Patents

Literature

55results about How to "Improve vegetable cutting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

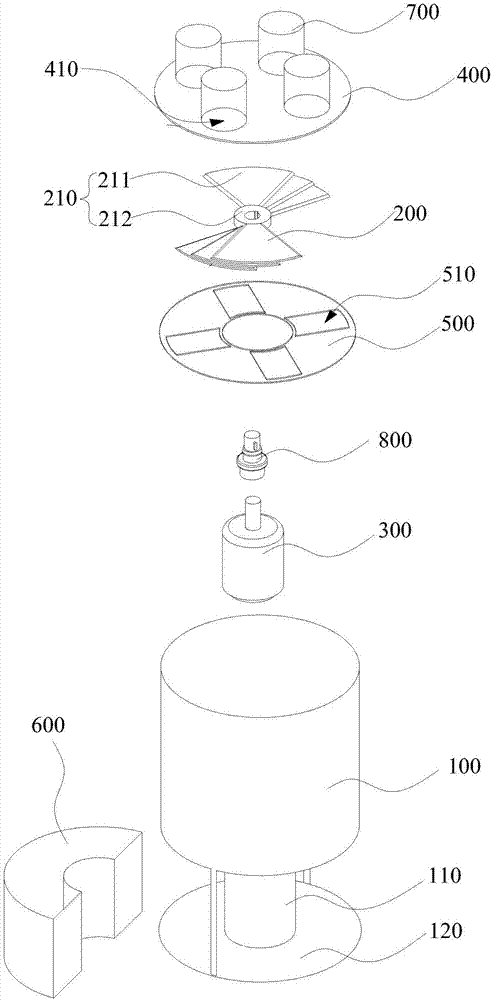

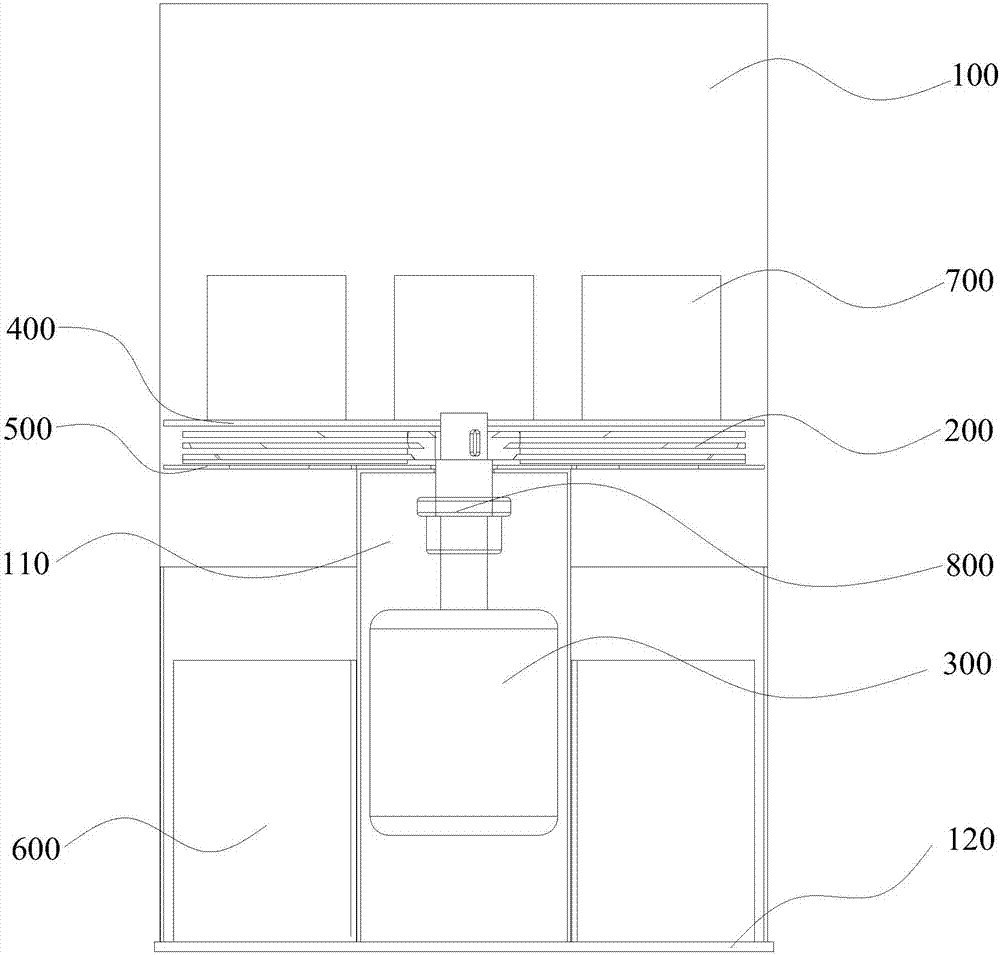

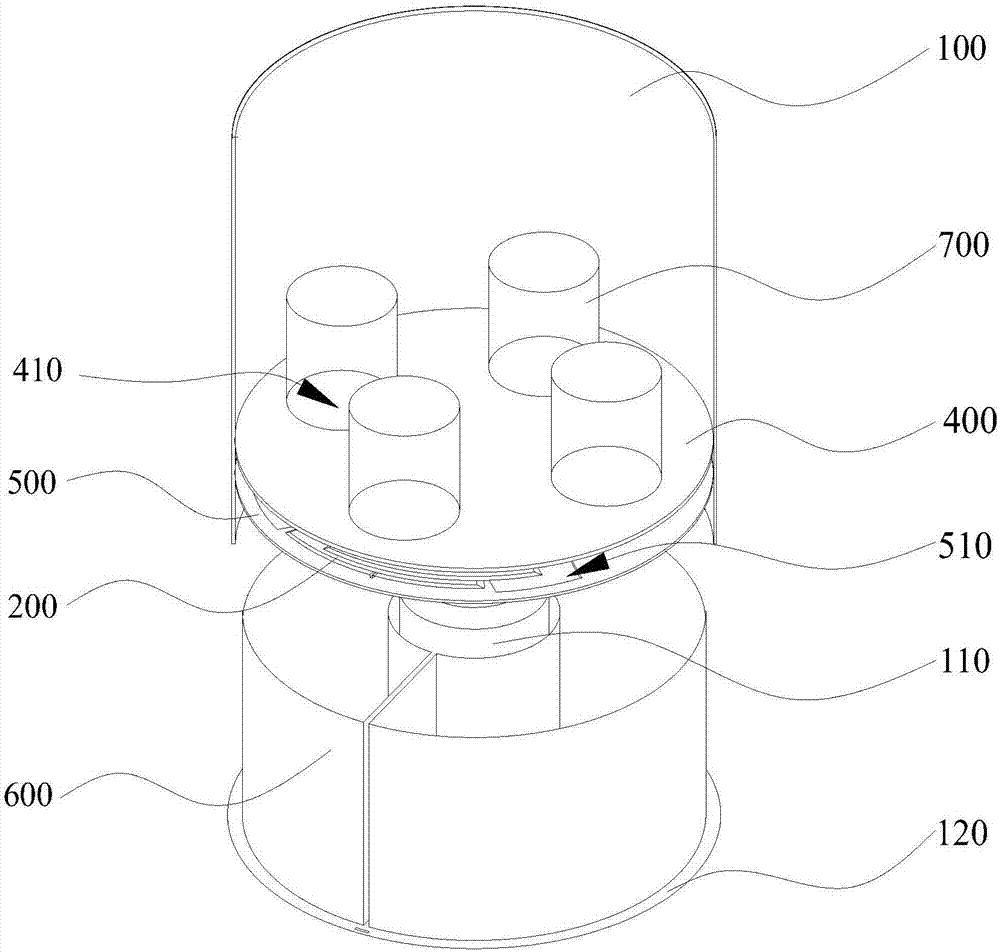

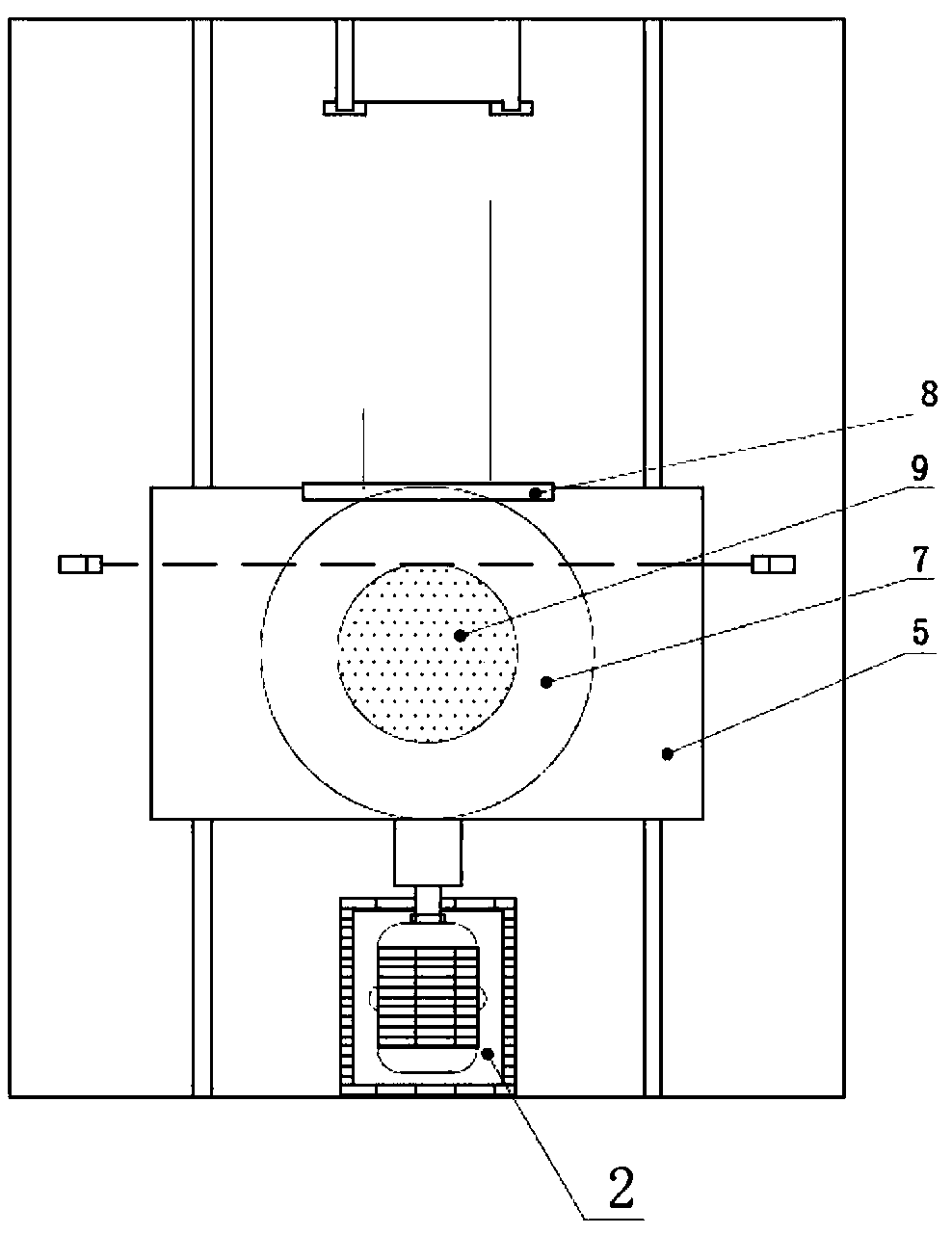

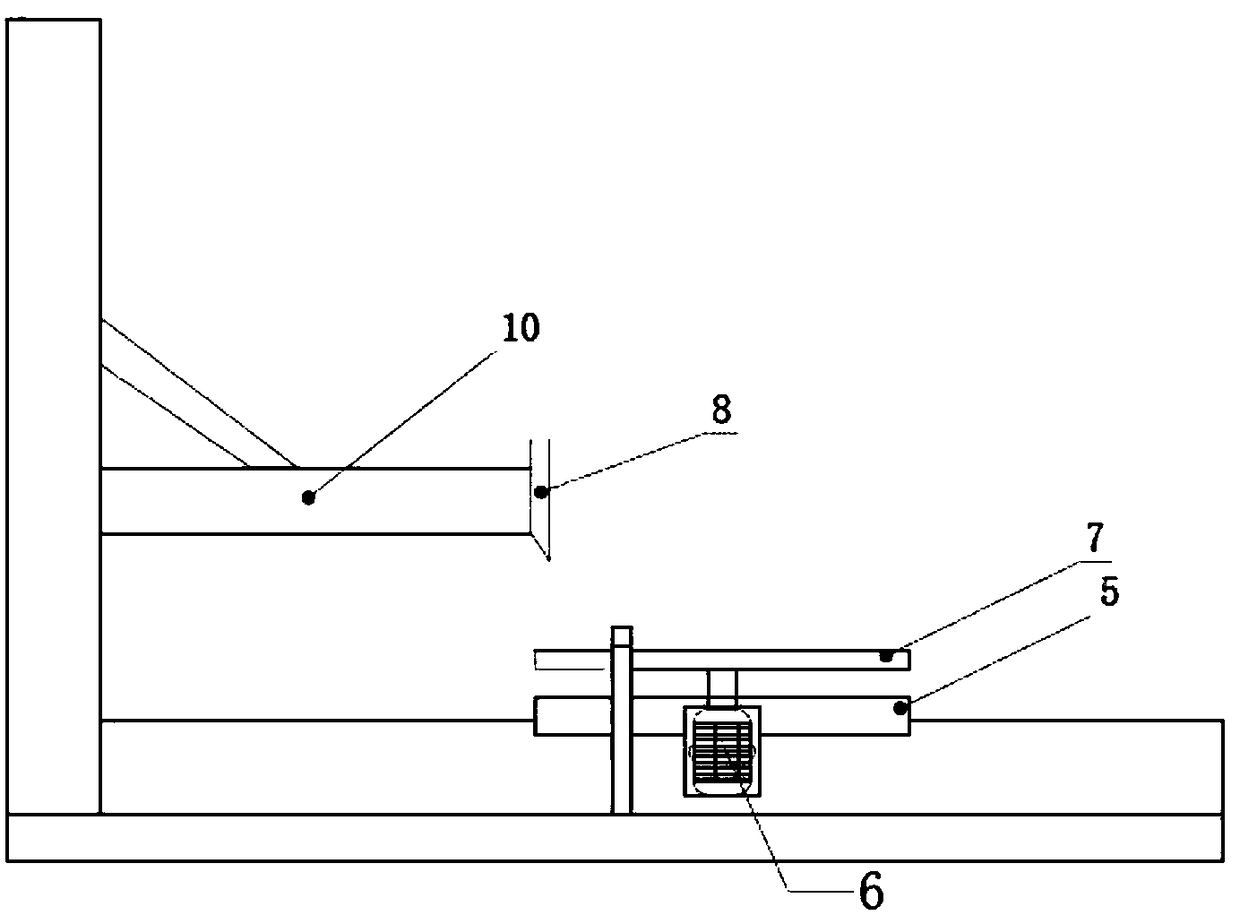

Efficient vegetable cutter capable of achieving slicing and vegetable cutting method

ActiveCN106956314AImprove vegetable cutting efficiencyGuaranteed hygienic performanceMetal working apparatusVegetable processingAgricultural engineering

The invention discloses an efficient vegetable cutter capable of achieving slicing and a vegetable cutting method. The efficient vegetable cutter capable of achieving slicing comprises a barrel, a cutting knife and a motor. The cutting knife and the motor are both arranged in the barrel, and the motor and the cutting knife are in transmission connection. The motor is used for driving the cutting knife to rotate, the cutting knife comprises at least two blades, and the at least two blades are arranged in a staggered and stacked manner. According to the efficient vegetable cutter and the vegetable cutting method, vegetables can be at least cut into two sections in one cutting process; compared with traditional vegetable cutting equipment, the efficient vegetable cutter capable of achieving slicing is higher in vegetable cutting efficiency; and meanwhile, a processing site of the vegetables is isolated from the external environment through the barrel, and the sanitation of vegetable processing is guaranteed.

Owner:GUANGZHOU INST OF RAILWAY TECH

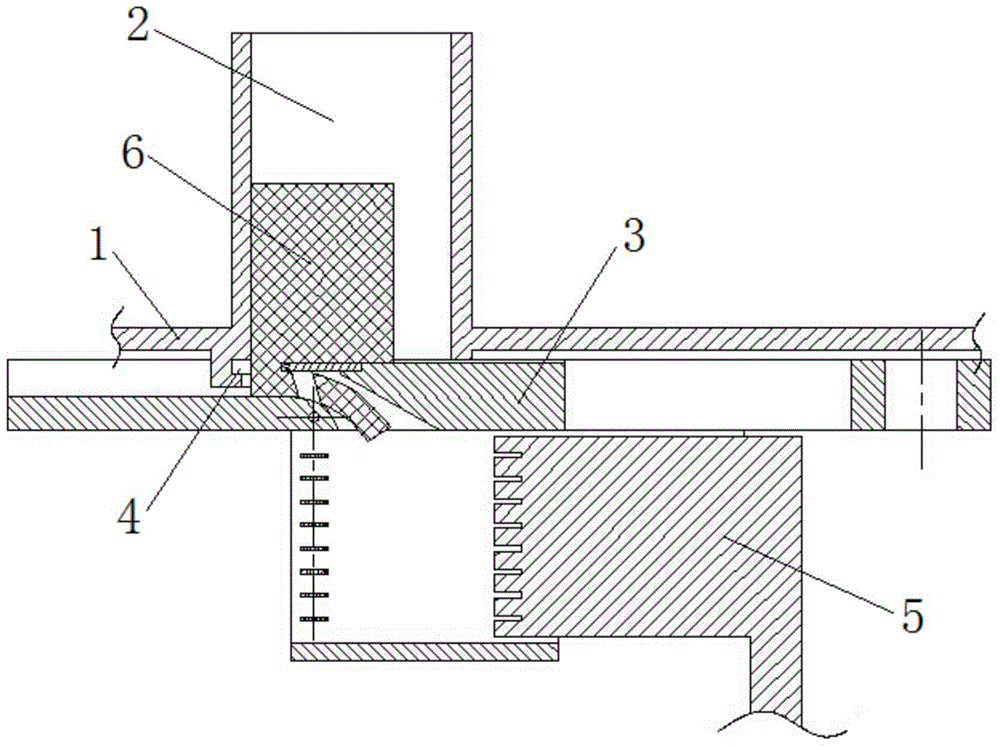

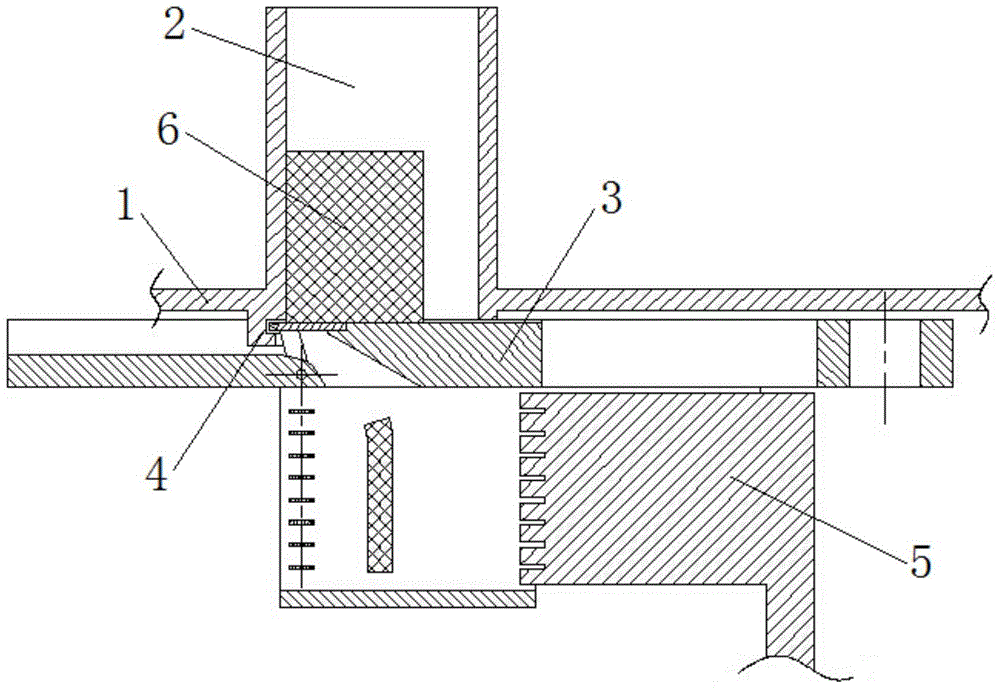

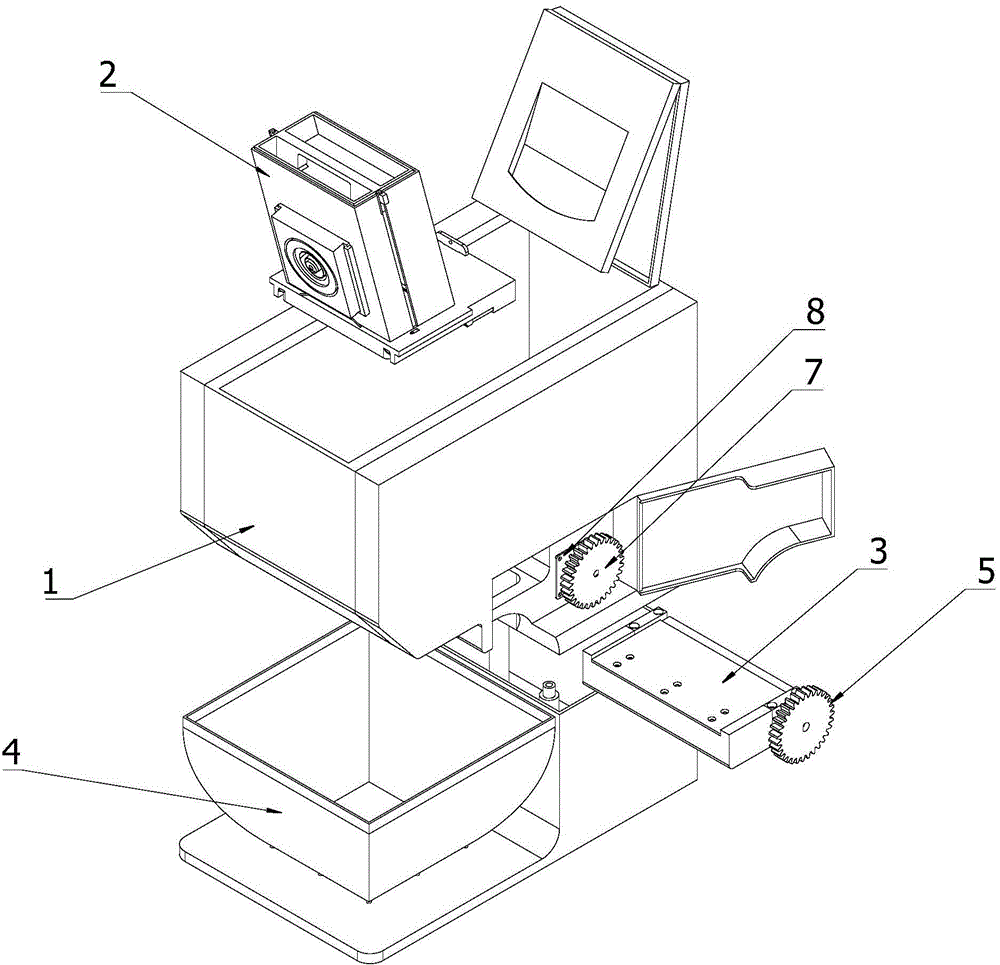

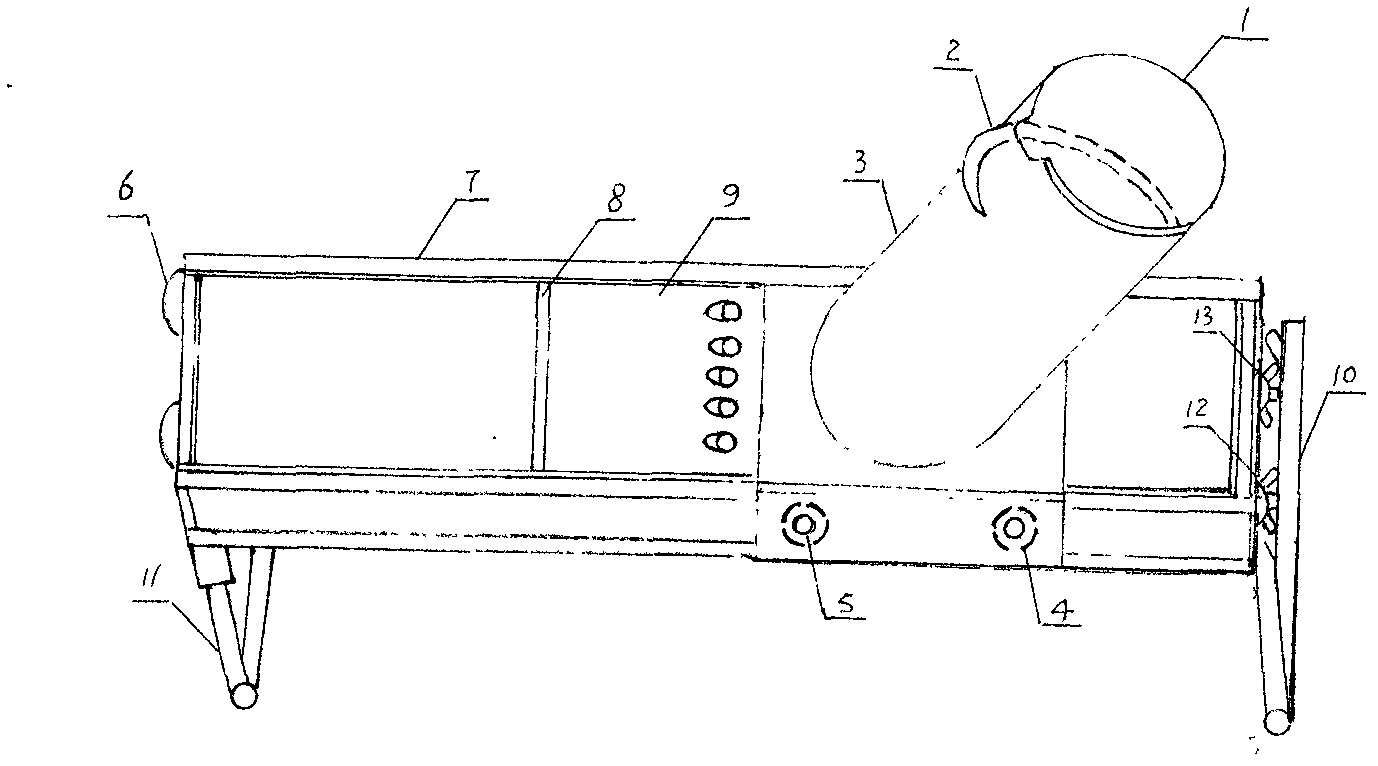

Multipurpose vegetable cutting mechanism and multifunctional vegetable cutting machine

InactiveCN104440984AQuality improvementCut off smoothlyMetal working apparatusAgricultural engineeringVegetable fibers

The invention discloses a multipurpose vegetable cutting mechanism and a multifunctional vegetable cutting machine and belongs to the technical field of vegetable cutting machines. According to the multipurpose vegetable cutting mechanism, an inclined vegetable guiding opening is formed between a vegetable baffle and a slicing knife fixing part which is horizontally provided with a slicing knife located on a vegetable inlet of the vegetable guiding opening, and a secondary vegetable cutting cavity is formed below a vegetable outlet of the vegetable guiding opening; a blade assembly is installed below a vegetable hopper, and a horizontal movement starting point and an end point of the slicing knife are located on the two sides of a vegetable entrance of the vegetable hopper respectively; longitudinal shredding knifes which are vertically arranged and located on the vegetable inlet of the vegetable guiding opening are selectively installed on the vegetable baffle; transverse shredding knifes which are horizontally arranged and used in cooperation with a cutting-off chopping board are selectively installed in the secondary vegetable cutting cavity. The invention further discloses the multifunctional vegetable cutting machine. On the basis that the principle of the cutting mechanism and the cutting machine is similar to that of manual vegetable cutting, vegetables are fast cut off, vegetable fiber texture is kept intact, the cut vegetables taste good, and the problem that vegetables are seriously extruded when the vegetables are shredded and cut into blocks through single procedures is solved in the aspect of the principle.

