Patents

Literature

37 results about "Cut fingers" patented technology

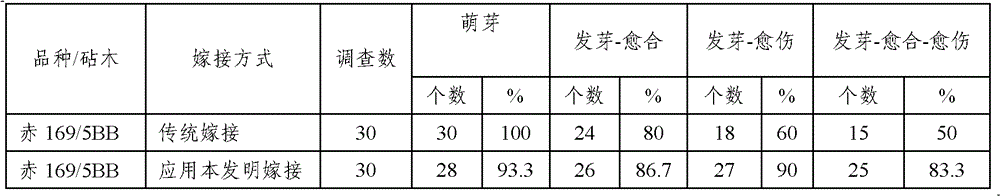

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

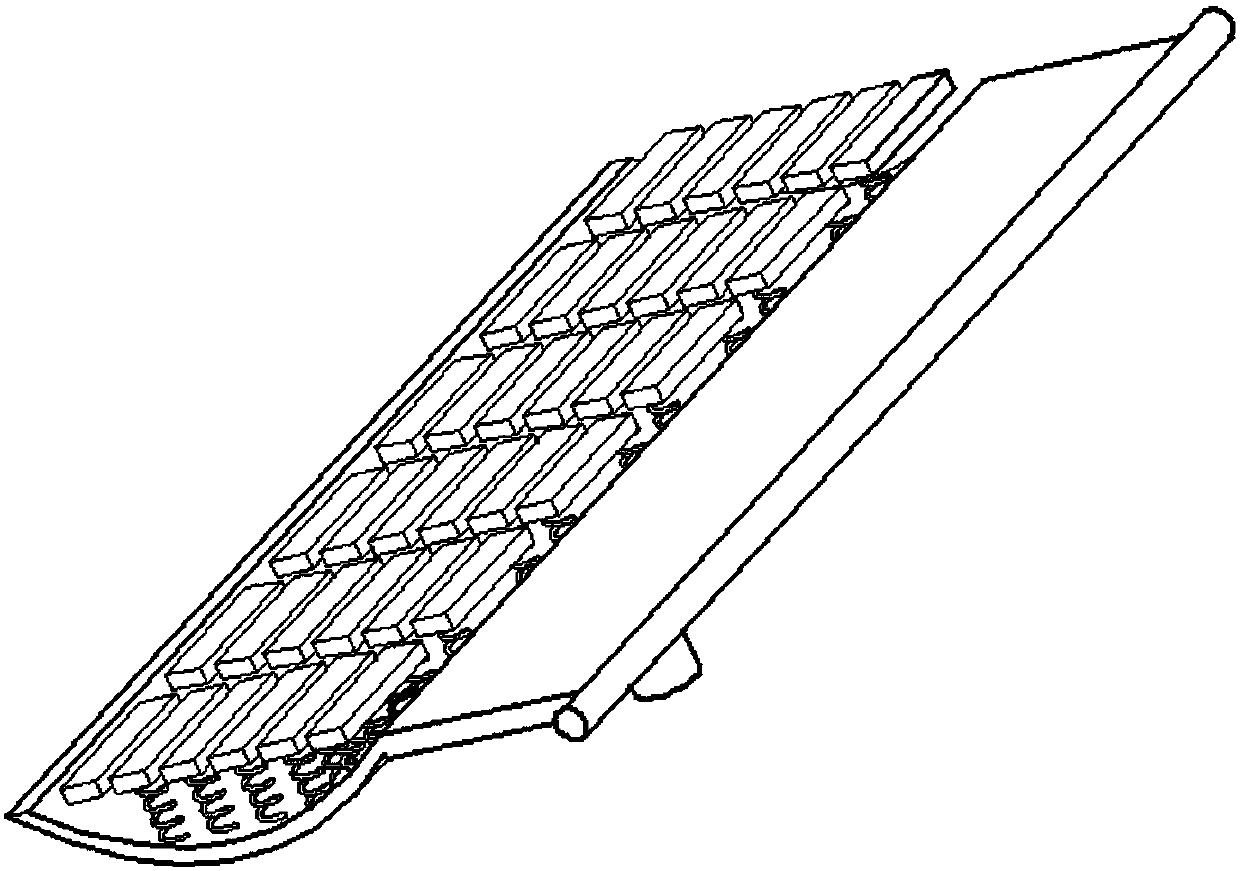

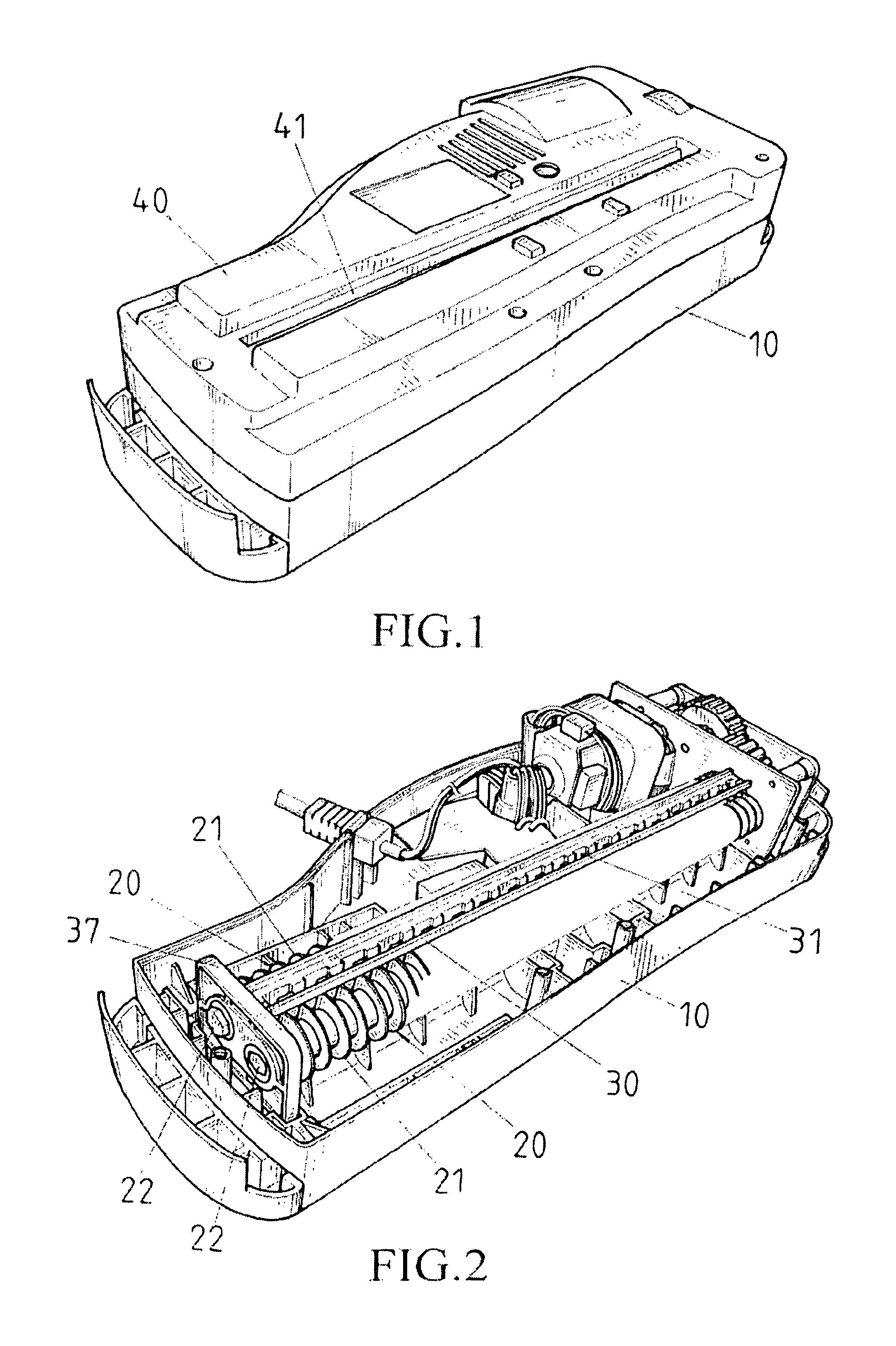

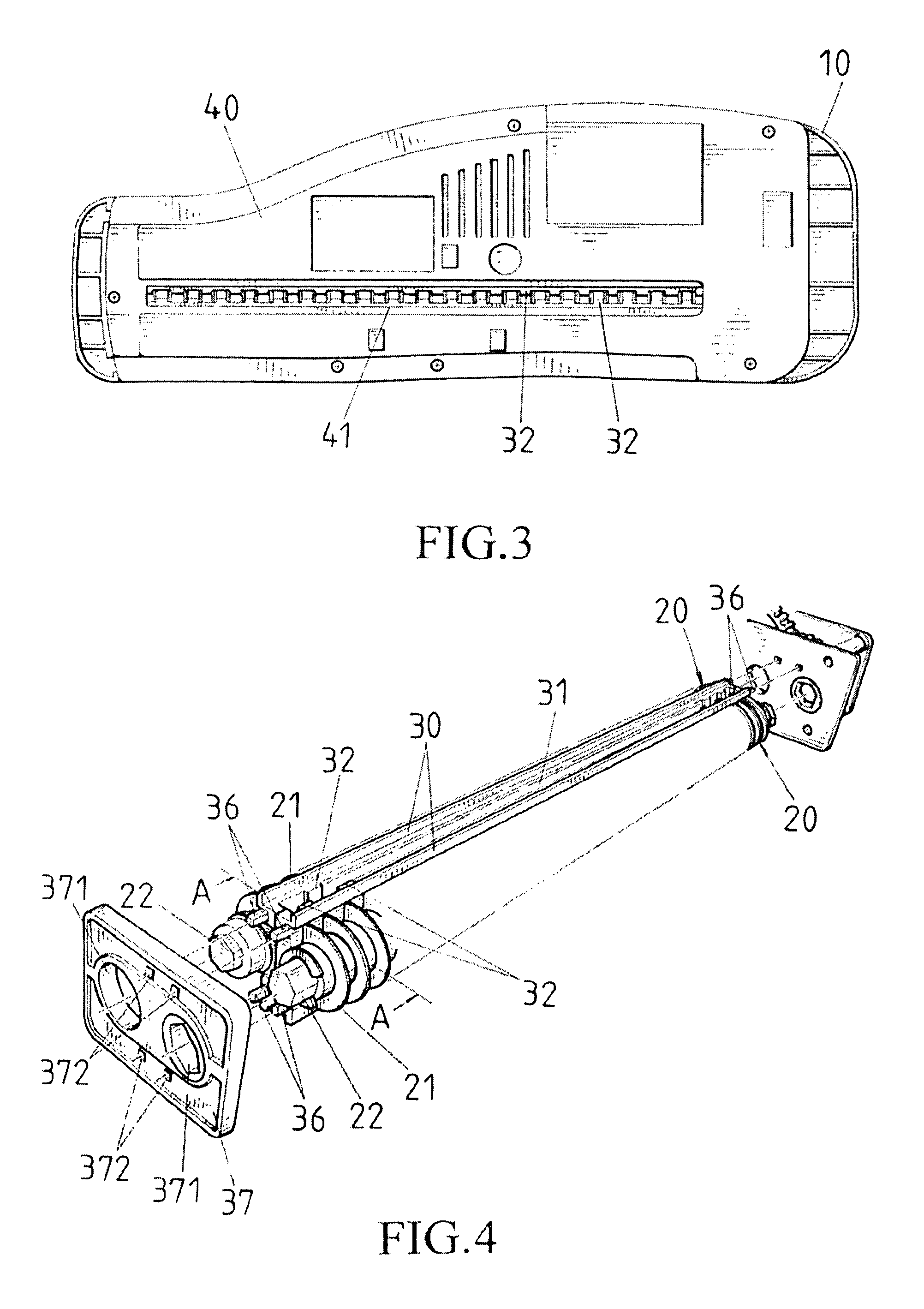

Cutter bar

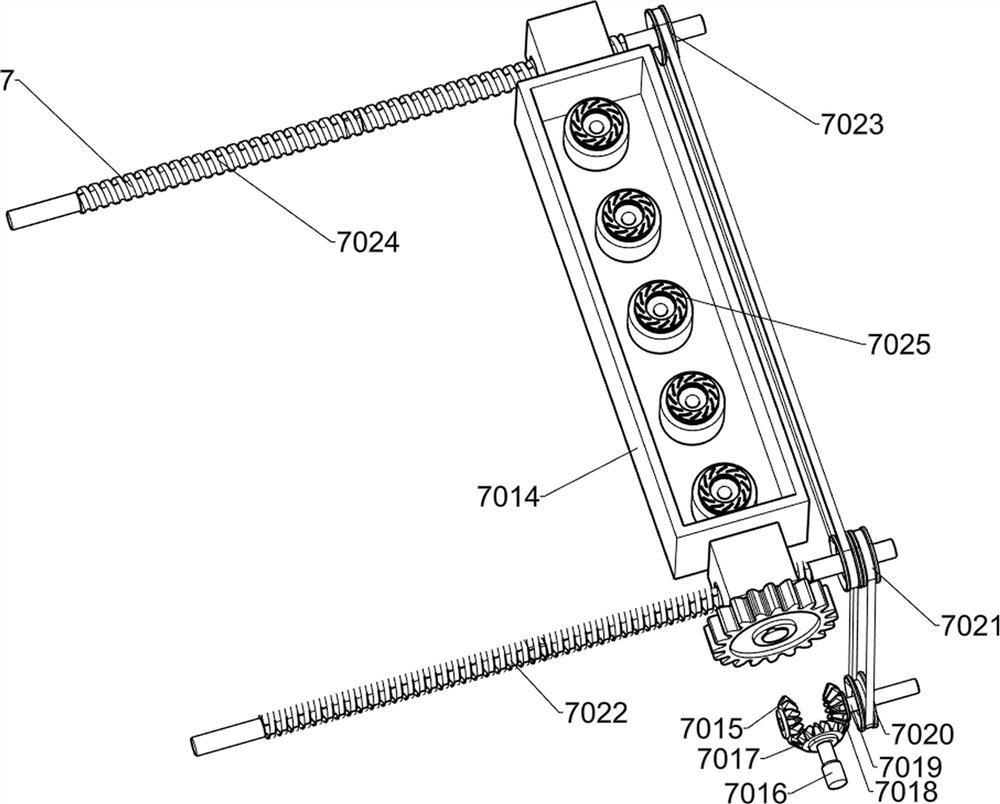

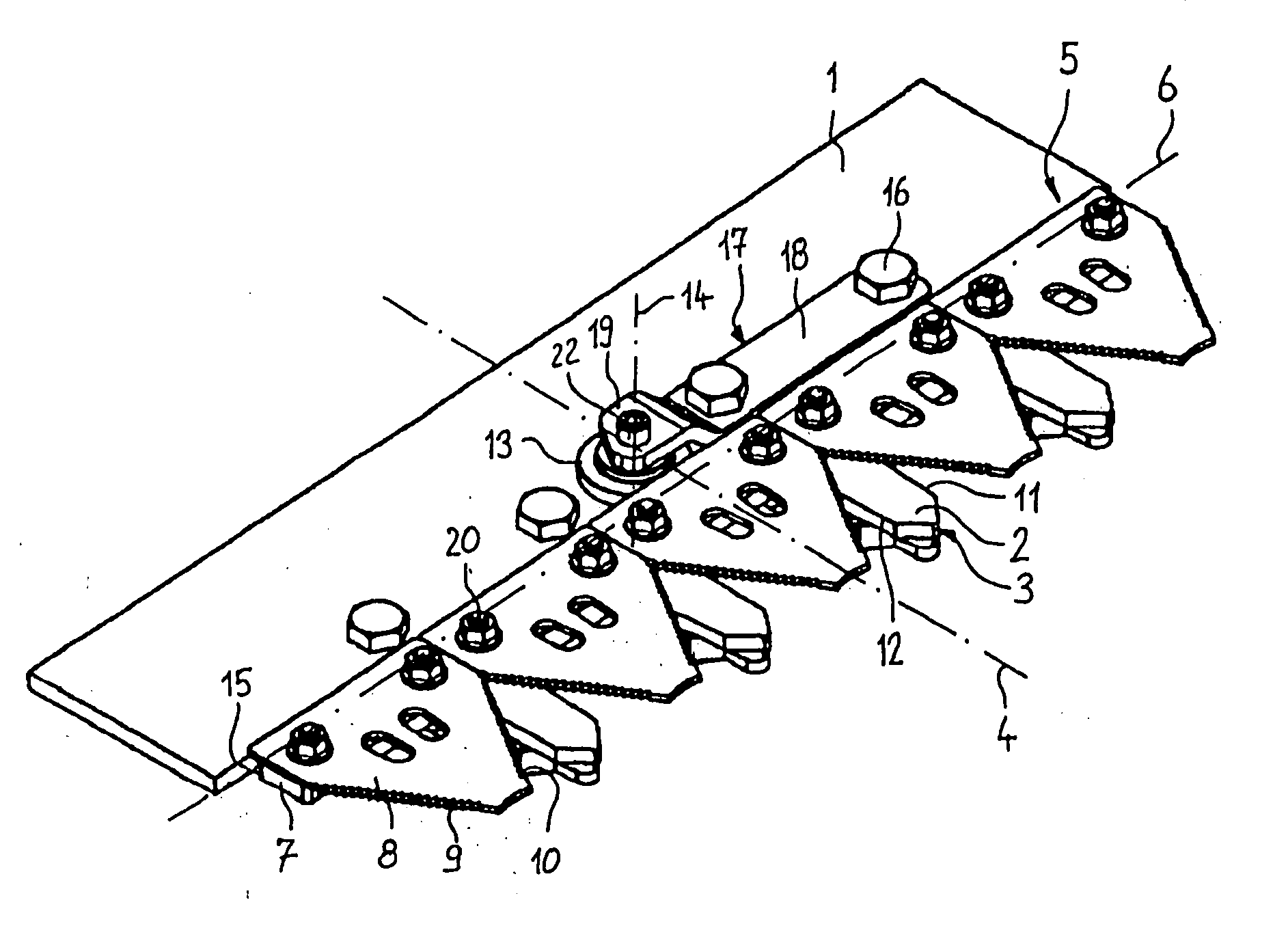

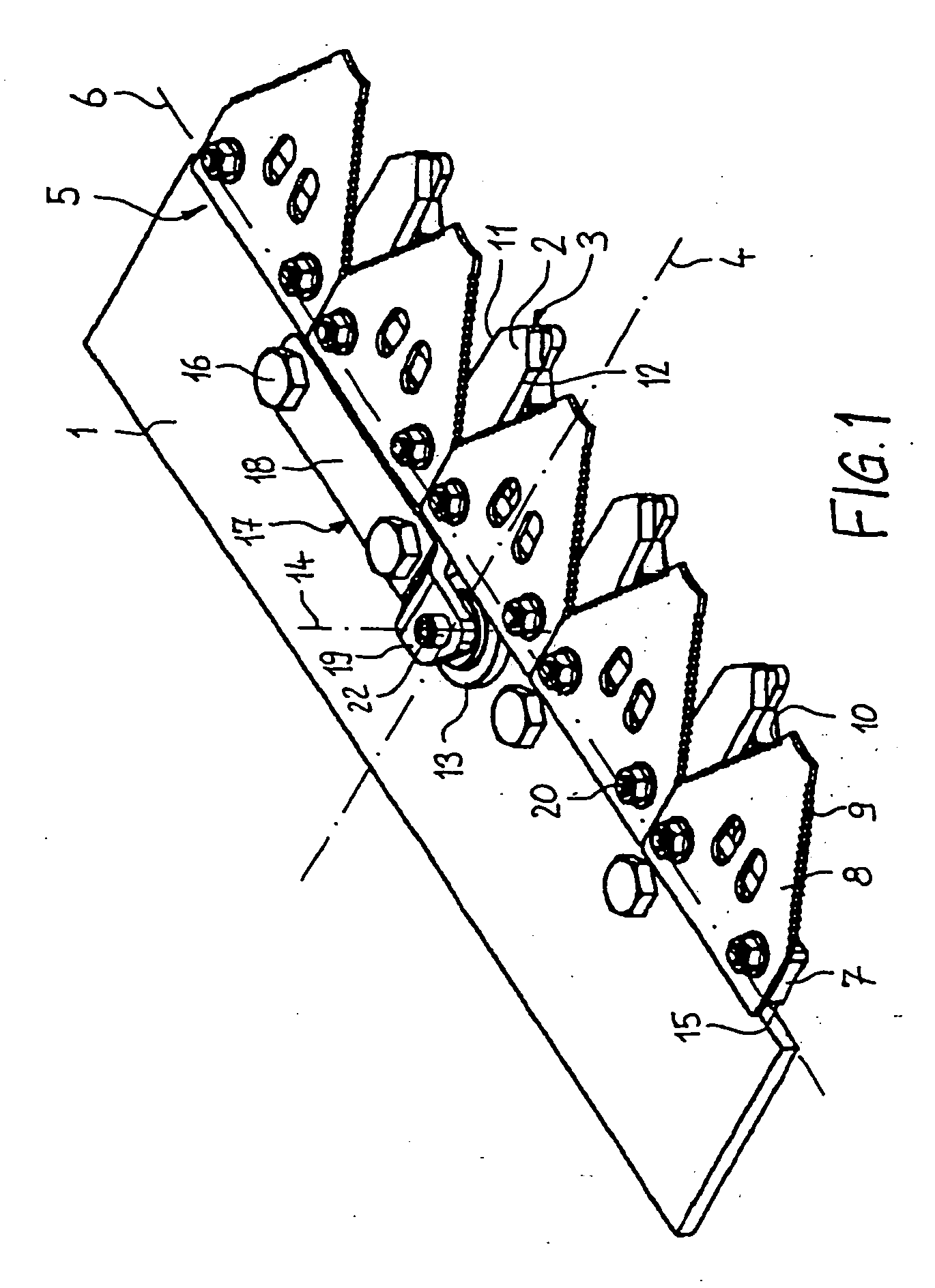

ActiveUS7313903B2Solution to short lifeNo frictional resistance between the knife and the finger barMowersTransverse axisGear wheel

