Household chili sauce making machine

A technology of chili sauce and making machine, which is applied in the directions of household appliances, applications, kitchen utensils, etc., can solve the problems of low chili mincing efficiency, easy to cut hands, and skin damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

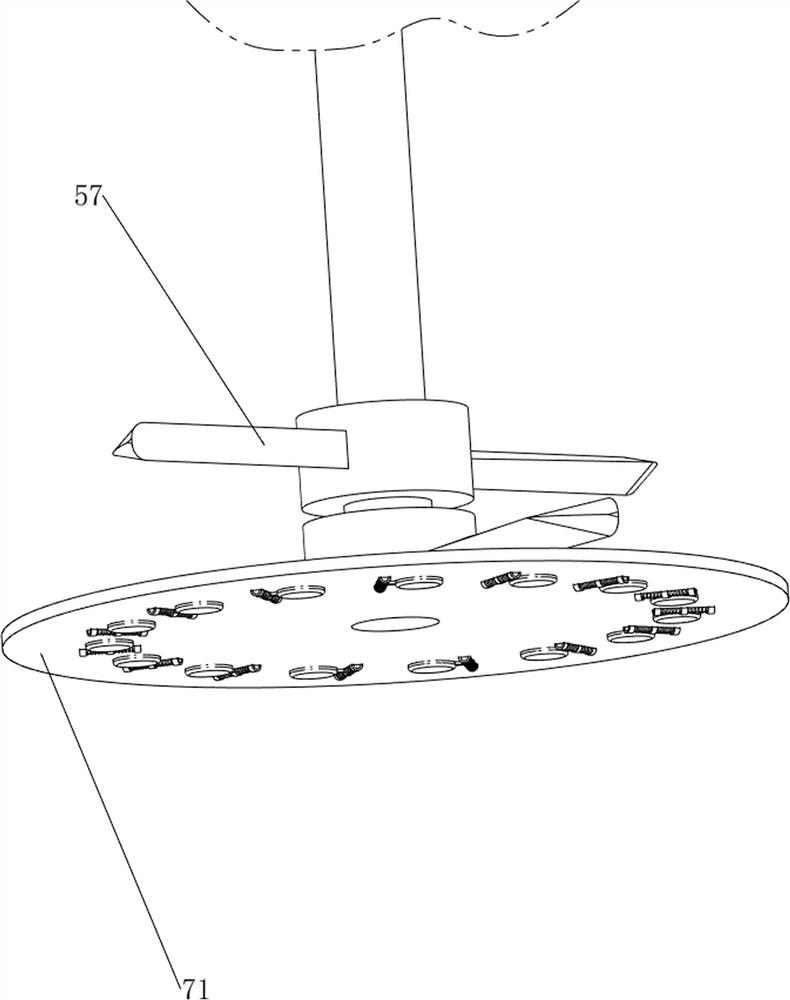

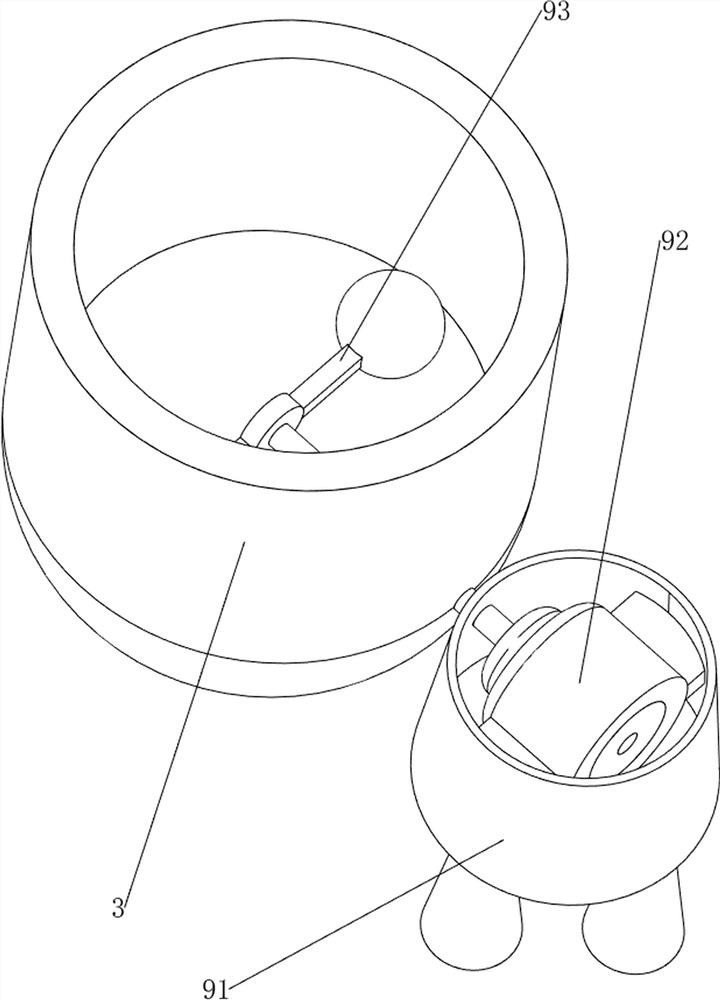

[0034] A domestic chili sauce making machine, such as Figure 1-7 As shown, it includes a base 1, a heating ring 2, a finished product frame 3, a baffle plate 4, a rotary cutting mechanism 5, a feeding mechanism 6 and a material selection mechanism 7. The base 1 is provided with a heating ring 2, and the heating ring 2 is placed with The finished frame 3 has a baffle plate 4 on the rear side of the base 1, a rotary cutting mechanism 5 on the front side of the upper part of the baffle plate 4, a feeding mechanism 6 on the middle part of the baffle plate 4, and a material selection mechanism 7 on the inner side of the rotary cutting mechanism 5. .

[0035] When people need to make chili sauce, people can use this household chili sauce making machine. First, people pour the peppers into the rotary cutting mechanism 5 through the feeding mechanism 6, and then people start the rotary cutting mechanism 5, and the rotary cutting mechanism 5 operates to cut At the same time, the oper...

