a second support frame 81 is arranged symmetrically front and back in the middle of the upper part of the bottom plate 1, a third rotating shaft 82 is arranged in a rotating manner between the second supporting frame 81, and a heater 83 is arranged on the third rotating shaft 82 , the upper middle of the bottom plate 1 is provided with a third support 86 symmetrically front and back, the third support 86 is provided with a fourth rotating shaft 84, the fourth rotating shaft 84 on the upper side is provided with a second full gear 85, and the fourth rotating shaft 84 on the lower side is provided with a second full gear 85. The third full gear 87 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com