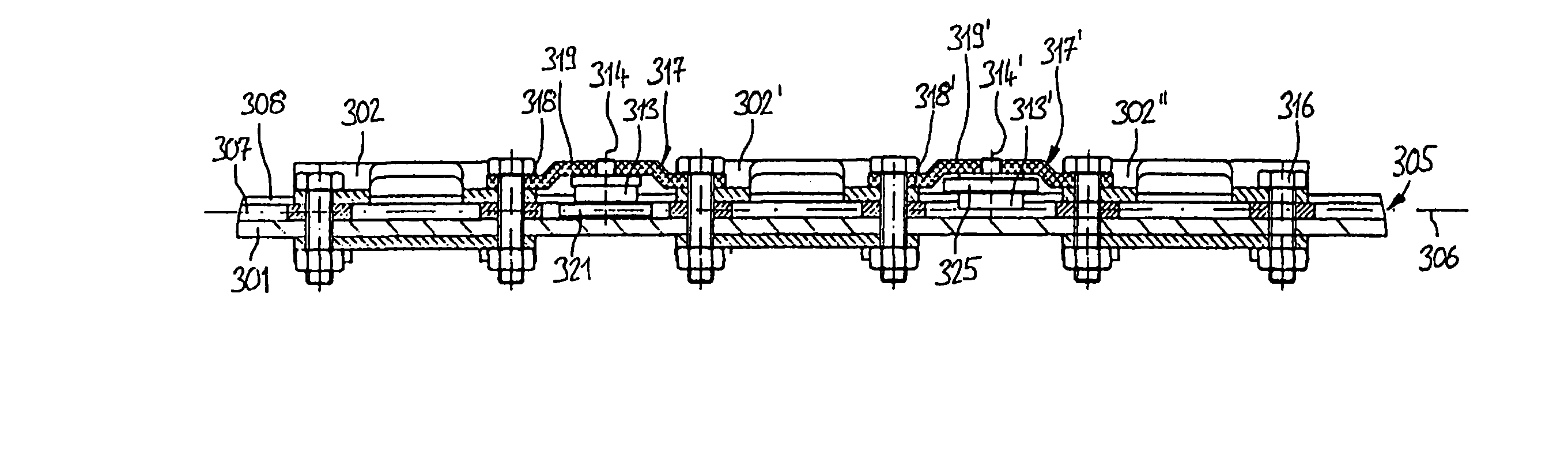

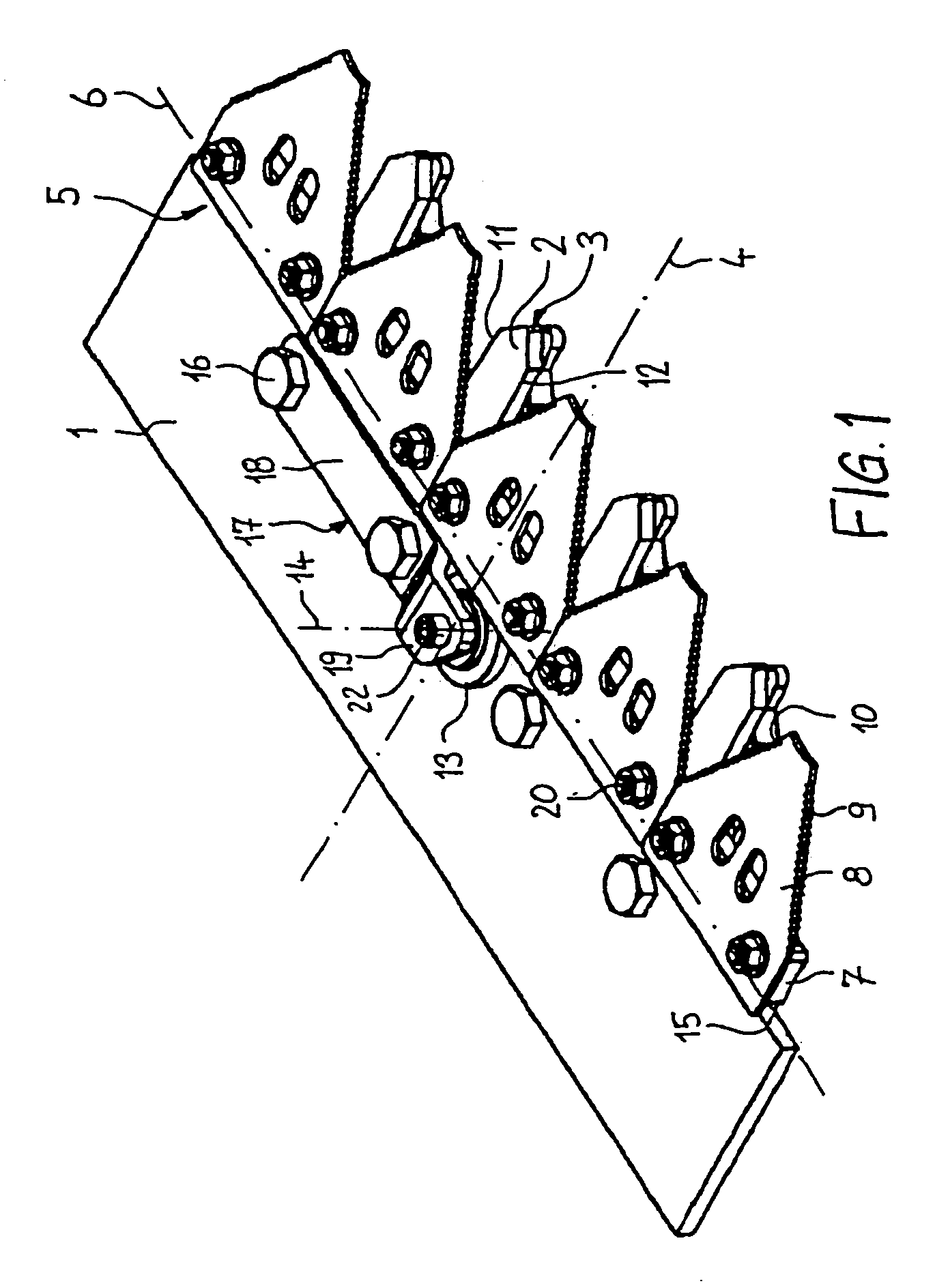

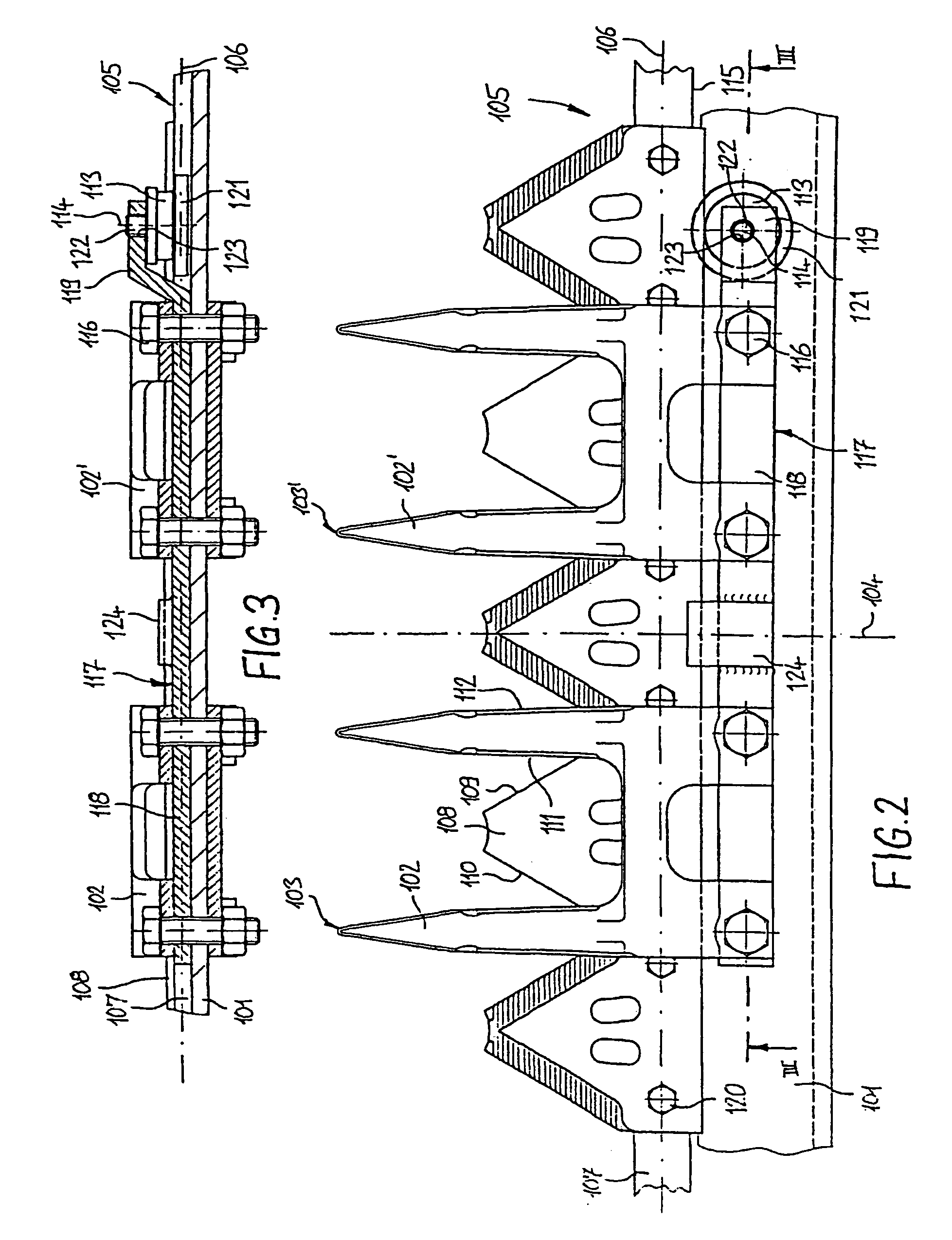

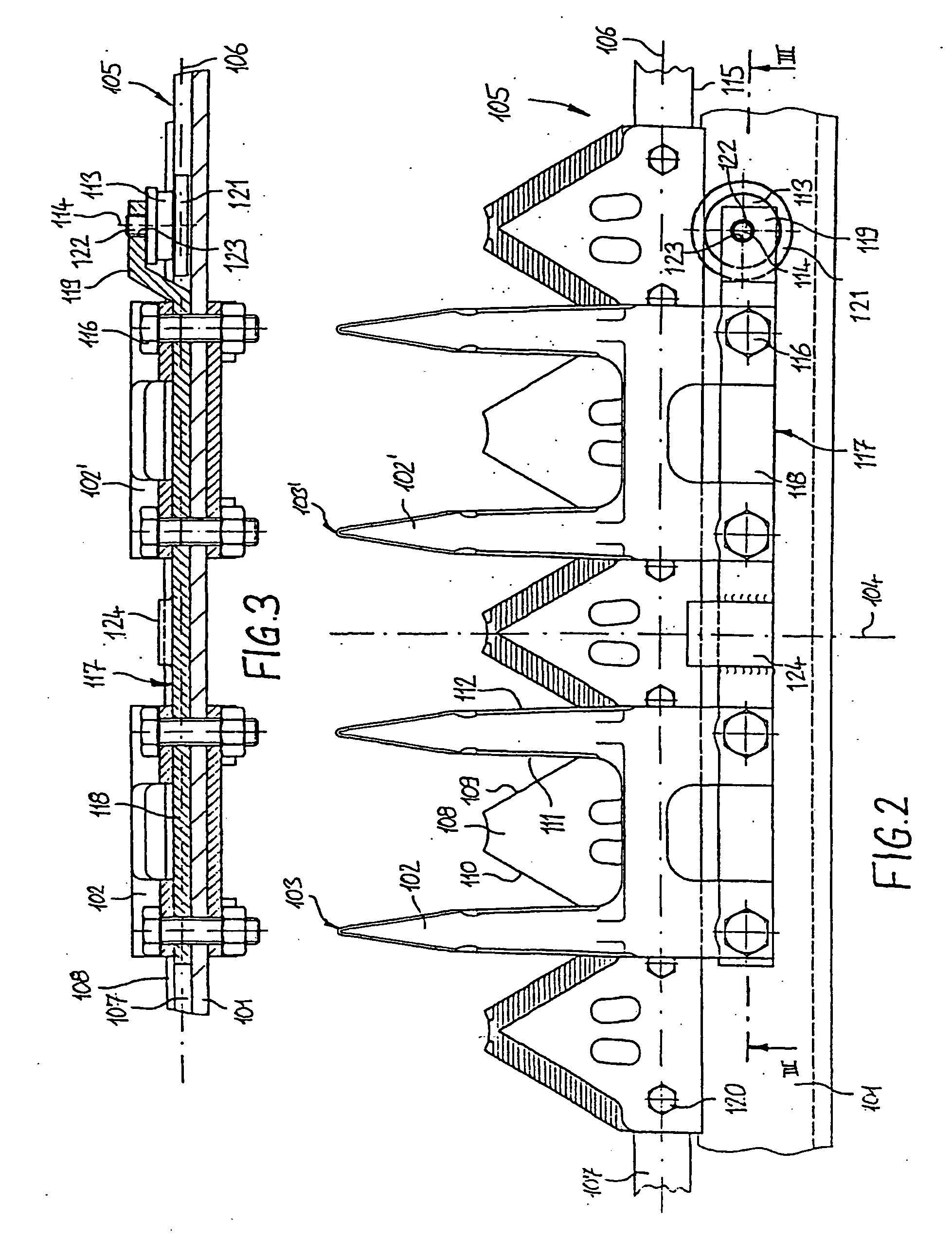

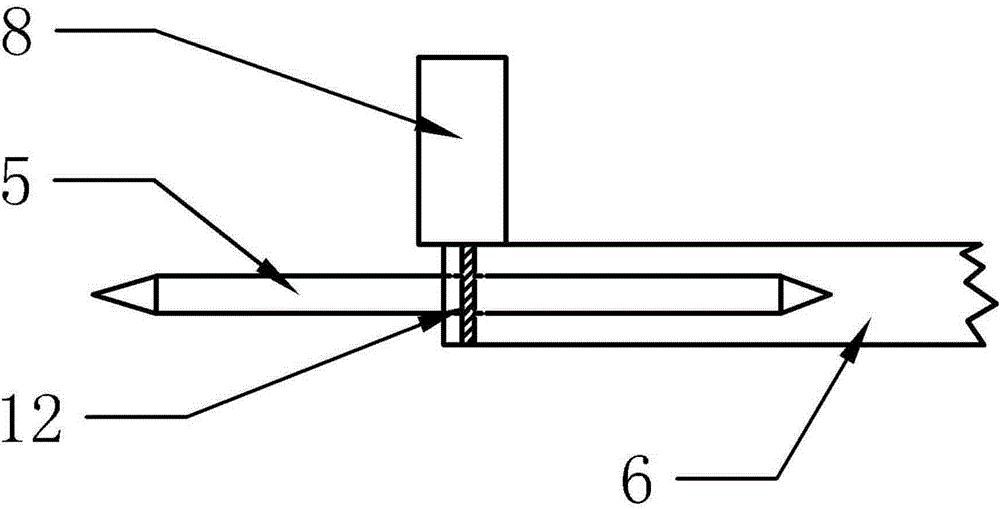

The invention relates to a reciprocating cutting bar for the cutting gear of an agricultural machine, comprising a longitudinal axis (4) along which the reciprocating cutting bar may be moved in a working direction for crop cutting, a finger bar (1), cutting fingers (2), which are fixed to the finger bar (1), each forming counter cutters (11), a knife (5) with a knife bar (7), having knife blades (8) fixed to the knife bar (7) which each have cutters (9), whereby the knife (5) is made to oscillate relative to the finger bar (1) along a transverse axis (6), which is arranged horizontally and perpendicular to the longitudinal axis (4), rollers (13), by means of which the knife (5) is supported against the finger bar (1) to the rear when viewed in the working direction. The rollers (13) are each mounted to rotate on a roller holder (17) and the roller holders (17) are fixed to the finger bar (1).

Owner:SCHUMACHER GUSTAV

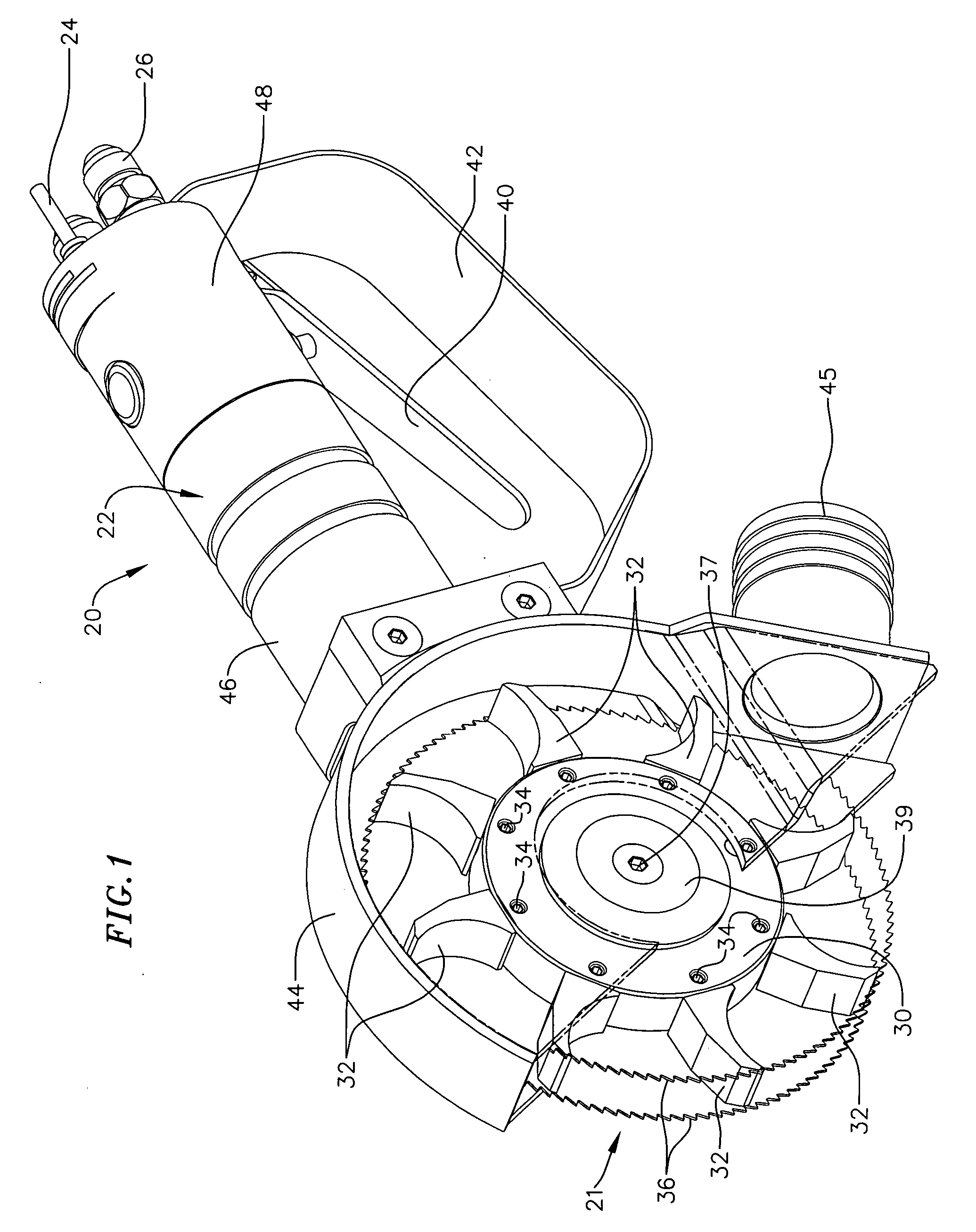

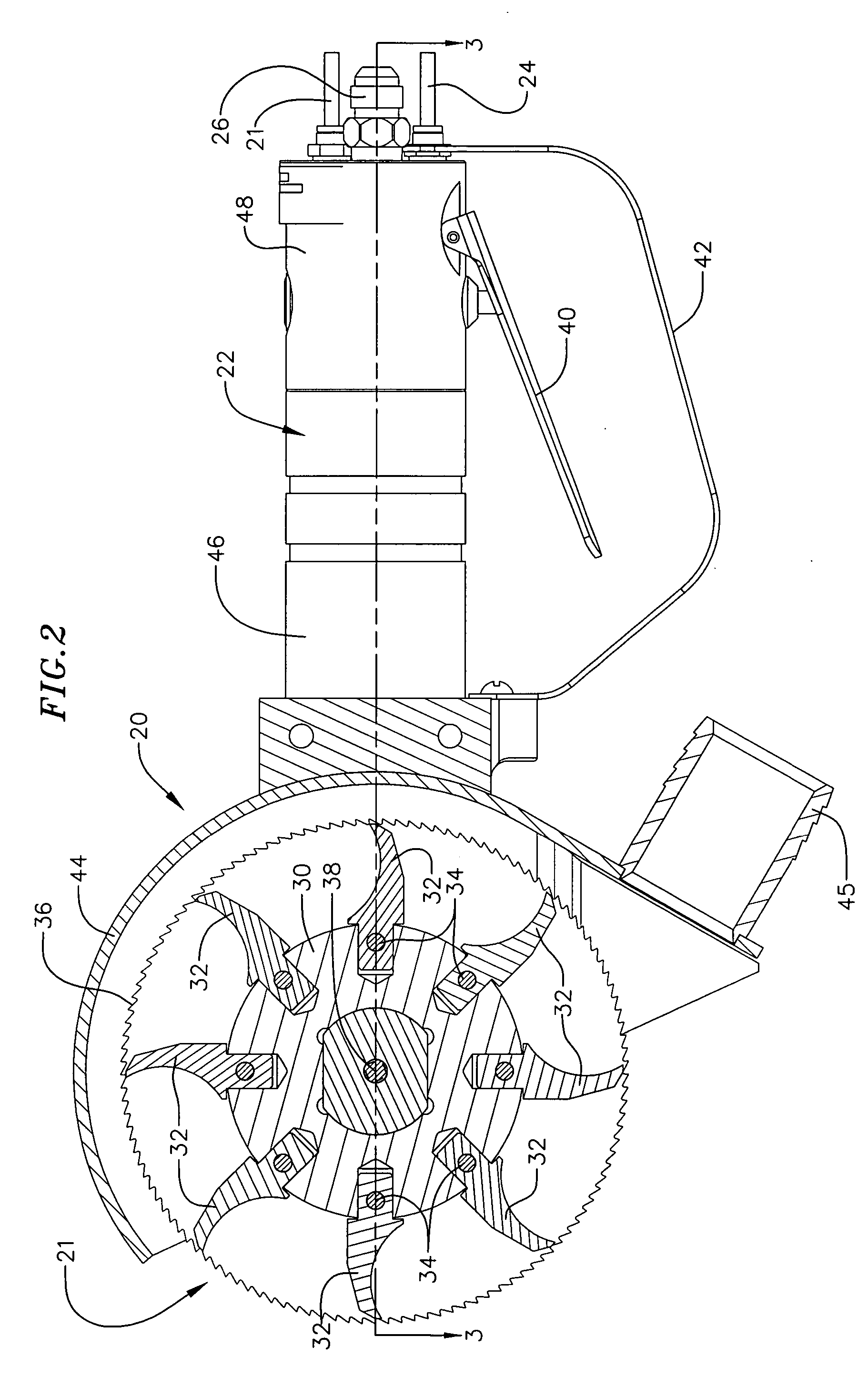

Multi-purpose cutting tool

InactiveUS20060200152A1Efficient removalMaterial removalMetal sawing devicesEviscerating scissorsSpinal cordCircular saw

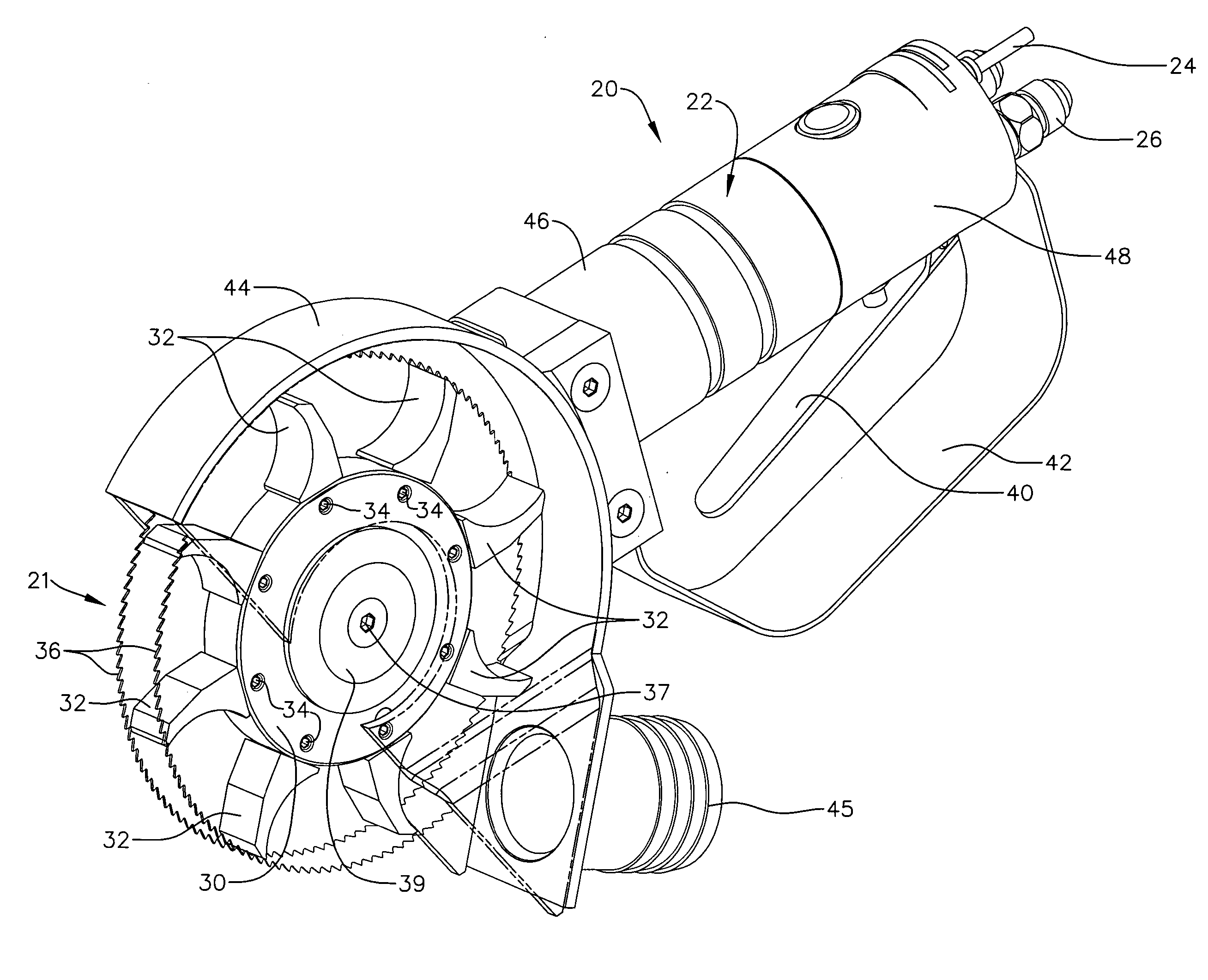

A multi-purpose cutting device for removing the spinal cord and spinal meninx lining of the spinal cord of a slaughtered animal which has been longitudinally cut in two along the length of the spinal cord. The cutting device comprises a rotary cutting tool having a hub with radially outwardly projecting cutting fingers equidistantly spaced apart around the hub. The cutting fingers have blunt ends and are of substantially uniform length. A pair of circular saw blades are rigidly secured to opposite faces of the cutting tool. The saw blades have a circumference that approximately matches the effective circumference of the working ends of the cutting fingers. In use, when the cutting device is powered by a drive motor, the cutting fingers and saw blades rotate in unison. The cutting fingers rotate to remove the spinal cord and spinal meninx from the carcass while the saw blades cut into bone along opposite sides of the meninx. The saw blades assist the cutting fingers in dislodging regions of bone material in which the spinal cord or meninx materials may be lodged.

Owner:KENTMASTER MFG

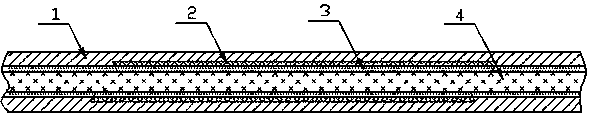

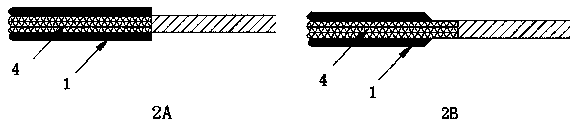

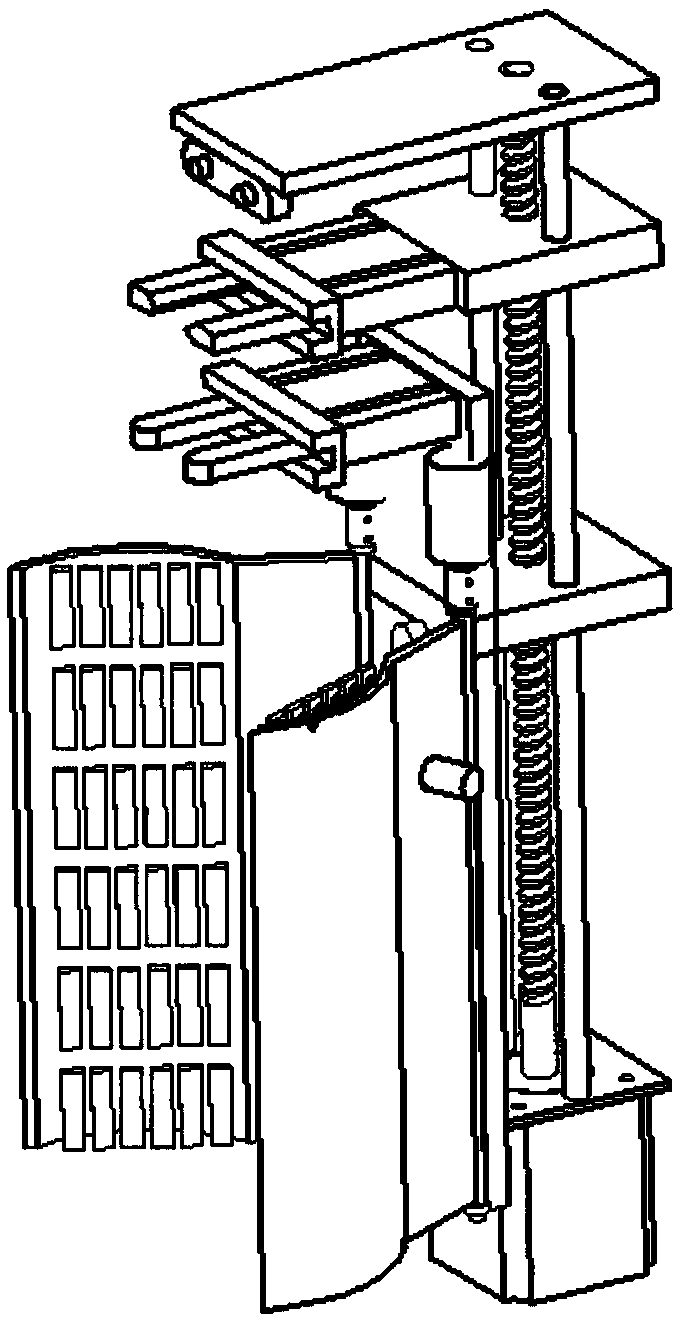

Finger-shaped connector of aramid fiber conveying belt and preparation method of finger-shaped connector

The invention relates to a finger-shaped connector of an aramid fiber conveying belt and a preparation method of the finger-shaped connector. The preparation method comprises the following steps: stripping coverage glue, cleaning residual glue, cutting finger shapes, coating mucilage, splicing the finger shapes, forming and coating glue, reinforcing by a fabric layer, covering glue, and sulfurizing a specimen, thereby obtaining the finger-shaped connector on the aramid fiber conveying belt. According to the invention, the problems of extraction, edge wrapping, water seepage, glue failure of seams and the like of the connector of the conveying belt in the dynamic running process are solved; a certain gap is reserved in splicing the finger shapes so as to guarantee that the pasting glue can seep fully toward the finger shapes, the extraction force is increased, the stress uniformity is improved, and the phenomena of extraction and cracking which are caused by stress uniformity are prevented; the length of the stripped coverage glue is greater than the length of each finger by 5cm, and the connector glue and the coverage glue are lapped into an oblique slope, so that the phenomenon of water seepage of a framework material because of glue failure of the seam is prevented, and the service life of the connector of the aramid fiber conveying belt is prolonged greatly.

