Transportation limiting device

A technology of a limiting device and a power device, applied in the field of kitchen utensils, can solve the problems of increasing the workload of operators, inconsistent vegetable cutting size, low vegetable cutting efficiency, etc., so as to improve the vegetable cutting efficiency, ensure the vegetable cutting size, and reduce the work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

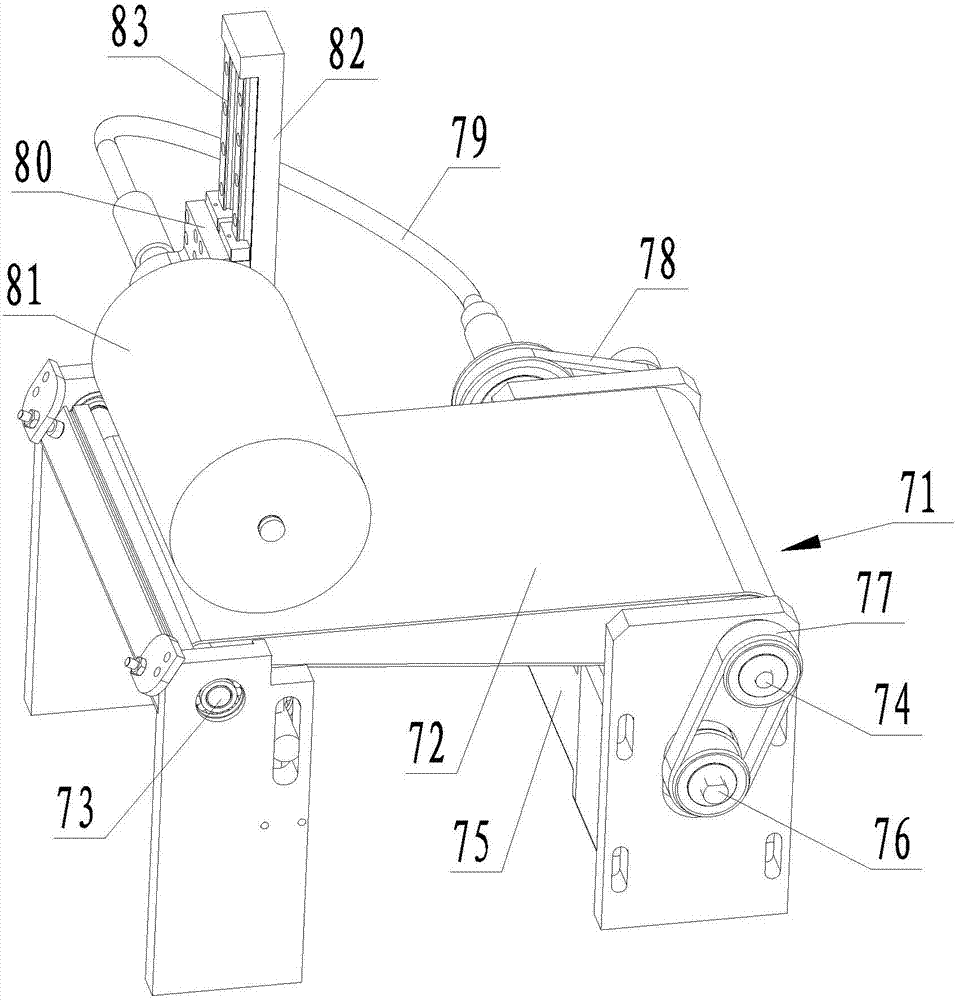

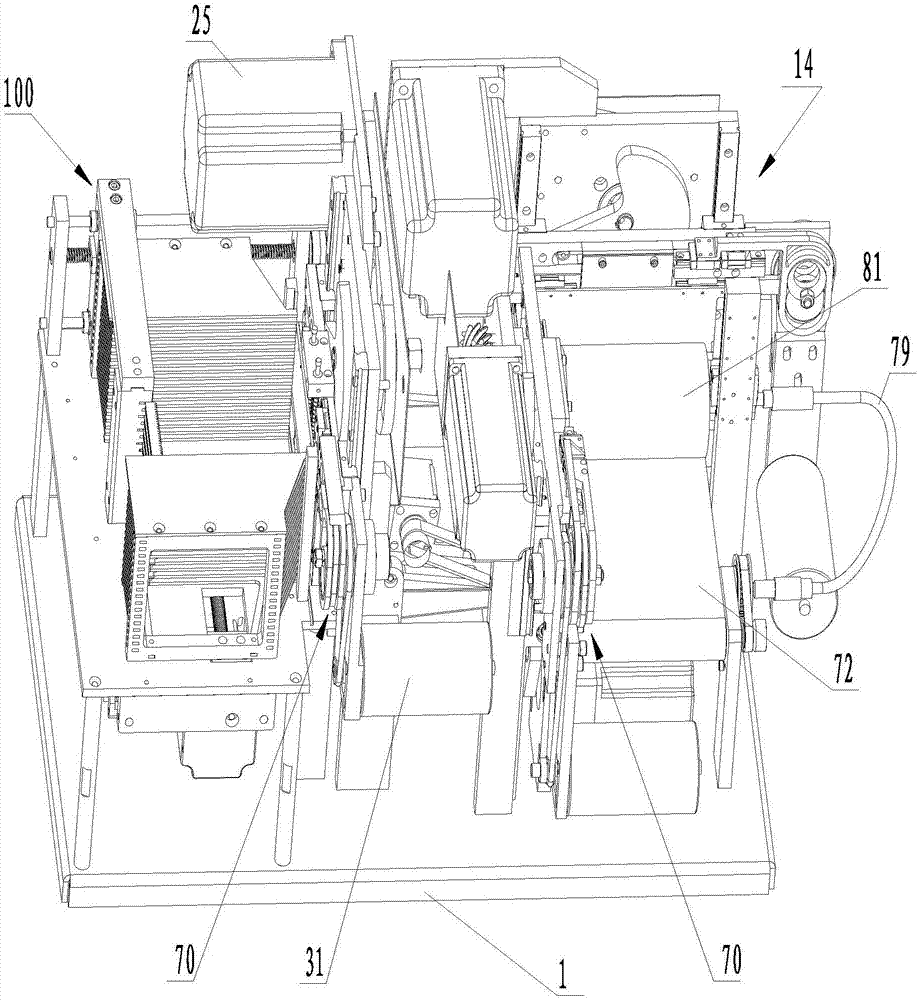

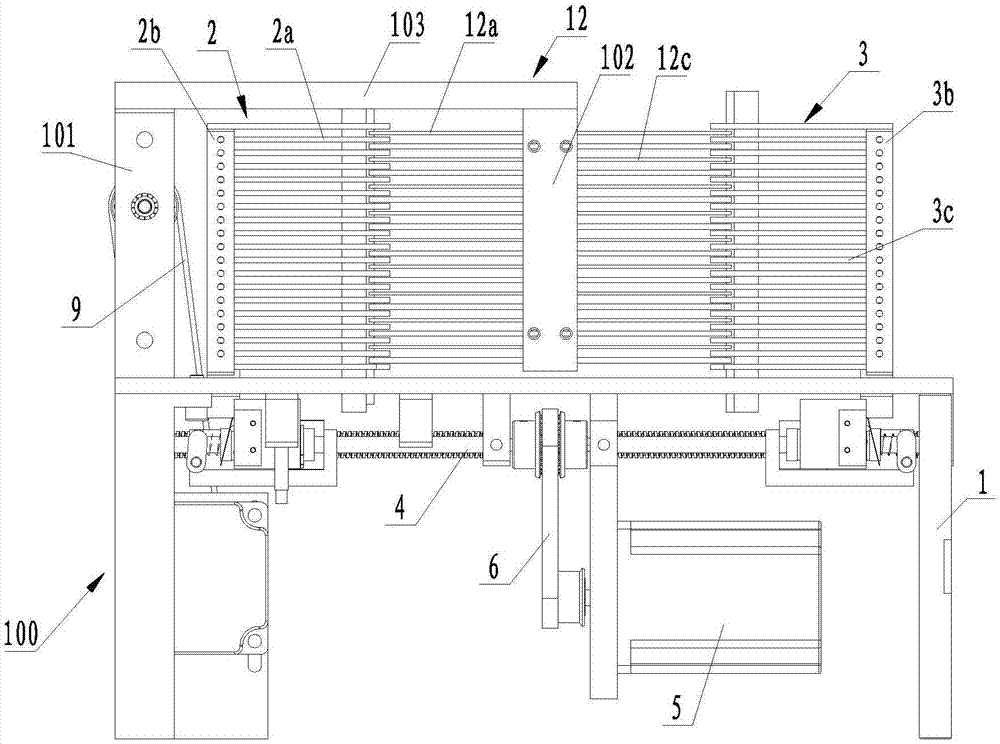

[0025] as follows Figure 1 to Figure 11 As shown, a conveying limiting device includes a frame 1, a second conveyor belt 72 is arranged on the frame 1, and the second conveyor belt 72 is transmitted through a first rotating shaft 73 and a second rotating shaft 74, and the bottom of the frame 1 is provided with a second Seven power units 75, the output shaft 76 of the seventh power unit 75 is connected to one end of the second rotating shaft 74 through the seventh belt 77; the frame 1 is provided with a first guide rod 82, and the first guide rod 82 is provided with a longitudinal guide rail 83 , a slidable fifth connecting member 80 is arranged on the longitudinal guide rail 83 , and a pressing roller 81 is arranged on the fifth connecting member 80 , and the pressing roller 81 is rotatably arranged on the second conveyor belt 72 . The other end of the second rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com