Owner:吴守林

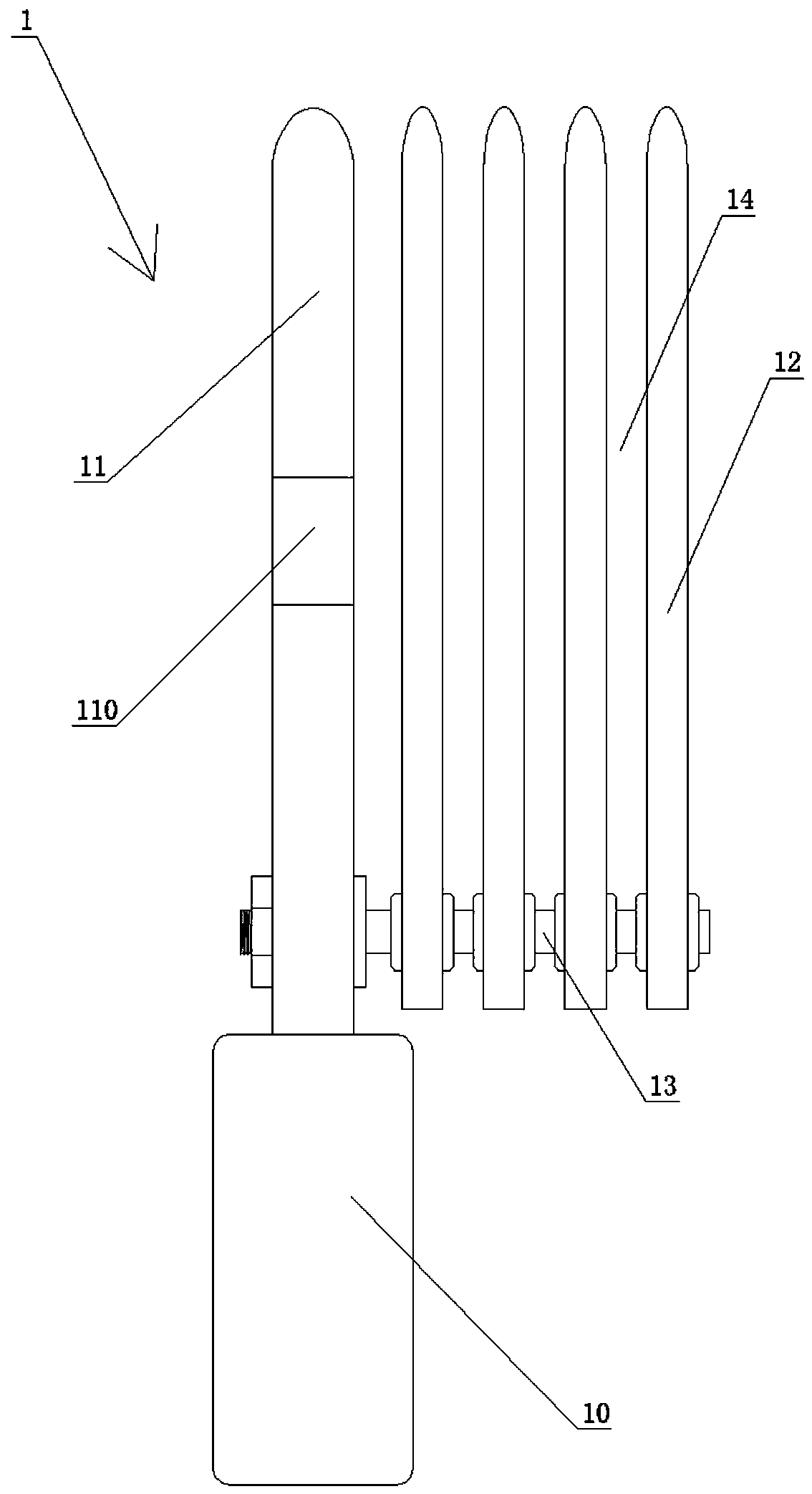

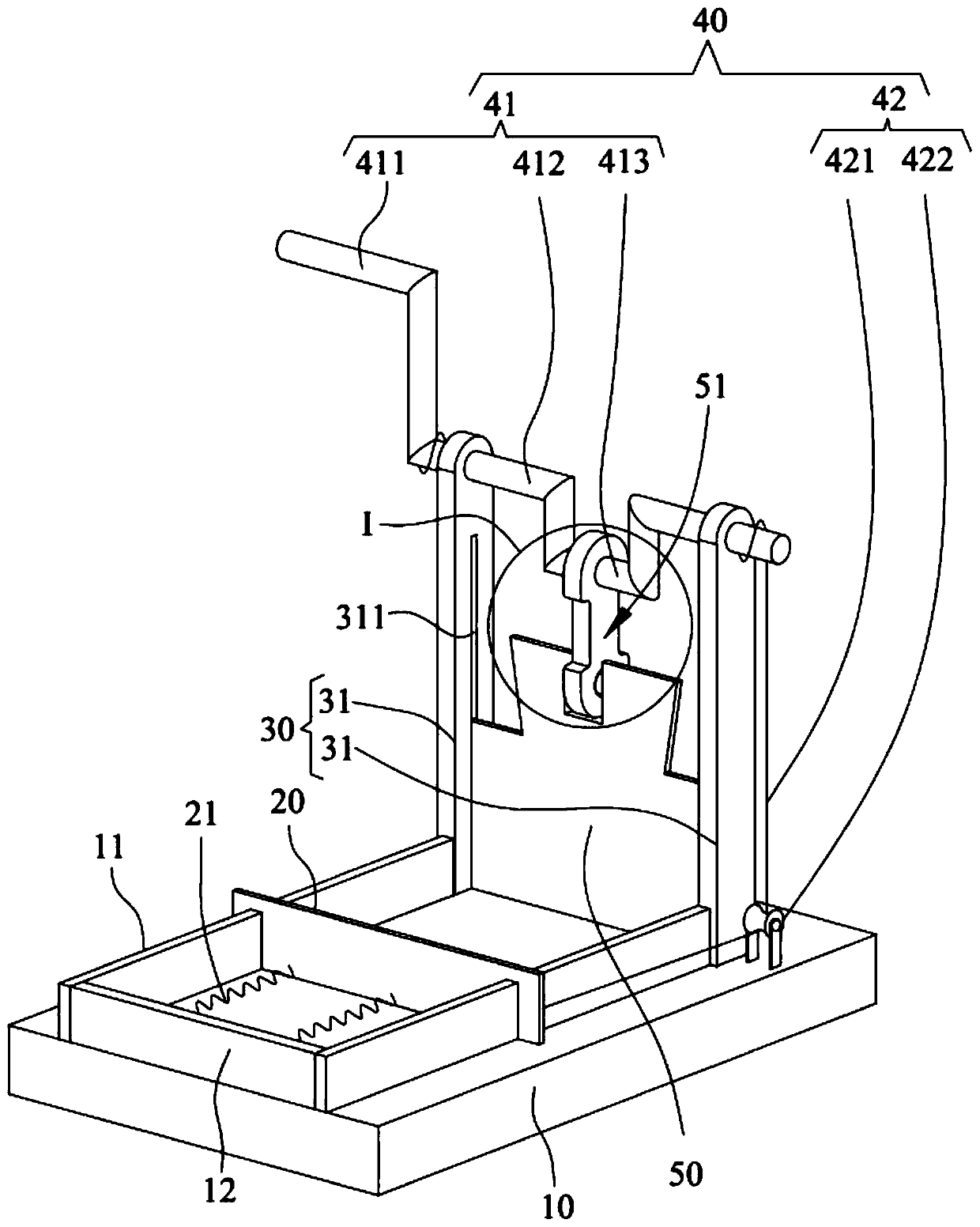

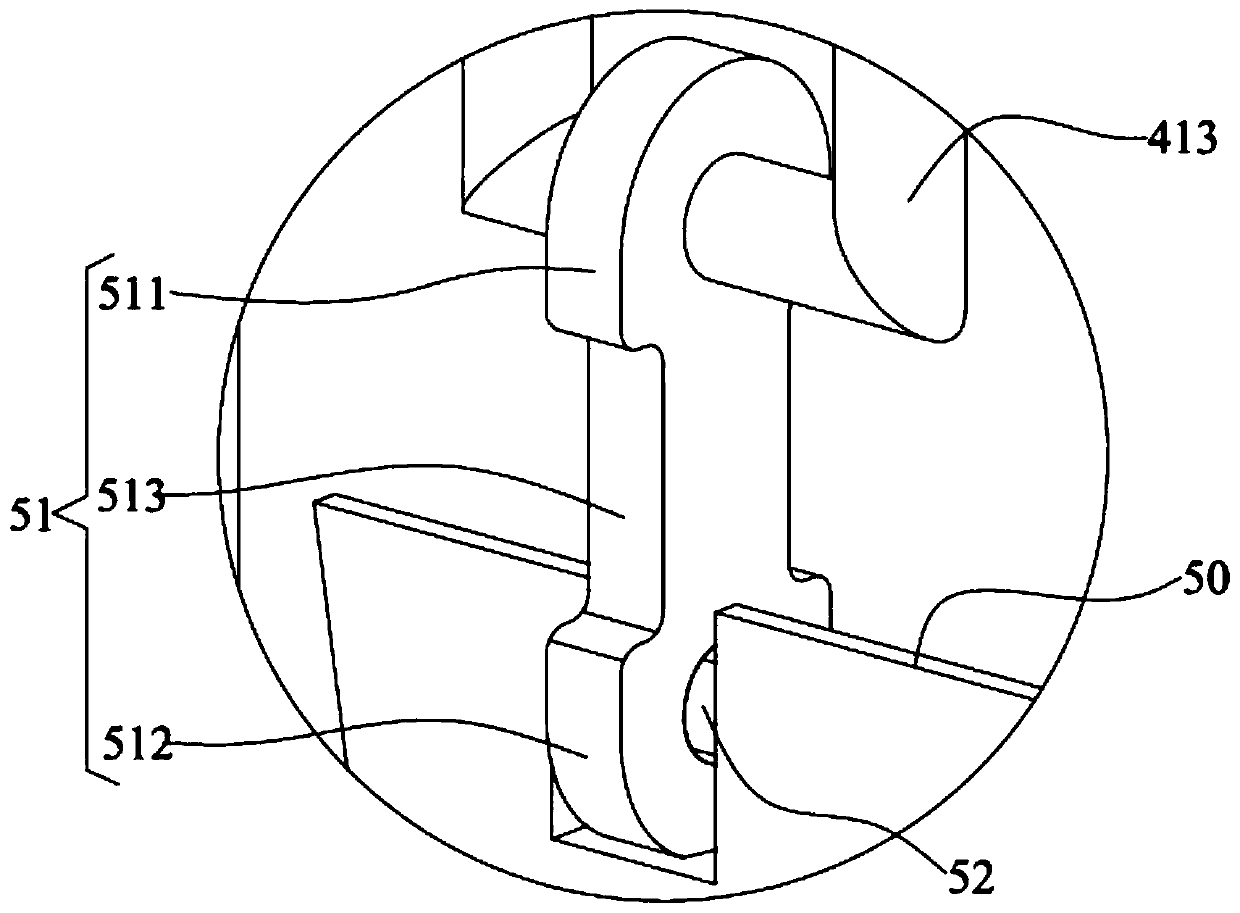

Vegetable cutter

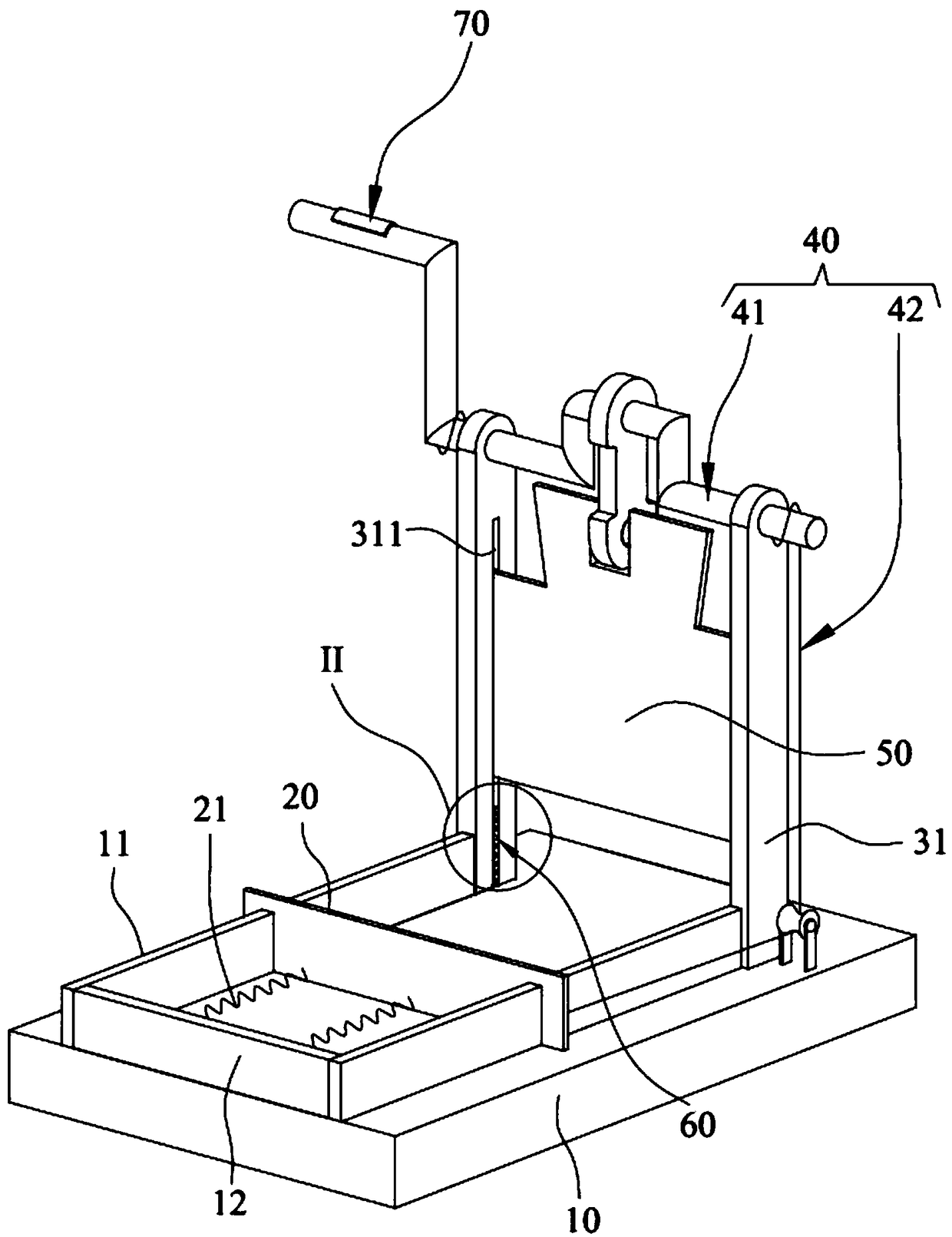

PendingCN109465880AUniform lengthPlay the role of cutting vegetablesMetal working apparatusAgricultural engineering

The invention discloses a vegetable cutter. The vegetable cutter comprises a base and a vegetable cutting device, wherein the vegetable cutting device is fixed to the base; the base is composed of middle connecting plates and supporting pipes symmetrically arranged on the two sides of the middle connecting plates; a connecting pipe is arranged between the two symmetrical supporting pipes; verticalplates are arranged at the two ends of the supporting pipes; the vegetable cutting device comprises U-shaped plates, a rotating shaft and blades; the U-shaped plates are uniformly arranged on the middle connecting plates; the rotating shaft is rotatably connected with the vertical plates; one ends of the blades are fixedly connected with the rotating shaft; the blades are positioned between clearances of every two adjacent U-shaped plates; a connecting rod is fixedly arranged at the other ends of the blades; and a handle is arranged on the connecting rod. According to the vegetable cutter, auser places vegetables on the U-shaped plates, the other hand presses the handle, the blades rotate around the rotating shaft, when the blades are downwards pressed to the positions between every twoadjacent U-shaped plates, the vegetables are cut, the length of the cut vegetables is uniform, vegetable cutting efficiency is improved, and utilization is safe.

Owner:董承

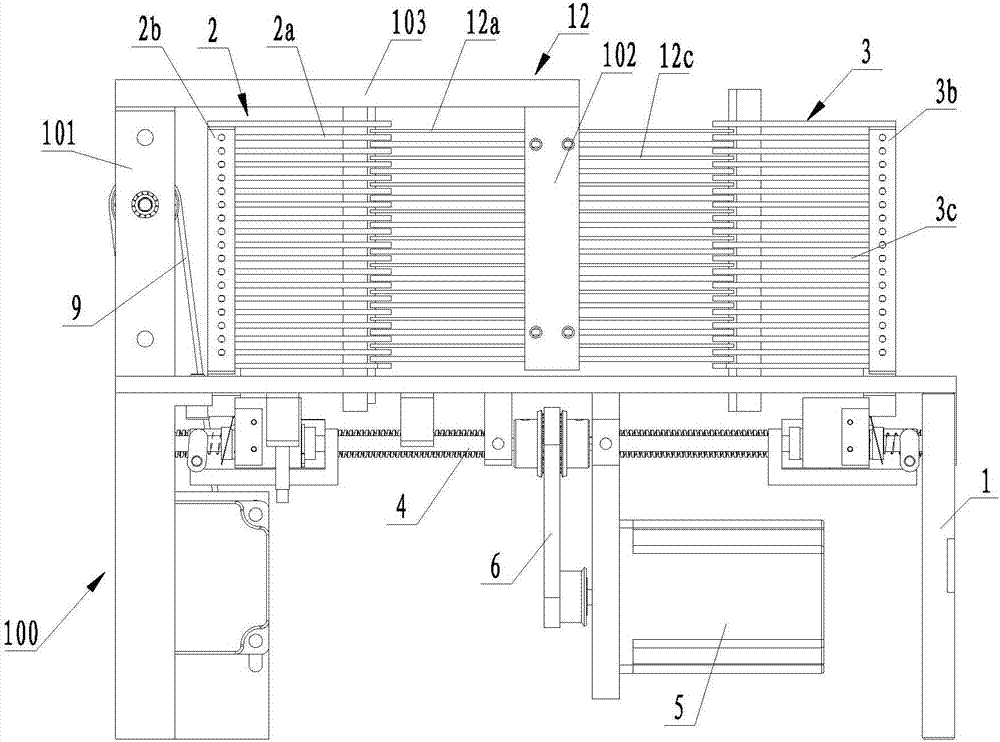

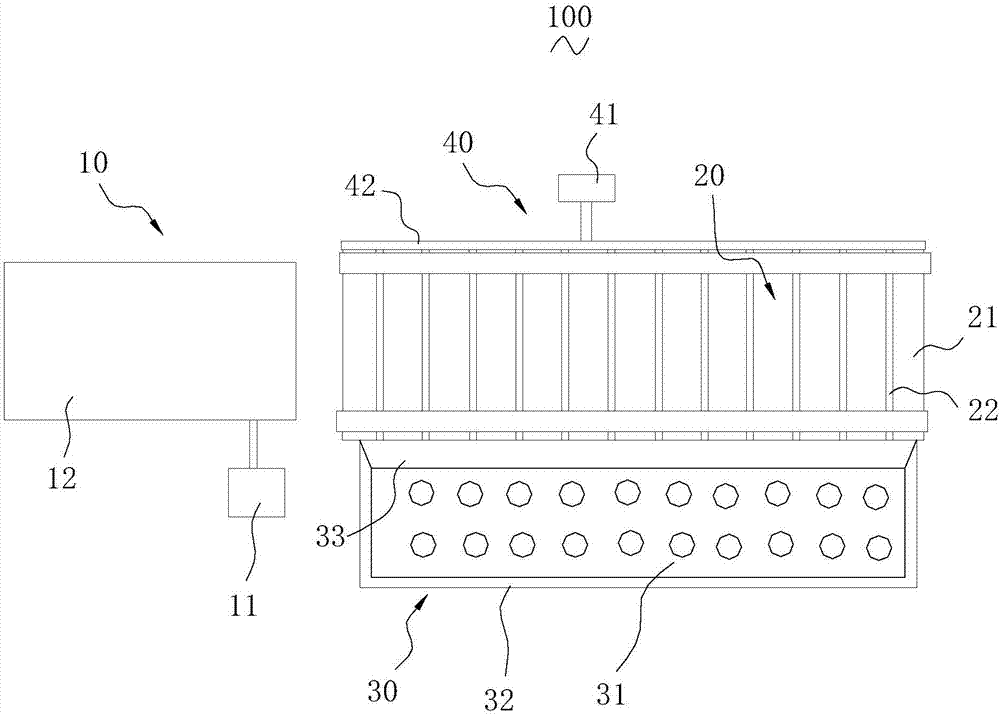

Vegetable cutting device

ActiveCN107097287AReduce workloadImprove vegetable cutting efficiencyMetal working apparatusPulp and paper industry

The invention discloses a vegetable cutting device. The vegetable cutting device comprises a rack, a clamping device, a slicing device, a first limiting device, a shredding device, a second limiting device and a dicing device are sequentially arranged on the rack from front to back, the clamping device comprises a first clamping frame and a second clamping frame which are symmetric, the first clamping frame comprises multiple first clamping plates, a first screw is rotatably fixed to the bottom of the rack, a first power device is arranged at the bottom of the rack, and an output shaft of the first power device is connected with the first screw through a first belt. According to the vegetable cutting device, vegetables can be cut into block, strip and particle shapes, the vegetable cutting efficiency is effectively improved, consistency of the size of cut vegetables can be ensured, the workloads of the operators can be effectively reduced, and the risk of finger cutting can be effectively avoided.