Owner:YANKUANG GRP CO LTD +1

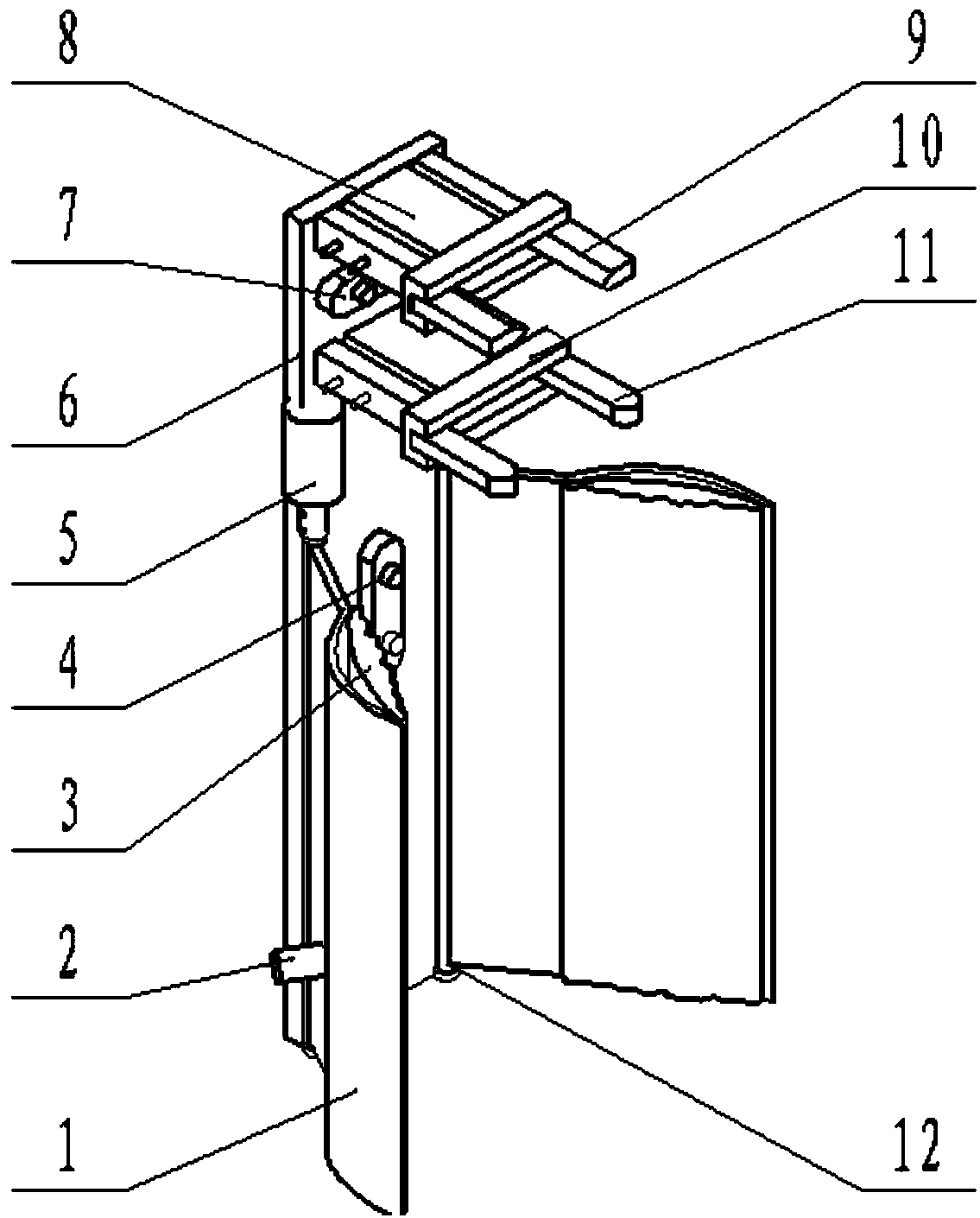

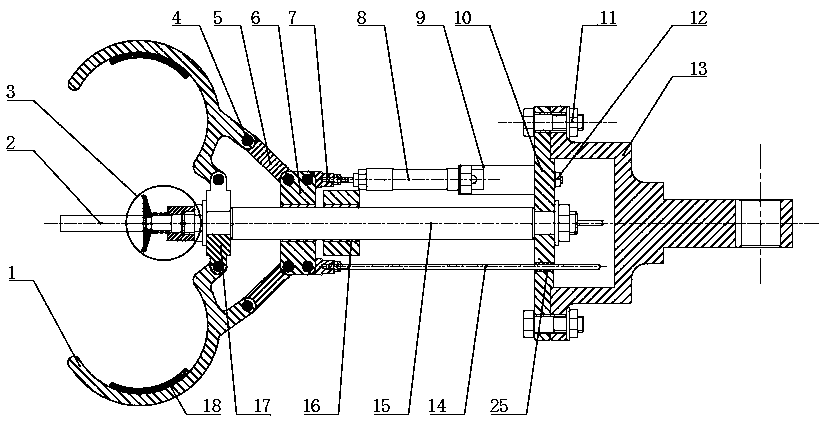

Cucumber flexible picking manipulator end executor and picking method

ActiveCN107696047ASolve efficiency problemsSolve the clampingGripping headsHarvestersKey pressingCucumber family

The invention provides a cucumber flexible picking manipulator end executor and a picking method and relates to the field of agricultural picking robots. The cucumber flexible picking manipulator endexecutor is composed of a stepping motor, polished shafts, a lead screw, a mounting plate, a supporting plate, a nut slide block, an ejector plate, a visual sensor, a cutting cylinder, cutting fingers, a clamping cylinder, clamping fingers, springs, flexible clamping walls, silica gel keys, a laser sensor, a clamping arm rotating shaft and a rotary motor. The cucumber flexible picking manipulatorend executor is characterized in that the flexible clamping walls are installed on the two sides of the mounting plate through clamping wall rotary shafts, the silica gel keys are connected with the flexible clamping walls through the springs, and the working processes of aligning at cucumbers, moving close to the cucumbers, clamping the upper sections of the cucumbers, flexibly clamping the middle lower sections of the cucumbers and cutting off stems are completed. By adoption the picking manners that the flexible clamping walls clamp the middle sections and the lower sections of the cucumbers, the clamping fingers clamp the upper sections of the cucumbers, and the cutting fingers cut off the stems, the technical problems that the cucumber picking efficiency is low and cucumbers are proneto being damaged during clamping and are liable to break off due to shaking are solved.

Owner:新昌县大菠萝农业发展有限公司

Airbag type cucumber picking manipulator terminal actuator and picking method

The invention provides an airbag type cucumber picking manipulator terminal actuator and a picking method, and relates to the field of agricultural picking robots. The airbag type cucumber picking manipulator terminal actuator consists of airbag clamping walls, airbag intake holes, airbags, a laser sensor, a motor, a mounting plate, a visual sensor, a cutting cylinder, cutting fingers, a clampingcylinder, clamping fingers and clamping wall rotating shafts. The airbag type cucumber picking manipulator terminal actuator is characterized in that the airbag clamping walls are mounted on two sidesof the mounting plate through clamping wall rotating shafts; the airbag intake holes are formed in the side surfaces of the airbag clamping walls; the airbags are arranged on the inner sides of the airbag clamping walls; under the precondition of not damaging cucumbers, the working process of aligning to the cucumbers, approaching the cucumbers, clamping the upper sections of the cucumbers, clamping the middle and lower sections of the cucumbers by the airbags and cutting off stems is finished; the middle sections and the lower sections of the cucumbers are clamped by adopting the airbags; the upper sections of the cucumbers are clamped by the clamping fingers; and the stems are cut by the cutting fingers, so that the technical difficulties of low picking efficiency of the cucumbers and easiness in breakage due to shaking are solved.

