A Reinforced Automatic Bonding Method

A reinforcement and automatic technology, applied in the direction of bendable/stretchable parts of the circuit, printed circuit parts, printed circuits, etc., can solve the problems of consumption of PET auxiliary materials, low efficiency, and scrapping when the reinforcement is expired. Reduce processing costs, reduce waste discharge processes, and avoid the effect of shortening the validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The thermosetting glue used in this embodiment is pure glue, and the release film is a PET film.

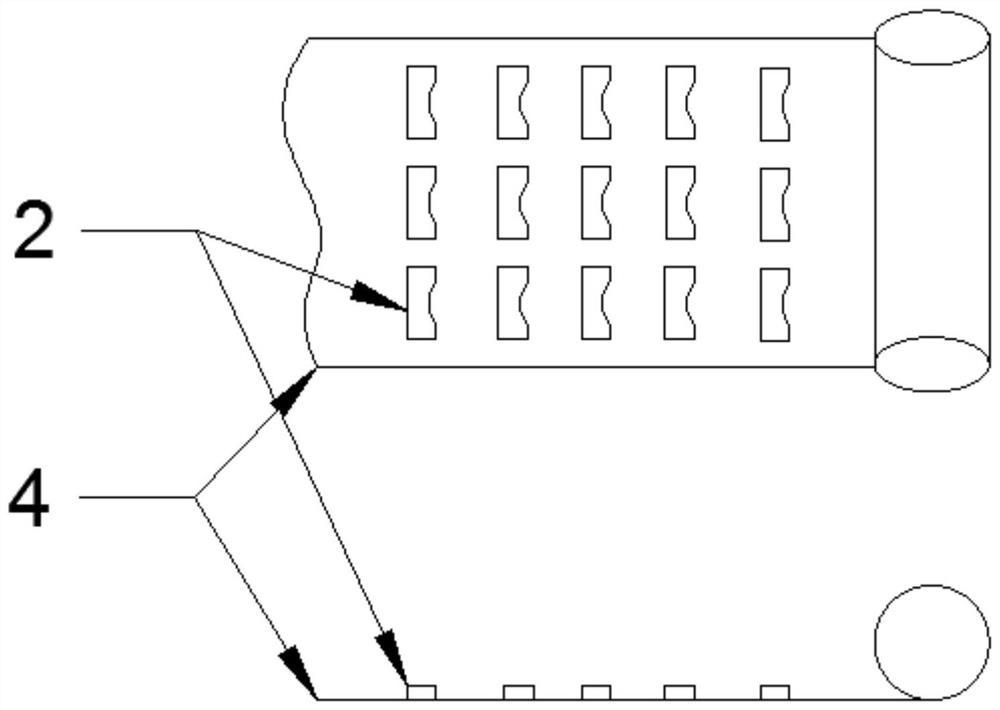

[0023] The steps of making pure rubber roll material: After removing the double-sided backing paper of pure rubber, cut it into the shape of the reinforced bonding surface to obtain pure rubber particles. The cutting method is die-cutting; cut the pure rubber particles according to Place them in the same direction and at equal intervals on the PET film to make a thermosetting film.

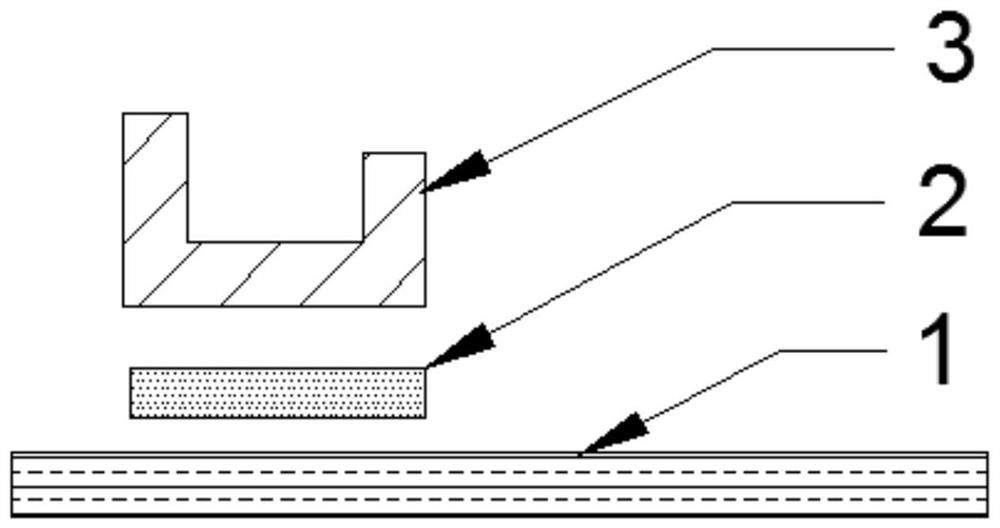

[0024] The steps of attaching the pure rubber particles to the FPC: place the FPC on the heating platform, the temperature of the platform is 40°C, the suction nozzle 1 absorbs the pure rubber particles from the pure rubber roll material and place them on the FPC bonding position, and the temperature of the suction nozzle 1 is 60°C ℃, use the temperature of the platform and the nozzle to attach the pure rubber particles to the FPC;

[0025] The steps of attaching the reinforcement to the FPC:...

Embodiment 2

[0027] The thermosetting glue used in this embodiment is pure glue, and the release film is a PET film.

[0028] The steps of making pure rubber roll material: After removing the double-sided backing paper of pure rubber, cut it into the shape of the reinforced bonding surface to obtain pure rubber particles. The cutting method is die-cutting; cut the pure rubber particles according to Place them in the same direction and at equal intervals on the PET film to make a thermosetting film.

[0029] The steps of attaching the pure rubber particles to the FPC: place the FPC on the heating platform, the temperature of the platform is 80°C, the suction nozzle 1 sucks the pure rubber particles from the pure rubber roll material and place them on the FPC bonding position, the temperature of the suction nozzle 1 is 100°C ℃, use the temperature of the platform and the nozzle to attach the pure rubber particles to the FPC;

[0030] The steps of attaching the reinforcement to the FPC: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com