Owner:兴化顶康食品科技有限公司

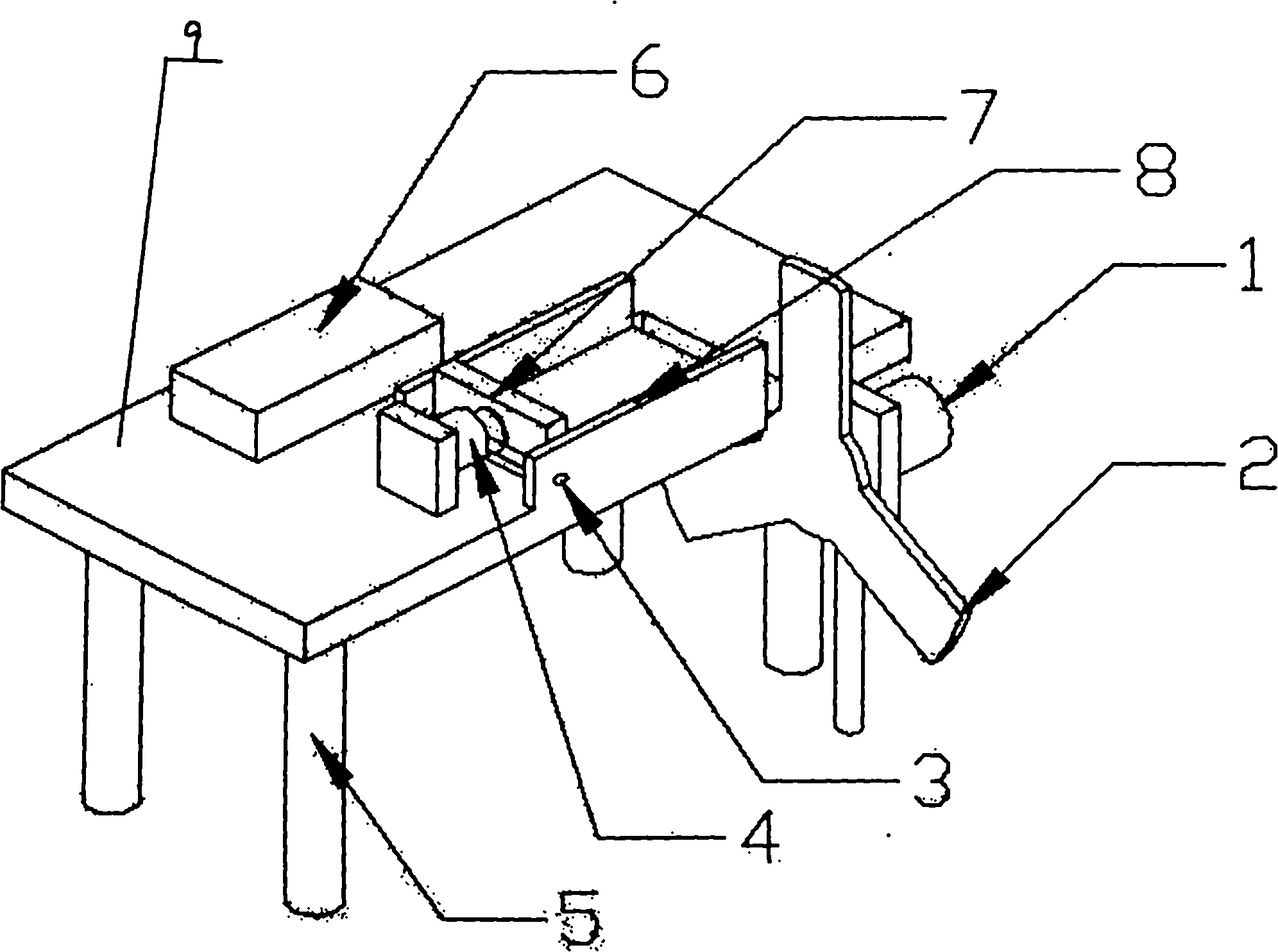

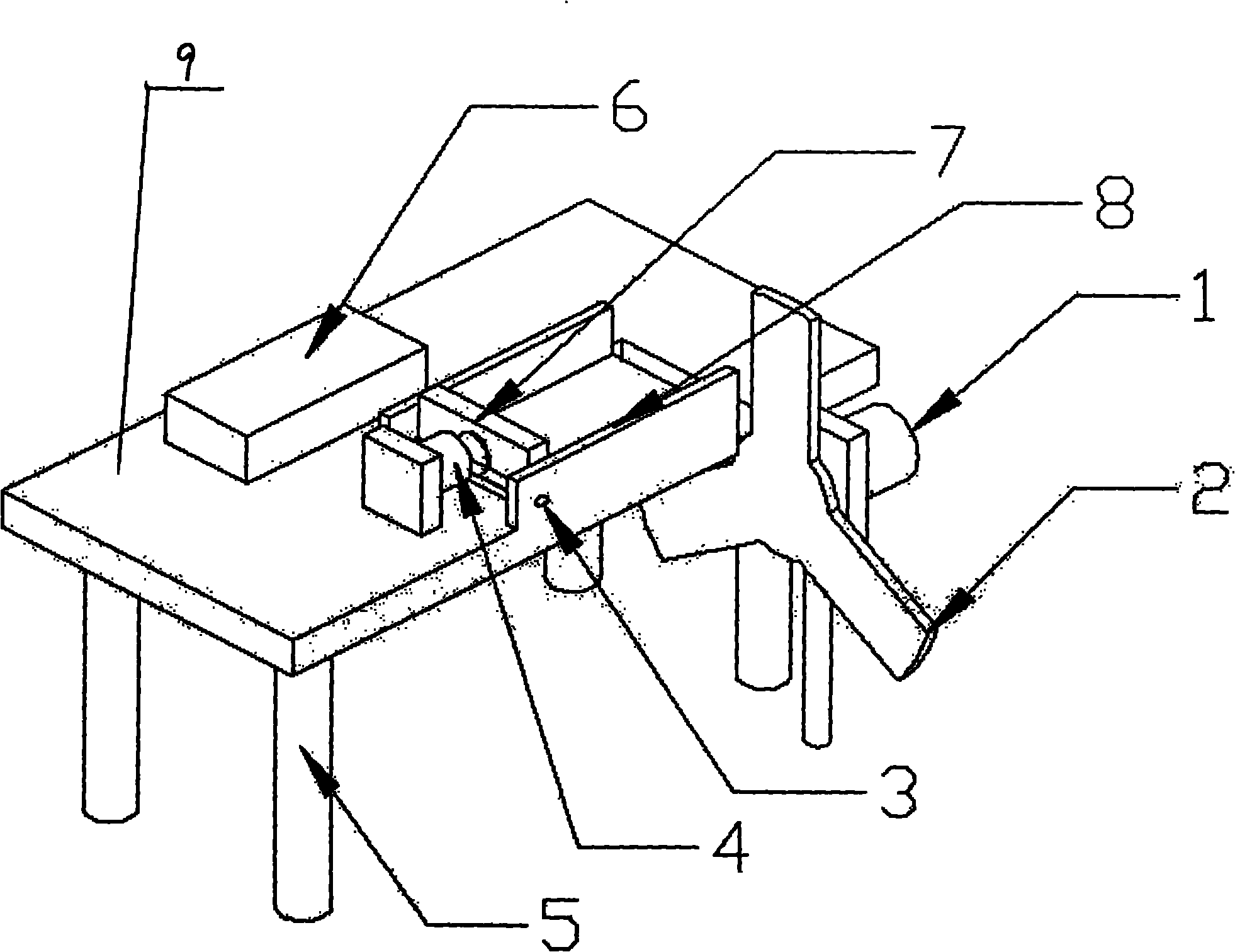

Automatic household small kraut cutter

The invention relates to an automatic household small kraut cutter comprising a bracket, a chopping board, an electronic motor, a three-leaf blade, a vegetable groove, a power supply control box, an electromagnet and a pushing board, wherein the chopping board is arranged on the bracket; the vegetable groove, the power supply control box, the electromagnet and the pushing board are all arranged on the chopping board; the electromagnet is in circuited connection with the power supply control box; the pushing board is connected with the electromagnet and arranged in the vegetable groove; the vegetable groove is provided with a screwing nut, and the screwing nut can clamp vegetables after screwed; the electronic motor is arranged on the side surface of the bracket; the three-leaf blade is connected with the electronic motor and is controlled by the electronic motor; and the electronic motor is in circuited connection with the power supply control box. The automatic household small kraut cutter provided by the invention has the advantages of simple structure, low cost, high chopping efficiency and the like.

Owner:杨勇

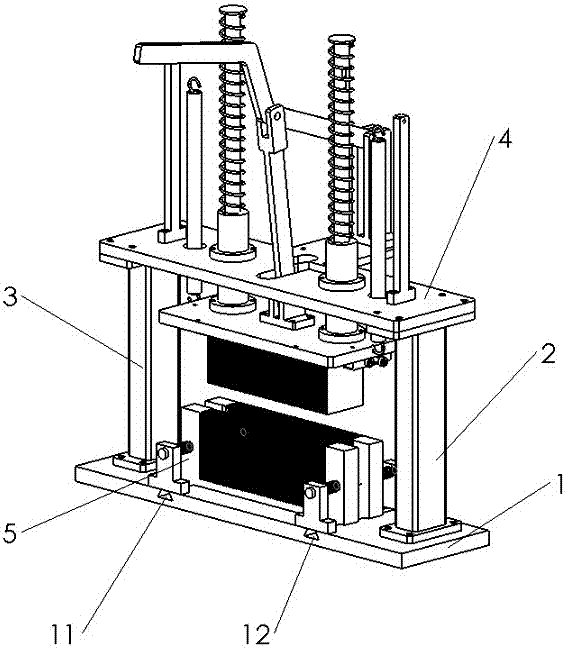

Device for cutting cylindrical vegetable

The invention discloses a device for cutting cylindrical vegetable. The device comprises a bottom plate, wherein a first chute and a second chute are symmetrically formed in the bottom plate; a first supporting leg is arranged at the right half part of the upper surface of the bottom plate, and a second supporting leg is arranged at the left half part of the upper surface of the bottom plate; a lower cutting die set is mounted at the upper ends of the first supporting leg and the second supporting leg; a positioning die set is arranged in the middle part of the upper surface of the bottom plate; a cutter is driven by the lower cutting die set to downwards cut the vegetable; the vegetable to be cut is positioned through the positioning die set. The device has the advantages of being high in safety, time saving, force saving, and high in generality.

Owner:上海老盛昌配送有限公司

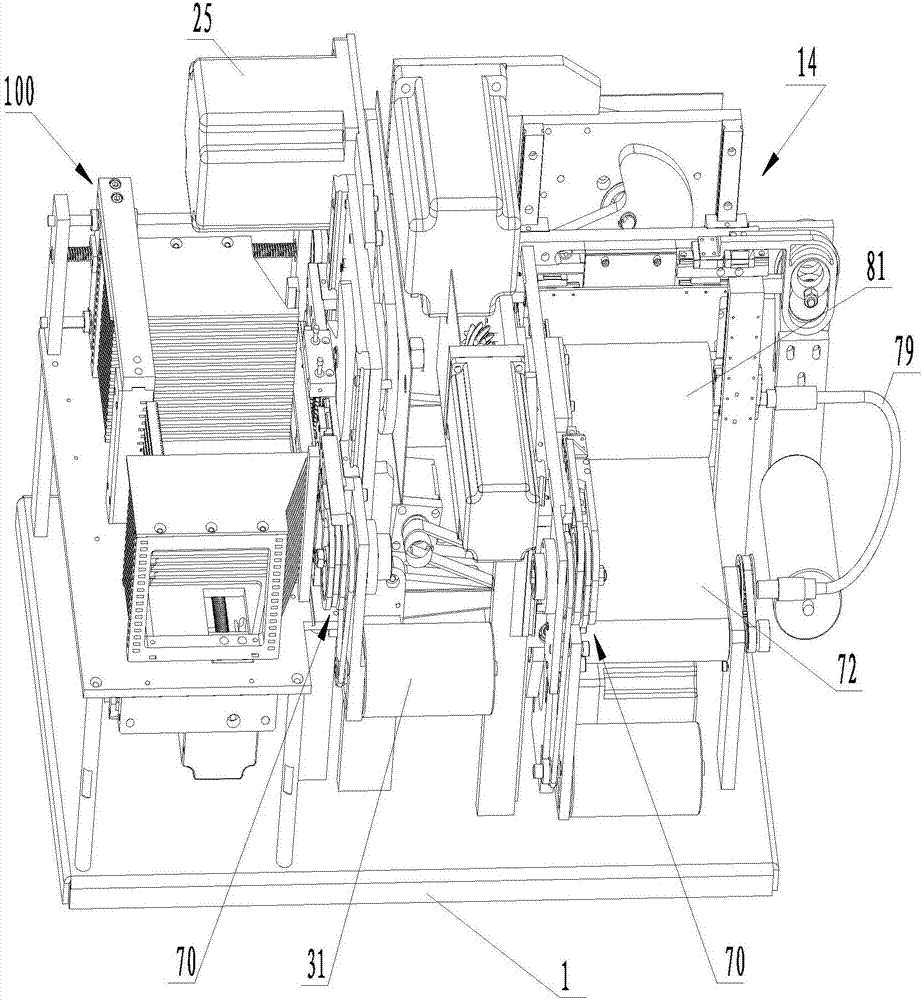

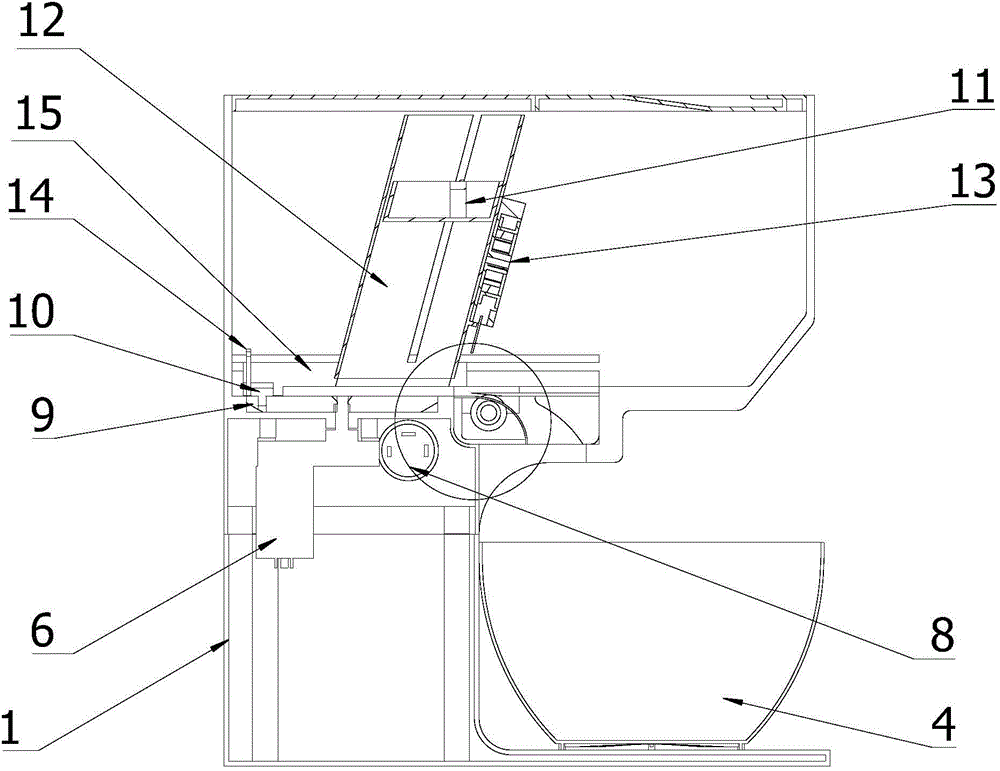

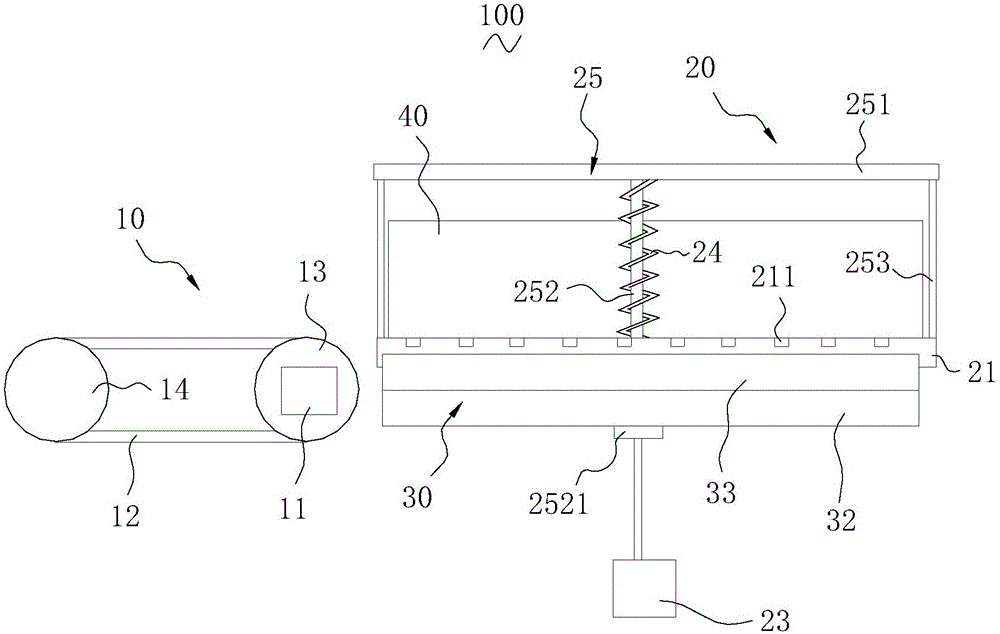

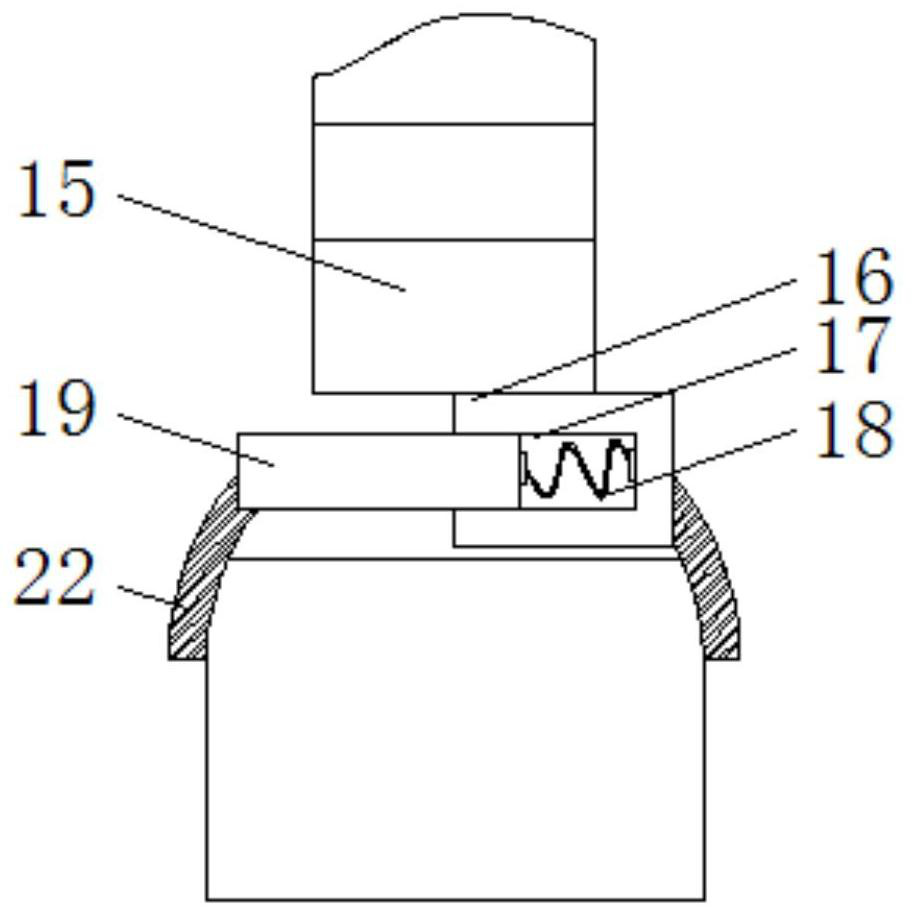

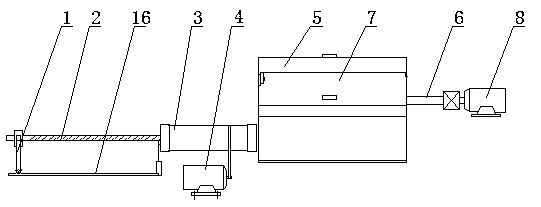

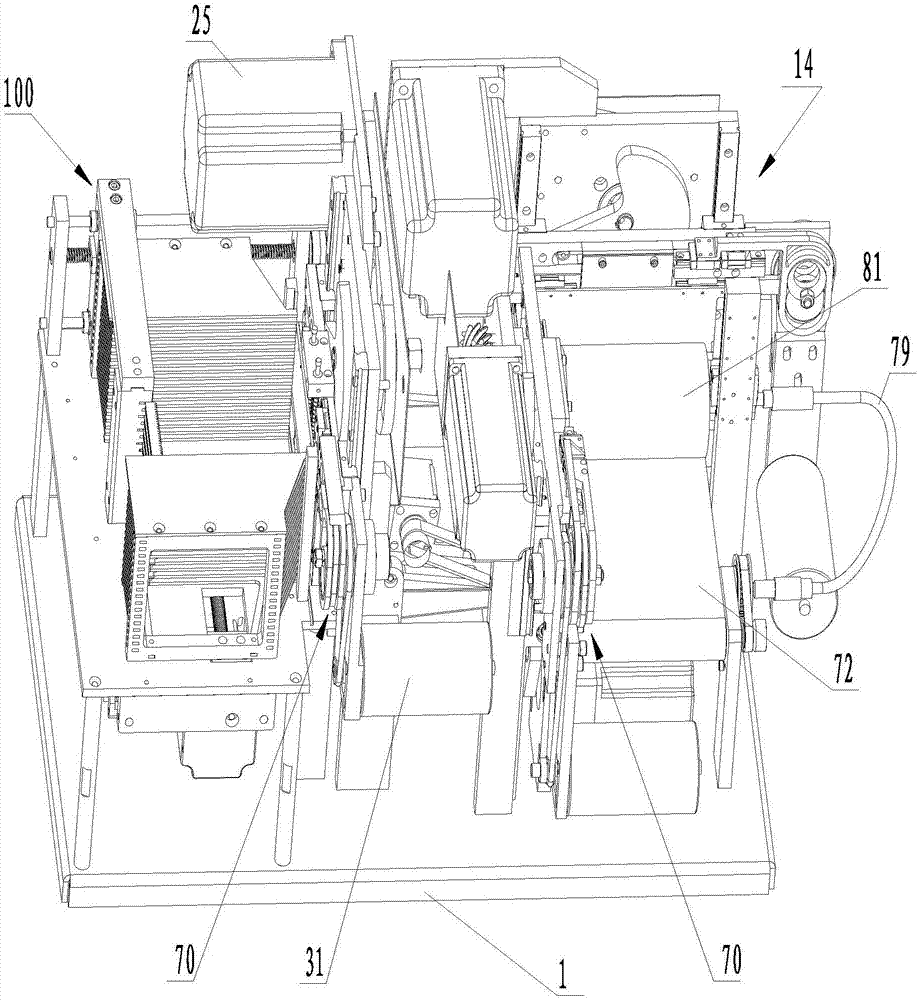

Fully automatic vegetable cutter

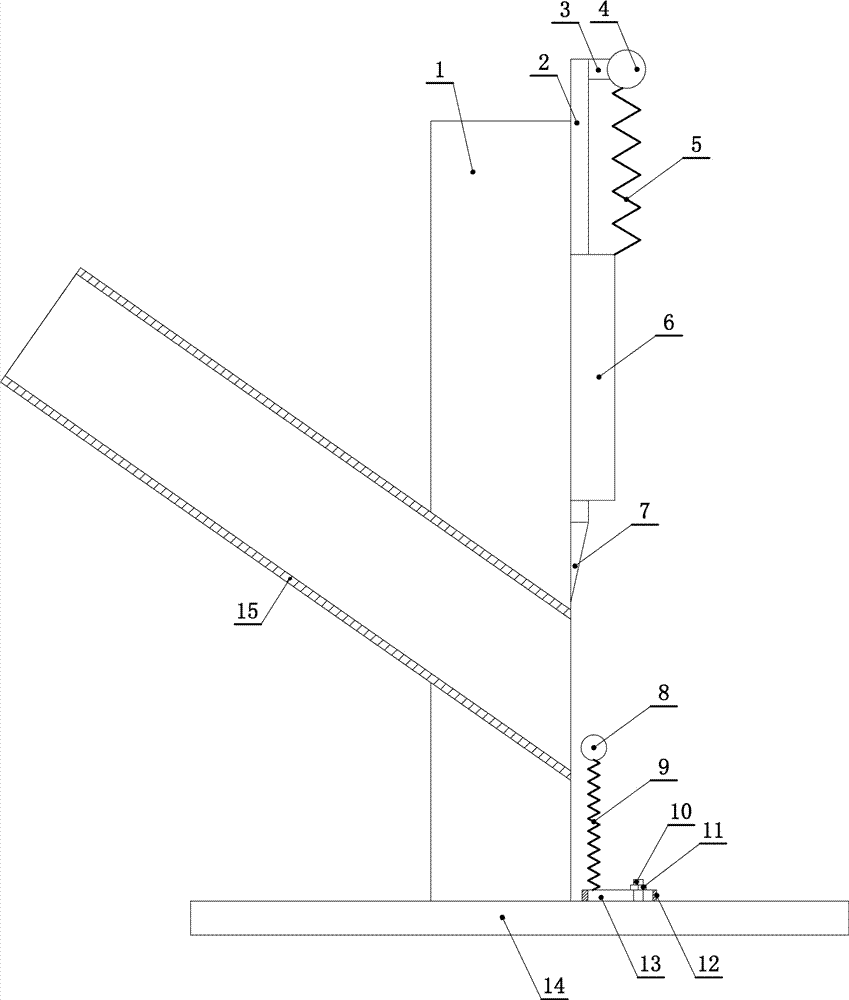

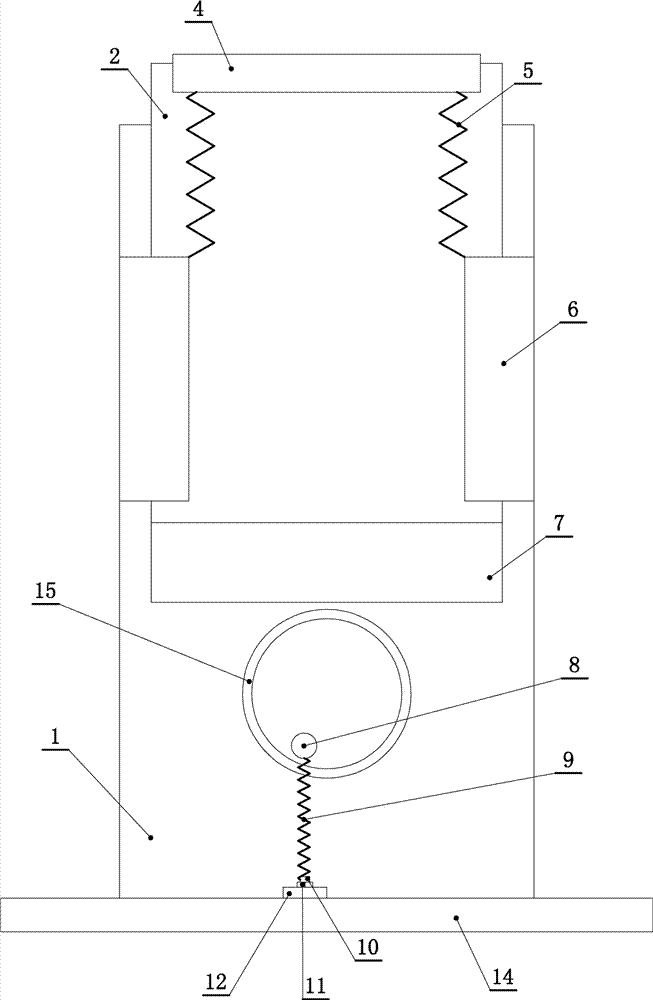

InactiveCN104908072AEasy reciprocating motionSave human effortMetal working apparatusReciprocating motionEngineering

The invention discloses a fully automatic vegetable cutter. A feeding mechanism, a feeding drive and transmission mechanism and a cutting mechanism are arranged in a shell of a main machine. The feeding mechanism comprises a material cylinder, a pressing plate, a spring mechanism and a material cylinder sliding block. The spring mechanism comprises a spring shell, a middle ring, a spring and a rope. The two ends of the rope sequentially penetrate through the spring shell and the material cylinder sliding block to be fixed to the pressing plate. The pressing plate is arranged in the material cylinder and slide vertically relative to the material cylinder. The material cylinder is provided with an upper opening and a lower opening and arranged on the material cylinder sliding block. A cam sliding groove is formed in the material cylinder sliding block. The feeding drive and transmission mechanism comprises a first motor, a rotating disc and a cam. An output shaft of the first motor is fixed to the center of the rotating disc. The cam is eccentrically arranged on the rotating disc and matched with the cam sliding groove. The material cylinder sliding block drives the material cylinder to conduct reciprocating rectilinear movement in the shell of the main machine. According to the fully automatic vegetable cutter, the rope is driven through the elasticity of the spring to pull the pressing plate to press food materials all the time, manual food material pressing is omitted, and reciprocating movement of the feeding mechanism is achieved easily.