Owner:石柱土家族自治县八龙农业开发有限公司

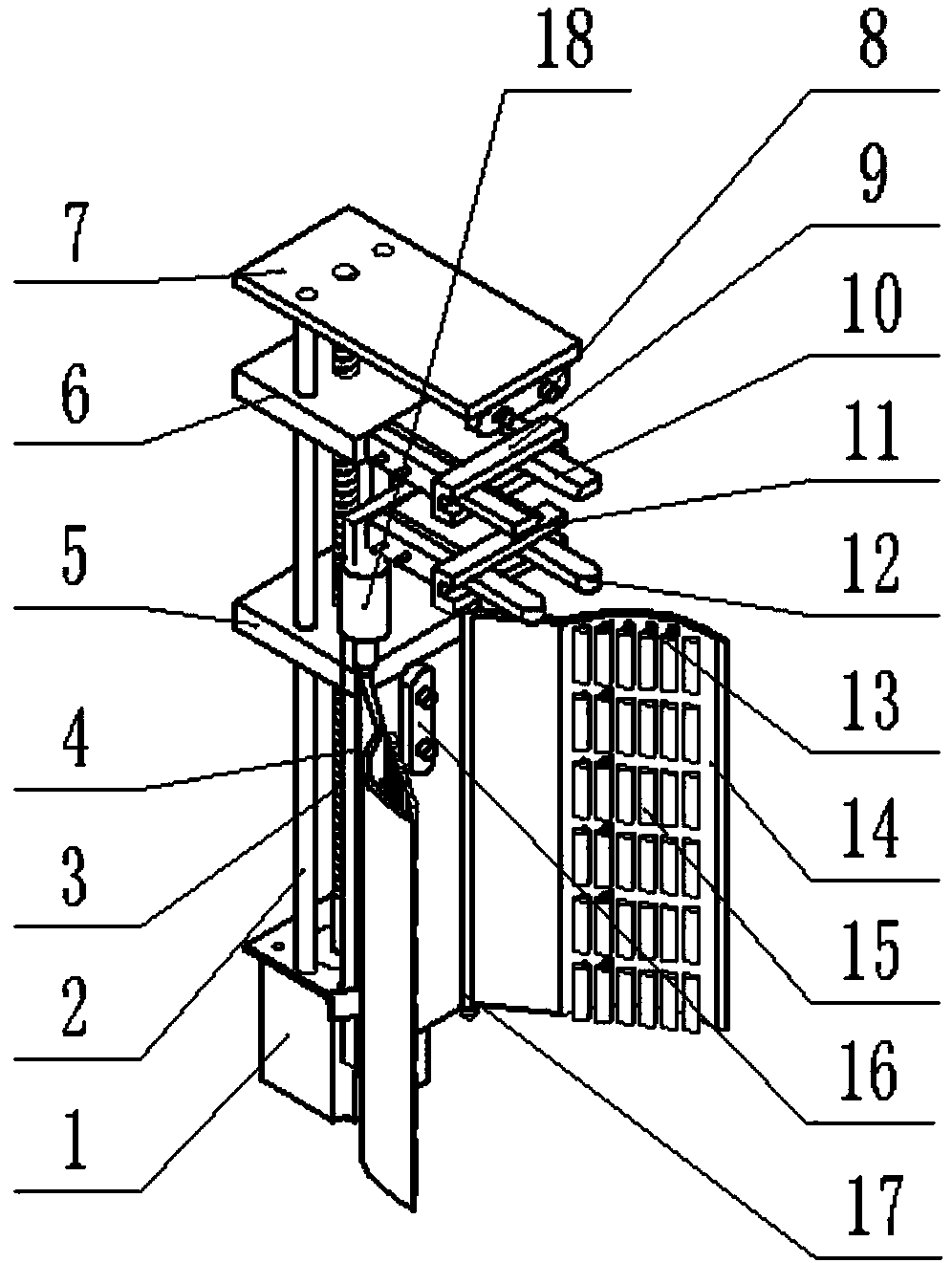

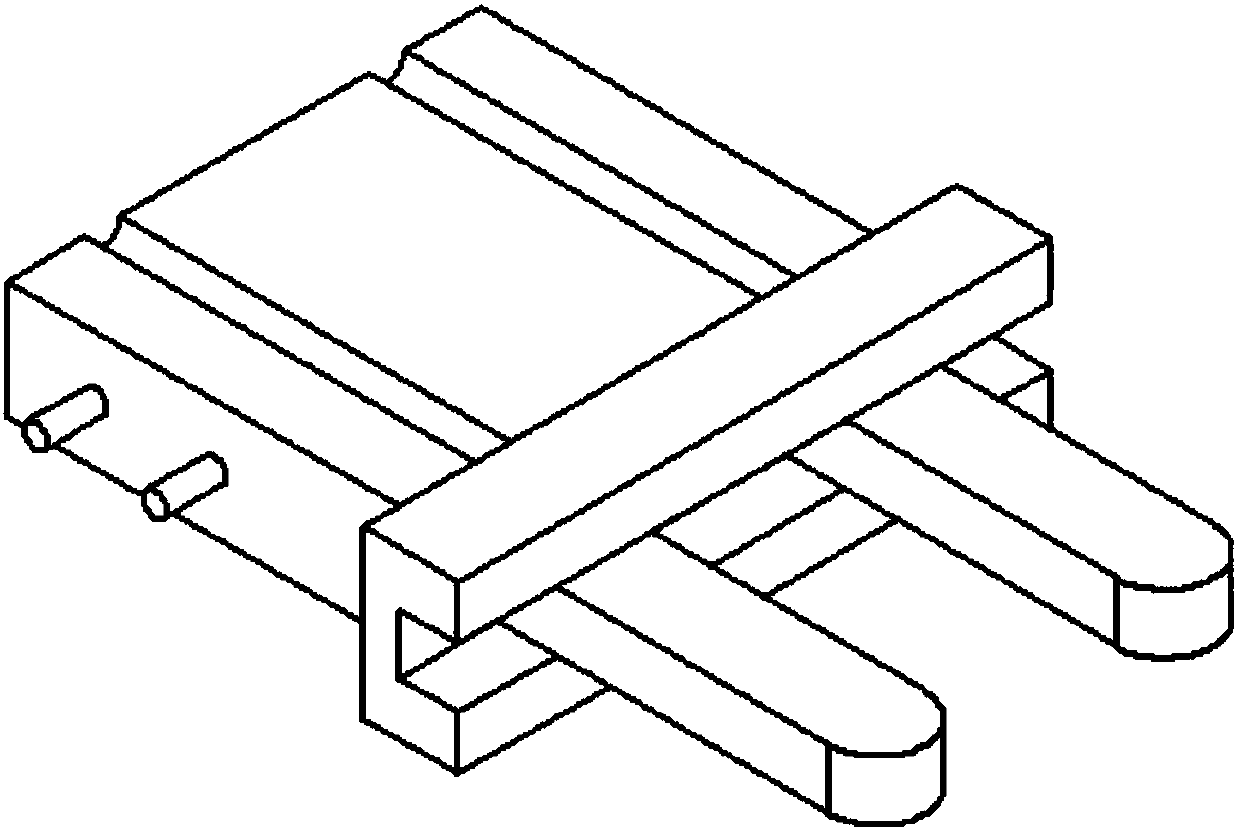

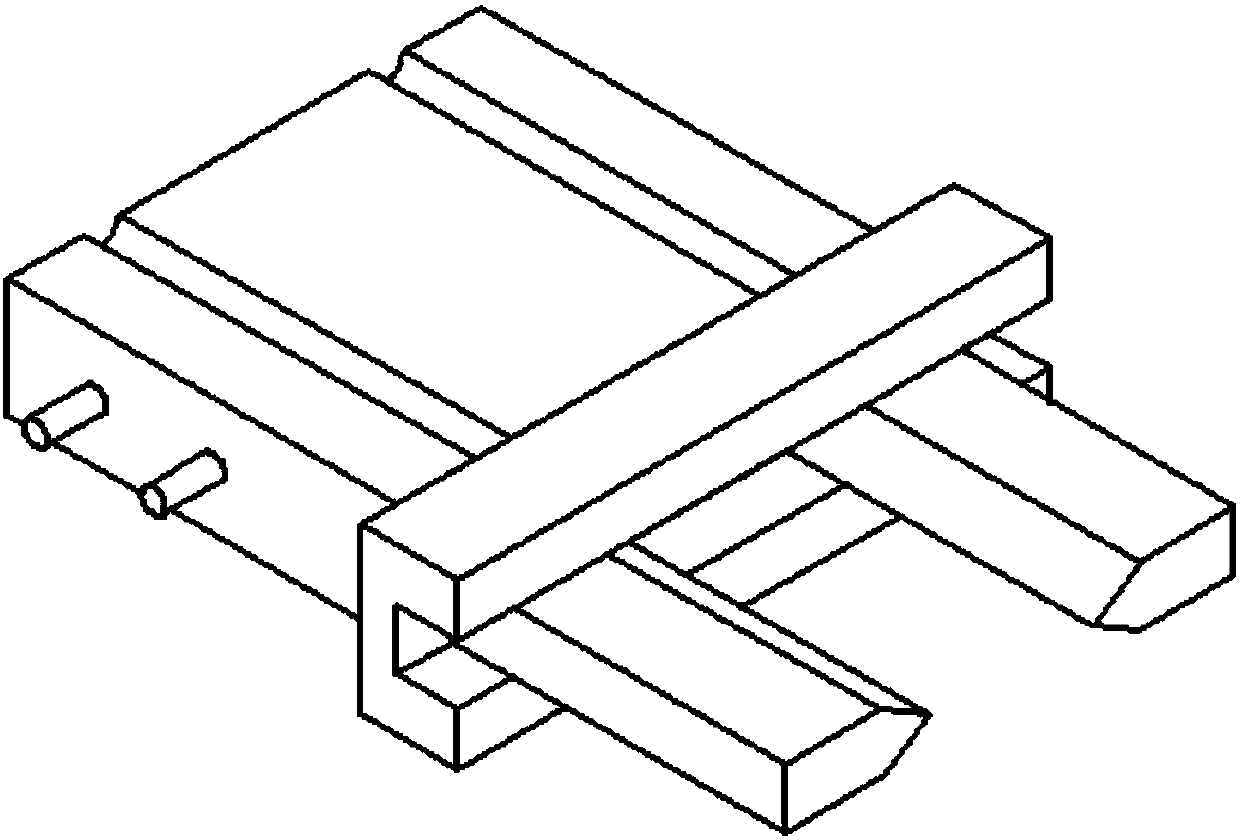

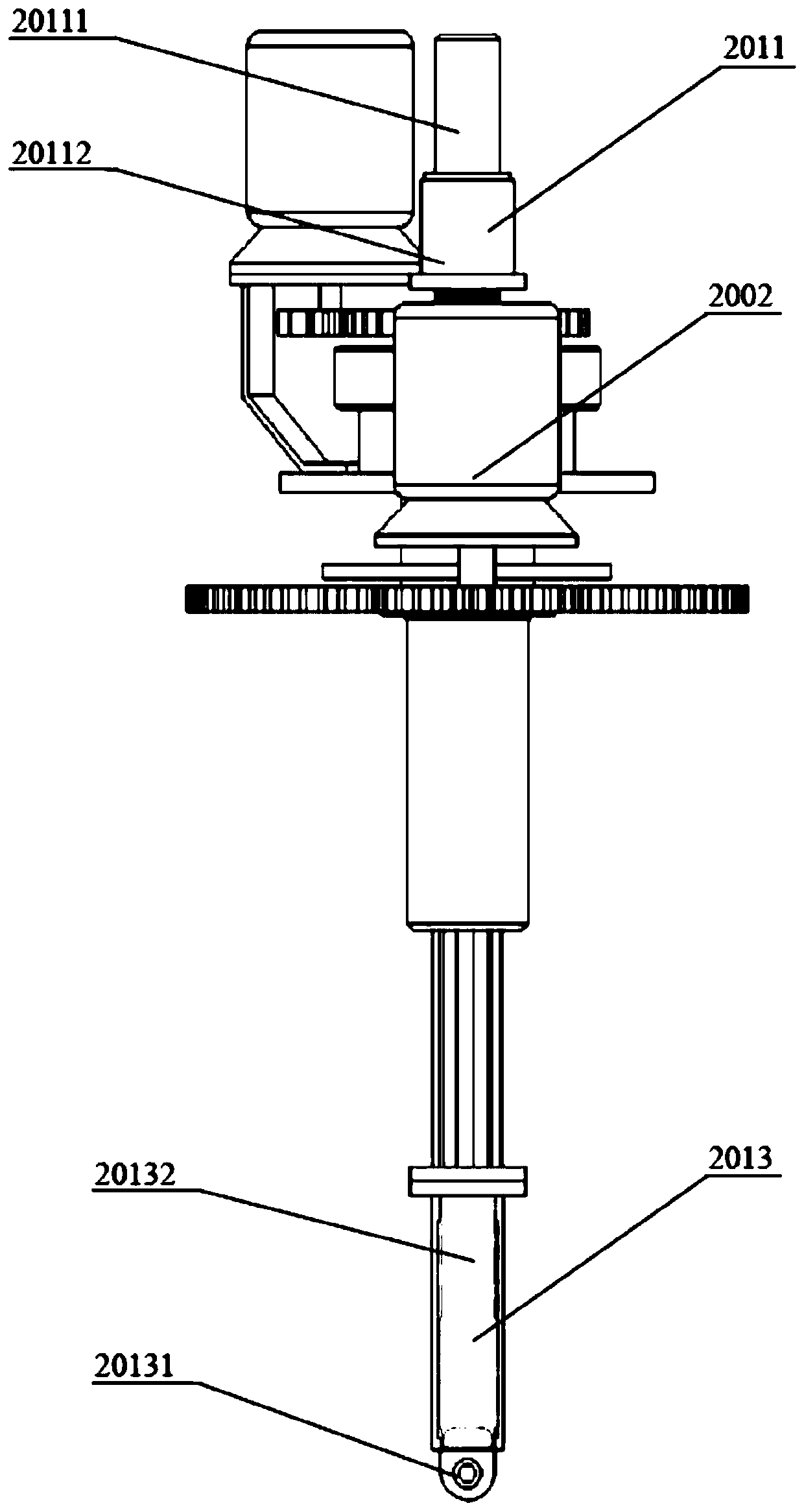

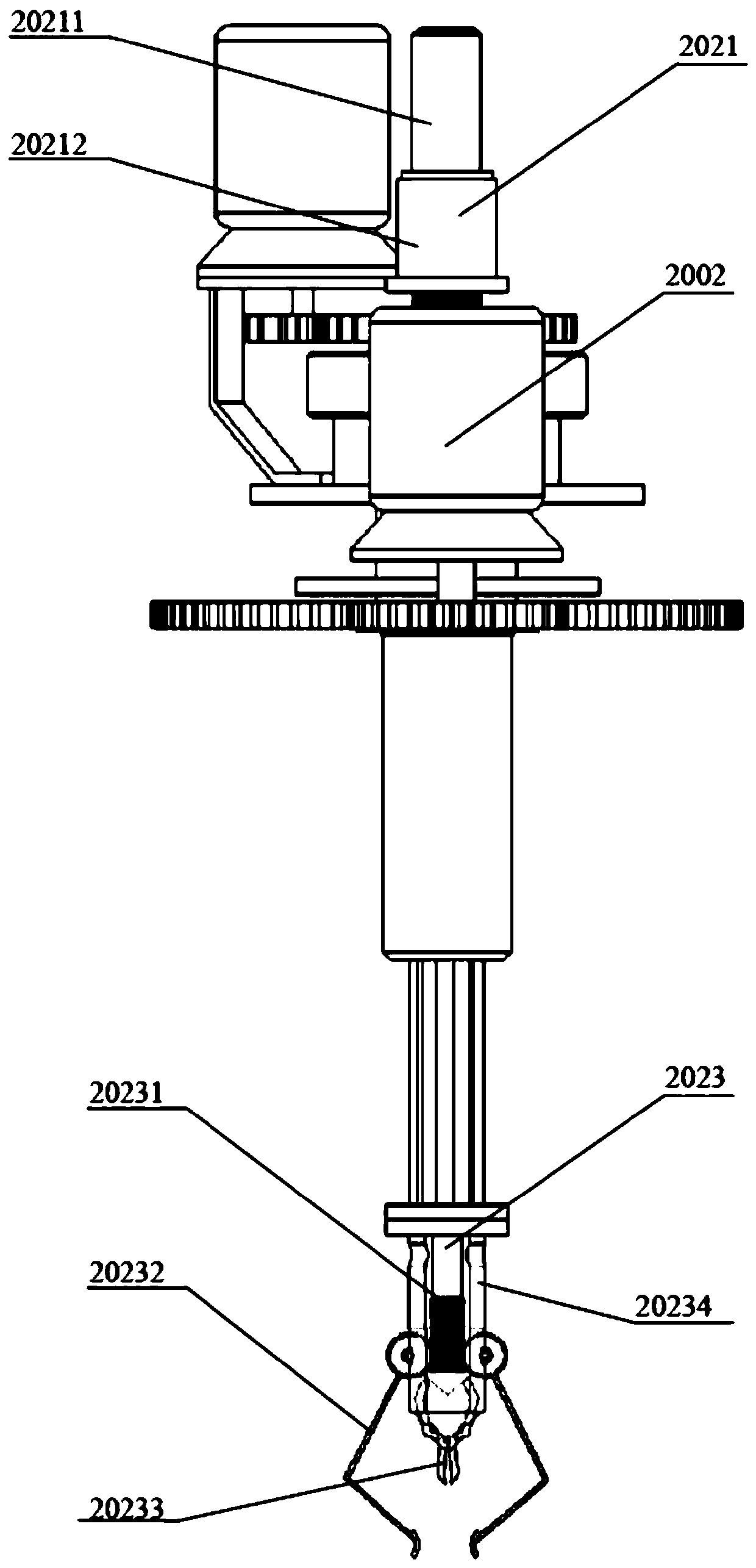

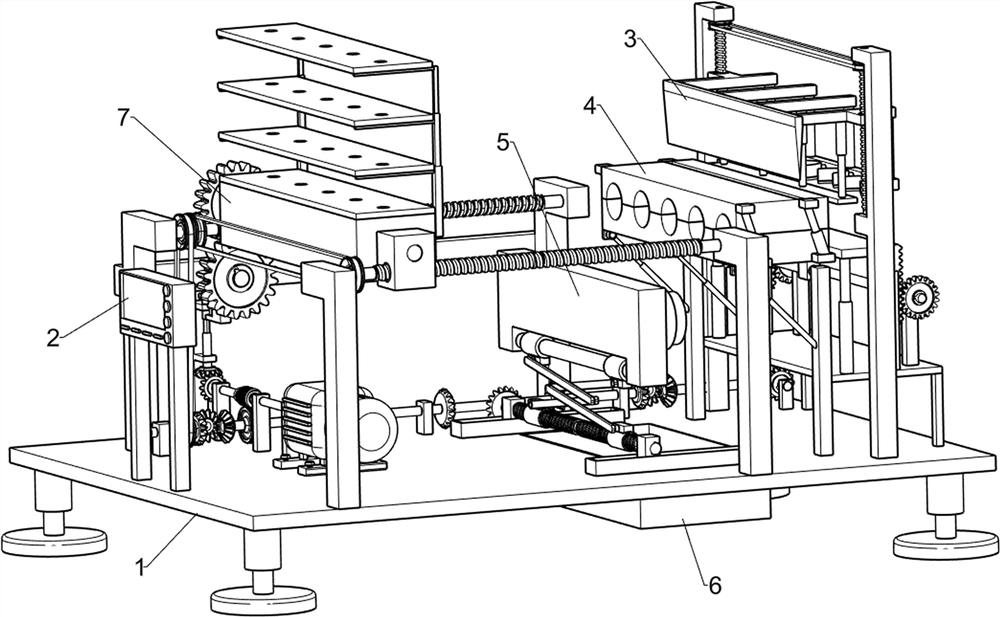

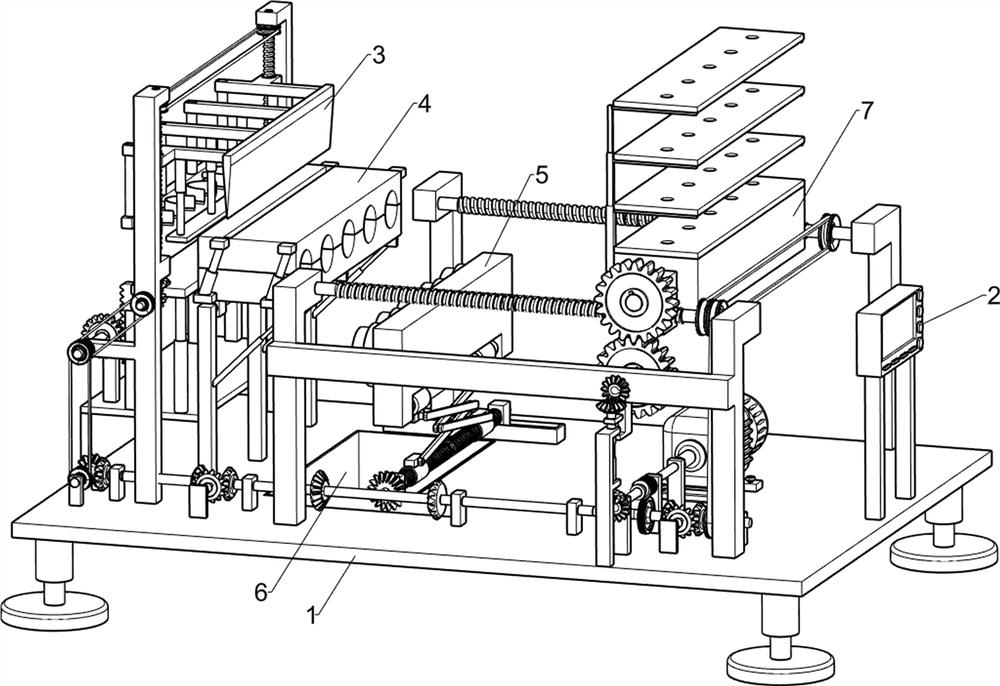

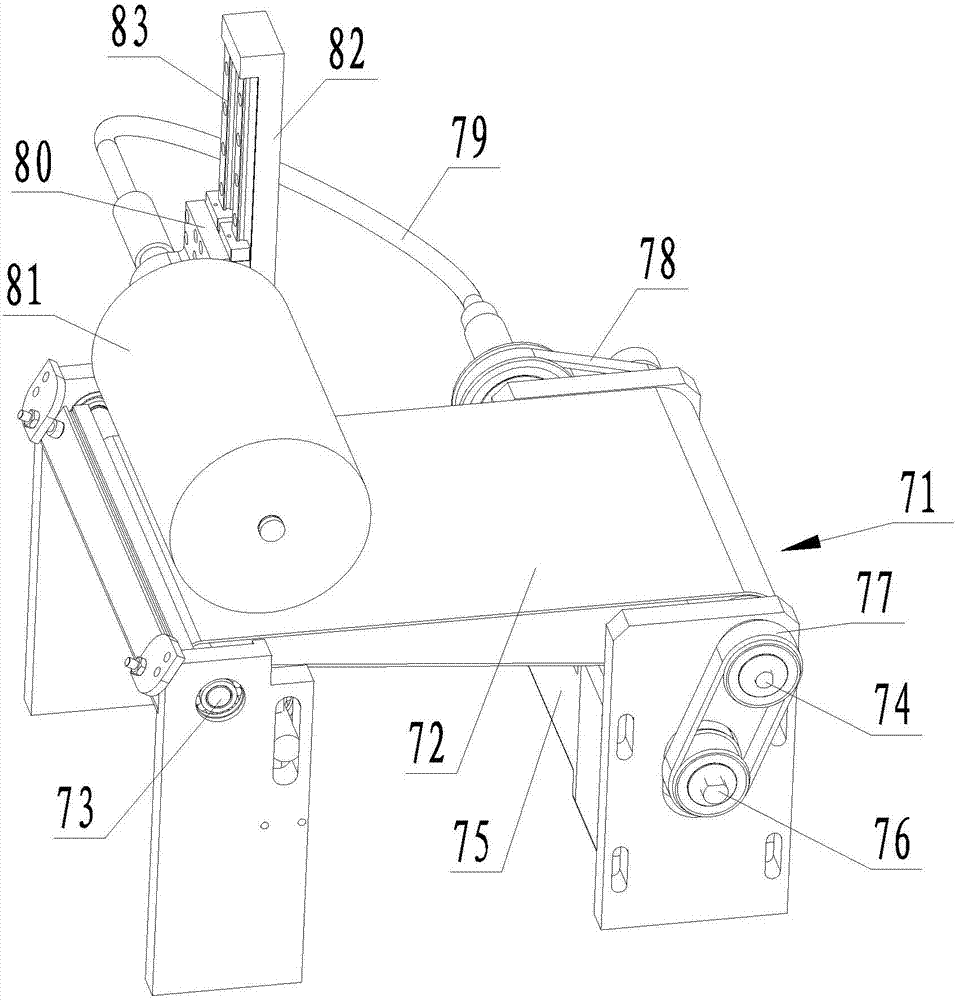

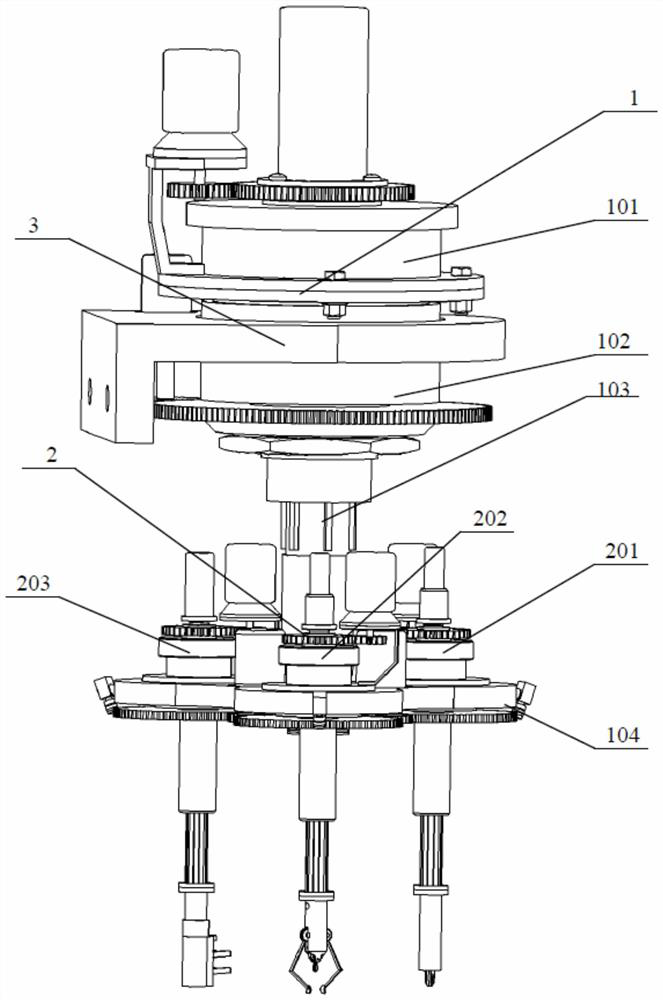

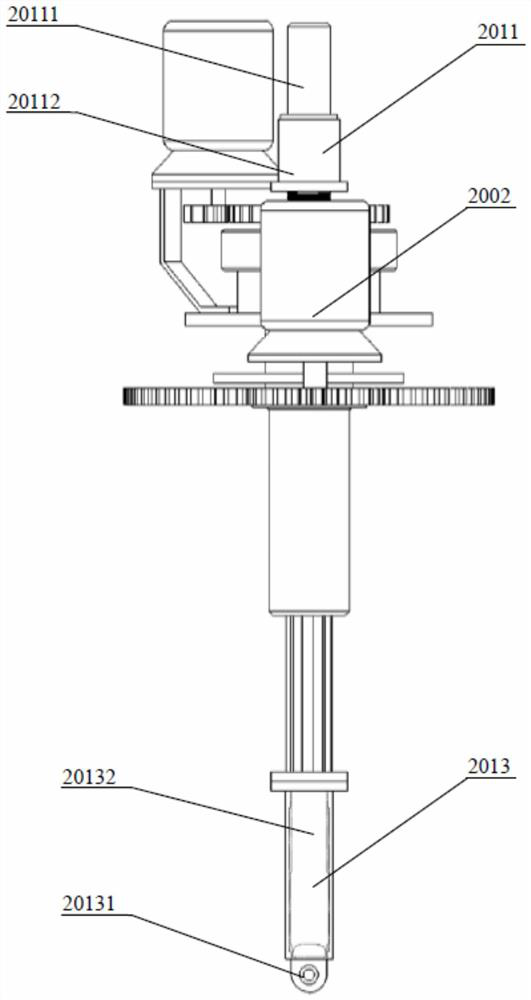

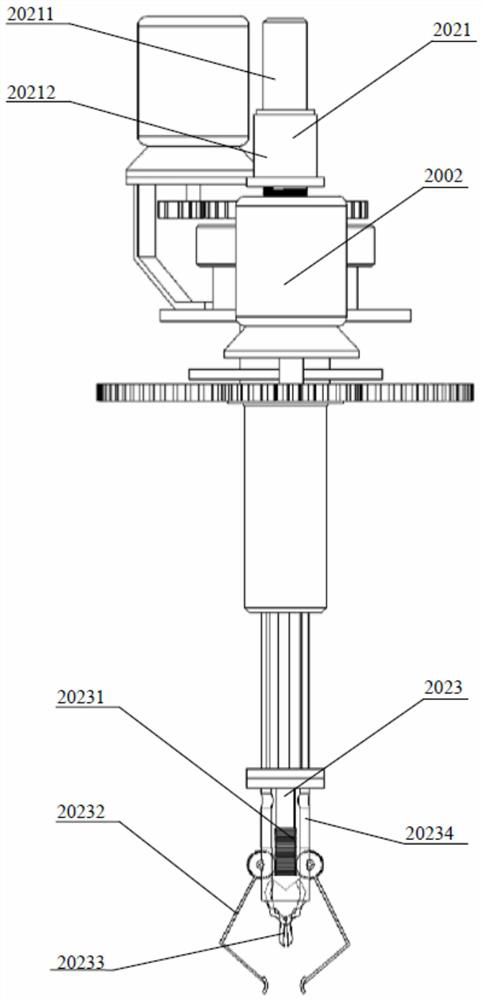

Bunched cable manufacturing multi-function intelligent manipulator and automatic cabling system thereof

ActiveCN110125920AVersatileAutoroutingProgramme-controlled manipulatorGripping headsControl engineeringManipulator

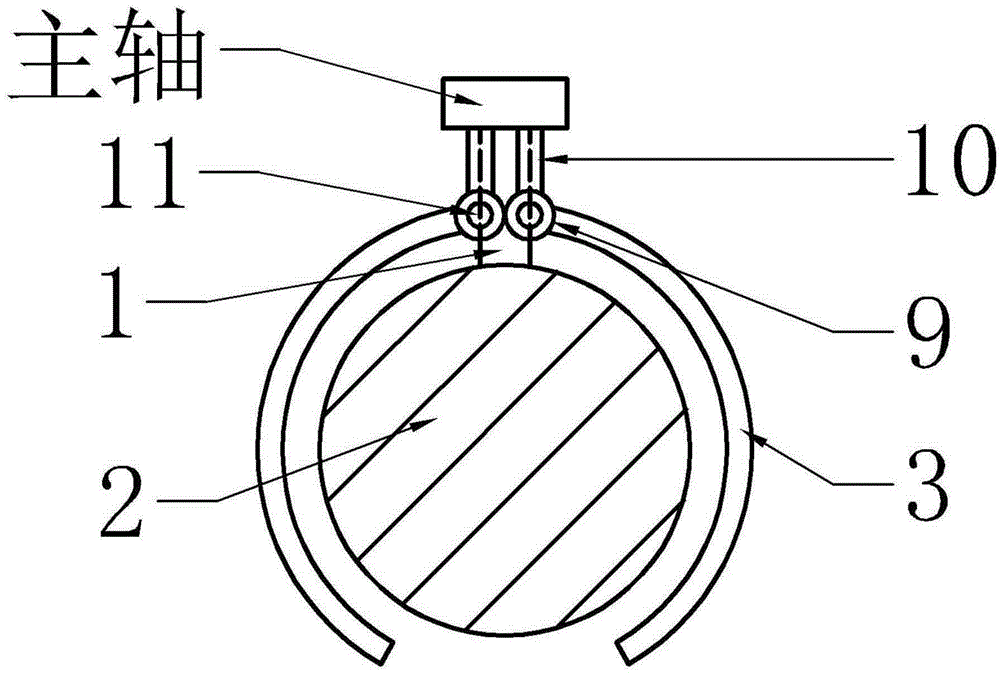

The invention discloses a bunched cable manufacturing multi-function intelligent manipulator and an automatic cabling system thereof. The manipulator comprises a wrist system, a multi-functional finger system and a movement base; the wrist system comprises a wrist lifting mechanism, a wrist rotation mechanism, a spindle and a finger assembly disc; the lower end of the spindle sequentially penetrates through the wrist lifting mechanism, the wrist rotation mechanism and the finger assembly disc; the upper part of the spindle is connected to the wrist lifting mechanism; the lower part of the spindle is connected to the wrist rotation mechanism; the wrist lifting mechanism is fixedly connected to the wrist rotation mechanism; the wrist rotation mechanism is fixedly connected to the movement base; the multi-function finger system comprises a cable drawing and cabling finger assembly, an inserting-pulling-cable-cutting finger assembly and a positioning post insertion finger assembly; each finger assembly is arranged on the finger assembly disc of the wrist system; the automatic cabling system comprises the manipulator; by adopting the bunched cable manufacturing multi-function intelligent manipulator and the cabling system thereof, automatic cabling of bunched cable networks of various lengths and widths as needed is realized; the automation degree is high; and operation is simple.