Embodiment 2

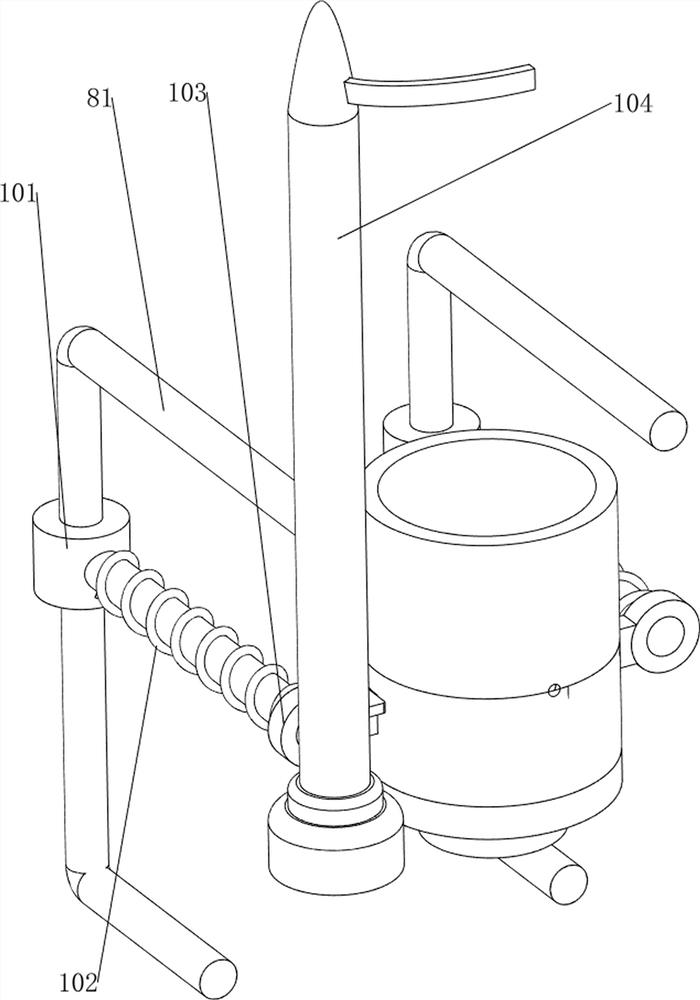

[0043] On the basis of Example 1, such as Figure 8-12 As shown, it also includes a blanking mechanism 8, and the blanking mechanism 8 includes a third fixed rod 81, a first slide rod 82, a first common spring 83, a fourth fixed rod 84, a fifth fixed rod 85, a second common spring Spring 86 and the first limit bar 87, baffle plate 4 rear wall bottoms are symmetrically provided with the 3rd fixed bar 81, two 3rd fixed bar 81 upper front ends are all slidably provided with the first slide bar 82, two first slide bars 82 inner sides are all connected with the blanking tray 52, and the first common spring 83 is all wound around the tops of the two third fixed rods 81, and the two ends of the first common spring 83 are respectively connected with the third fixed rod 81 and the first slide bar 82, and the base 1, the upper right side is provided with a fourth fixed rod 84, the inside of the fourth fixed rod 84 is provided with a fifth fixed rod 85, and the upper part of the fifth fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com