Owner:马晓东

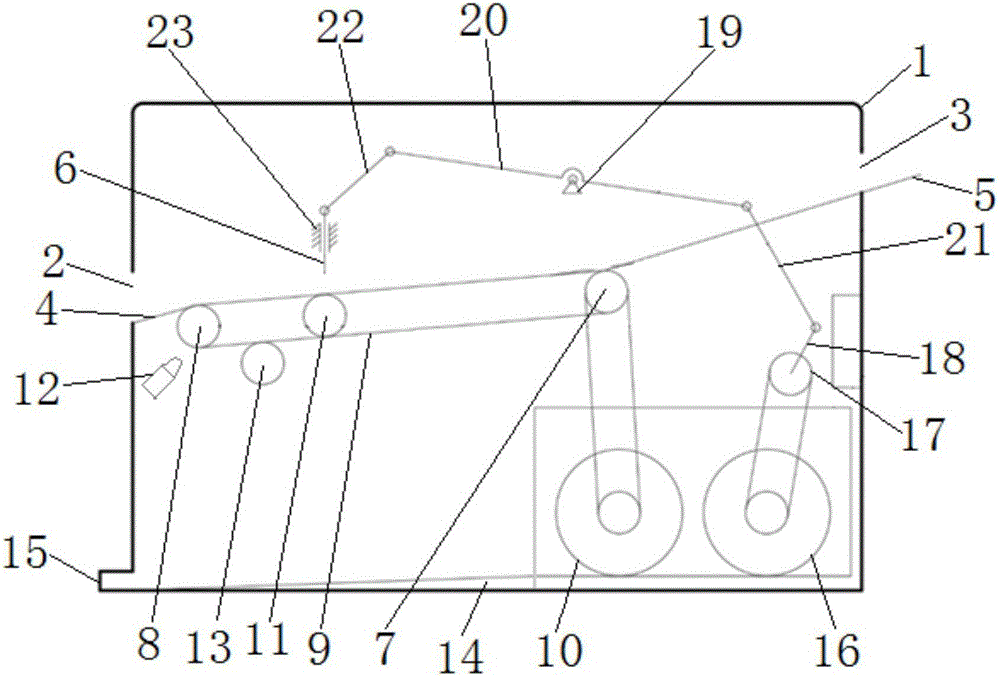

Continuous household vegetable cutting device

InactiveCN106826958AWith energy savingReduce weightMetal working apparatusEngineeringMaterials processing

The invention relates to a continuous household vegetable cutting device. The continuous household vegetable cutting device comprises a shell and further comprises a material conveying mechanism, a kitchen knife driving mechanism and a conveying belt cleaning mechanism, all of which are arranged in the shell. A discharging port and a feeding port are formed in the left side and the right side of the shell correspondingly. A discharging guide plate is arranged between the discharging port and the material conveying mechanism. A feeding guide plate is arranged between the feeding port and the material conveying mechanism. A kitchen knife in transmission connection with the kitchen knife driving mechanism is arranged above the material conveying mechanism. The kitchen knife is driven by the kitchen knife driving mechanism to cut materials on the material conveying mechanism. Compared with the prior art, when the continuous household vegetable cutting device is applied, the materials continuously enter the device and are sequentially cut through the kitchen knife. The vegetable cutting efficiency is high, the material processing time is shortened, and the work intensity of operators is lowered; noise during vegetable cutting is low, and higher safety is achieved; and cleaning is easy, and the continuous household vegetable cutting device is suitable for family kitchens and small restaurants.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

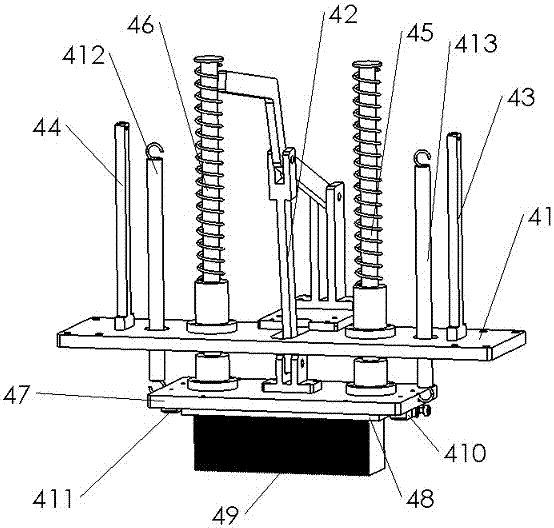

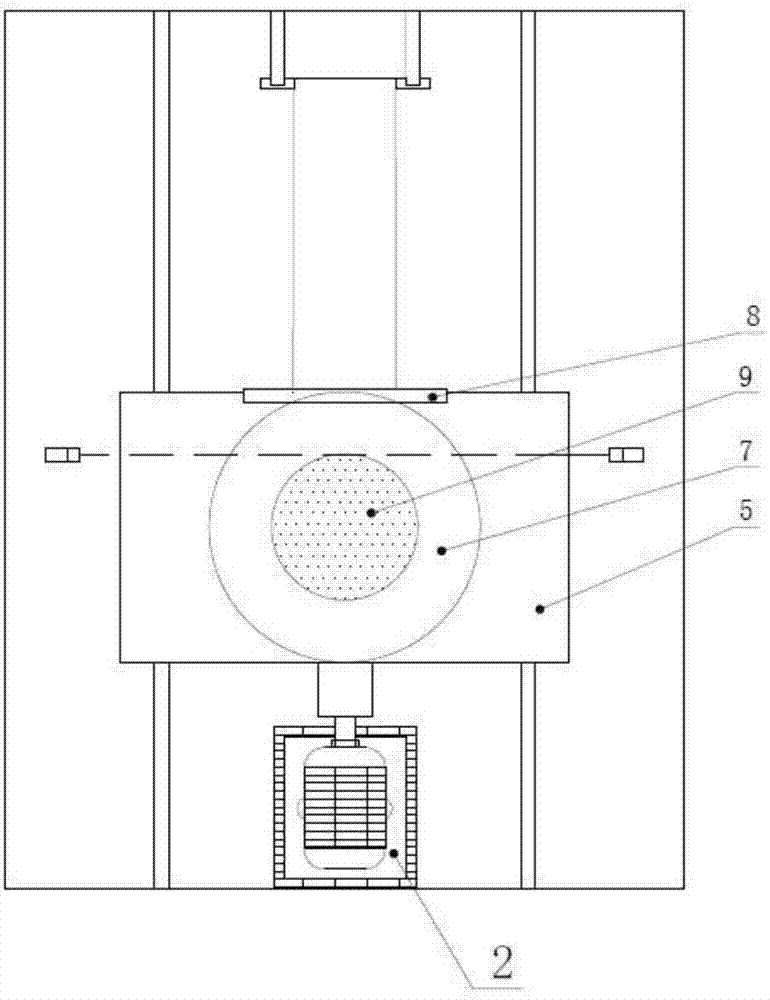

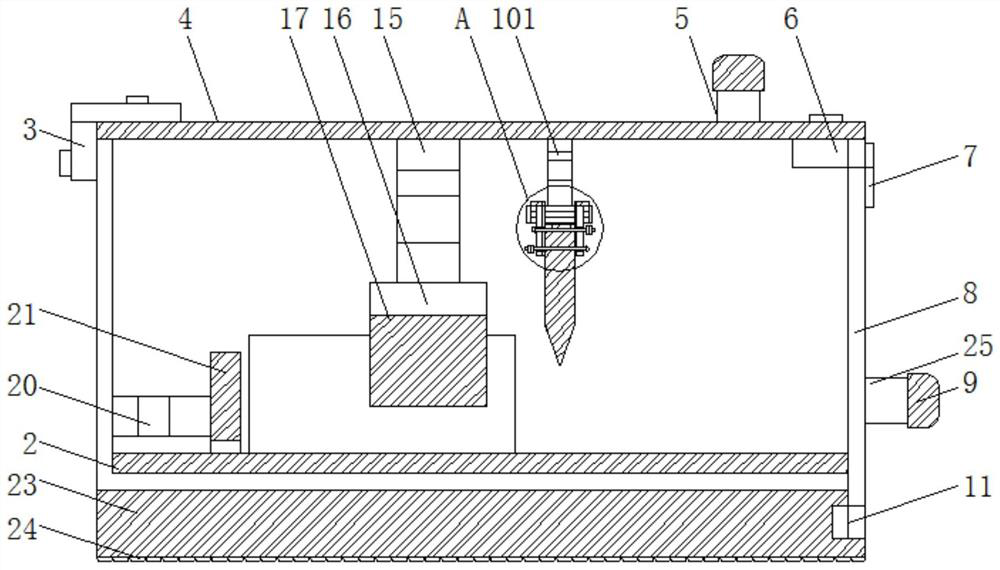

Multifunctional vegetable cutter for tuber and block vegetable cutting

PendingCN108501085ACause uneven cuttingImprove vegetable cutting efficiencyMetal working apparatusAgricultural engineeringPlant Tubers

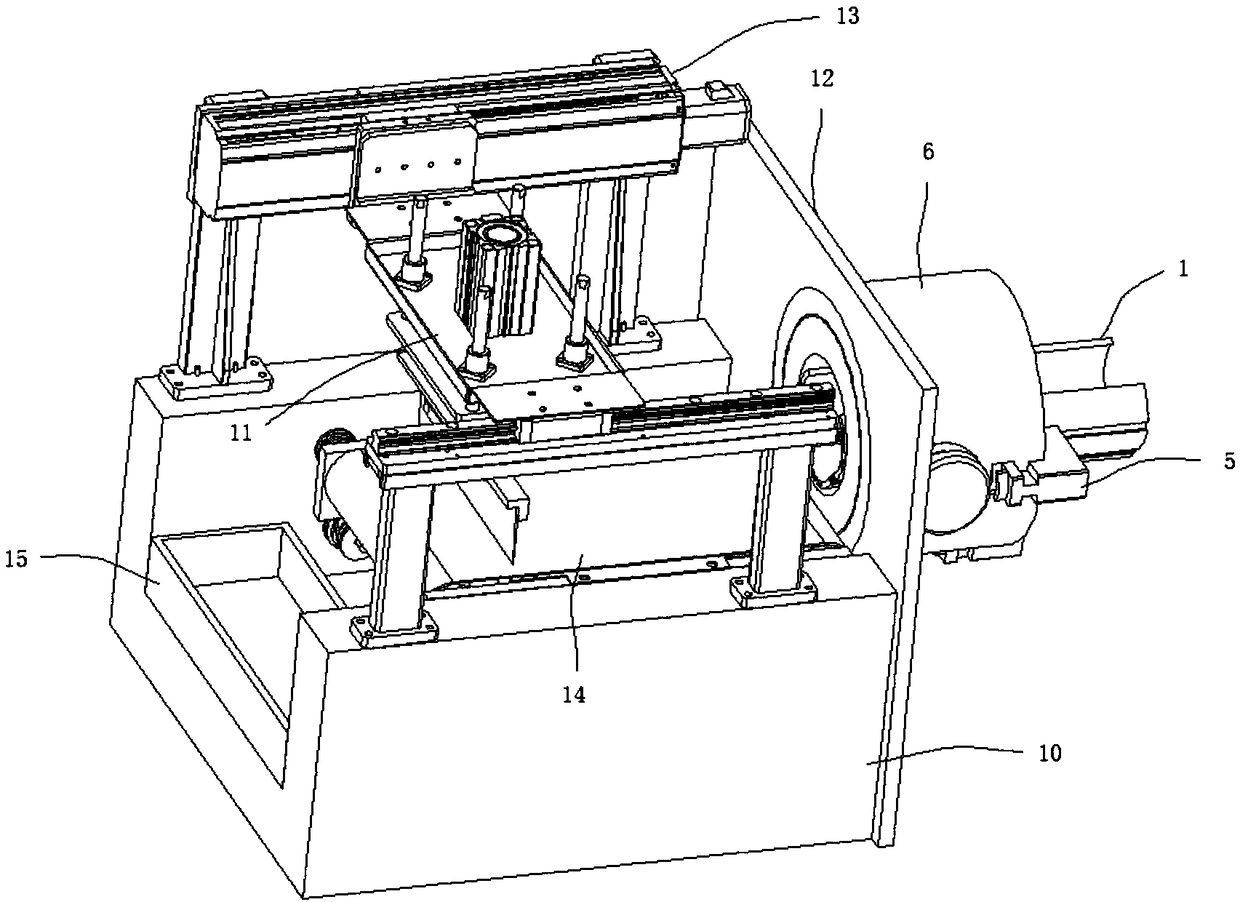

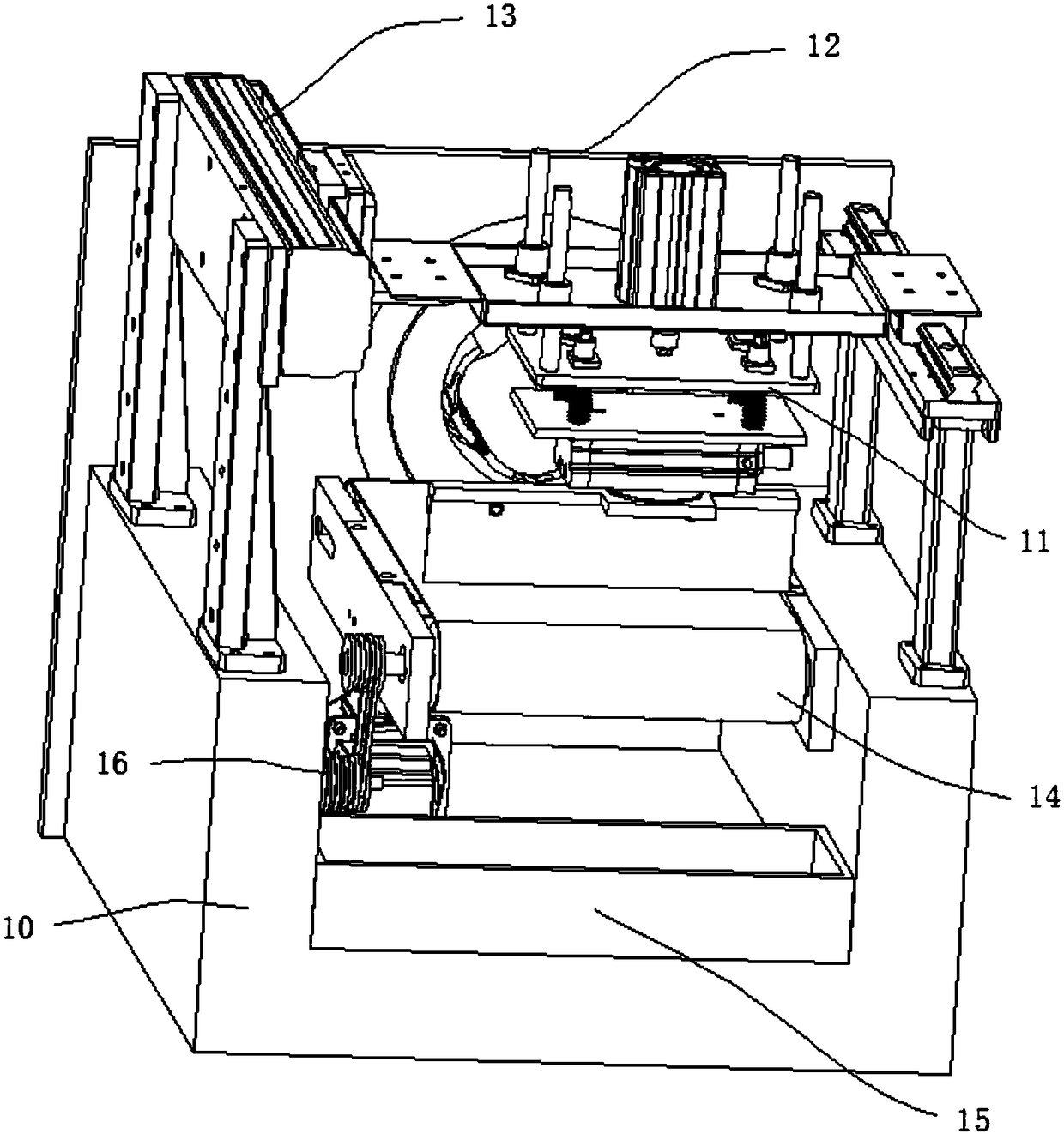

The invention discloses a multifunctional vegetable cutter for tuber and block vegetable cutting. The multifunctional vegetable cutter comprises a rack. A vegetable cutting device and a linear movement mechanism used for being connected with the vegetable cutting device are mounted on the rack. A transport mechanism is arranged at the position, below the vegetable cutting device, of the rack. A feeding mechanism is mounted at the end, close to the starting end of the transport mechanism, of the rack through an end plate. A vegetable collection tank is mounted at the other end of the rack. Thefeeding mechanism comprises a feeding tank. The feeding tank comprises a bottom plate. The two sides of the bottom plate are connected with two sets of adjusting plates through telescopic plates. Thetwo sets of adjusting plates are arranged symmetrically. Each adjusting plate is an arc plate with the radian. The two sets of adjusting plates on the two sides are arranged concentrically in the initial state. The telescopic amount, in the radial direction, of the two sets of adjusting plates is controlled through an adjusting device. According to the multifunctional vegetable cutter, when vegetables are conveyed into the vegetable cutting device, vegetable integrity is guaranteed, and therefore cutting of the vegetable cutting device to the vegetables is facilitated, and then the appearanceand taste of the vegetables are improved.

Owner:CHAOHU UNIV

Vegetable cutting device

InactiveCN107116593ARealize semi-automatic up and down movementControl thicknessMetal working apparatusFree stateEngineering

A vegetable cutter, the left end of the guide cylinder is inclined upwards, the right port of the guide cylinder does not exceed the right side of the vertical plate; the front and rear of the right side of the vertical plate are fixedly connected with splints, and the front and rear splints are connected up and down. Cutter, the cutter is set close to the right side of the vertical plate, the lower edge of the cutter has a knife toughness, and the vertical lifting spring is fixedly connected between the vertical plate and the splint. When the lifting spring is in a free state, the knife toughness is located on the vertical Above the perforation on the plate; the right side of the vertical plate is provided with a vertically arranged thickness adjustment spring, the upper end of the thickness adjustment spring is fixedly connected with a stopper, and the stopper is located on the right side of the perforation on the vertical plate. The chassis is fixedly connected to the bottom of the vertical plate, and the chassis and the vertical plate are perpendicular to each other. The screw is fixedly connected to the chassis. Passing through the adjustment slot, the screw above the slider is threadedly connected with a positioning nut, and the slider is positioned on the chassis through the positioning nut.