Owner:黑龙江润吉川科技有限公司

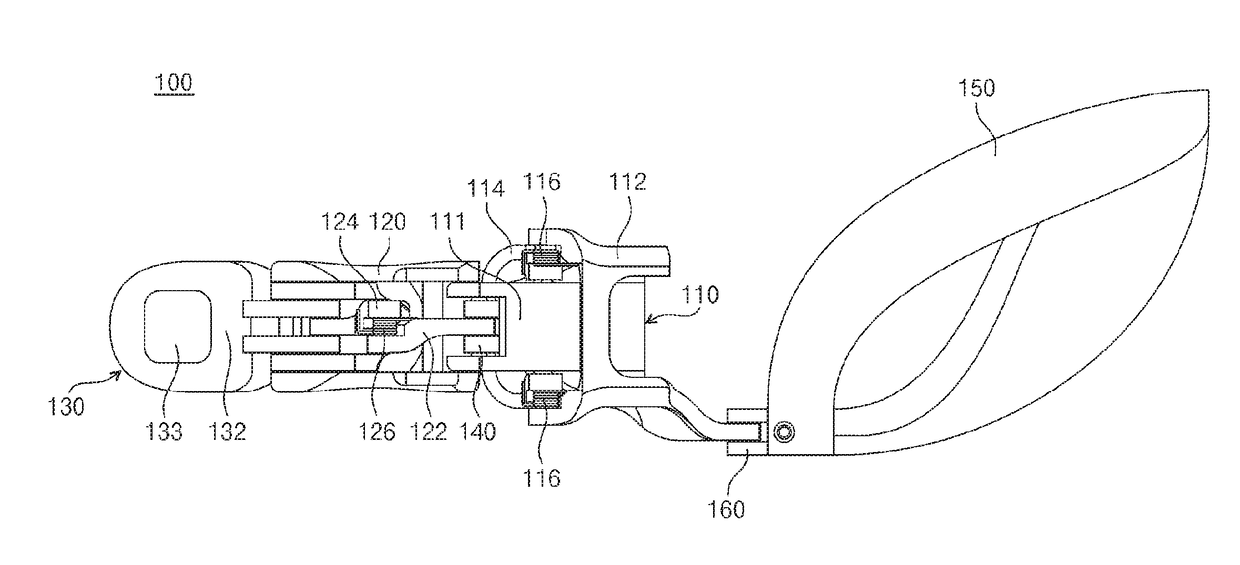

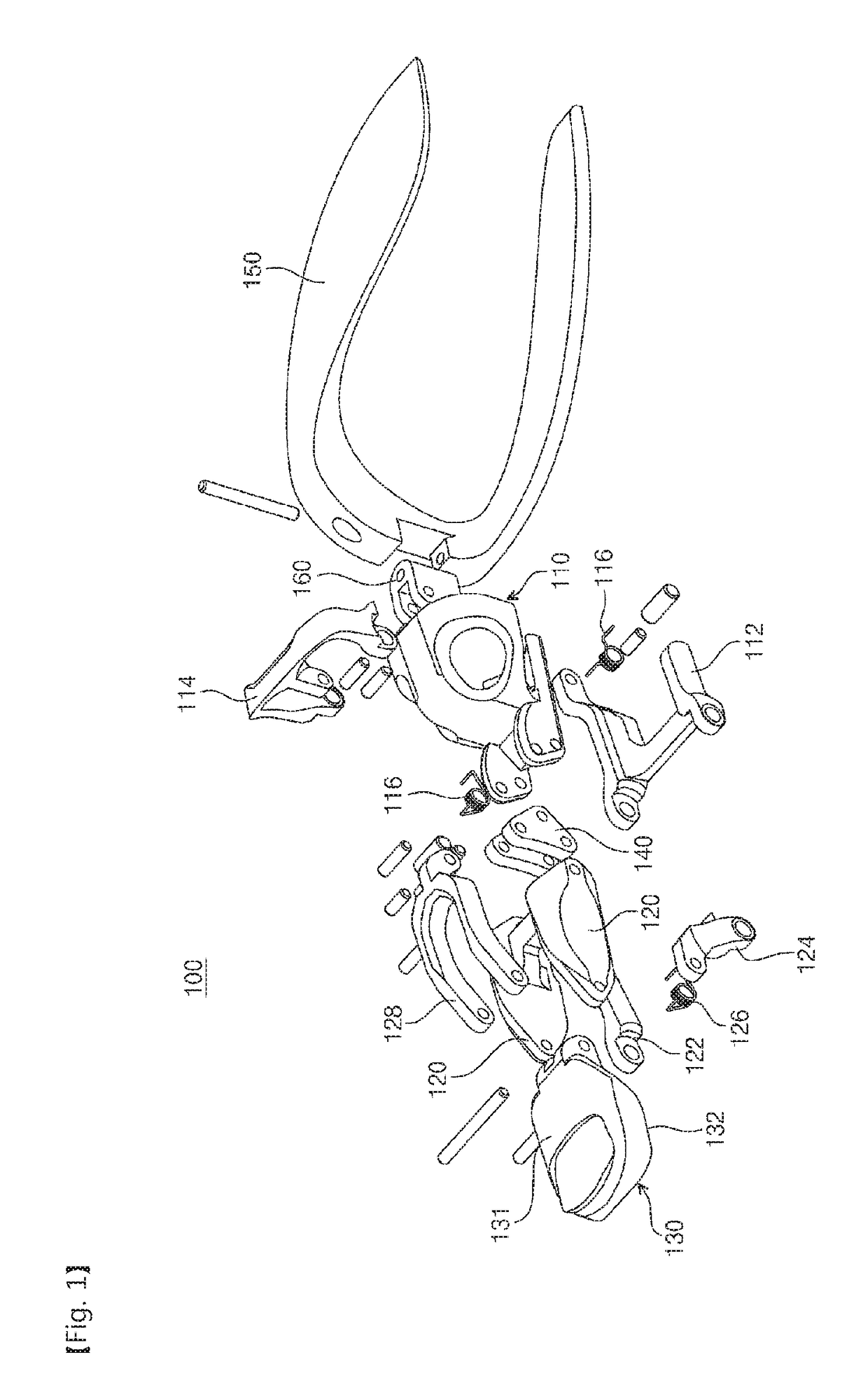

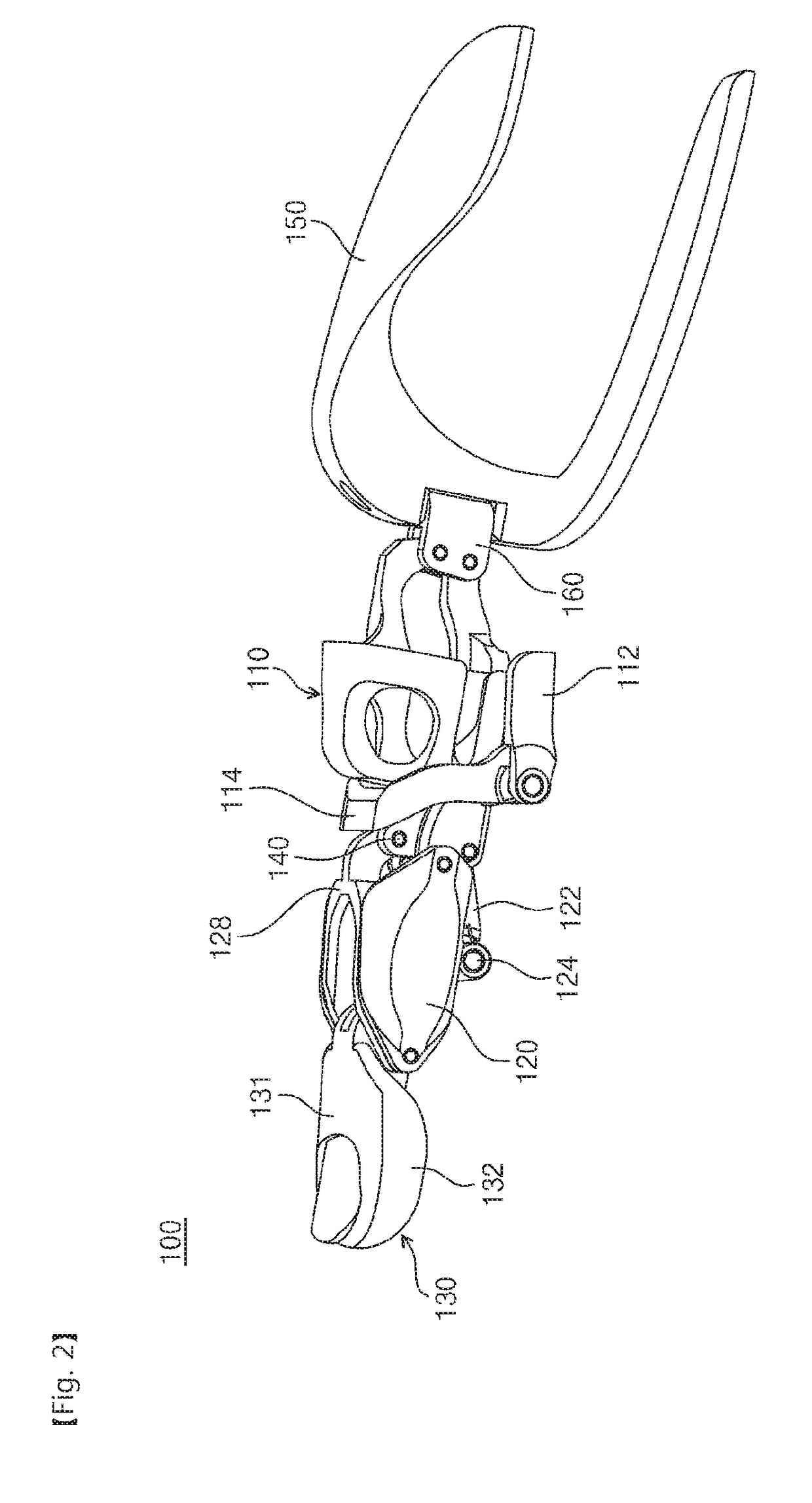

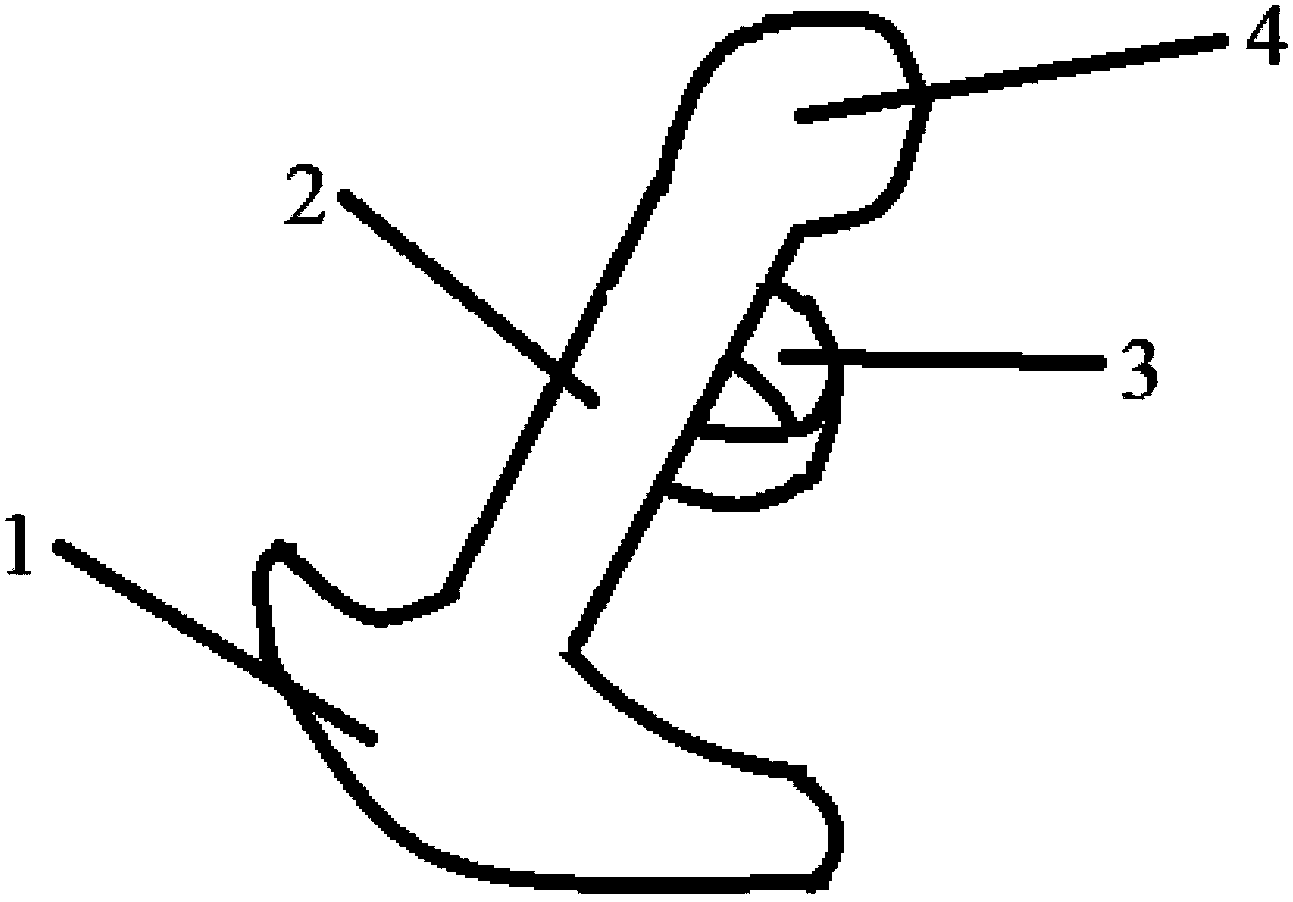

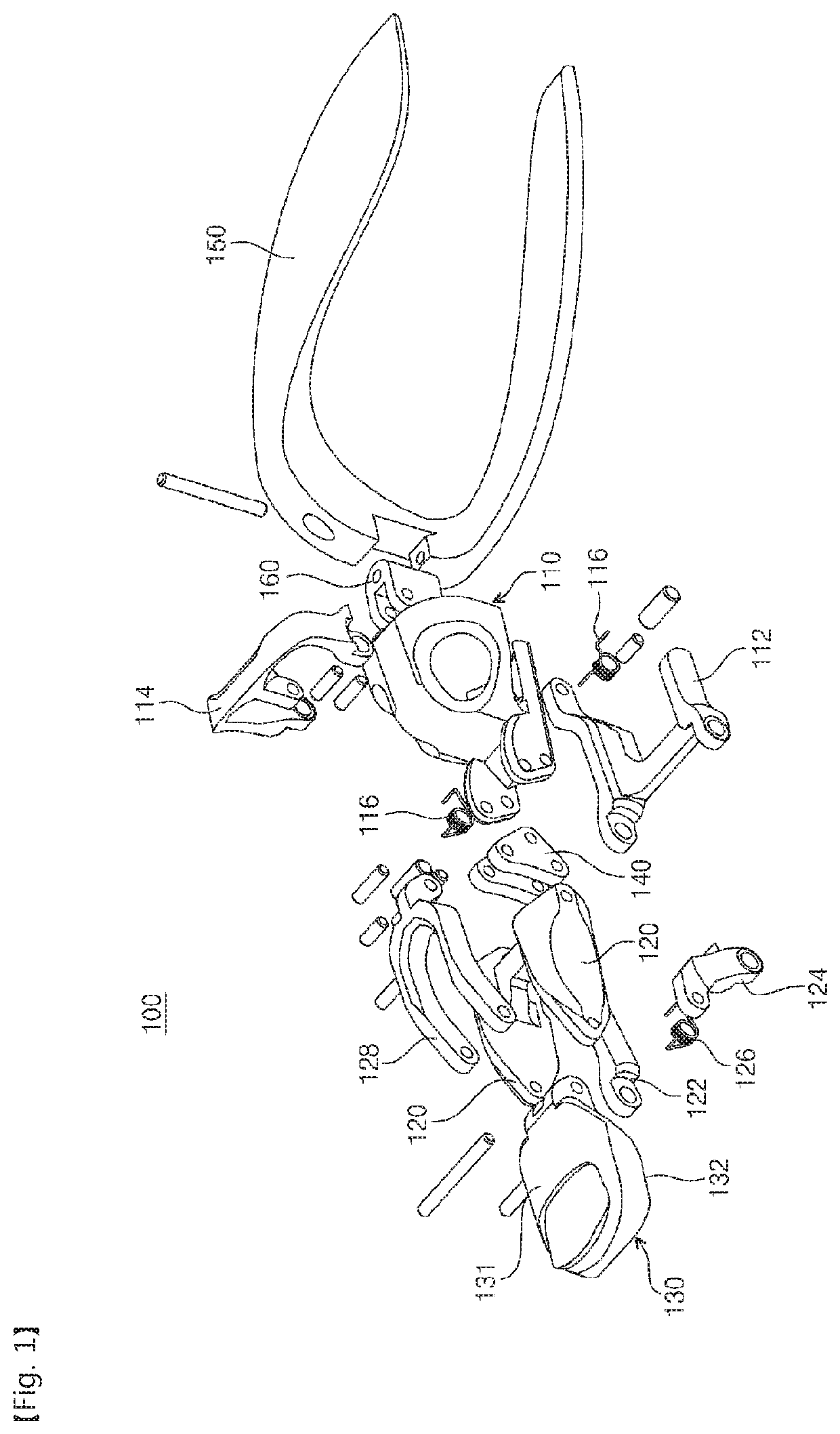

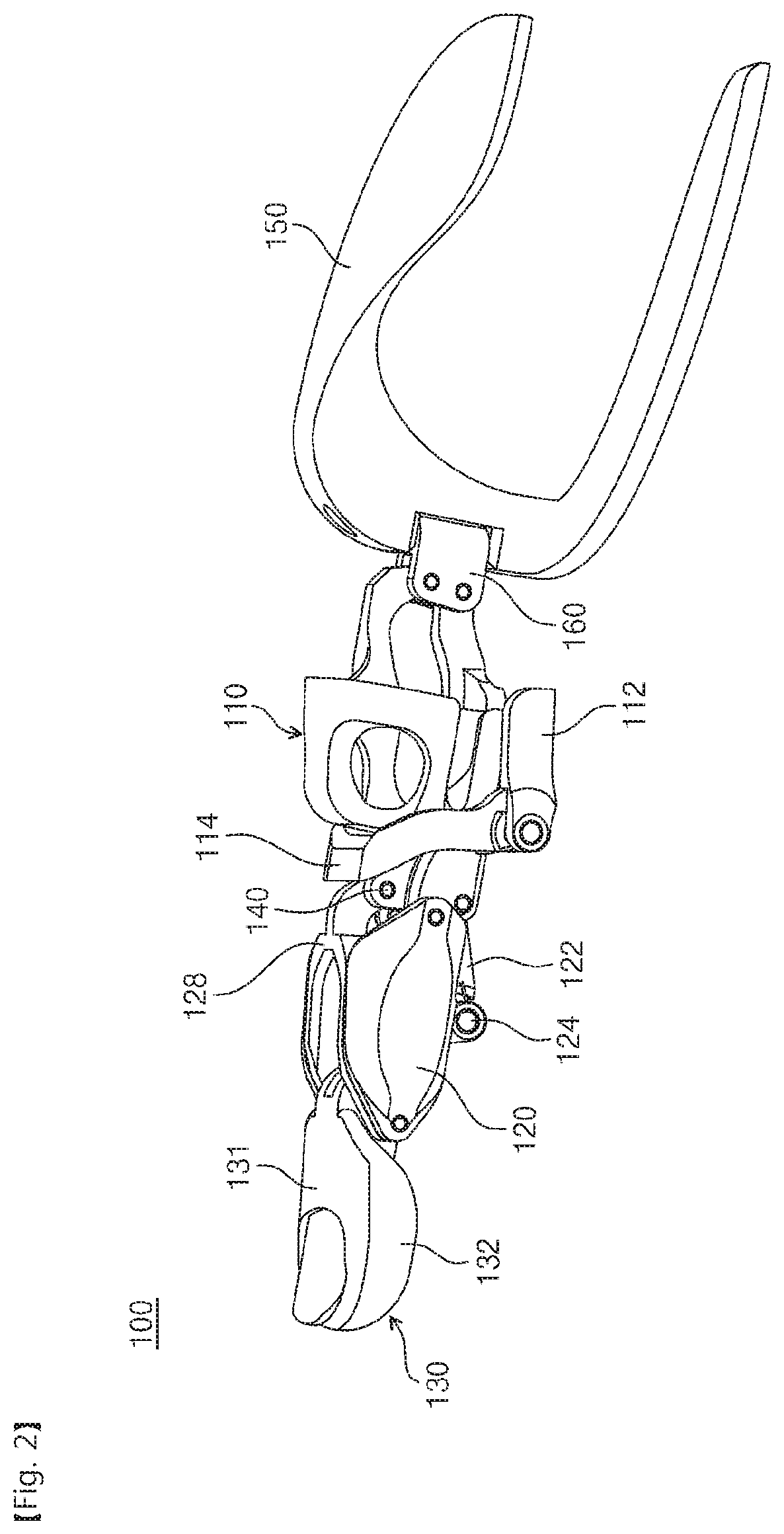

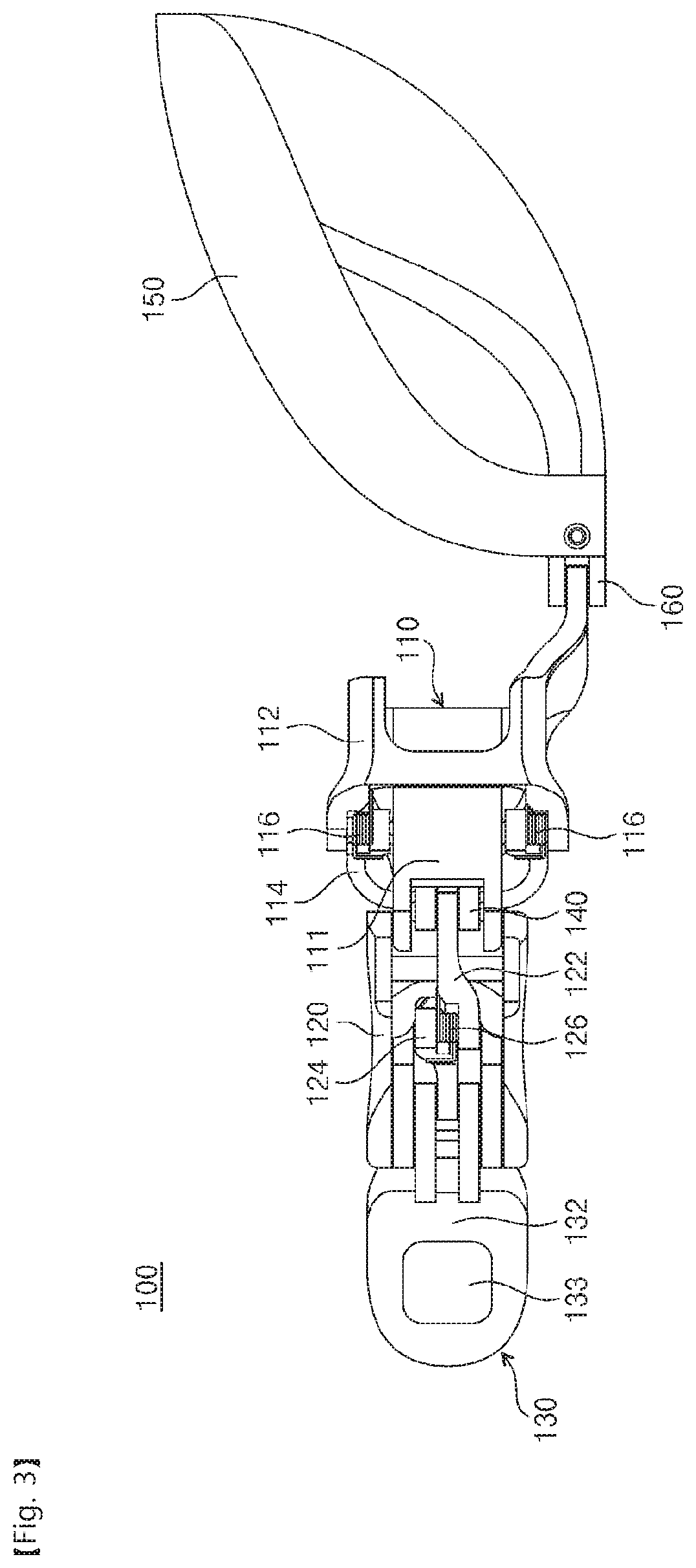

Adaptive robotic finger prosthesis for grasping arbitrary object shape

An adaptive robotic finger prosthesis according to the inventive concepts includes a proximal phalanx body configured to be worn on a proximal phalanx portion of a cut finger, a middle phalanx body connected to the proximal phalanx body and configured to function as a middle phalanx portion of the cut finger, a distal phalanx body connected to the middle phalanx body and configured to function as a distal phalanx portion of the cut finger, a first proximal phalanx link disposed under the proximal phalanx body, a second proximal phalanx link disposed on the proximal phalanx body and joint-connected to the first proximal phalanx link, and a proximal phalanx elastic member provided at a joint between the first proximal phalanx link and the second proximal phalanx link to provide elastic force.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

Apple picking robot hand structure

The invention provides an apple picking robot hand structure. The structure comprises a supporting flange and a supporting rod, the supporting flange is connected with the supporting rod, the supporting rod is connected with a fixing ring, the fixing ring is provided with movable grasping fingers and cutting fingers, the grasping fingers are movably connected with a telescopic mechanism I, and thecutting fingers are movably connected with the telescopic mechanism II. The structure has the advantages that a grasping mechanism and a cutting mechanism are included, and the cutting of fruits canbe achieved while the grasping is completed; the grasping mechanism and the cutting mechanism are independent of each other, and independent air cylinders are respectively used for driving to avoid mutual influence of the grasping mechanism and the cutting mechanism, which is beneficial to the dragging of the fruits; the structure includes adaptive assemblies, and improves the adaptability of a manipulator to the size of the fruits.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

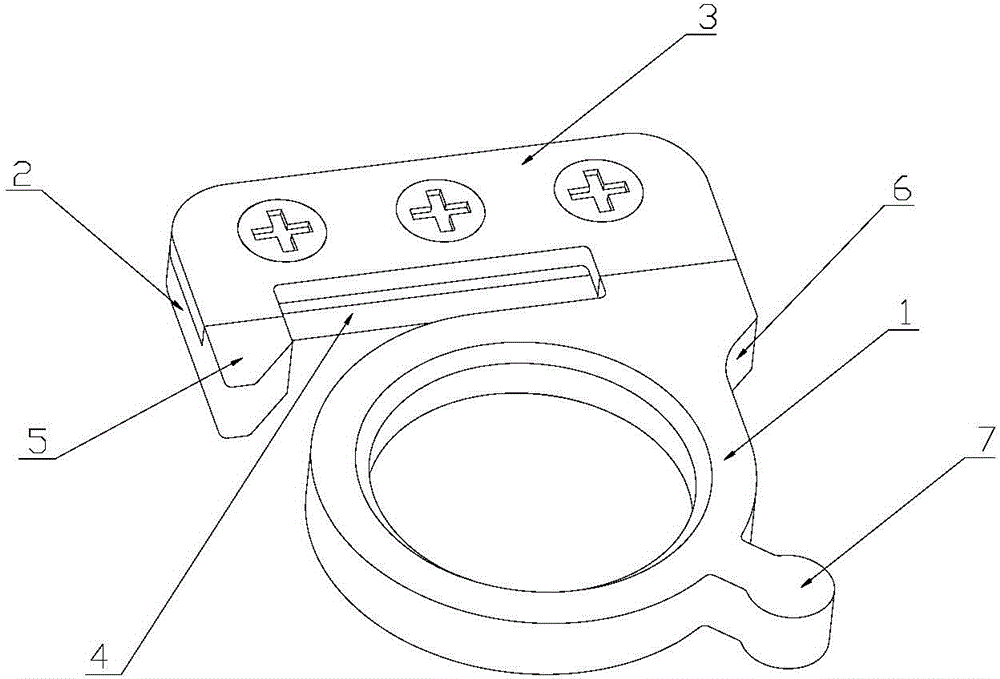

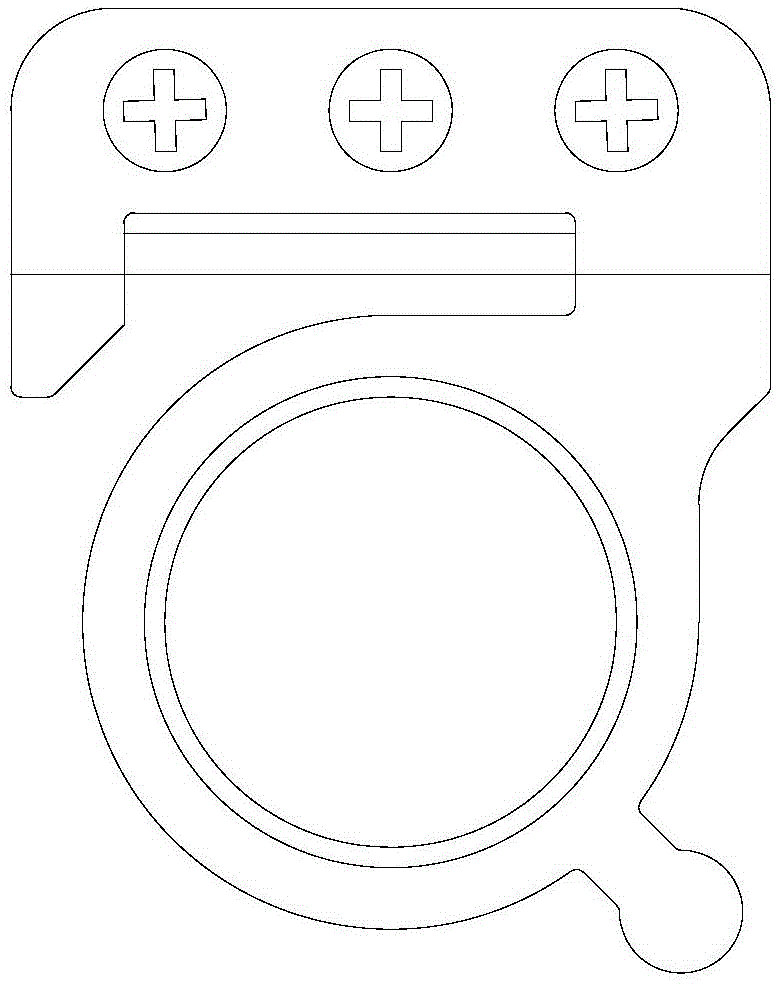

Cutting finger ring knife

InactiveCN105128038AEasy to operateImprove work efficiencyMetal working apparatusPlastic materialsEngineering

The invention provides a cutting finger ring knife. The cutting finger ring knife comprises a finger-ring-shaped body. The outer periphery of the finger-ring-shaped body extends in the radial direction and is bent to form a bent part. The side, opposite to the finger-ring-shaped body, of the bent part is provided with a bayonet. A knife rest plate is detachably connected to the interior of the bayonet. A blade is connected to the knife rest plate through a bolt. A cutting groove is formed between the blade and the outer periphery of the finger-ring-shaped body. An operator arranges the knife on a finger in a sleeving manner, adhesive tape can be dragged into the cutting groove by easily changing the position of the finger, the adhesive tape is cut off through the blade, operation is very convenient, and work efficiency is improved. The blade can be replaced, and cost consumption is substantially reduced. An inner arc concave part and a protruding part which are beneficial to holding and force application are arranged on the finger-ring-shaped body, and the structure is ingenious. The whole knife body is made of plastic materials, and therefore the cutting finger ring knife is light in weight, low in production cost and suitable for being widely popularized.

Owner:李尔汽车部件(济宁)有限公司

Chicken claw stringing device capable of completing decomposition

ActiveCN112568477AAchieve clampingAchieve upright positionPoultry deboningFood shapingChicken-clawsEngineering

The invention relates to the field of food processing, in particular to a chicken claw stringing device capable of completing decomposition. The technical problem of the invention is to provide the chicken claw stringing device capable of completing decomposition. According to the technical scheme, the chicken claw stringing device capable of completing decomposition comprises a rotary positioningsystem, a first collecting box, a bamboo stick clamping and steering system and the like; the first collecting box and the bamboo stick clamping and steering system are connected; the cutting systemis connected with the rotary positioning system; and the rotary positioning system is connected with the bamboo stick clamping and steering system. According to the invention, chicken claw stringing is designed, a conventional method of manual stringing is skipped, and nails of the chicken feet and a section of straight bone of the chicken feet are cut off; the working efficiency is improved, andthe phenomenon that the bone of the chicken claw is hard and easily slips to cut fingers is avoided; the current situation that existing equipment cannot remove nails of chicken claws and straight bones at the upper ends of the claws while stringing the chicken claws is changed.

Owner:泰安市新创科技服务有限公司

Finger protecting cover

A finger protecting cover comprises a finger protecting rod which is of a strip-shaped sheet shape, wherein a baffle is arranged at one end of the finger protecting rod, a finger protecting head is arranged at the other end of the finger protecting rod, and a finger stall is arranged in the middle of one side of the finger protecting rod; the baffle is in the shape of a sheet which slightly protrudes outwards. Since the finger protecting cover is provided with the finger stall and the baffle, the finger protecting cover can effectively prevent a user from cutting fingers of the user by accident when the user cuts vegetables with a kitchen knife; besides, the finger protecting cover is light and exquisite in size and convenient to use.

