One-time waste punching and forming method

A technology of scrap and outer frame, applied in metal processing and other directions, can solve problems such as increasing manufacturing costs and affecting work efficiency, and achieve the effects of saving processing costs, improving work efficiency, and reducing waste discharge procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

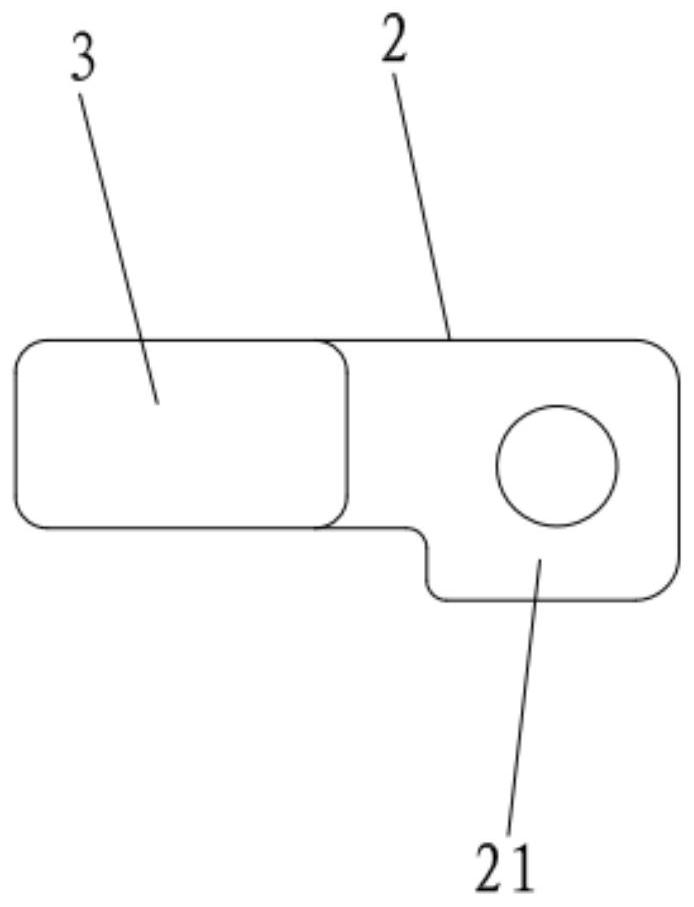

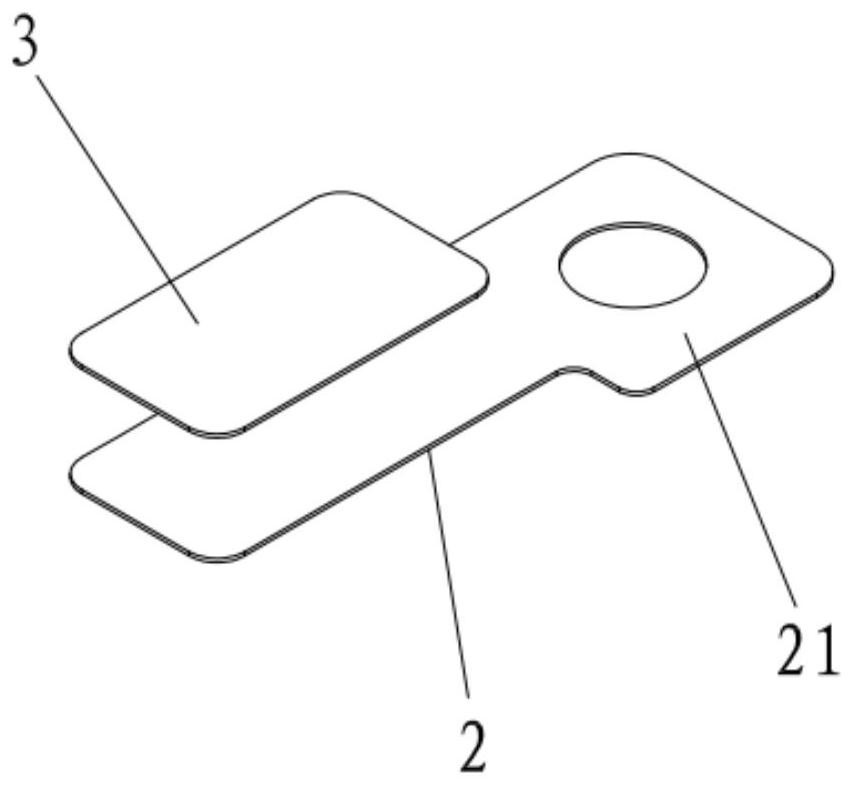

[0033] refer to Figure 1 to Figure 6 , A method of punching and molding for one-time waste discharge. The method is: half-cutting the product through multiple knife paths, so that the waste of the finger position 21 and the waste of the outer frame are connected together, so as to realize one-time waste discharge.