Owner:李新敏

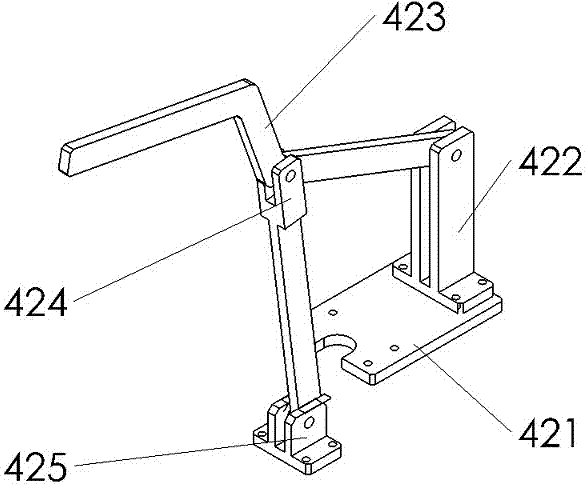

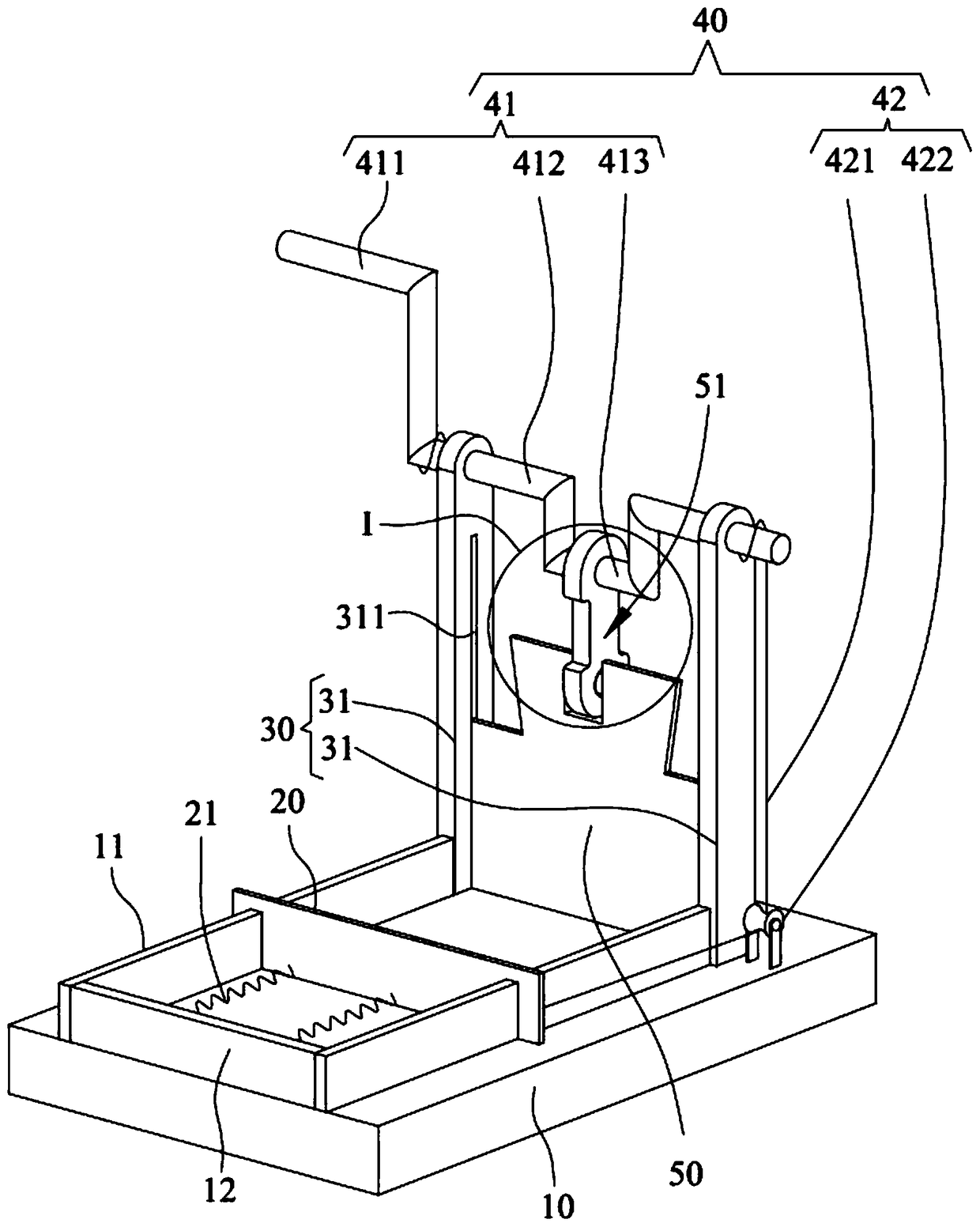

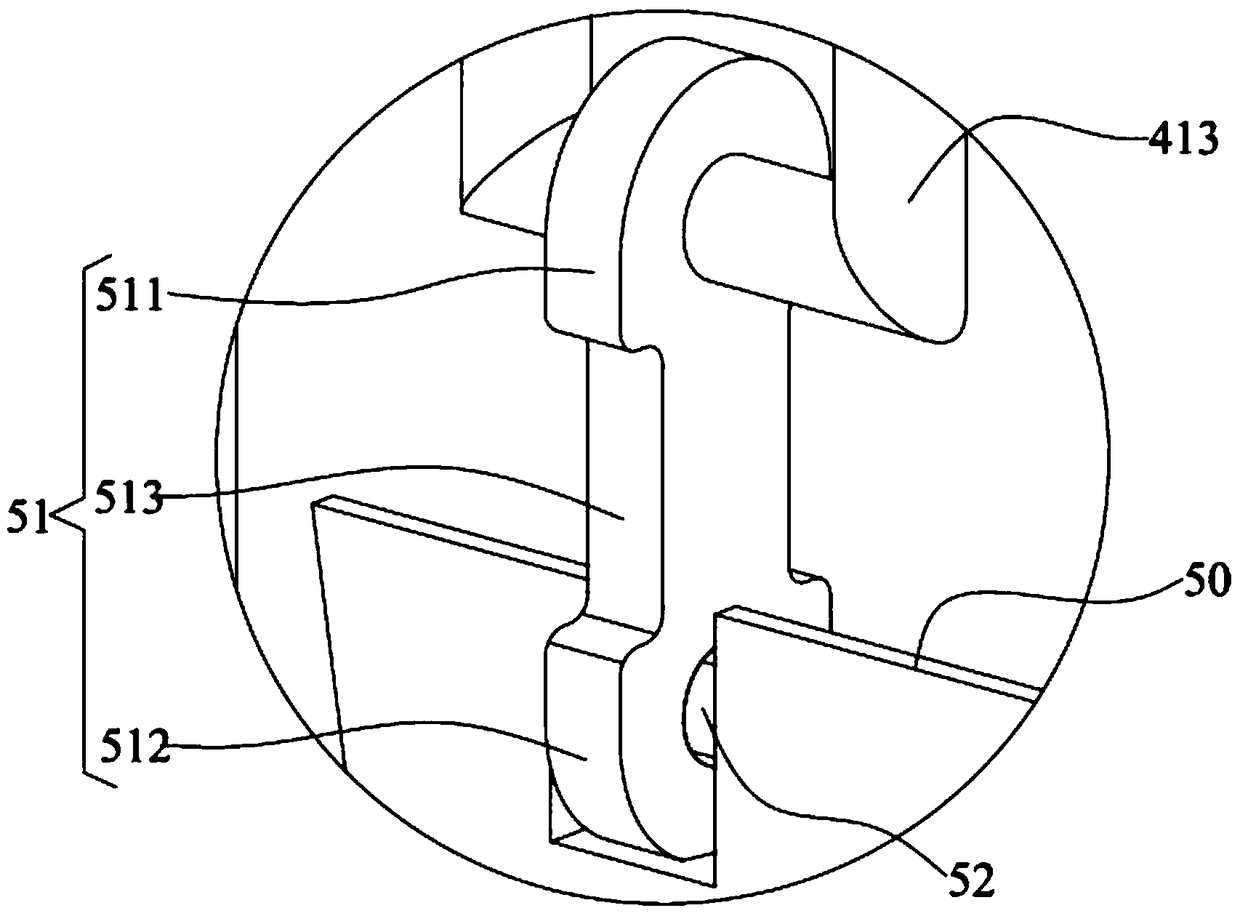

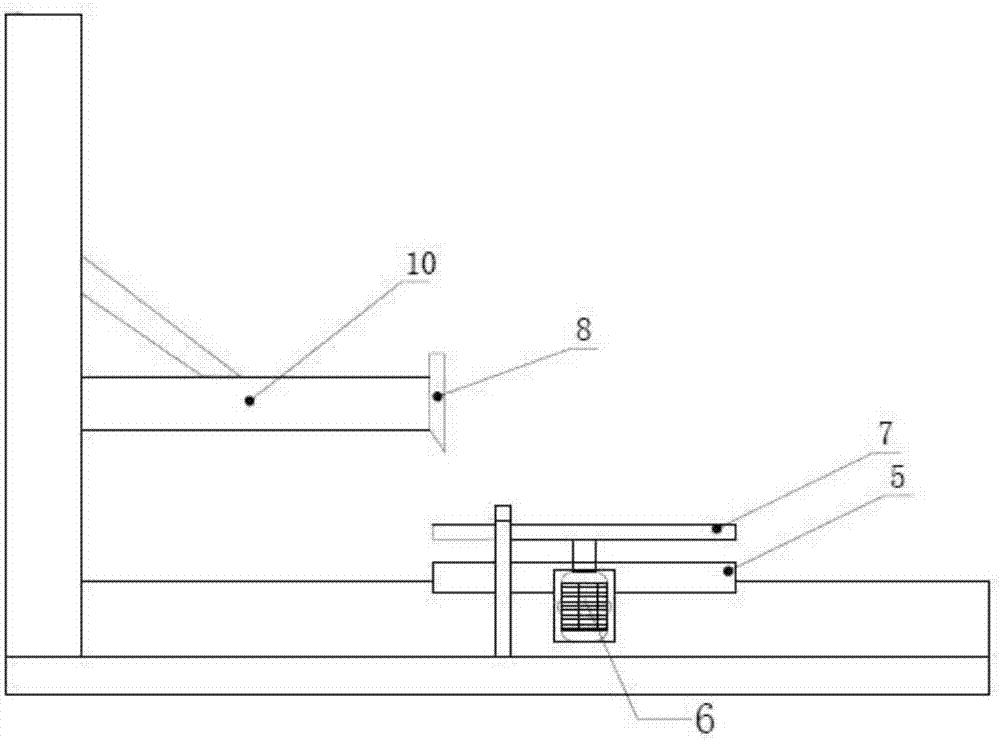

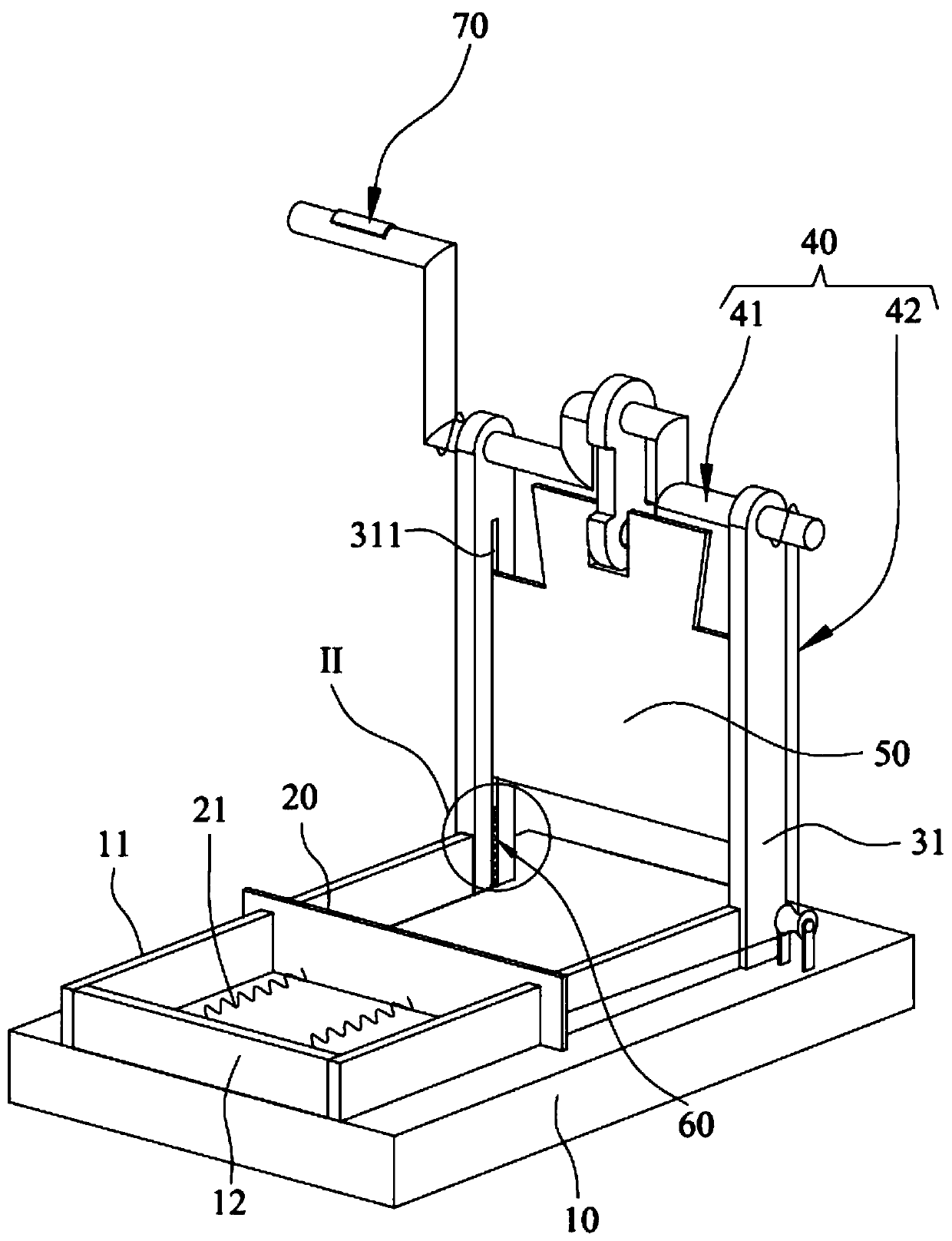

Manual vegetable cutting device

ActiveCN108772860AImprove vegetable cutting efficiencyCleaning using toolsMetal working apparatusAgricultural engineering

The invention discloses a manual vegetable cutting device. The manual vegetable cutting device comprises a bottom plate, a push plate, a supporting frame, a control mechanism and a cutter; the top ofthe bottom plate is provided with two guide rails and a fixing plate connected between the two guide rails; the push plate is installed on the two guide rails in a sliding mode, and reset springs areconnected between the push plate and the fixing plate; the supporting frame comprises two supporting columns, the supporting columns are fixedly arranged at the top of the bottom plate, a sliding groove is formed in each supporting column, and the sliding grooves penetrate through the bottoms of the supporting columns; the control mechanism comprises a control rod and two traction assemblies, wherein the operating rod is rotationally installed at the tops of the supporting columns, the corresponding traction assembly is arranged on the outer side of each supporting column, each traction assembly comprises a traction rope and a guide wheel, wherein the guide wheels are fixedly arranged at the top of the bottom plate, one ends of the traction ropes are wound around the operating rod, and theother ends of the traction ropes wind around the guide wheels to be fixedly connected with the push plate; and the cutter is hung on the operating rod through a connecting block, and the cutter is arranged between the two sliding grooves in a sliding mode. According to the manual vegetable cutting device, the vegetable cutting action can be completed only by shaking the operating rod, so that theefficiency and experience of vegetable cutting are improved undoubtedly.

Owner:华东交通大学理工学院

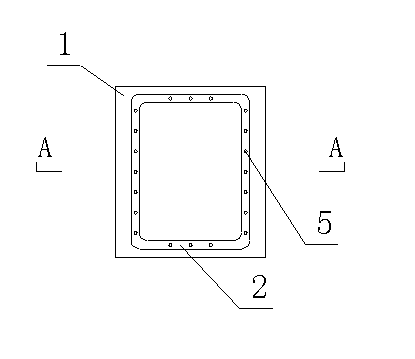

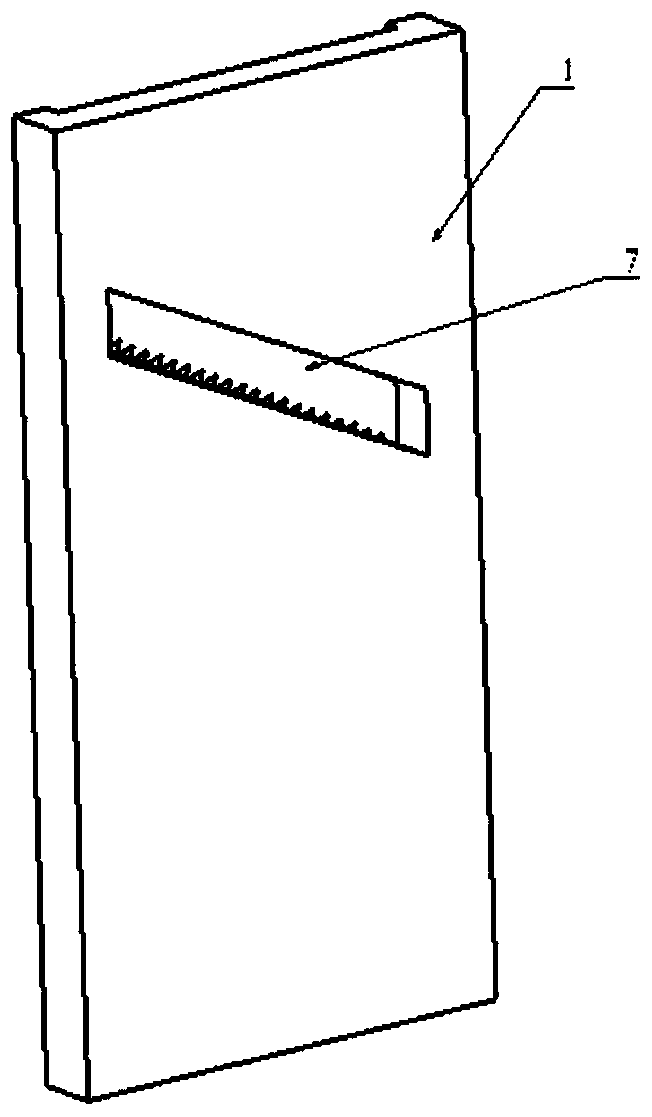

PVC anti-skidding chopping board

InactiveCN103251335AGood stabilityImprove vegetable cutting efficiencyKitchen equipmentToxinEngineering

The invention discloses a PVC anti-skidding chopping board which comprises a chopping face board, a leaking groove, a water storage box and anti-skidding strips. The left end of the chopping face board and the right end of the chopping face board are bent inwards by 180 degrees, the leaking groove is arranged on the periphery outside the chopping face board, so that a rectangular shape is defined, and the bottom faces at two ends inside the chopping board are provided with the anti-skidding strips respectively. The water storage box is inlaid in a cavity inside the chopping face board and of a cuboid shape. The water storage box is arranged in a drawn and inserted mode. Leaking holes are evenly formed in the leaking groove. The PVC anti-skidding chopping board is made of a PVC material which is free of toxin and smell and strong in moisture resistant performance. The anti-skidding strips are arranged at the bottom ends inside the chopping face board so that the chopping board can not skid in a chopping process, stability is good, and chopping efficiency is greatly improved. Meanwhile, due to the fact that the leaking groove is formed in the periphery outside the chopping face board, the water storage box is arranged on the bottom face, leaked water can not flow to a kitchen range face directly, and the PVC anti-skidding chopping board is prevented from generating bacteria in long-time use.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

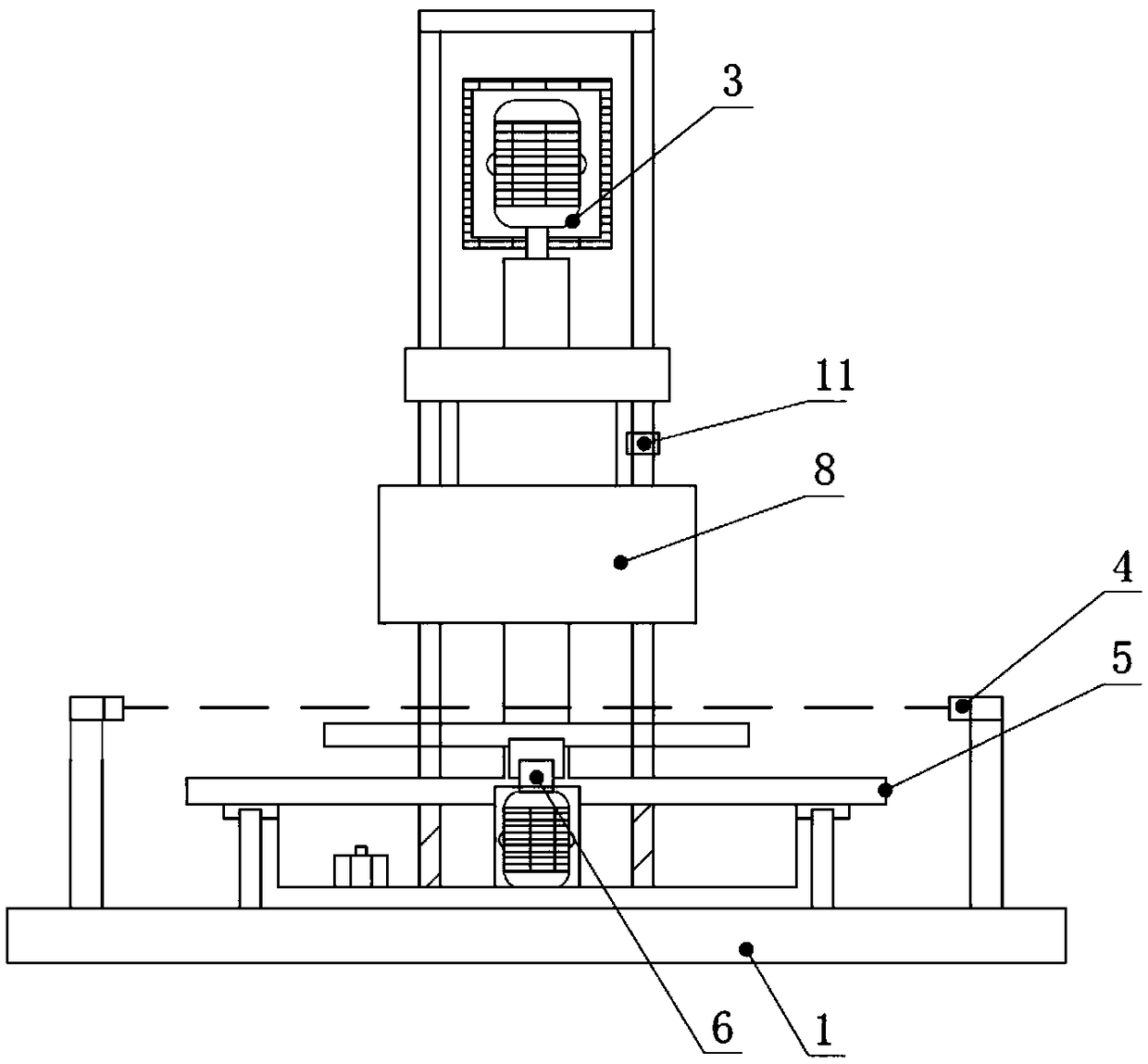

Automatic vegetable cutting equipment

InactiveCN106142169ANo manualAvoid safety hazardsMetal working apparatusElectric machineryElectric control

The invention provides automatic vegetable cutting equipment and relates to the technical field of automation. The automatic vegetable cutting equipment comprises a bottom plate, a bracket, a lifting motor, a knife, a pushing plate, a pushing motor, a guide rod, a limiting plate and an electric control box, wherein one side of the upper part of the bottom plate is connected with the electric control box through the bracket, the lifting motor is arranged in the electric control box, the knife is connected to an output shaft of the lifting motor, the pushing motor is arranged at the other side of the upper part of the bottom plate, the pushing plate is connected to an output shaft of the pushing motor, and the guide rod is arranged between the pushing plate and the side edge of the bottom plate; and the limiting plate is arranged at one side of the pushing plate. The automatic vegetable cutting equipment can avoid a series of potential safety hazards caused by manual vegetable cutting, greatly improves vegetable cutting efficiency and safety and is stronger in use properties.

Owner:XINGUANG NUMERICAL CONTROL TECH

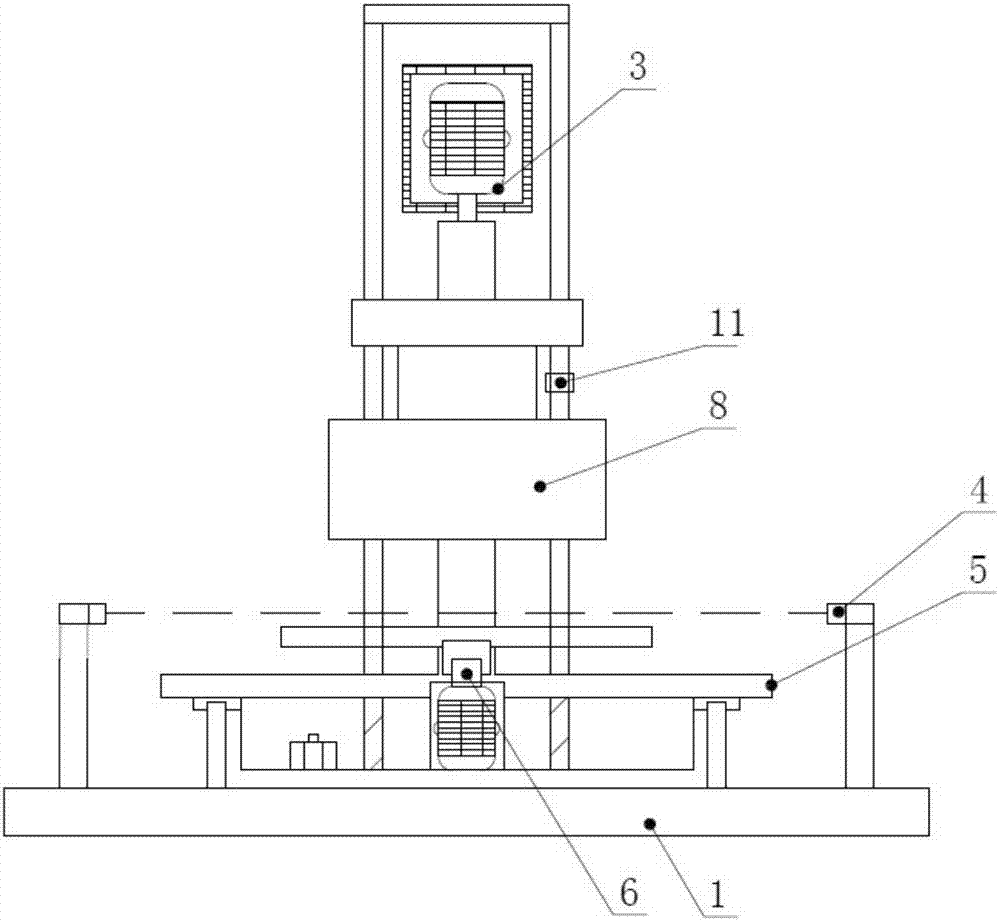

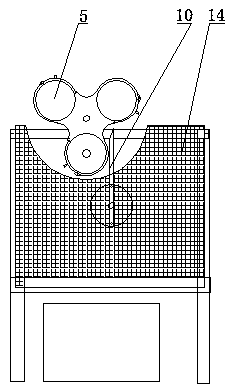

Fan-shaped tuber vegetable stripping and slicing machine

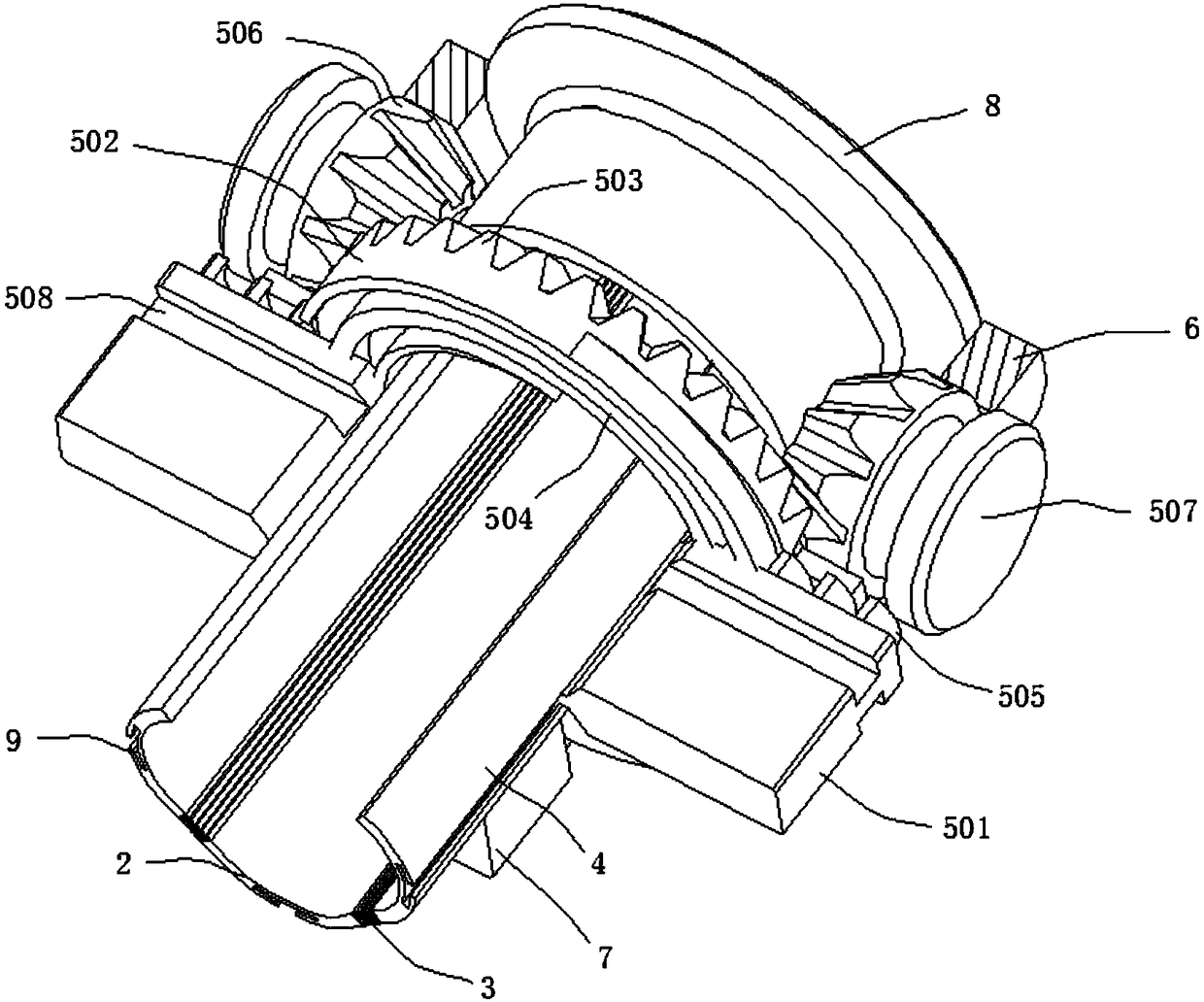

ActiveCN107498616AAchieve separationReduce labor intensityMetal working apparatusAgricultural engineeringEngineering