Owner:张力

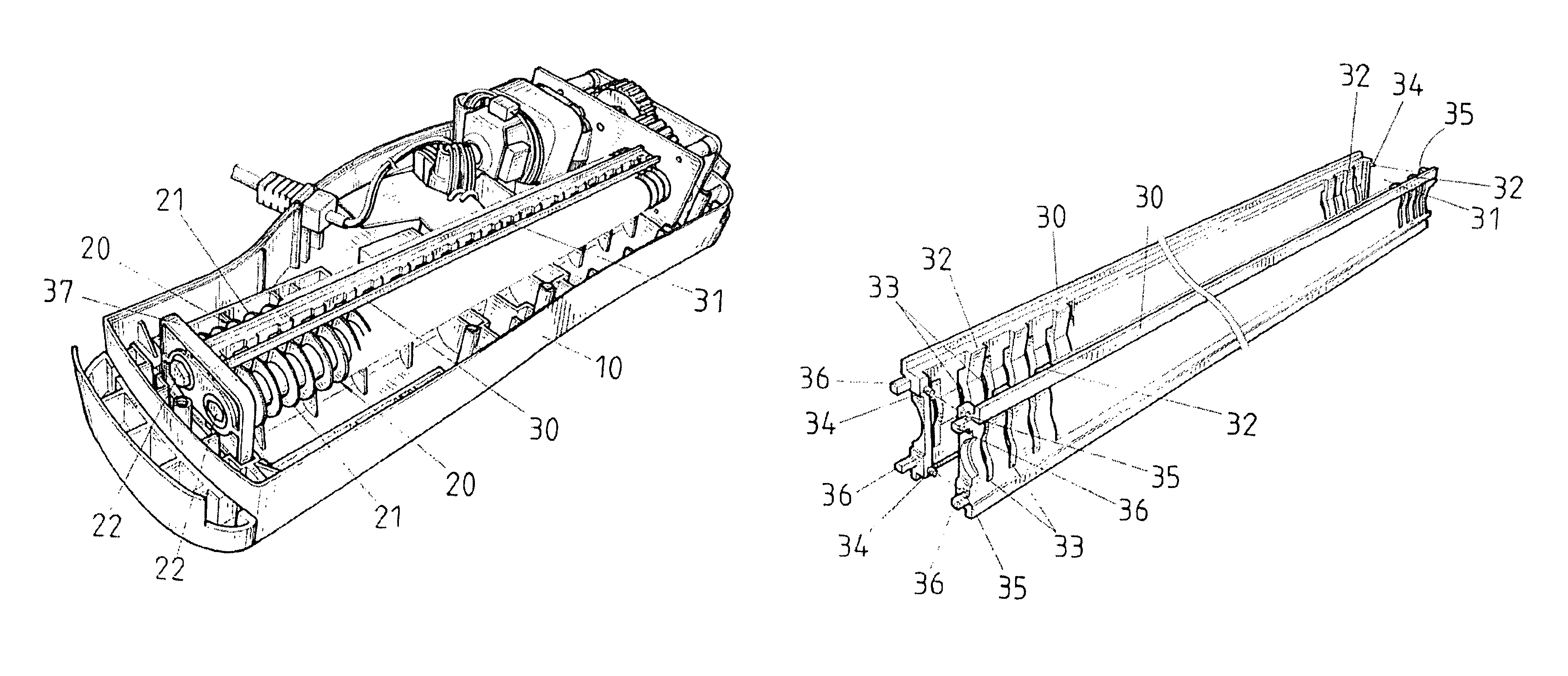

Cutter bar

ActiveUS20060150607A1Solution to short lifeNo frictional resistance between the knife and the finger barMowersTransverse axisGear wheel

The invention relates to a reciprocating cutting bar for the cutting gear of an agricultural machine, comprising a longitudinal axis (4) along which the reciprocating cutting bar may be moved in a working direction for crop cutting, a finger bar (1), cutting fingers (2), which are fixed to the finger bar (1), each forming counter cutters (11), a knife (5) with a knife bar (7), having knife blades (8) fixed to the knife bar (7) which each have cutters (9), whereby the knife (5) is made to oscillate relative to the finger bar (1) along a transverse axis (6), which is arranged horizontally and perpendicular to the longitudinal axis (4), rollers (13), by means of which the knife (5) is supported against the finger bar (1) to the rear when viewed in the working direction. The rollers (13) are each mounted to rotate on a roller holder (17) and the roller holders (17) are fixed to the finger bar (1).

Owner:SCHUMACHER GUSTAV

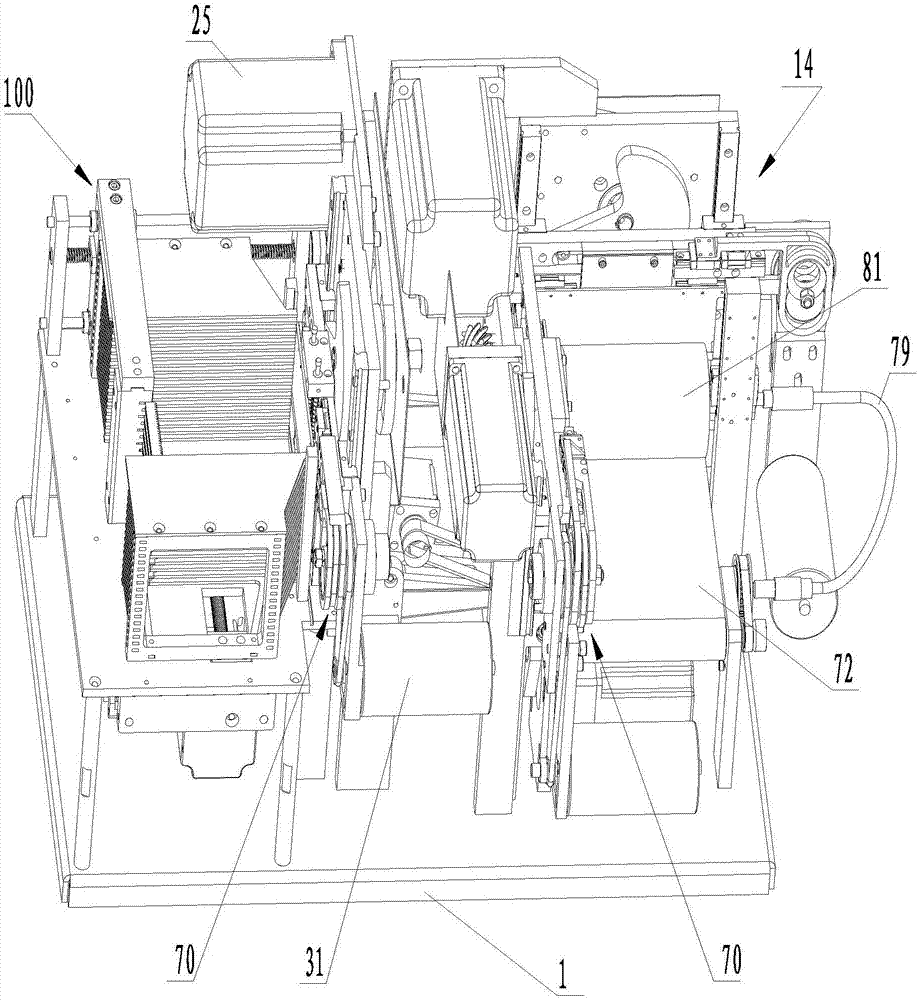

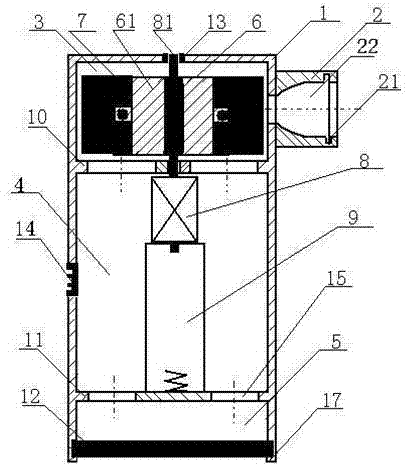

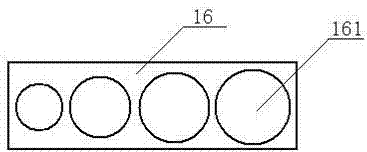

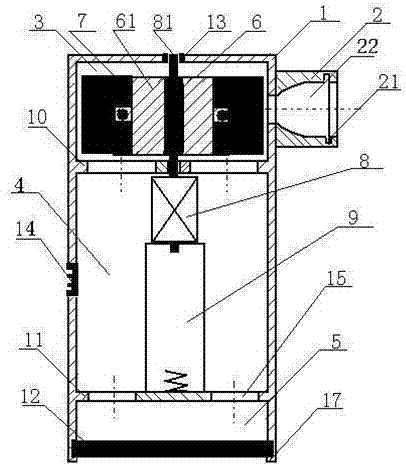

Electric silkworm cocoon cutting machine for silkworm egg production

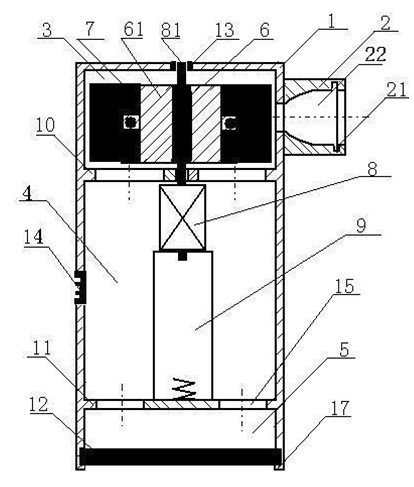

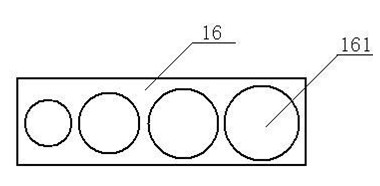

InactiveCN102125004AReduce labor intensityCocooning speed increasedAnimal husbandryEngineeringCut fingers

The invention discloses an electric silkworm cocoon cutting machine for silkworm egg production. A shell is internally provided with a feeding cavity, a blanking cavity and a storage cavity, wherein a partition plate A is arranged between the feeding cavity and the blanking cavity; a partition plate B is arranged between the blanking cavity and the storage cavity; the feeding cavity is internally provided with a tool apron and connected with a cutting knife through a tool rest arranged on the tool apron; the side wall of the blanking cavity is provided with a cocoon cutting port and a cocoon inlet passage thereof; the blanking cavity is internally provided with a power supply device and a power device, wherein the power device penetrates through the partition plate A to connect with the tool apron; and the bottom of the storage cavity is provided with a movable pulling plate. The invention not only can solve the problem that a silkworm raiser is easy to cut fingers or a silkworm pupae in the silkworm cocoon cutting process, but also is economic and practical and approaches to maturity and can save the labor and the time and greatly enhance the work efficiency, thereby solving the problems that a large amount of manpower is needed when silkworm cocoons are cut and the silkworm pupae are already incubated into moths when the silkworm cocoons are not cut.

Owner:郑玉林

Paper shredder which prevents cutting fingers

A paper shredder which prevents cutting fingers is composed of a plurality of stops at two sides of a slot hole of a rack of two blade tools inside the paper shredder. The stops, which are aligned in alternation, are emplaced respectively between two blades. When a paper drop opening at a bottom cap is aligned with the slot hole of the rack, the stops will limit space the paper drop opening extending into the blade tool, which prevents from inserting fingers into the paper drop opening to be cut by the blade tool, and also prevents from putting in extraneous material to cause malfunction of the paper shredder.

Owner:LO EMILY

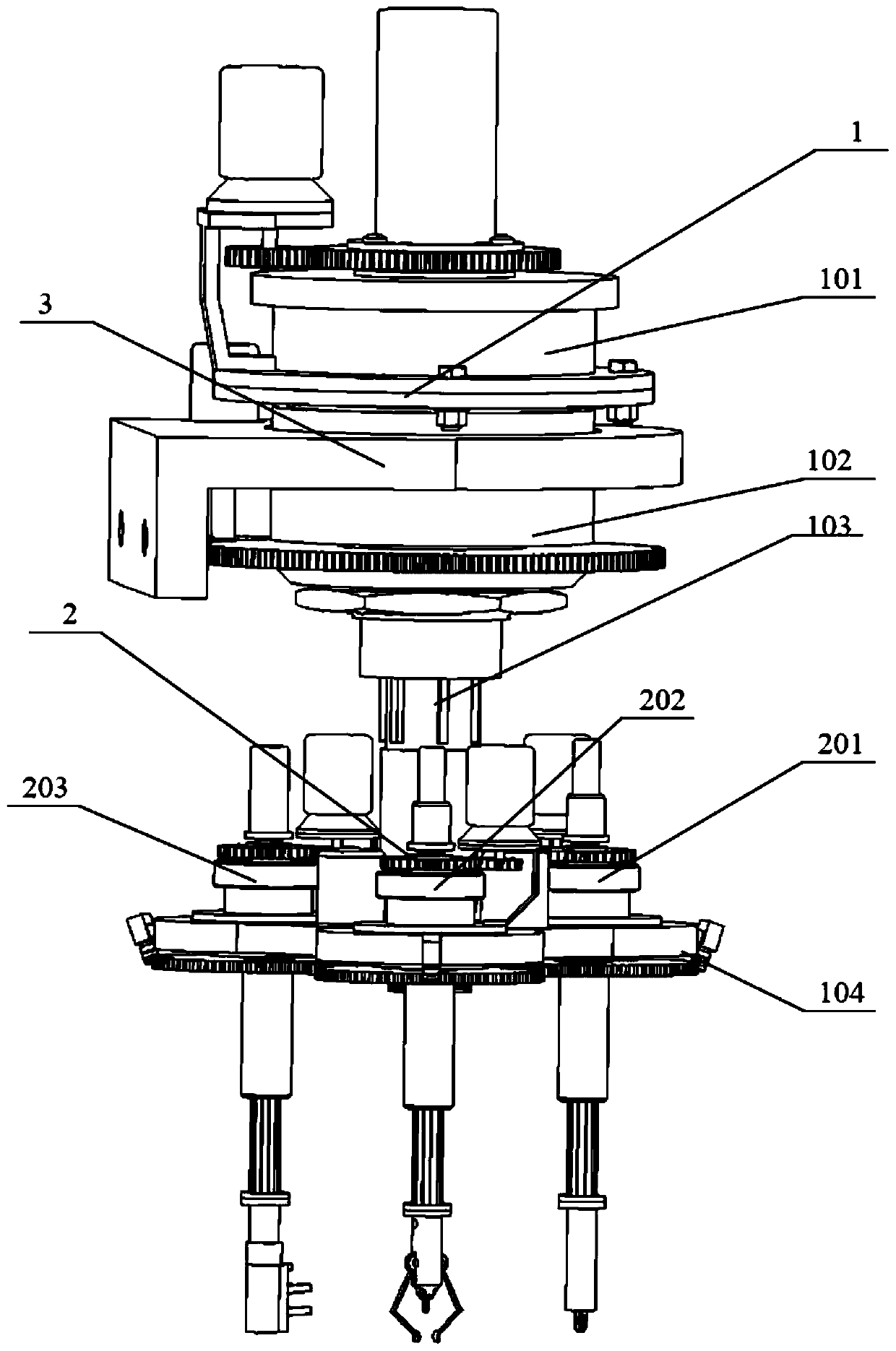

Mechanical arm clamping device

The invention discloses a mechanical arm clamping device. The mechanical arm clamping device is provided with a spindle, and a cutting finger, a clamping finger and a tray are sequentially mounted on the spindle from top to bottom. The cutting finger is provided with a cutting arm, one end of the cutting arm is connected with the spindle, and a cutting wheel is disposed at the other end of the cutting arm. The clamping finger is provided with two circular arc finger bodies, and tail ends of the finger bodies, which are close to the spindle, are connected with a rotating shaft respectively and connected with the spindle through clamping finger connecting rods. The tray is circular and connected with the spindle through a tray connecting rod. According to the mechanical arm clamping device, a modular design is applied to the mechanical arm, the structure is simple, manufacturing and maintaining costs are low, and modules can be replaced to perform simple repair if mechanical faults occur.

Owner:宁夏巨能机器人股份有限公司

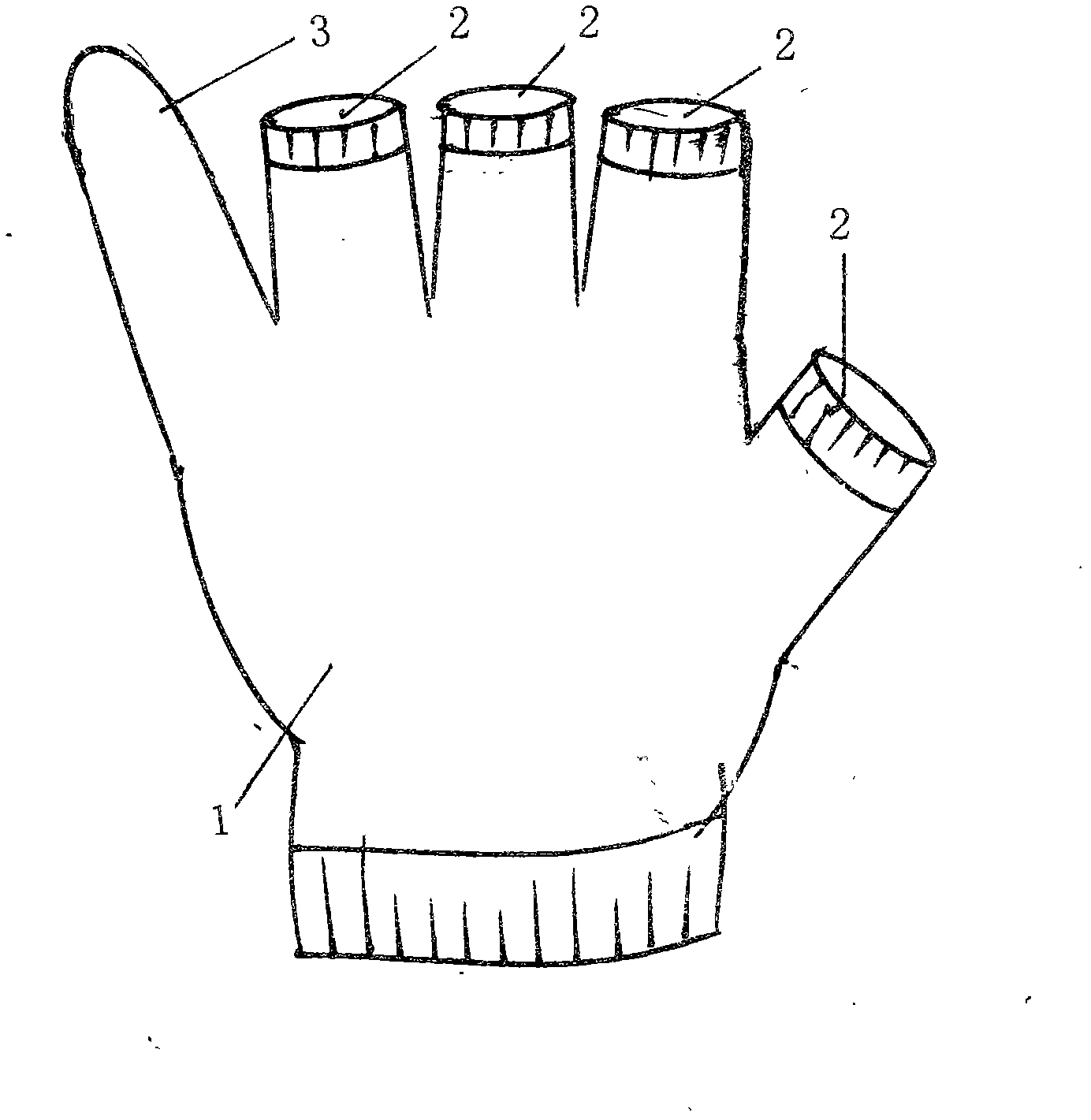

Student glove

The invention provides a student glove. A little finger complete glove is arranged on a glove body of the glove. A thumb, an index finger, a middle finger and a third finger are all bucket cutting finger gloves that the fingers can be exposed. By means of the student gloves, a pen is convenient to hold and a book is convenient to turn by the thumb, the index finger, the middle finger and the third finger when a student use the gloves in winter. Due to the fact that the little finger can be closely attached to a desk surface when the student writes, thus the little finger glove can play a role in insulating cold and keeping warm. The student gloves are beneficial to studying for the student.

Owner:张琼

Chopping block capable of avoiding cutting fingers

InactiveCN109730554APreventing the Danger of Cut FingersImprove practicalityKitchen equipmentEngineeringCut fingers

The invention provides a chopping block capable of avoiding cutting fingers. The chopping block comprises a chopping block body and a protection sheet with one end being fixedly arranged at one side of the chopping block body; the fixed end, fixed on the chopping block body, of the protection sheet is a groove which is turnover to be inserted into the chopping block body; the middle of the other end of the protection sheet is split to form a first protection sheet and a second protection sheet; the first protection sheet is bent to be pressed on the upper surface of the chopping block body; and the second protection sheet is fixedly arranged on a knifepoint of a kitchen knife by two magnets. The chopping block is capable of avoiding cutting fingers, safe and high in practicability.

Owner:SHANGHAI GEZHI HIGH SCHOOL

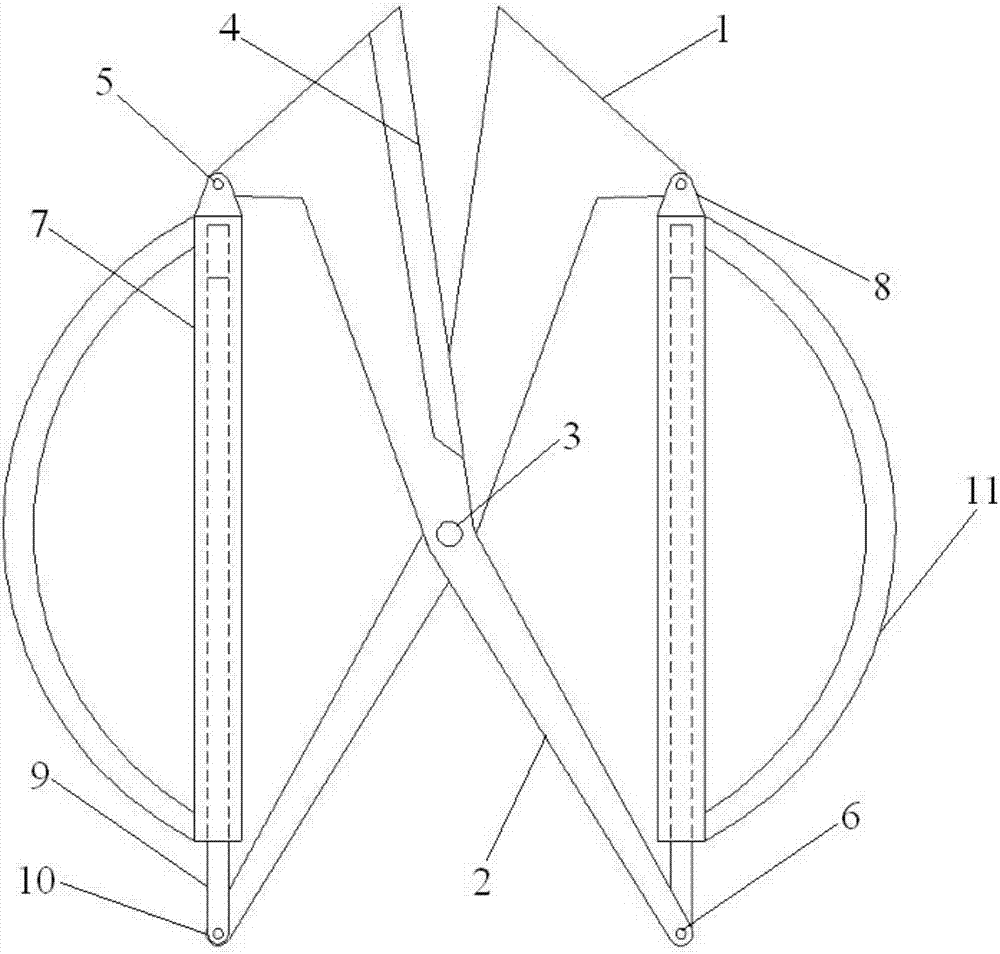

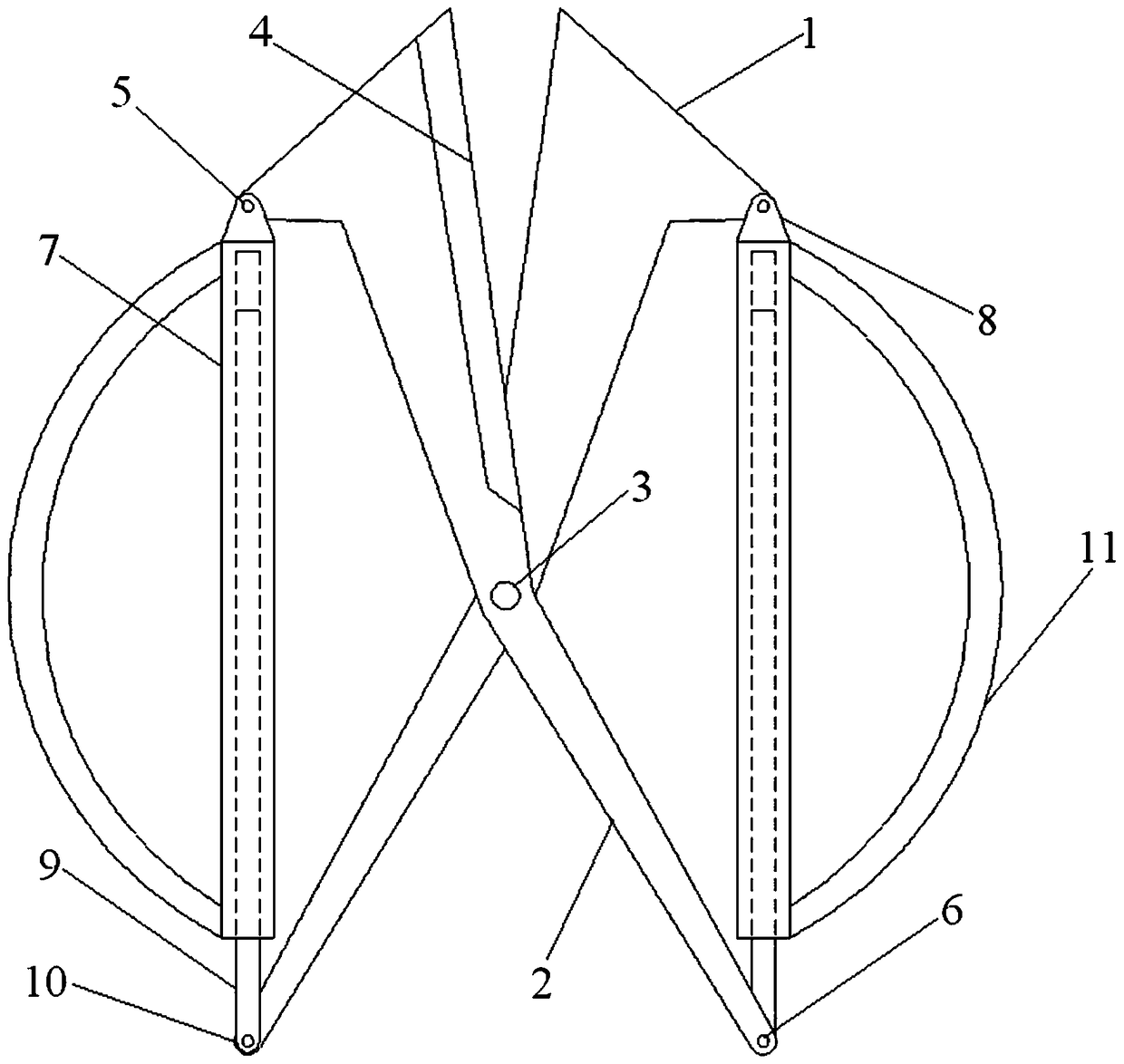

Safe craft scissor

The invention belongs to the technical field of study articles and discloses a safe craft scissor. The safe craft scissor comprises two shear blades and two telescopic handles. One end of shear blades are scissor tips and the other end are scissor tails. The middle of the shear blades is provided with a main hinging hole. The inner edge of each scissor tip is provided with a cutting edge and the outer edge of each scissor tip is provided with a first assistant hinging hole. Each scissor tail is provided with a second assistant hinging hole. Two shear blades are mutually hinged through the main hinging hole. One end of each telescopic handle is mutually hinged with the first assistant hinging hole on the two shear blades correspondingly. The other end of each telescopic handles is mutually hinged with the second assistant hinging hole on the two shear blades correspondingly. The safe craft scissor has a high shear ability, a rigid paper can be cut by kids with the safe craft scissor, the expandable angle of the two scissor tips is constrained by the telescopic handles, the fact that fingers of the kids stretch between the cutting edges of the two scissor tips can be prevented, and the injury of cutting fingers of kids is avoided.