[0034] Further description, the method includes:

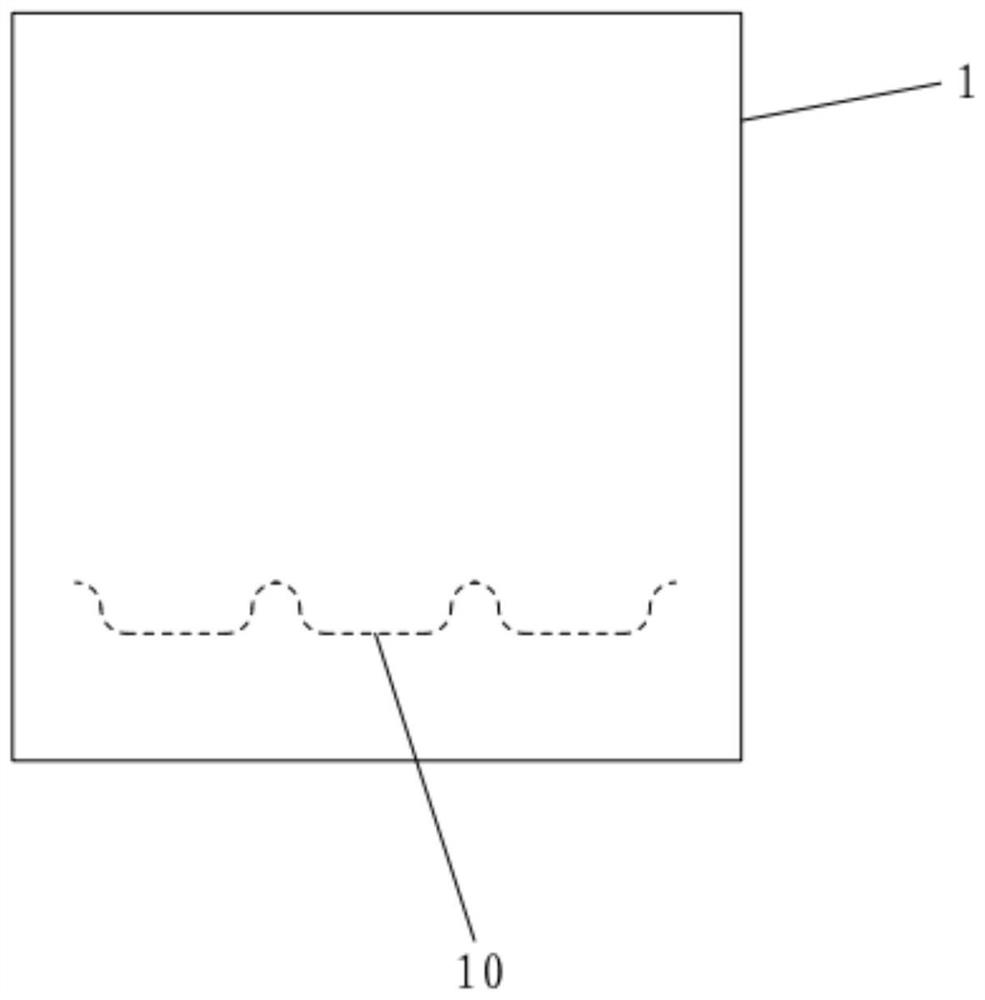

[0035] S1: the bottom edge 10 of the outer frame of the half-cut substrate 2;

[0036] S2: Half-cutting the edge knife 30 at the finger position 21 at the rear of the composite main material 3, and half-cutting the edge 20 of the outer frame;

[0037] Wherein, in step S2, the bottom edge 10 of the outer frame is not punched.

[0038] To further illustrate, in step S1 , the substrate 2 is first compounded on the support base 1 , and then the bottom edge 10 of the outer frame of the substrate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com