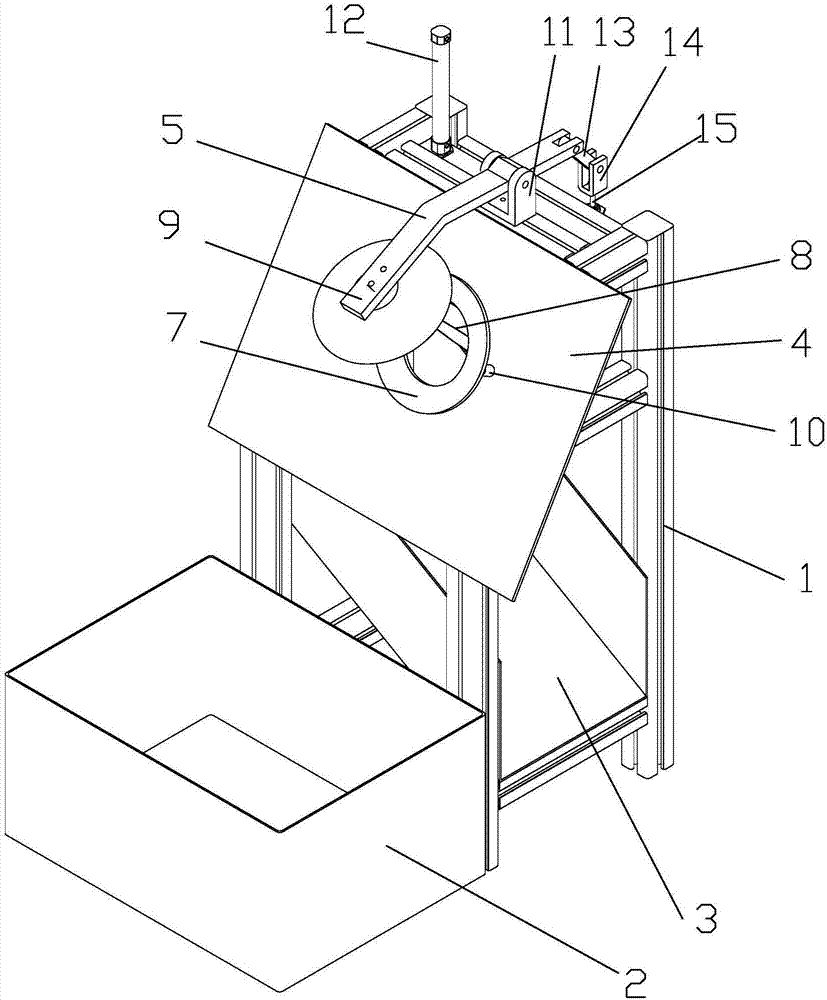

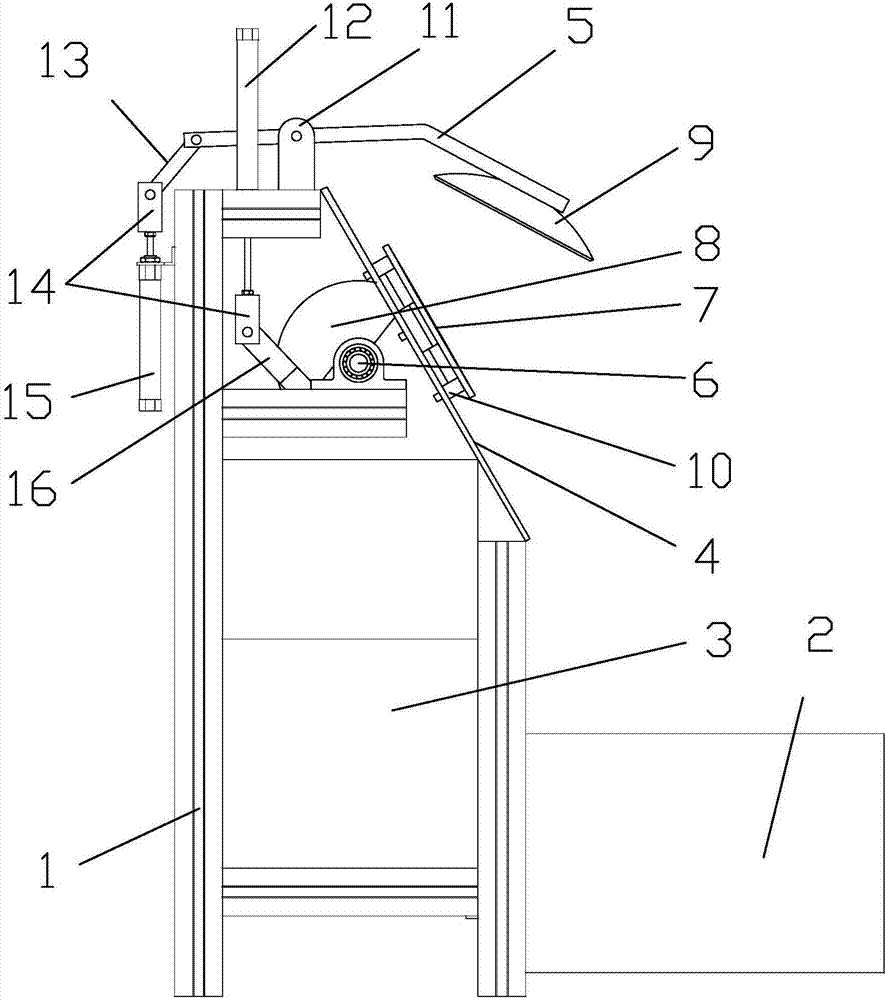

The invention relates to the technical field of vegetable stripping and slicing, and provides a fan-shaped tuber vegetable stripping and slicing machine. The fan-shaped tuber vegetable stripping and slicing machine can achieve stripping and slicing operation to umbrella-shaped vegetables and has the characteristics of being high in vegetable cutting speed, low in labor intensity and high in efficiency. According to the technical scheme, the fan-shaped tuber vegetable stripping and slicing machine comprises a supporting device, a clamping device, a cutting device and a material receiving device; the fan-shaped tuber vegetable stripping and slicing machine is characterized in that the supporting device comprises a supporting frame, a supporting plate and an adjusting ring, wherein the supporting plate is fixed on the supporting frame, and the adjusting ring is positioned on the supporting plate through a rotating hinge; the clamping device comprises a broken-line rod, a U-shaped disc pressing plate, a pressing plate connecting rod and a pressing plate driving cylinder, wherein the broken-line rod is rotatably positioned on the supporting frame, the U-shaped disc pressing plate is fixed to one end of the broken-line rod, and the pressing plate driving cylinder is used for driving the pressing plate connecting rod; the cutting device comprises a rotating cutter shaft, a bowl-shaped cutter, a cutter shaft connecting rod and a cutter shaft driving cylinder, wherein the rotating cutter shaft is rotatably positioned on the supporting frame, the bowl-shaped cutter is fixed on the cutter shaft, and the cutter shaft driving cylinder drives the cutter shaft connecting rod to swing through a fork-shaped connecting rod; and the material receiving device comprises a material receiving hopper and a waste material discharging hopper.

Owner:ZHEJIANG SCI-TECH UNIV

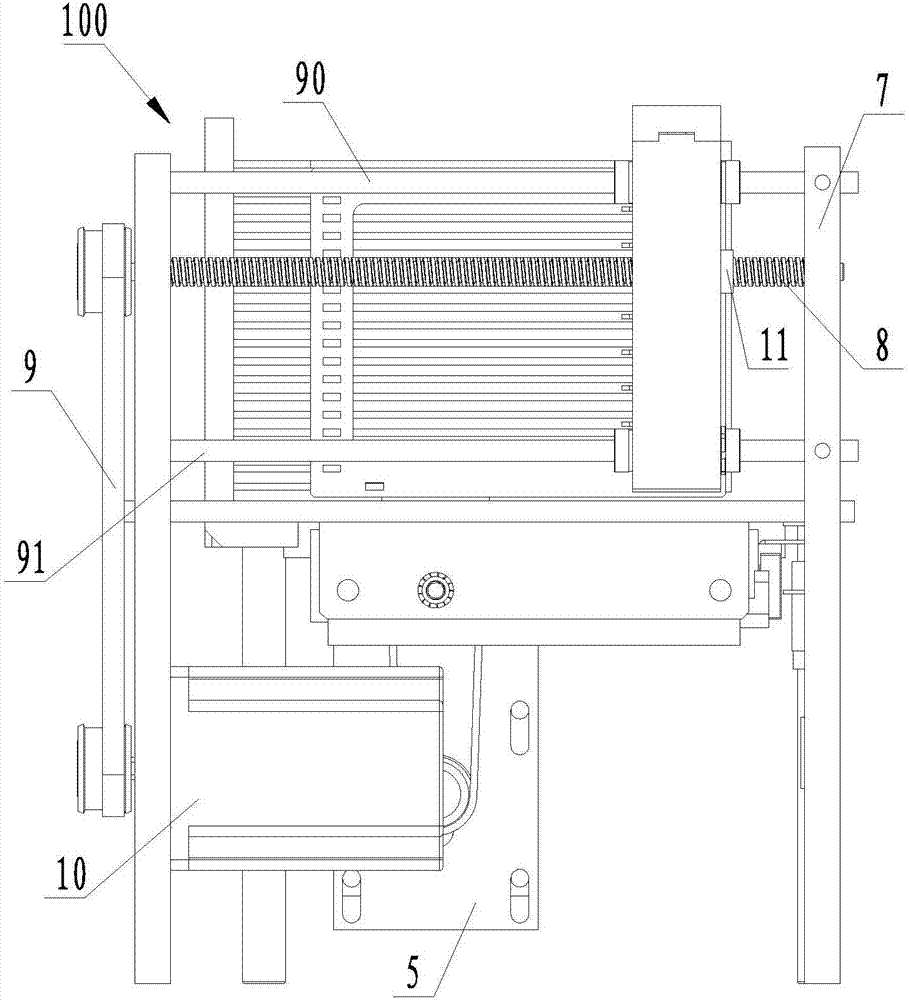

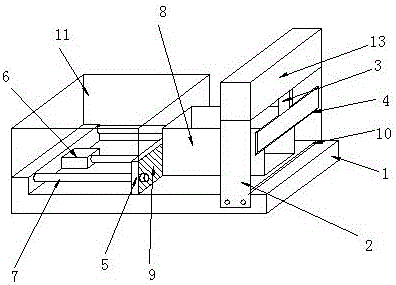

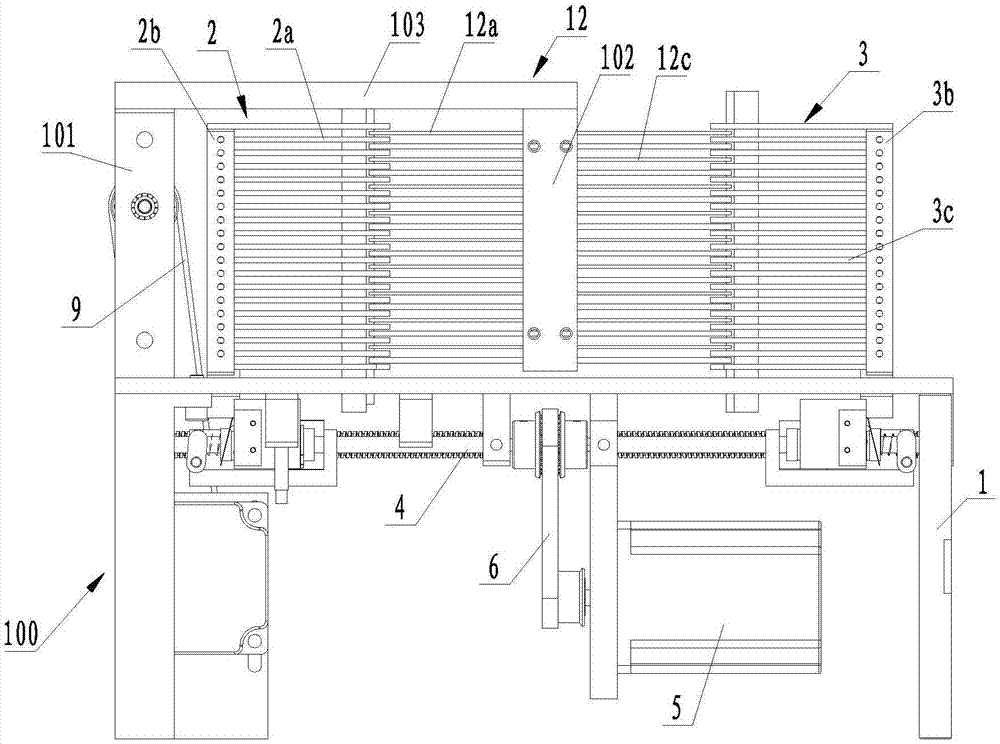

Multifunctional automatic vegetable cutting device for smart kitchen and control method

InactiveCN106938476AAdapt to development needsMeet cutting requirementsMetal working apparatusDrive shaftEngineering

The invention provides a multifunctional automatic vegetable cutting device for a smart kitchen and a control method. The multifunctional automatic vegetable cutting device comprises a feeding mechanism, a cutting mechanism, a cutting angle automatic adjustment mechanism and a controller, wherein the feeding mechanism comprises a conveying platform, a first driving unit and a first guide rail component; the cutting mechanism comprises a second driving unit, a second guide rail component, an upright, a cutter and a connecting bracket; the cutting angle automatic adjustment mechanism comprises a cutting board and a third driving unit; the third driving unit is fixed at the bottom of the conveying platform through a support; the cutting board is arranged above the conveying platform and connected with the third driving unit through a transmission shaft; a third encoder is arranged in the third driving unit; and the controller comprises a PLC. According to the multifunctional automatic vegetable cutting device, the required cutting thickness and size can be selected, the automatic vegetable cutting device is started up to efficiently finish the cutting requirements of users, and through step-by-step motion of the feeding mechanism, together with the cutting speed of the cutting mechanism, adjustment of different cutting thicknesses can be realized.

Owner:JIANGSU UNIV

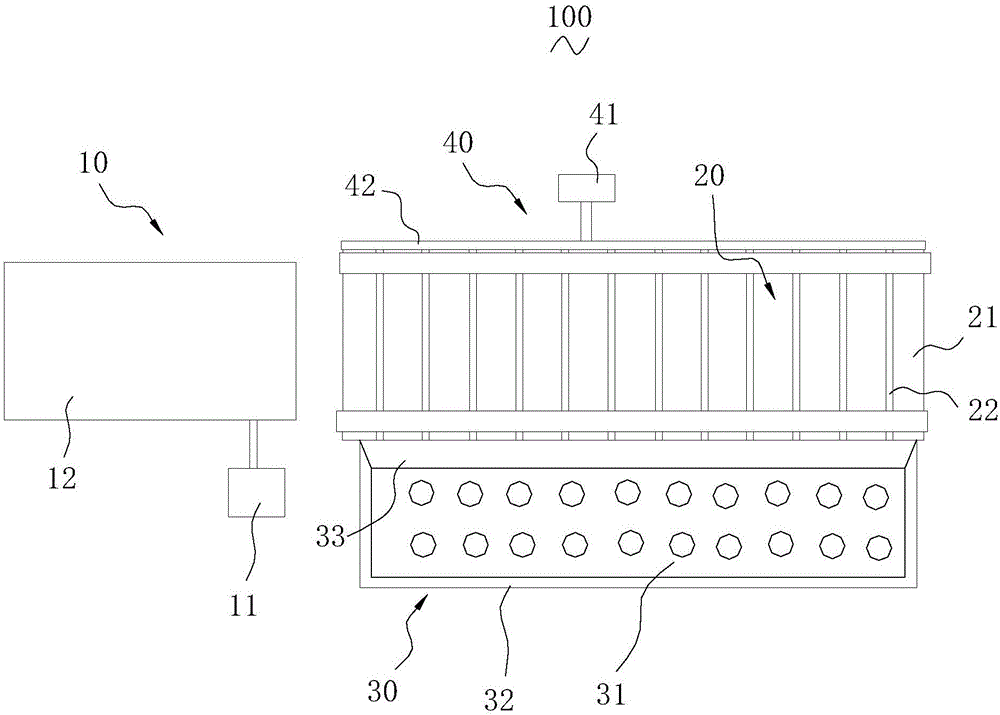

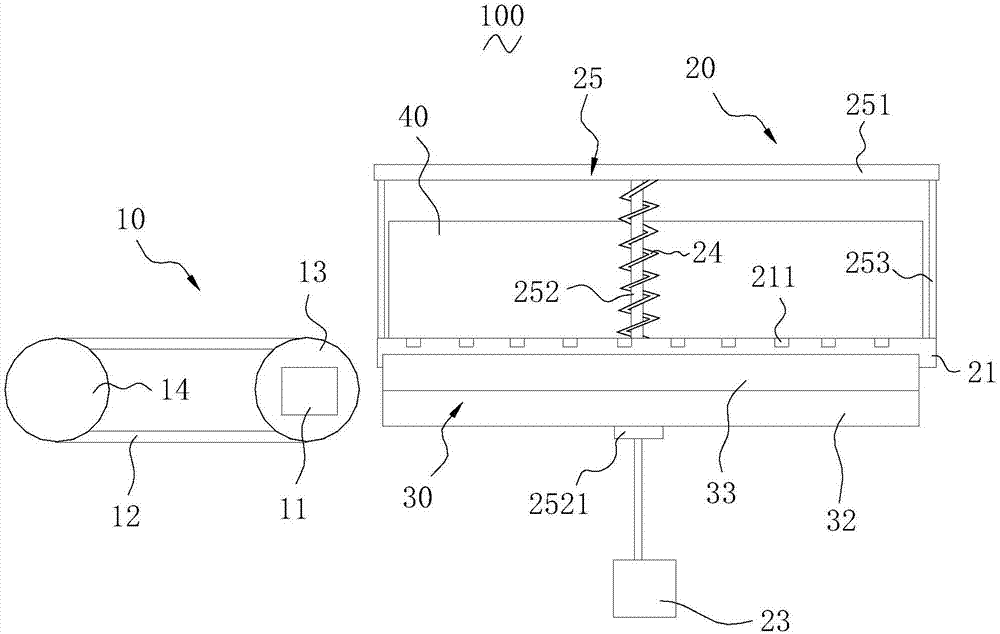

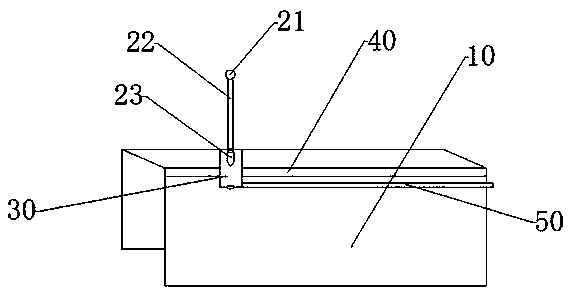

Kitchen appliance

InactiveCN106584563AFully automatedImprove vegetable cutting efficiencyMetal working apparatusElectric machineryEngineering

The invention relates to a kitchen appliance. The kitchen appliance comprises a conveying assembly, a cutting assembly and a containing body. The conveying assembly comprises a motor and a conveying belt. The cutting assembly comprises a bearing plate, a plurality of cutting wires and a driving part. The bearing plate is connected with the conveying belt. A plurality of narrow cutting grooves are formed in the bearing plate at intervals. A cutting space is formed between the multiple cutting wires and the bearing plate. A containing cavity is formed in the containing body. The containing body comprises a base body part and a connecting part formed on one side of the base body part. A guiding oblique plane is formed on the connecting part. The containing cavity is formed in the base body part. The kitchen appliance is high in vegetable cutting efficiency and safe.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Household efficient vegetable cutting knife

InactiveCN108312186AIdeal structural designEasy to useGrinding/polishing hand toolsMetal working apparatusAgricultural engineering

The invention discloses a household efficient vegetable cutting knife. The household efficient vegetable cutting knife comprises a knife body, and the knife body comprises a handle and an edge part fixedly connected with the handle, wherein the edge part comprises a main edge single body fixedly connected with the handle and an auxiliary edge group which is detachably connected to the side edge ofthe main edge single body; the auxiliary edge group comprises a plurality of auxiliary edge single bodies which are arranged at equal intervals and a connecting bolt which connects the tail parts ofthe plurality of auxiliary edge single bodies together; a strip-shaped discharge channel is formed between every two adjacent auxiliary edge single bodies; a mounting hole is formed in side wall of the main edge single body; and one end part of the connecting bolt is locked in the mounting hole, so that the auxiliary edge group is detachably connected with the main edge single body. According to the household efficient vegetable cutting knife, structural design is ideal, the auxiliary edge group is detachable, utilization of the knife is more convenient, vegetable cutting efficiency is greatlyimproved, time and effort are saved, and vegetables are cut quite uniformly.