Owner:黄润盛

Transportation limiting device

The invention discloses a transportation limiting device. The transportation limiting device comprises a rack, and a second conveyer belt is arranged on the rack; the second conveyer belt transmits vegetables through a first rotating shaft and a second rotating shaft; a seventh power device is arranged at the bottom of the rack; an output shaft of the seventh power device is connected with one end of the second rotating shaft through a seventh belt; a first guide rod is arranged on the rack; and a longitudinal guide rail is arranged on the first guide rod. According to the transportation limiting device, food materials which are cut into blocks and strips can be transported to a slitting or dicing device to be continuously cut, and a limiting function is achieved while cutting, so that on one hand, vegetable cutting efficiency is effectively improved, the food materials are arranged trimly, vegetable cutting quality is guaranteed, and size uniformity of cut vegetables can be guaranteed, on the other hand, workload of operators is effectively reduced, and further, the risk of cutting fingers is effectively reduced.

Owner:FUYANG WANRUI ELECTRONICS LOCKS CO LTD

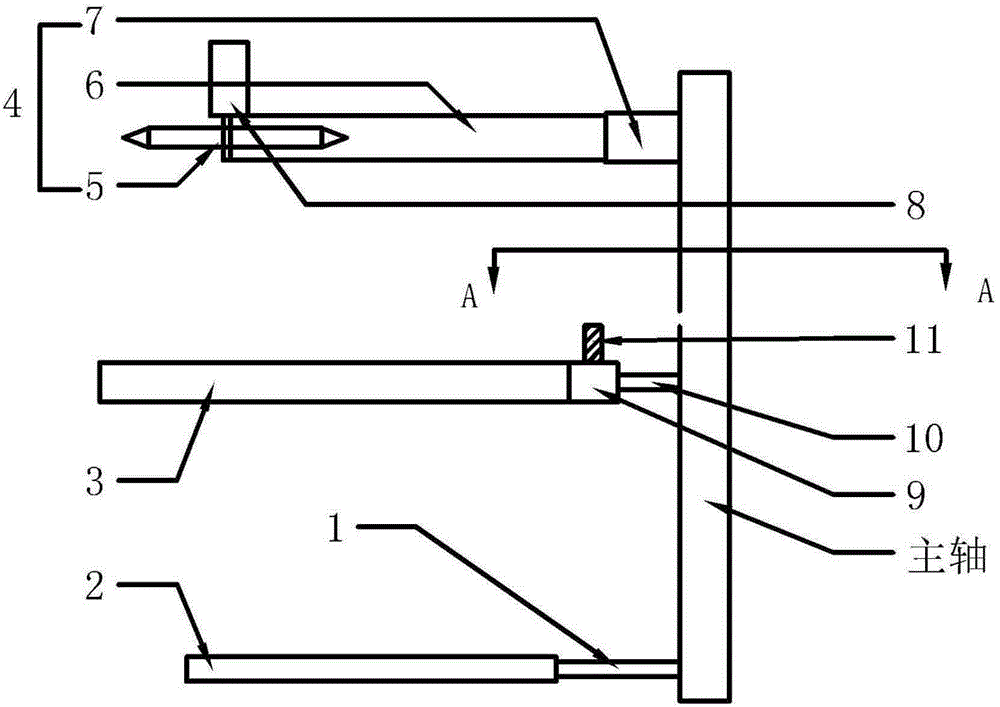

Manufacture of multifunctional intelligent manipulator and its automatic routing system for bundled cable network

ActiveCN110125920BVersatileAutoroutingProgramme-controlled manipulatorGripping headsRobot handCable net

The invention discloses a multifunctional intelligent robotic hand for manufacturing bundled cable nets and its automatic wiring system. The robotic hand includes a wrist system, a multifunctional finger system and a motion base. The wrist system includes a wrist lifting mechanism, a wrist rotating mechanism, a main shaft and fingers. Mounting plate, the lower end of the main shaft passes through the wrist lifting mechanism, the wrist rotating mechanism and the finger mounting plate in turn, the upper part of the main shaft is connected with the wrist lifting mechanism, the lower part of the main shaft is connected with the wrist rotating mechanism, the wrist lifting mechanism is fixedly connected with the wrist rotating mechanism, and the wrist rotates The mechanism is fixedly connected with the motion base; the multi-functional finger system includes a wire-drawing and wiring finger assembly, a plugging-cutting finger assembly and a positioning column insertion finger assembly, and each finger assembly is installed on the finger mounting plate of the wrist system respectively. The automatic wiring system includes the above-mentioned robot arm, and the invention can realize the automatic wiring of bundled cable networks with any required length and width, with high degree of automation and simple operation.

Owner:黑龙江润吉川科技有限公司

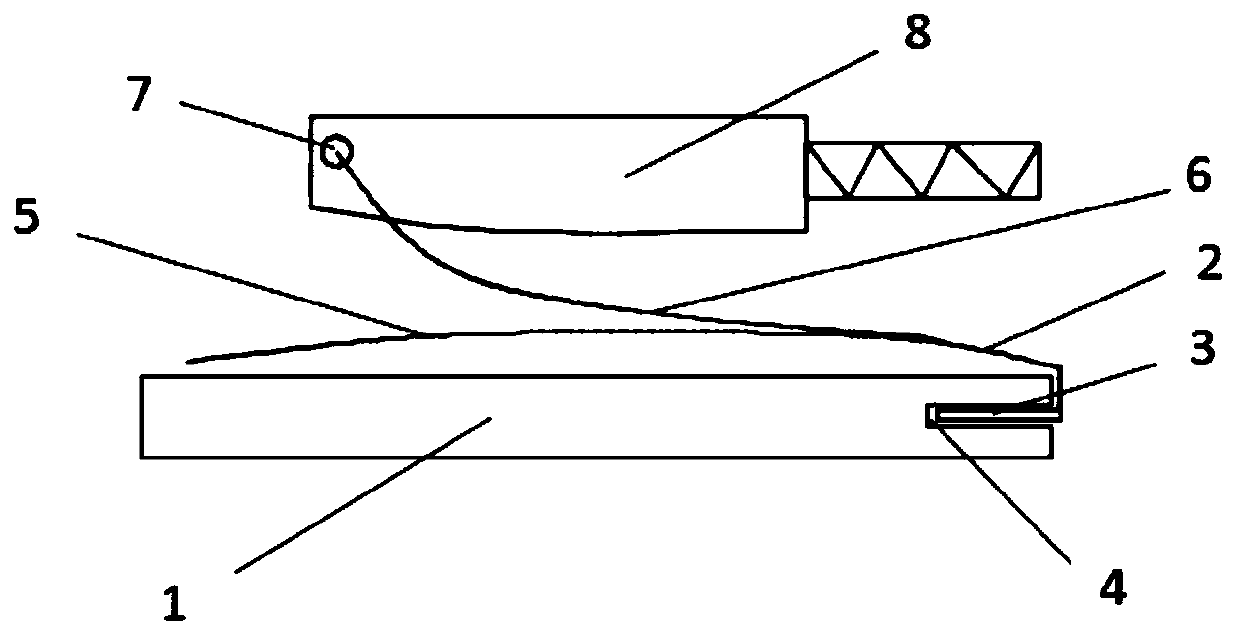

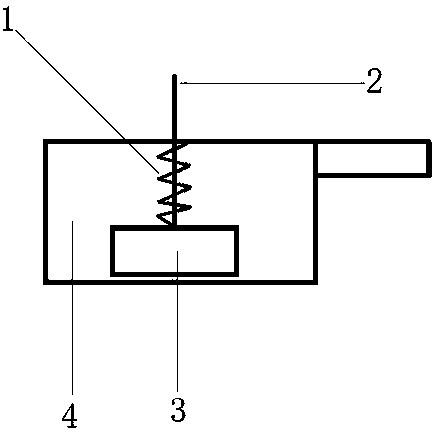

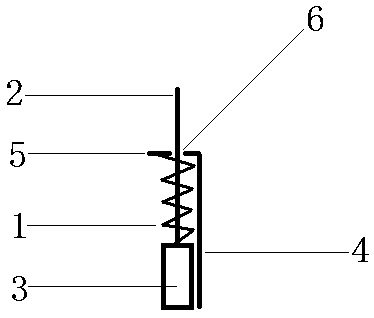

Kitchen cutting tool based on protective structure

InactiveCN107838954AAvoid scratchesMetal working apparatusMetal-working hand toolsNatural stateEngineering

The invention discloses a kitchen cutting tool based on a protective structure. The kitchen cutting tool is composed of a spring, a sliding rod, a baffle, a tool face, a fixed plate and a sliding hole. The tool face is in a rectangular shape, the fixed plate is perpendicularly arranged on the tool face and coincides with the opposite side of a tool edge, and the sliding hole is formed in the middle of the fixed plate; and the baffle is attached to the tool face and located at the lower end of the fixed plate, the upper end and the lower end of the spring are connected with the fixed plate andthe baffle correspondingly, the sliding rod is fixed to the baffle, and the upper end of the sliding rod penetrates through the sliding hole. The baffle is located at the tool edge under the natural state, the tool face vertically moves downwards and is embedded into vegetables in the vegetable cutting process, the baffle is stopped on the surfaces of the vegetables due to resistance, the tool face and fingers pressing the vegetables are always separated by the baffle, and thus a kitchen knife cannot cut the fingers; the baffle vertically slides relative to the tool face in the vegetable cutting process, the sliding rod slides along the sliding hole in the middle of the fixed plate, and the spring is compressed; and after the kitchen knife is lifted up, the spring pushes the baffle to return back to the original position, the vegetables can be safely cut through repetitive operation, and the kitchen knife is prevented from cutting the fingers.

Owner:MIANYANG ANZHI SHENGDA CREATIVE TECH

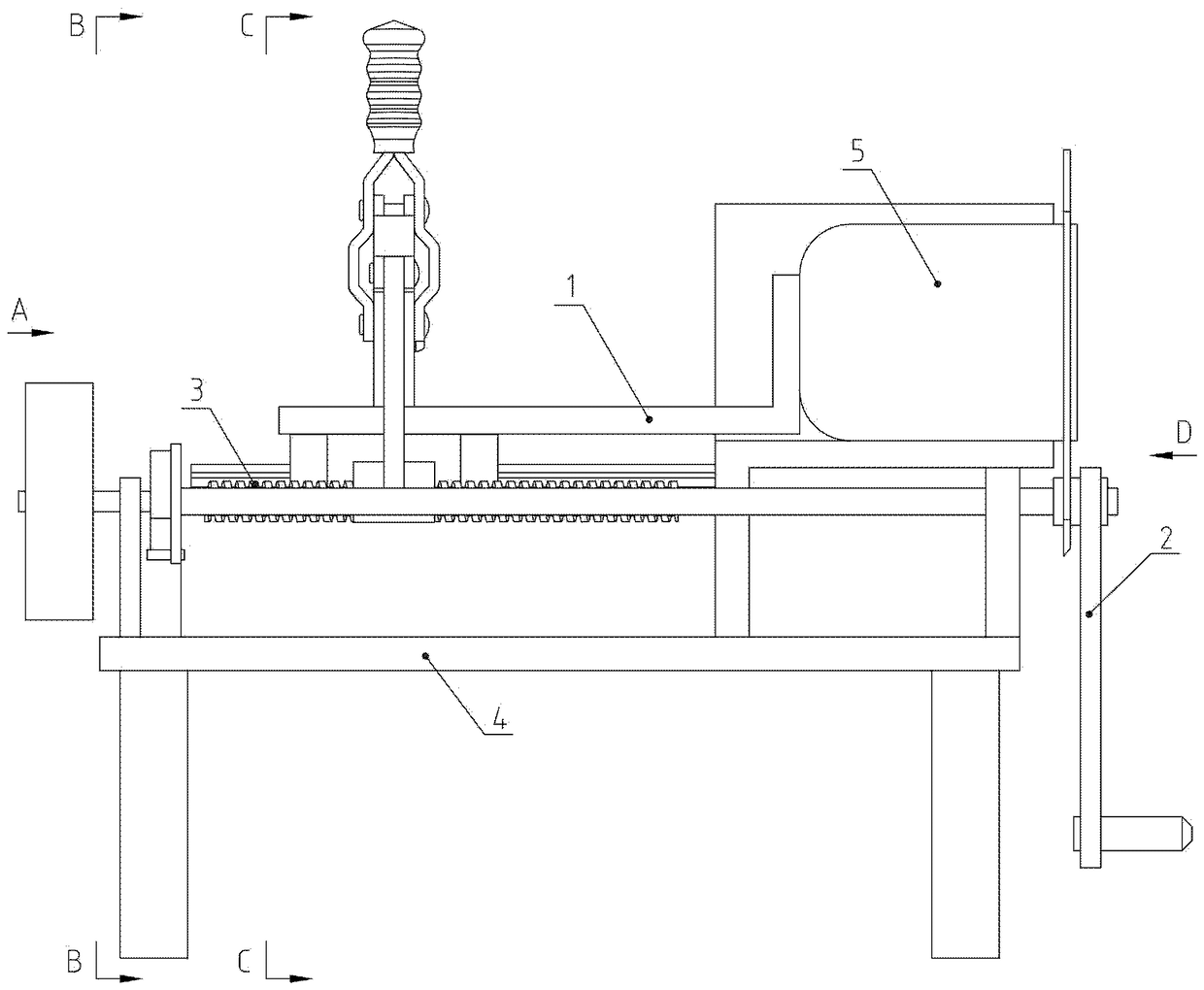

Hand-cranking-type bulk fruit and vegetable slicer

The invention belongs the technical field of kitchen tools, and relates to a hand-cranking-type bulk fruit and vegetable slicer is characterized in that a rocking handle is cranked at a constant speed; the edge of a cutter streaks for one time in a space on the right side of a cutting table while the rocking handle rotates for one cycle, and a slice is cut off from fruit and vegetables. When the outer arc of the stirring wheel is locked with the inner arc of a groove wheel the cutter scratches the space on the right side of the cutting table; when the groove wheel is stirred by a stirring pin,the groove wheel drives a translation component to translate in the direction of the cutter; the translation distance is the same as the thickness of the slice to be cut from the fruit and vegetables; at the time, the cutter is on the rear side of the driving shaft and is far away from the fruit and vegetables; and the cutter does not hinder the fruit and vegetables from translating rightwards. When the hand-cranking-type bulk fruit and vegetable slicer is used, the fruit and vegetable slicing speed is high; the efficiency is high; labor is saved; the thickness is uniform; and the risk of cutting fingers is avoided.

Owner:杜宗英

Electric silkworm cocoon cutting machine for silkworm egg production

InactiveCN102125004BReduce labor intensityCocooning speed increasedAnimal husbandryEngineeringPower apparatus

The invention discloses an electric silkworm cocoon cutting machine for silkworm egg production. A shell is internally provided with a feeding cavity, a blanking cavity and a storage cavity, wherein a partition plate A is arranged between the feeding cavity and the blanking cavity; a partition plate B is arranged between the blanking cavity and the storage cavity; the feeding cavity is internallyprovided with a tool apron and connected with a cutting knife through a tool rest arranged on the tool apron; the side wall of the blanking cavity is provided with a cocoon cutting port and a cocoon inlet passage thereof; the blanking cavity is internally provided with a power supply device and a power device, wherein the power device penetrates through the partition plate A to connect with the tool apron; and the bottom of the storage cavity is provided with a movable pulling plate. The invention not only can solve the problem that a silkworm raiser is easy to cut fingers or a silkworm pupaein the silkworm cocoon cutting process, but also is economic and practical and approaches to maturity and can save the labor and the time and greatly enhance the work efficiency, thereby solving the problems that a large amount of manpower is needed when silkworm cocoons are cut and the silkworm pupae are already incubated into moths when the silkworm cocoons are not cut.

Owner:郑玉林

Adaptive robotic finger prosthesis for grasping arbitrary object shape

An adaptive robotic finger prosthesis according to the inventive concepts includes a proximal phalanx body configured to be worn on a proximal phalanx portion of a cut finger, a middle phalanx body connected to the proximal phalanx body and configured to function as a middle phalanx portion of the cut finger, a distal phalanx body connected to the middle phalanx body and configured to function as a distal phalanx portion of the cut finger, a first proximal phalanx link disposed under the proximal phalanx body, a second proximal phalanx link disposed on the proximal phalanx body and joint-connected to the first proximal phalanx link, and a proximal phalanx elastic member provided at a joint between the first proximal phalanx link and the second proximal phalanx link to provide elastic force.

Owner:IND UNIV COOPERATION FOUND HANYANG UNIV ERICA CAMPUS

A safety craft scissors

The invention belongs to the technical field of study articles and discloses a safe craft scissor. The safe craft scissor comprises two shear blades and two telescopic handles. One end of shear blades are scissor tips and the other end are scissor tails. The middle of the shear blades is provided with a main hinging hole. The inner edge of each scissor tip is provided with a cutting edge and the outer edge of each scissor tip is provided with a first assistant hinging hole. Each scissor tail is provided with a second assistant hinging hole. Two shear blades are mutually hinged through the main hinging hole. One end of each telescopic handle is mutually hinged with the first assistant hinging hole on the two shear blades correspondingly. The other end of each telescopic handles is mutually hinged with the second assistant hinging hole on the two shear blades correspondingly. The safe craft scissor has a high shear ability, a rigid paper can be cut by kids with the safe craft scissor, the expandable angle of the two scissor tips is constrained by the telescopic handles, the fact that fingers of the kids stretch between the cutting edges of the two scissor tips can be prevented, and the injury of cutting fingers of kids is avoided.