Owner:张加全

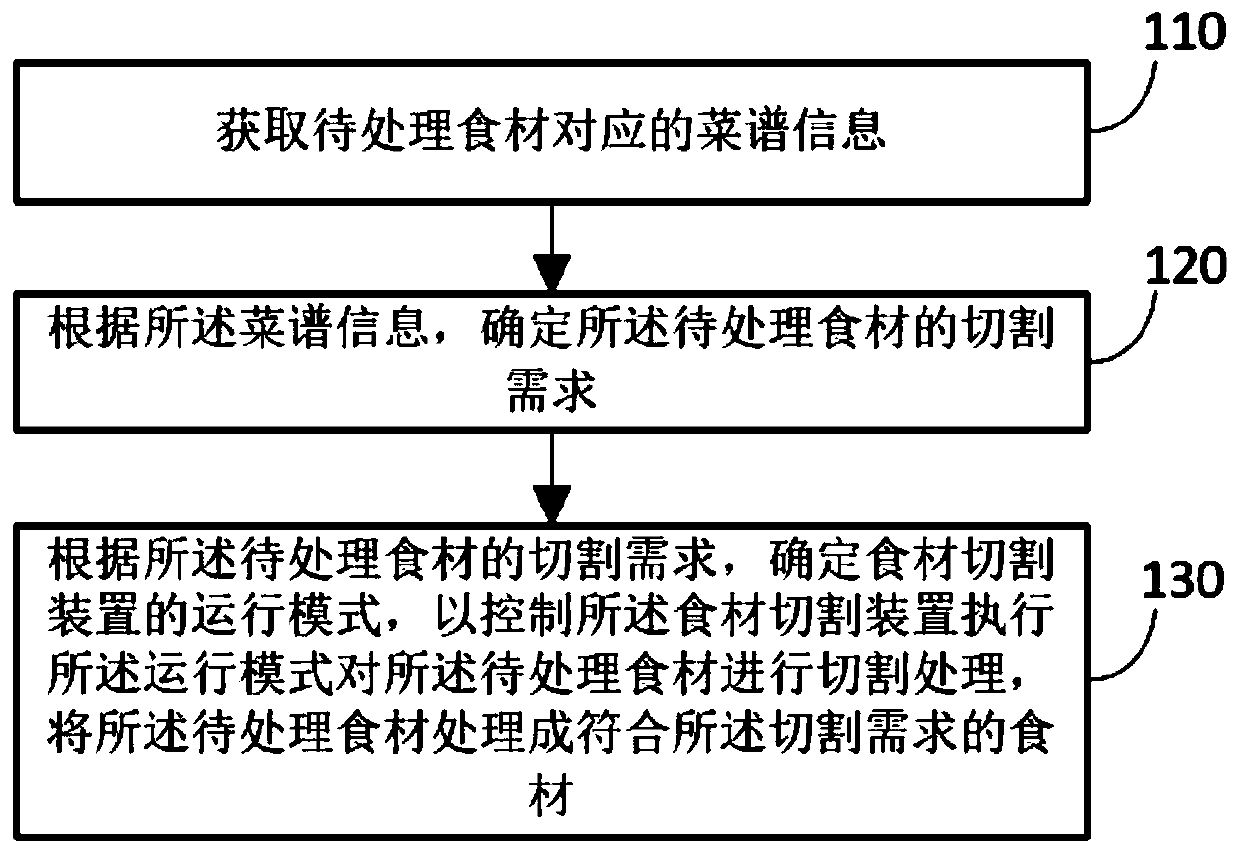

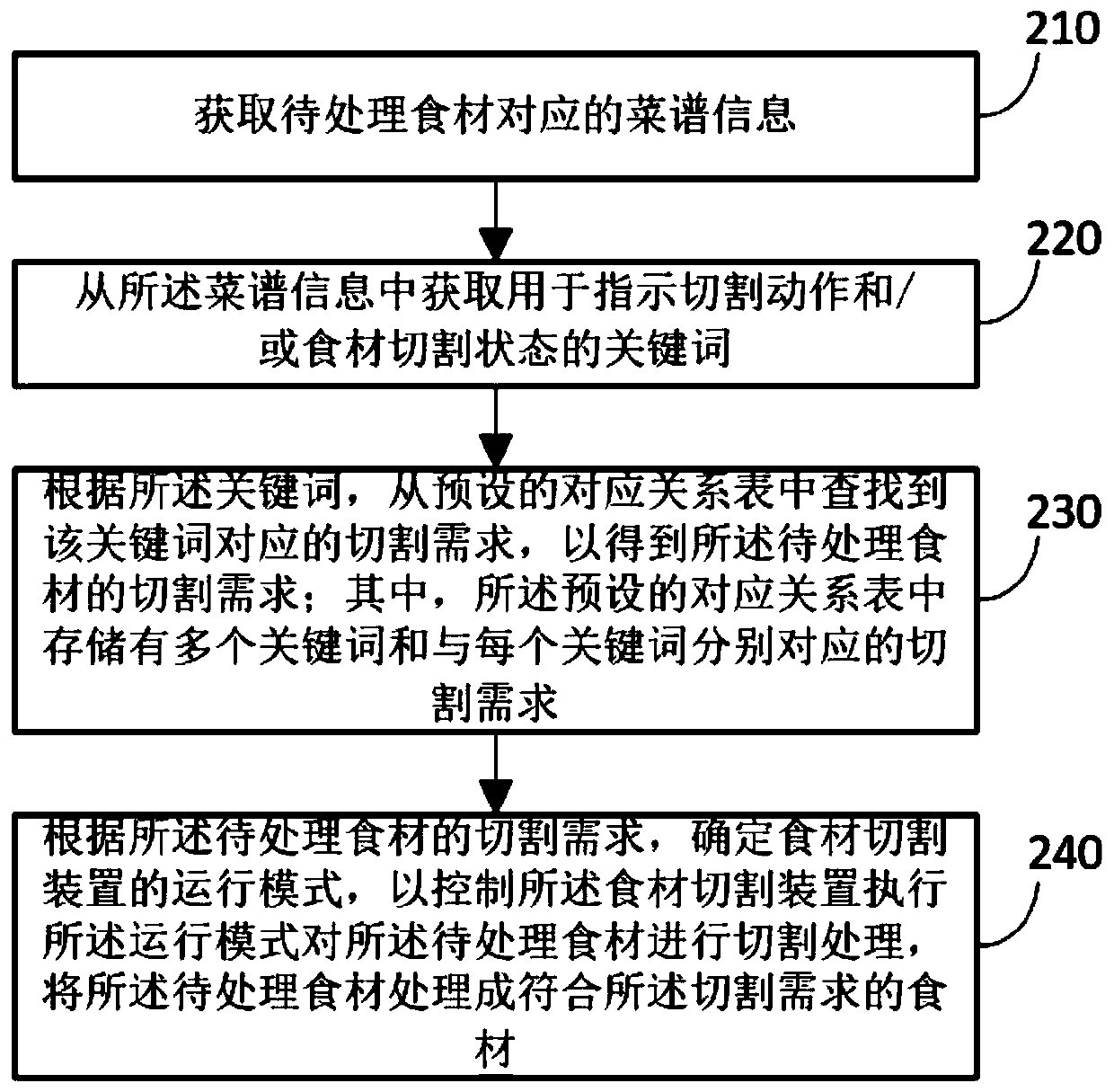

Food material processing method, storage medium and vegetable cutting device

ActiveCN111086049AMeet cutting needsResolve dependenciesMetal working apparatusMeat shaping/cuttingProcess engineeringFood material

The invention discloses a food material processing method, a storage medium and a vegetable cutting device, and relates to the technical field of kitchens. The method comprises the steps that cookbookinformation corresponding to-be-processed food materials is obtained; according to the menu information, the cutting requirement of the to-be-processed food materials is determined; and according tothe cutting requirement of the to-be-processed food materials, the operation mode of a food material cutting device is determined so as to control the food material cutting device to execute the operation mode to cut the to-be-processed food materials, and the to-be-processed food materials are processed into the food materials meeting the cutting requirement. The food material processing method,the storage medium and the vegetable cutting device have the beneficial effects that the cutting requirements of different food materials can be met, the food materials can be processed into the shapeneeded by a menu, and cooking is more scientific and simpler. The technical problem that in the traditional vegetable cutting process, the food materials meeting the requirement can be accurately cutout only by depending on experience and proficiency is solved, automation of vegetable cutting is achieved, and the vegetable cutting efficiency and the vegetable quality are improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

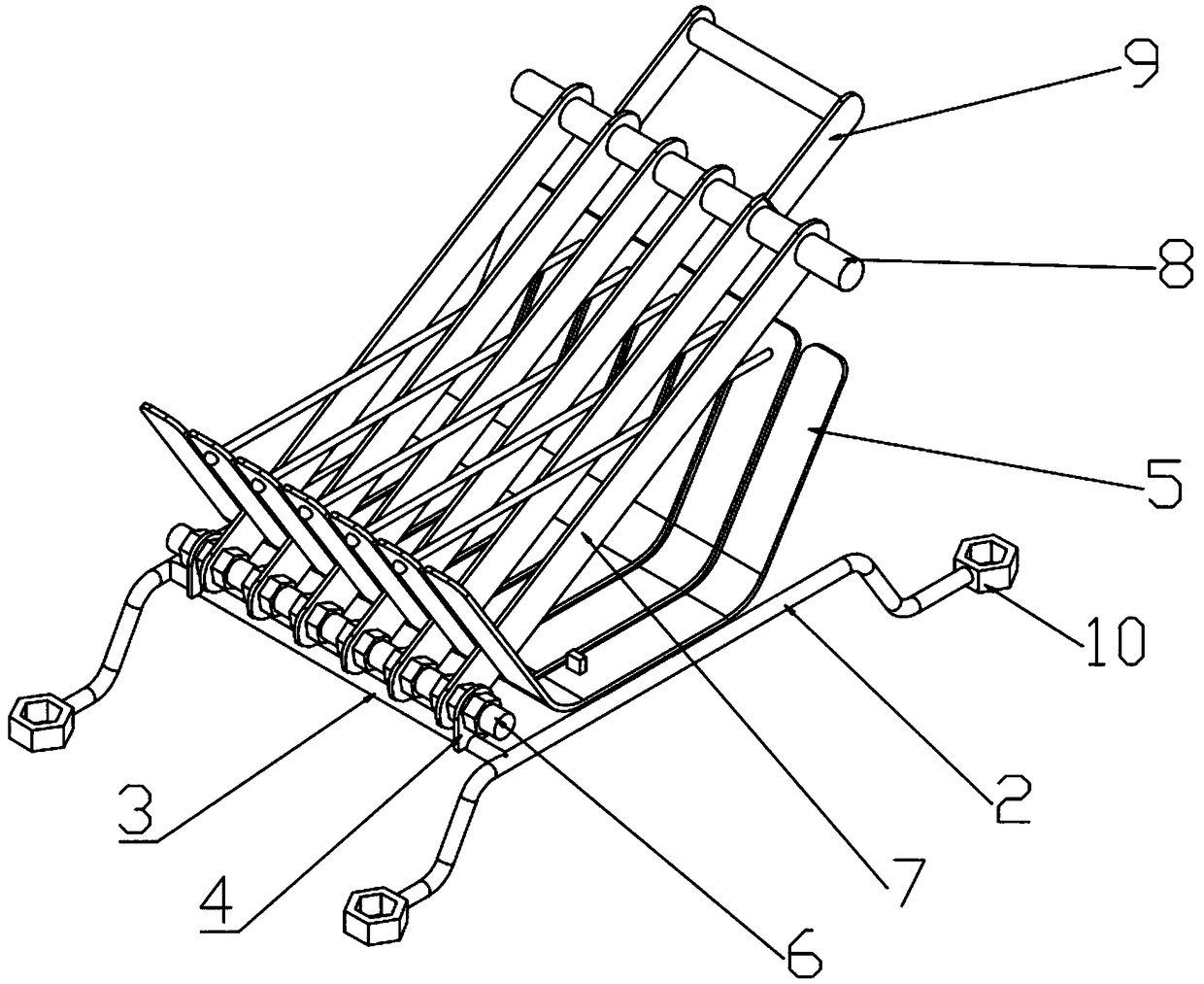

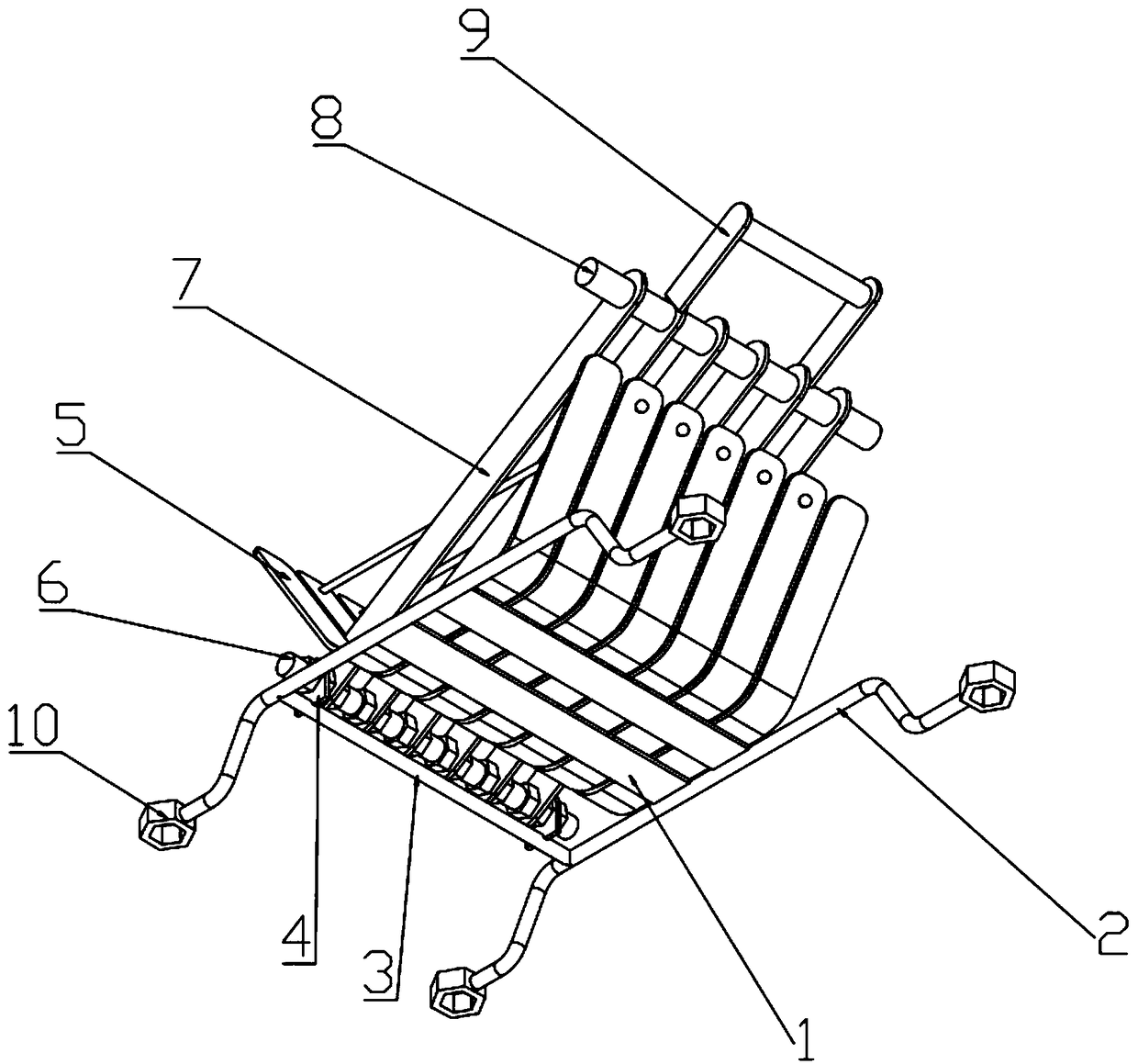

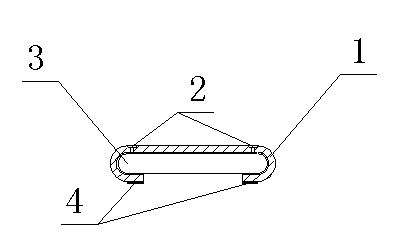

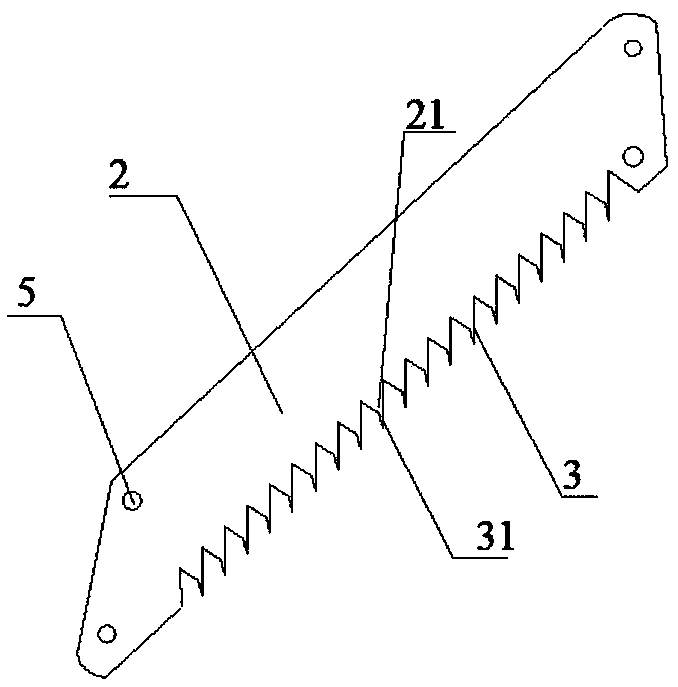

Vibration-reducing and anti-blocking vegetable cutting device

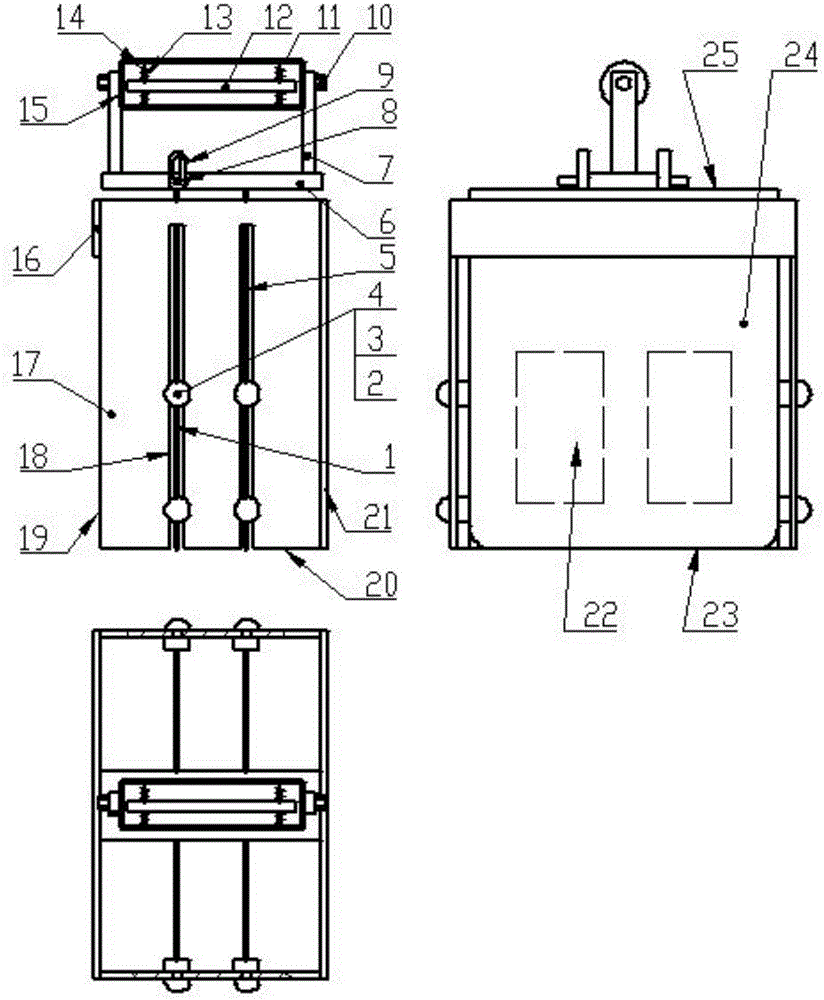

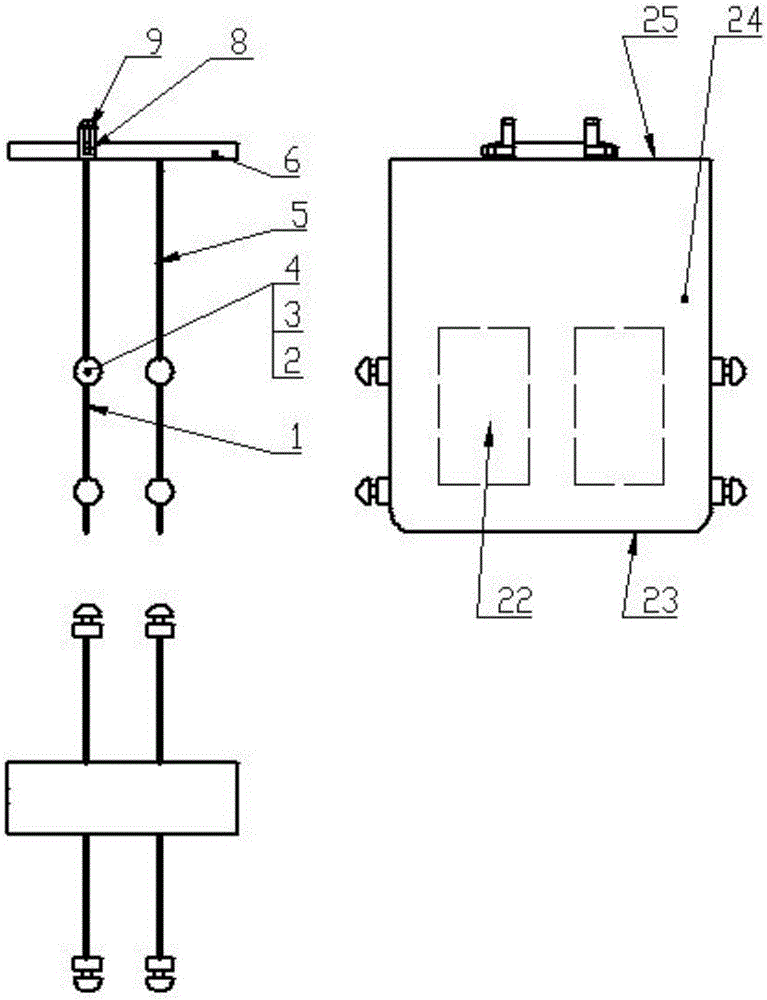

ActiveCN106826989AImprove cut qualityImprove vegetable cutting efficiencyMetal working apparatusAgricultural engineeringVibration damper

The invention discloses a vibration-reducing and anti-blocking vegetable cutting device. The vibration-reducing and anti-blocking vegetable cutting device comprises a combined blade structure, short shafts B, supports, screws, a tool holder and a box, wherein the combined blade structure comprises a blade A, pulleys A, O-shaped slideways, a blade B, pulleys B and a connecting plate, the pulleys A are arranged on two sides of the blade A, the O-shaped slideways are fixedly connected above the blade A, the pulleys B are arranged on two sides of the blade B, and the blade B is fixedly connected with the connecting plate; the connecting plate is fixedly connected with the short shafts B sleeved with the O-shaped slideways, and the connecting plate is fixedly connected with the supports; the tool holder comprises a cylinder, a vibration damper and an end cover, and the screws penetrate through holes in the supports to be connected with the end cover on the tool holder; the box comprises a reinforcing plate, a guiding support plate and a vegetable blocking plate, the guiding support plate is inserted into the slideways of the pulleys A and the pulleys B through opening ends of rectangular grooves; the vegetable blocking plate is fixedly connected with the guiding support plate. The vibration-reducing and anti-blocking vegetable cutting device is simple in structure and convenient to use, can realize equal-section cutting, is anti-splashing and anti-blocking, prevents hands from vibration and is suitable for cutting segmented food materials.

Owner:HT METALFORMING EQUIP MFG

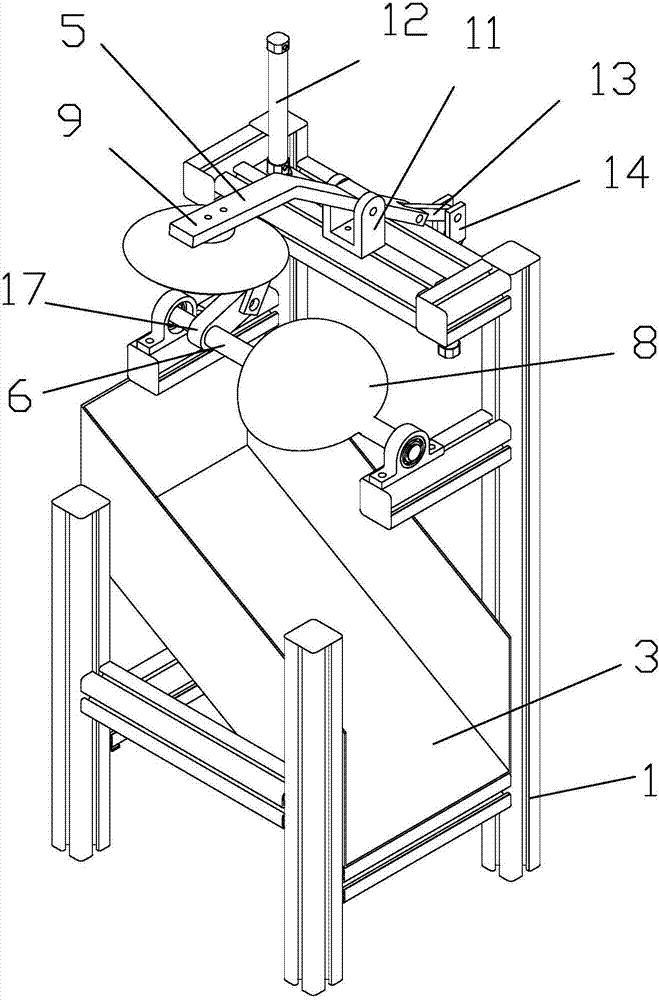

Double-track multifunctional vegetable cutter

The invention discloses a double-track multifunctional vegetable cutter comprising a double-slide track, a blade frame, a vegetable loading device, wherein two suckers are arranged in front of a track frame, and the track frame is provided with a front bracket and a rear bracket; the blade frame can be arranged in the track frame, and blades for cutting knives are exchangeable in a small blade frame; the vegetable loading device has the slope of 45-50 degrees, and is provided with a small tackle with four small pulleys; and the vegetable loading device is provided with a thruster, and the cutter can make reciprocating movement on the track by pulling a pull handle on the vegetable loading device with the right hand of a user. A use method comprises the following steps: the cutter is assembled and sucked on a wall with tiles in a kitchen by the two suckers in front of the vegetable cutter; vegetables are loaded into the vegetable loading device and pressed by the thruster, the pull handle is pulled on the vegetable loading device with a right hand and the end face of the thruster is forcefully pressed with the right palm or the left hand so that the cutter moves forwards, and the small pull handle on the vegetable loading device is pulled so that the cutter moves backwards, so that the cutter can make reciprocating movement and cut up the vegetables through the blades; and the double-track multifunctional vegetable cutter can cut up, slice and shred the vegetables, and is suitable for households, restaurants and mess halls, and with the cutter, the vegetable cutting efficiency is improved.