Owner:黄润盛

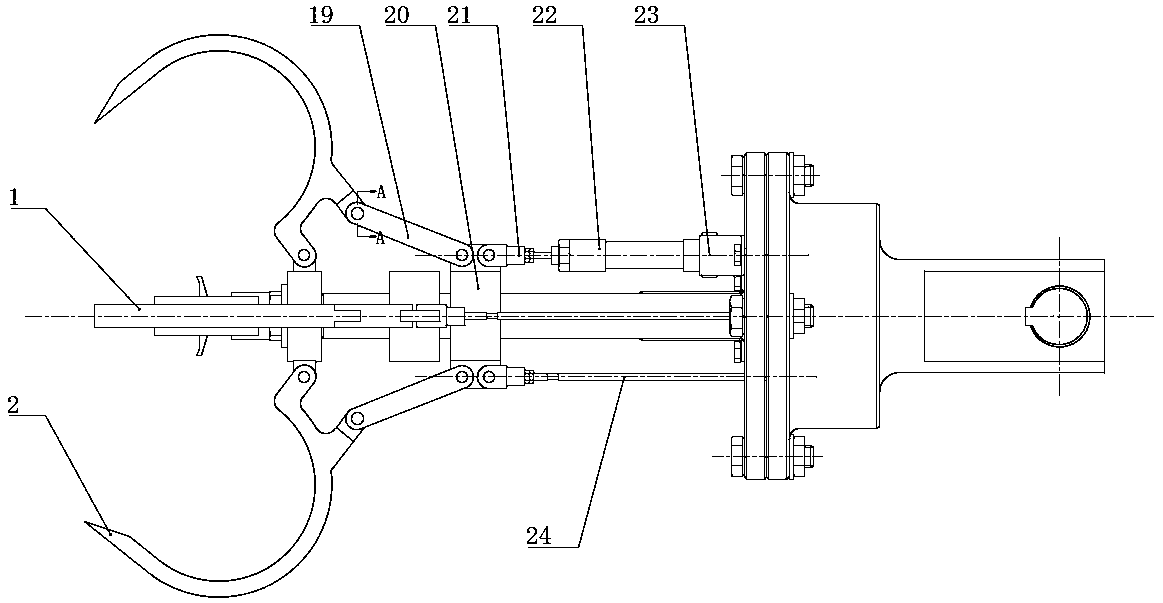

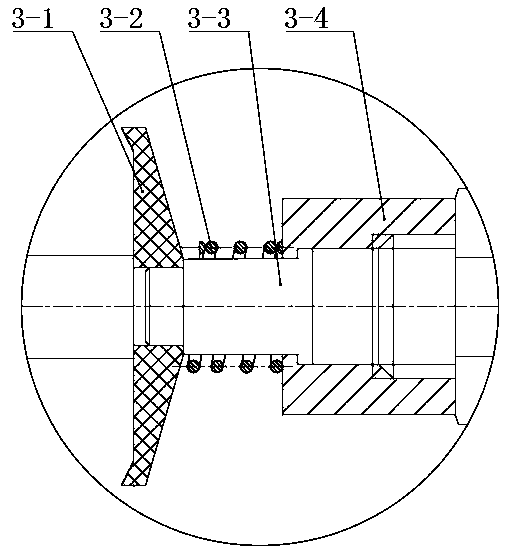

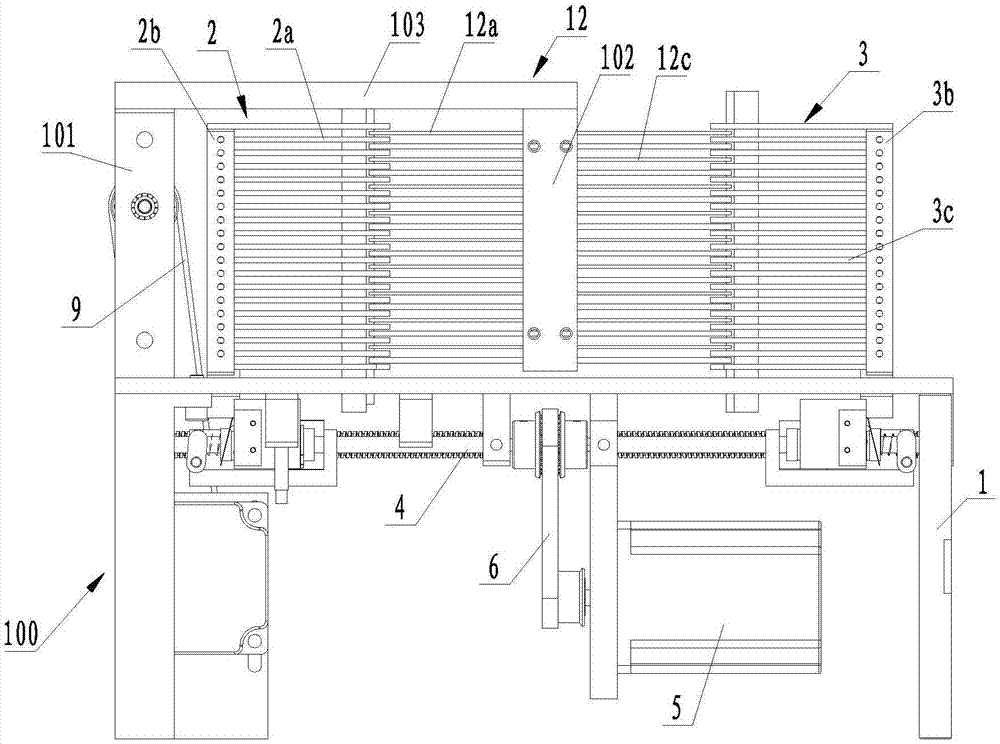

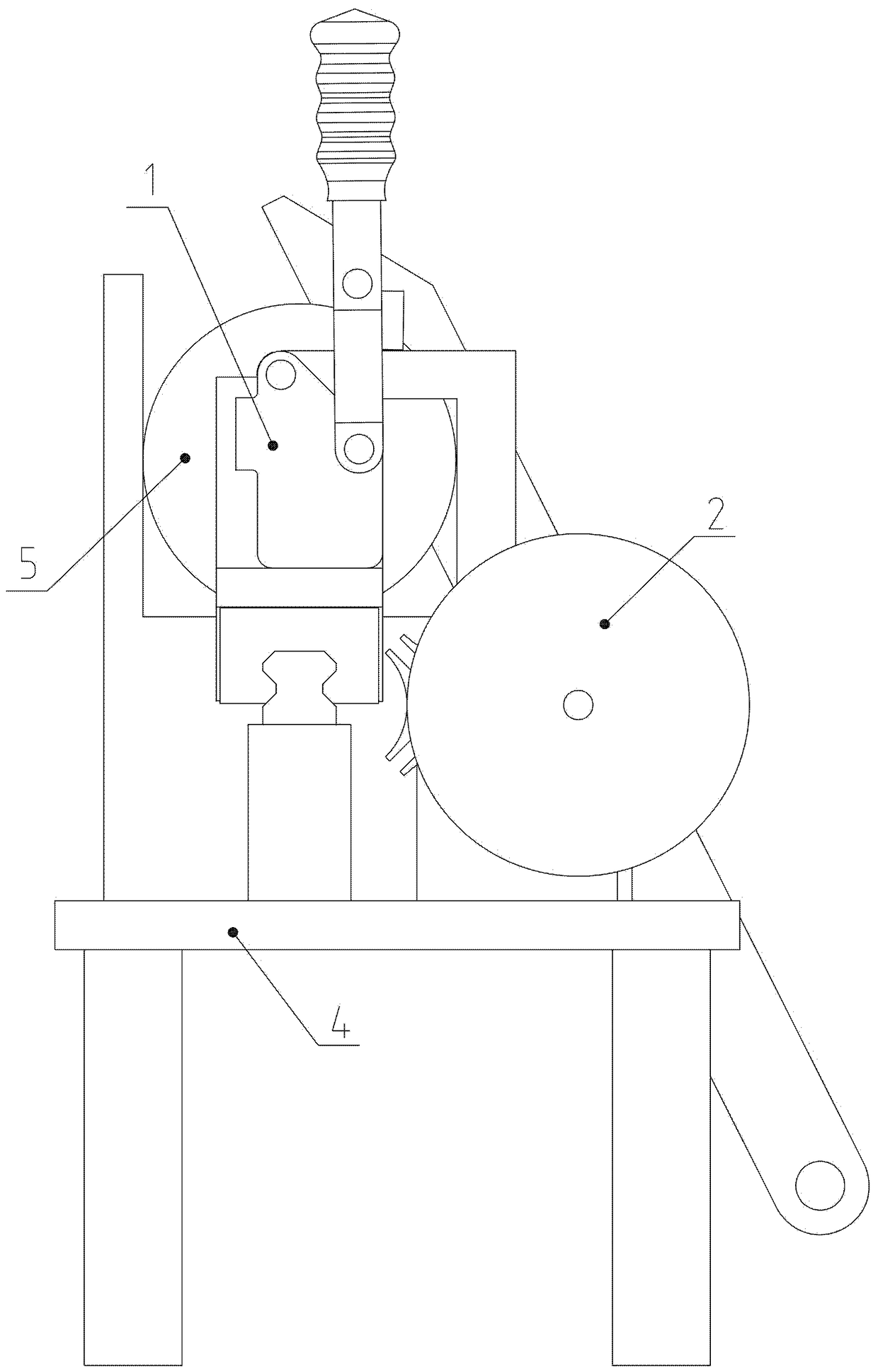

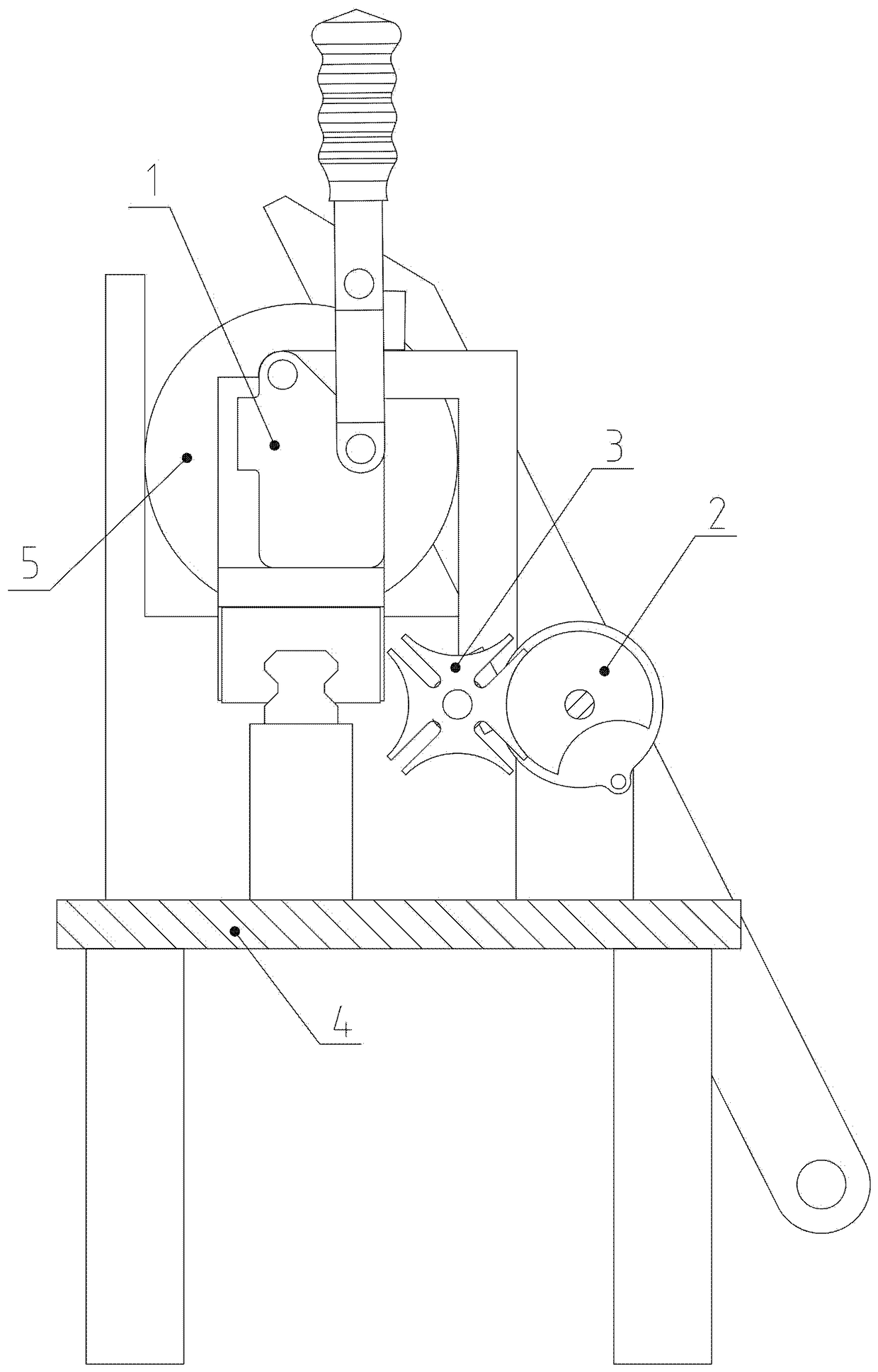

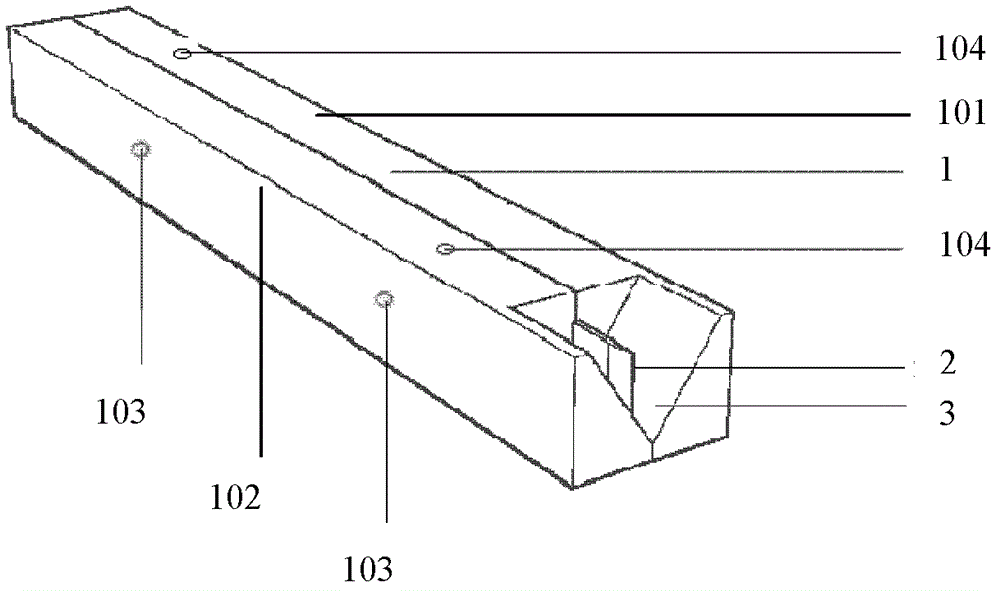

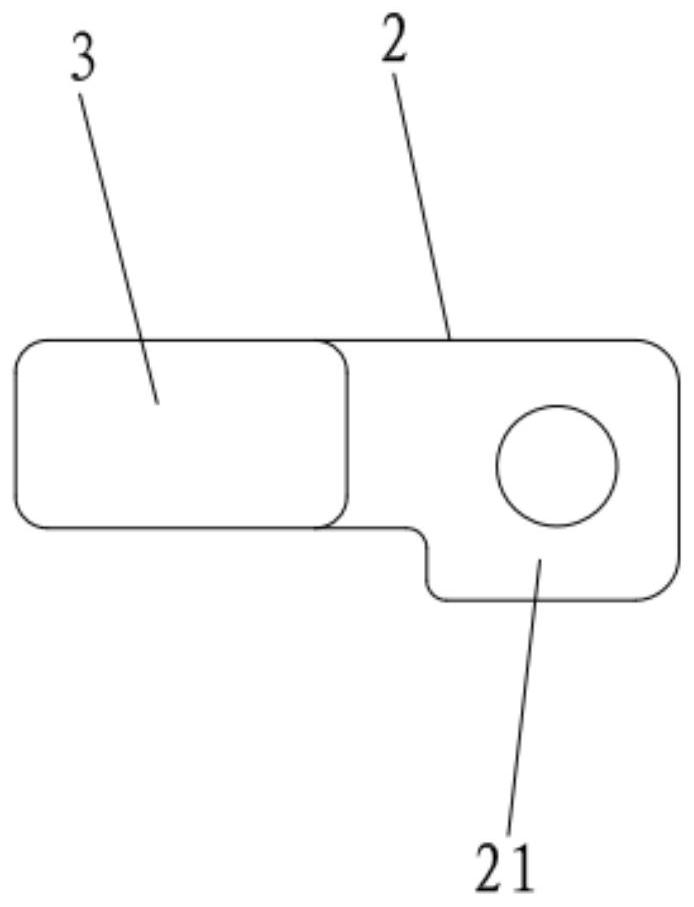

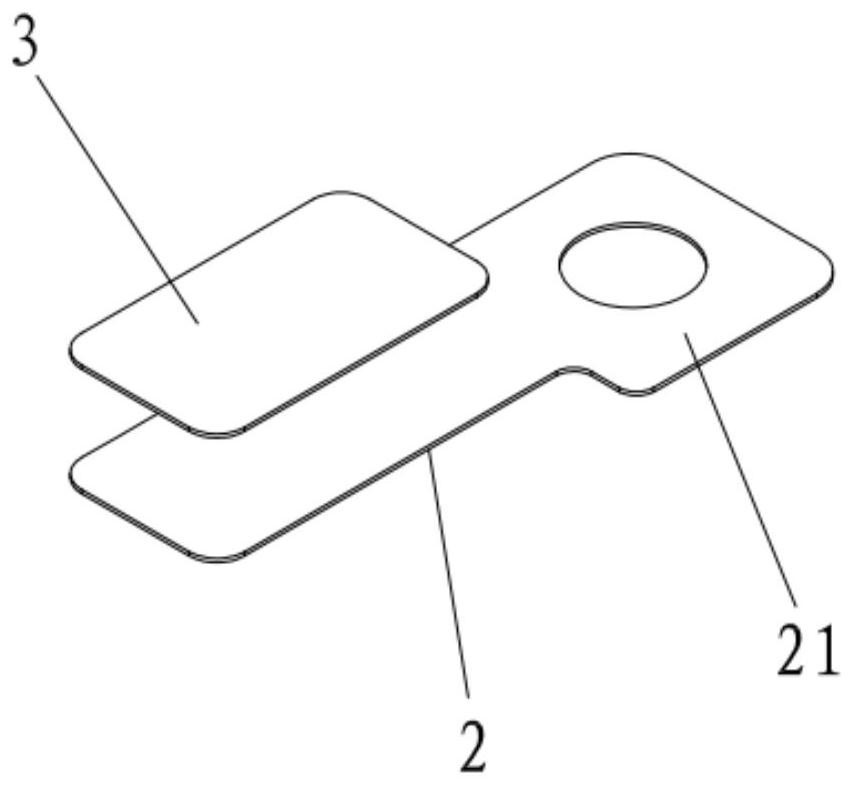

Rootstock opening-cleaving device and application thereof

InactiveCN102550306BImprove securityImprove work efficiencyCuttersCutting implementsRootstockEngineering

The invention discloses a rootstock opening-cleaving device. The rootstock opening-cleaving device comprises a detachable body 1 and a blade 2, wherein the detachable body 1 comprises two parts, namely a101 and b102, which are clamped through a clamping device 103, a V-shaped slot 3 is arranged at one end of the detachable main body 1, and the blade 2 is arranged at the middle part of the V-shaped slot 3. The rootstock opening-cleaving device disclosed by the invention has the advantages of not only largely improving operating efficiency and success rate of grafting and increasing the rate of qualified cleaved openings of a rootstock to 100%, but also effectively improving safety of grating operation, and basically preventing accidents of cutting fingers during the process of cleaving an opening on the rootstock.

Owner:CHANGLI INST OF POMOLOGY HEBEI ACADEMY OF AGRI & FORESTRY SCI

One-time waste punching and forming method

ActiveCN112809807BReduce waste processImprove work efficiencyMetal working apparatusPunchingStructural engineering

The invention discloses a method for punching and forming with one-time waste discharge. The method comprises the following steps: S1 half-cutting the bottom edge of the outer frame of the substrate; S2 half-cutting the finger-position edge cutter at the rear of the composite main material, and half-cutting the outer frame edge, wherein, in step In S2, the bottom edge of the outer frame is not punched, so half-cutting is carried out through multiple tool paths, so that the finger waste and the outer frame waste are connected together, optimizing the waste discharge process, realizing one-time waste discharge, improving work efficiency and saving processing costs. , improve product competitiveness.

Owner:郑州领胜科技有限公司

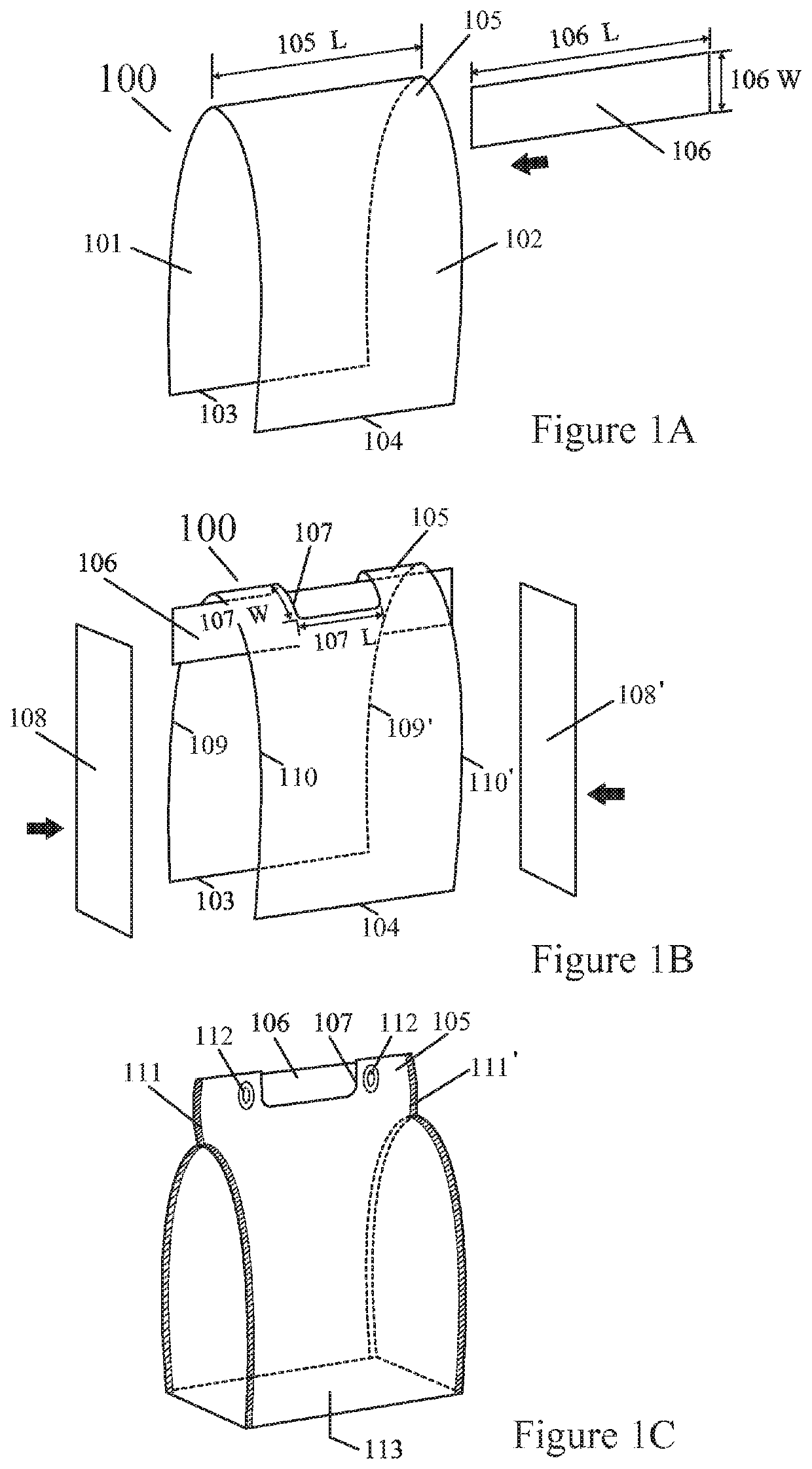

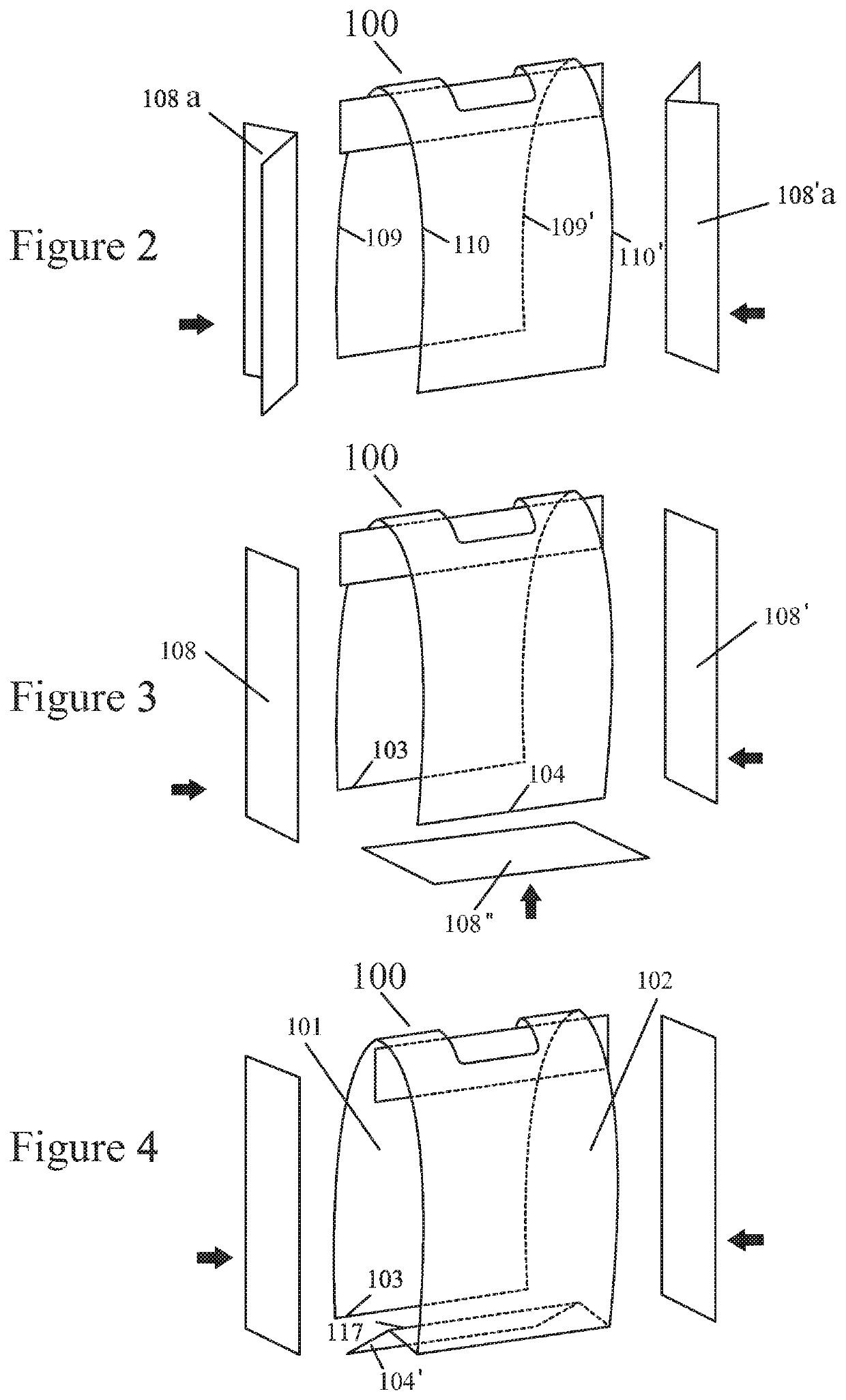

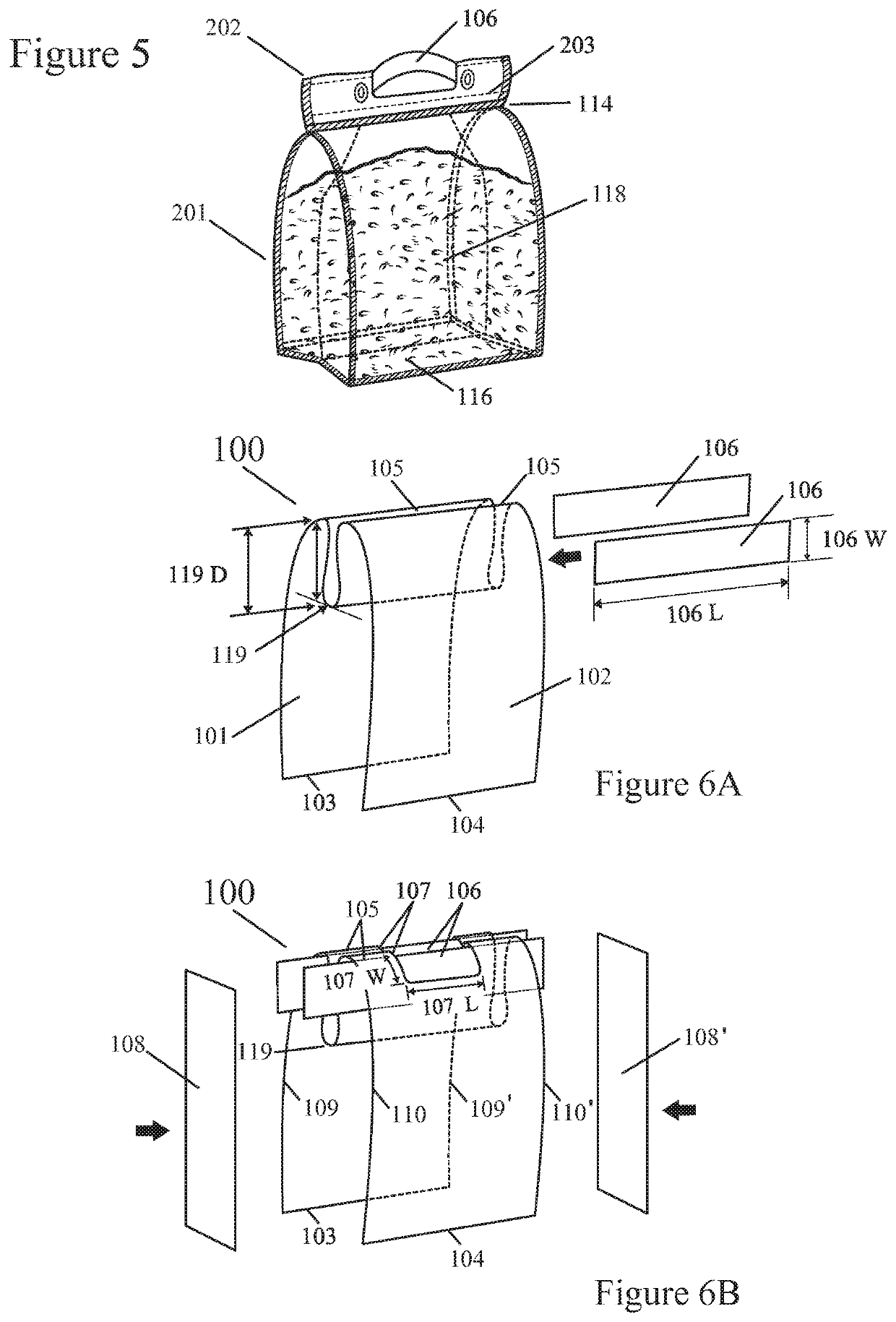

Bag With Handle And Method For Manufacture Thereof

ActiveUS20190389627A1Improve featuresSolve the real problemPackage recyclingBag making operationsEngineeringHeavy load

A bag with handle and method for producing the bag that incorporates the features of four seal bag body with a new handle part to obtain a new bag with a durable bag body that can carry a heavy load, can be stacked in high number without falling, consume less space in storage and transportation, has large front space and side spaces for product information display while on shelf, that is convenient to hold, strong and secure, that does not cut fingers in use, and that may be applied to shopping bags or reusable or resealable packaging bags. The concept of the method of producing said bag is steps of folding, assembling, and sealing a plurality of sheet materials which are not obvious to a person ordinarily skilled in the art.

Owner:FUTURE FLEX CO LTD

Anti-hand-cutting nail protecting device

InactiveCN108621211ASolve the problem of easy to cut fingersMetal working apparatusCutting nailsEngineering

The invention provides an anti-hand-cutting nail protecting device which aims to solve the problem that people are prone to cutting fingers during vegetable cutting. When people cut the vegetables, akitchen knife can be abutted against a nail for vegetable cutting, at the moment, if cutting is performed too fast, the nail can have the risk of being cut, the probability that finger is cut in lifecan be relatively large, and moreover, a nail protecting device which can be purchased on the market is not available at present. According to the device, by refitting a common object around, the riskof people during vegetable cutting is reduced, the safety of people during vegetable cutting is improved, and the efficiency of people during vegetables cutting is also improved; and moreover, manufacturing is simple, and the use is convenient.

Owner:李小龙

Special tool for cutting finger nails and toenails

The invention relates to a special tool for cutting fingernails and toenails, and relates to the field of machinery. The purpose of the present invention is to provide a special tool for cutting fingernails and toenails with novel structure and strong practicability. A cap opening tool is arranged at the end of the pressing part. The invention has novel structure and strong practicability, and can be conveniently and quickly opened wine bottle during meal time by being arranged on special tools for cutting fingernails and toenails. The special tool main body is made of stainless steel; it also includes a plastic sheath; and also includes a small file specially used for sharpening fingernails and toenails. The present invention has the advantage of being multifunctional.

Owner:刘凤娇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com