Owner:纪福顺

Vegetable cutting device for the handicapped with one arm

ActiveCN109129600BExtended service lifeEasy to replaceMetal working apparatusAgricultural engineeringKitchen utensils

The invention discloses a vegetable cutting device for the one-arm disabled, and relates to the technical field of kitchen utensils. The vegetable cutting device for the one-arm disabled comprises a vegetable cutting box; a vegetable cutting board is arranged at the bottom of the inner wall of the vegetable cutting box; the left side of the upper end of the vegetable cutting box is fixedly connected with a cover board through a hinge; the right end of the upper surface of the cover board is fixedly connected with a first handle; the upper side of the right end of the vegetable cutting box is movably connected with a door board through a hinge; and the right end of the inner wall of the first handle is fixedly connected with a vegetable cutting device body. Through arrangement of the vegetable cutting device body, a first electric push rod, a supporting board, a first groove, a second groove, a first slide rod, a second slide rod, a slide block, a damping layer, a kitchen knife and a threaded rod, the function of conveniently replacing or dismounting the kitchen knife is achieved, a knife edge of the kitchen knife is dismounted and ground even if the kitchen knife is blunt and cannot cut vegetables after being used for a long time, and the service life of the vegetable cutting device can be prolonged.

Owner:温州市简弈科技有限公司

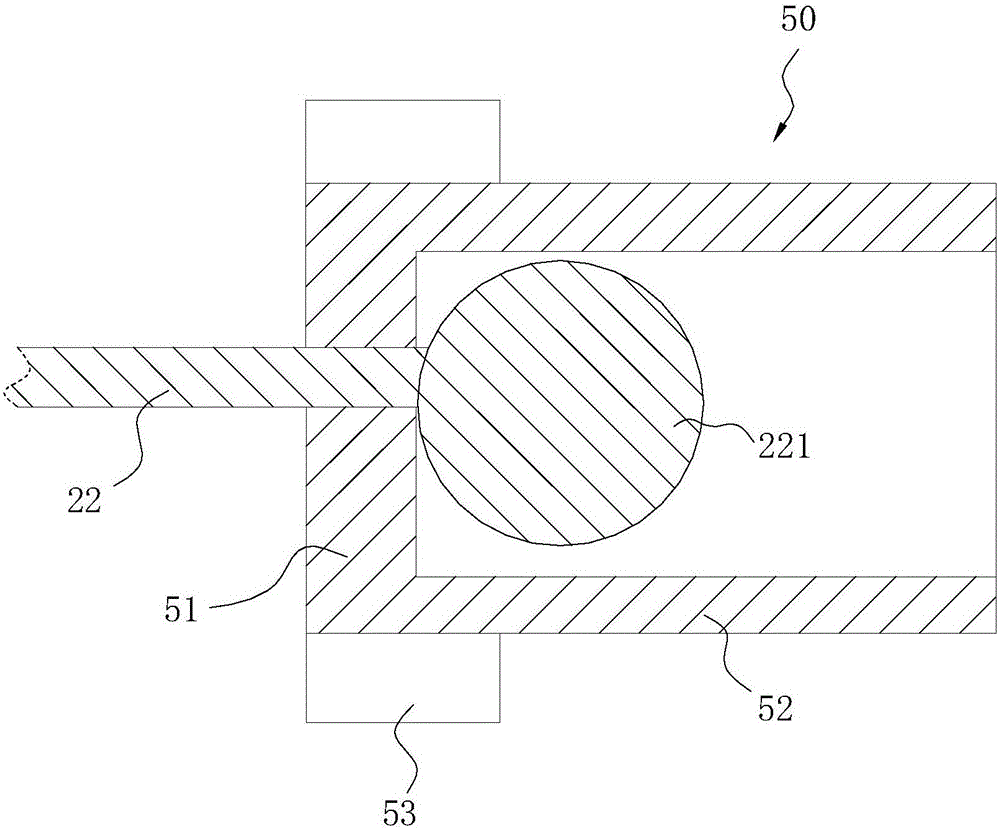

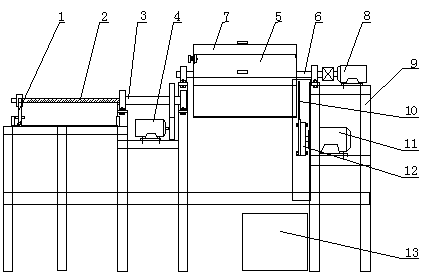

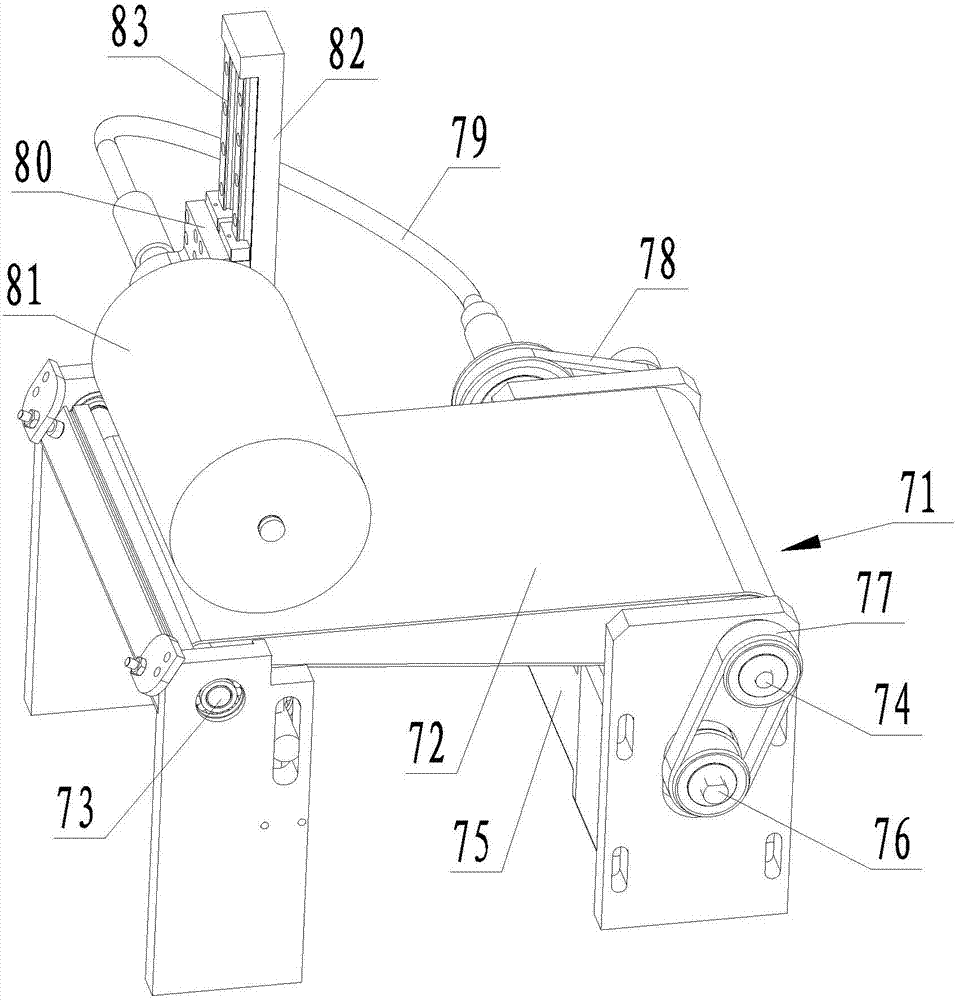

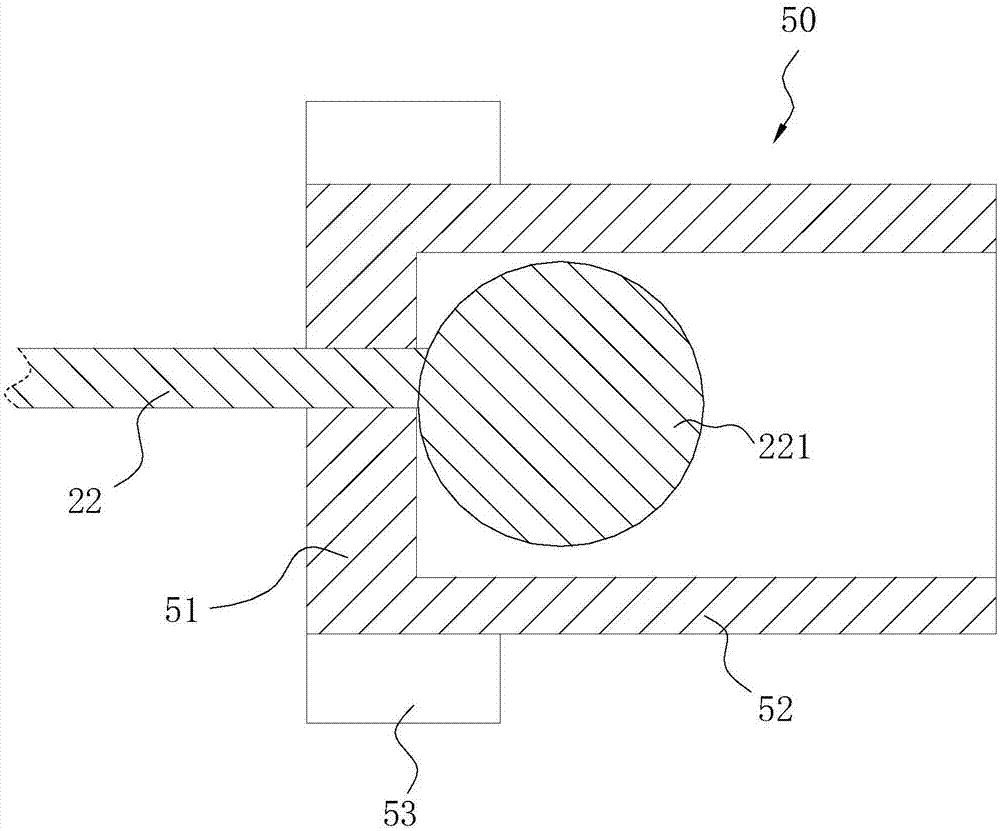

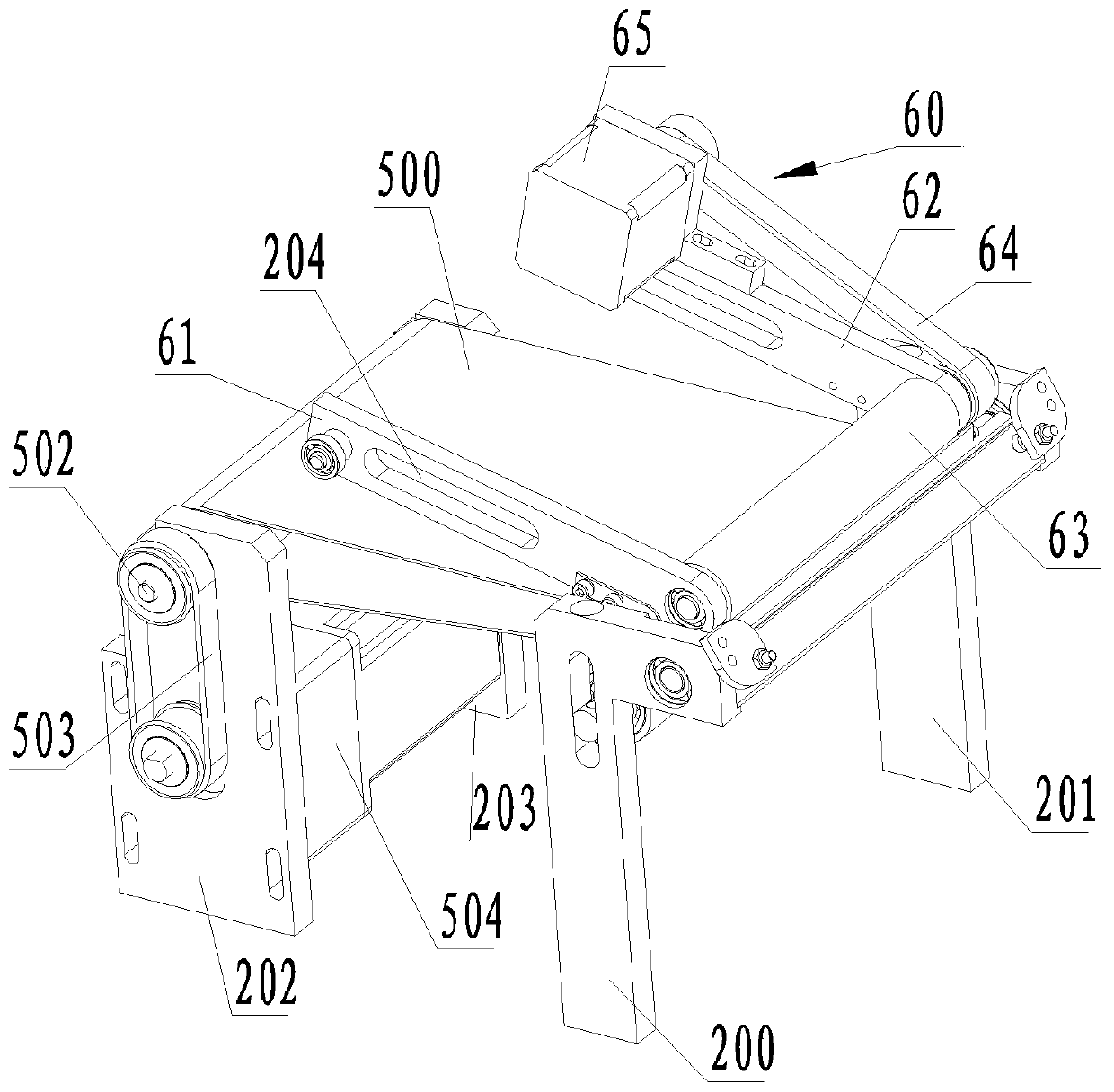

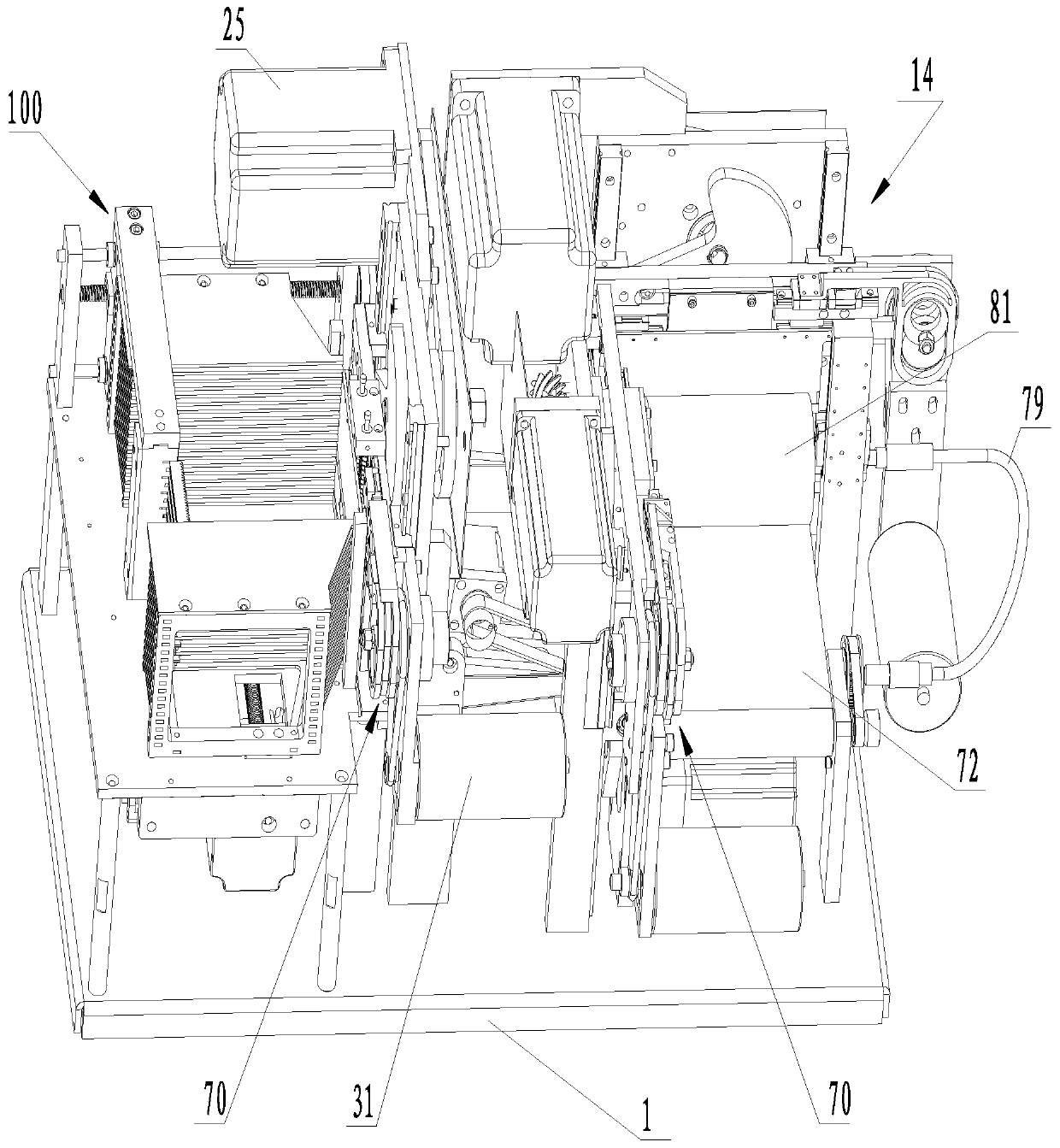

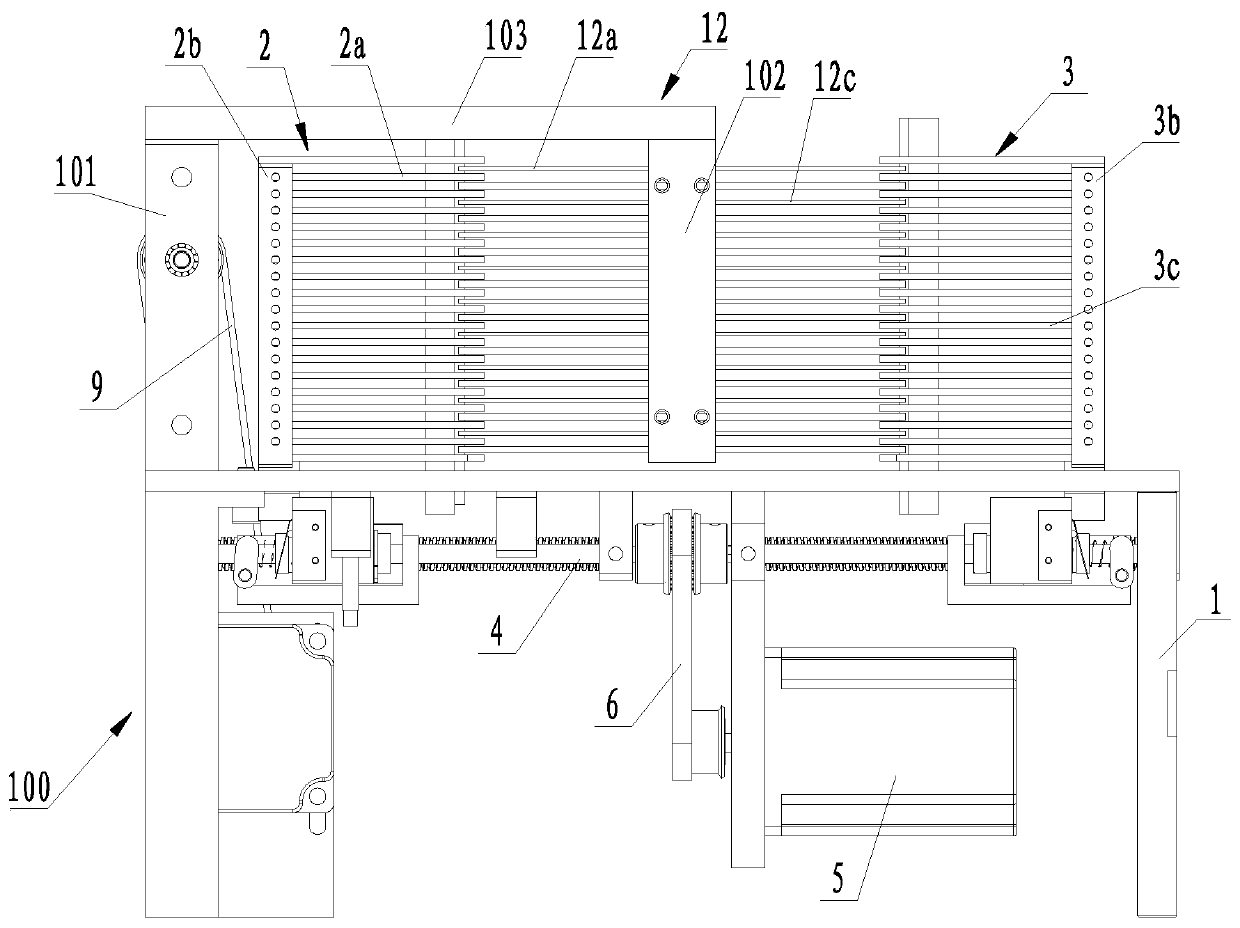

A bullet-bore vegetable conveying device for a vegetable cutter

ActiveCN107009417BSimple structureEasy to operateMetal working apparatusVegetable processingEngineering

The invention relates to a chamber type vegetable conveying device used for a vegetable cutting machine and belongs to the field of vegetable processing machines. The chamber type vegetable conveying device is composed of a feeding screw rod, a screw rod sleeve, an installation shaft and multiple vegetable conveying cylinders. The multiple vegetable conveying cylinders are fixedly arranged on the installation shaft. One ends of the vegetable conveying cylinders are provided with a support through a sliding rail in a sliding manner. The part between the sliding rail and the vegetable conveying cylinders is provided with the screw rod sleeve through a bearing block. The feeding screw rod is installed in the screw rod sleeve in a threaded manner. One end of the feeding screw rod extends to the outer end of the screw rod sleeve, and the part, extending to the outer end of the screw rod sleeve, of the feeding screw rod is connected with the support. By means of the vegetable conveying device, due to the fact that the vegetable conveying cylinders are arranged in a delta shape on the circumference of the installation shaft so that adding of to-be-cut vegetables and cutting of the vegetables can be synchronously conducted, and the vegetable cutting efficiency is improved. Meanwhile, the chamber type vegetable conveying device has the beneficial effects that use and maintenance are convenient, and use is safe; and the chamber type vegetable conveying device is particularly suitable for being installed on the vegetable cutting machine.

Owner:YANGTZE UNIVERSITY

A multifunctional automatic vegetable cutting device and control method for a smart kitchen

InactiveCN106938476BAdapt to development needsMeet cutting requirementsMetal working apparatusDrive shaftEngineering

The invention provides a multifunctional automatic vegetable cutting device for a smart kitchen and a control method. The multifunctional automatic vegetable cutting device comprises a feeding mechanism, a cutting mechanism, a cutting angle automatic adjustment mechanism and a controller, wherein the feeding mechanism comprises a conveying platform, a first driving unit and a first guide rail component; the cutting mechanism comprises a second driving unit, a second guide rail component, an upright, a cutter and a connecting bracket; the cutting angle automatic adjustment mechanism comprises a cutting board and a third driving unit; the third driving unit is fixed at the bottom of the conveying platform through a support; the cutting board is arranged above the conveying platform and connected with the third driving unit through a transmission shaft; a third encoder is arranged in the third driving unit; and the controller comprises a PLC. According to the multifunctional automatic vegetable cutting device, the required cutting thickness and size can be selected, the automatic vegetable cutting device is started up to efficiently finish the cutting requirements of users, and through step-by-step motion of the feeding mechanism, together with the cutting speed of the cutting mechanism, adjustment of different cutting thicknesses can be realized.

Owner:JIANGSU UNIV

Manual vegetable cutting device

ActiveCN108772860BImprove vegetable cutting efficiencyCleaning using toolsMetal working apparatusAgricultural engineeringStructural engineering

The invention provides a manual vegetable cutting device, which includes: a base plate, the top of which is provided with two guide rails and a fixed plate connected between the two guide rails; a push plate, which is slidably mounted on the two guide rails, and the push plate is connected to the two guide rails. A return spring is connected between the fixed plates; the bracket includes two support columns, which are fixed on the top of the base plate and has a chute on it, which runs through the bottom of the support column; the operating mechanism includes a joystick and Two traction assemblies, the control rod is rotated and installed on the top of the support column. There is a traction assembly on the outside of each support column. The traction assembly includes a traction rope and a guide wheel fixed on the top of the bottom plate. One end of the traction rope is wrapped around the control On the rod, the other end is fixedly connected to the push plate around the guide wheel; the cutter is hoisted on the joystick through a connecting block, and the cutter is slidably mounted between the two chutes. The manual vegetable cutting device in the present invention only needs to shake the joystick to complete the vegetable cutting action, which undoubtedly improves the efficiency and experience of vegetable cutting.

Owner:华东交通大学理工学院

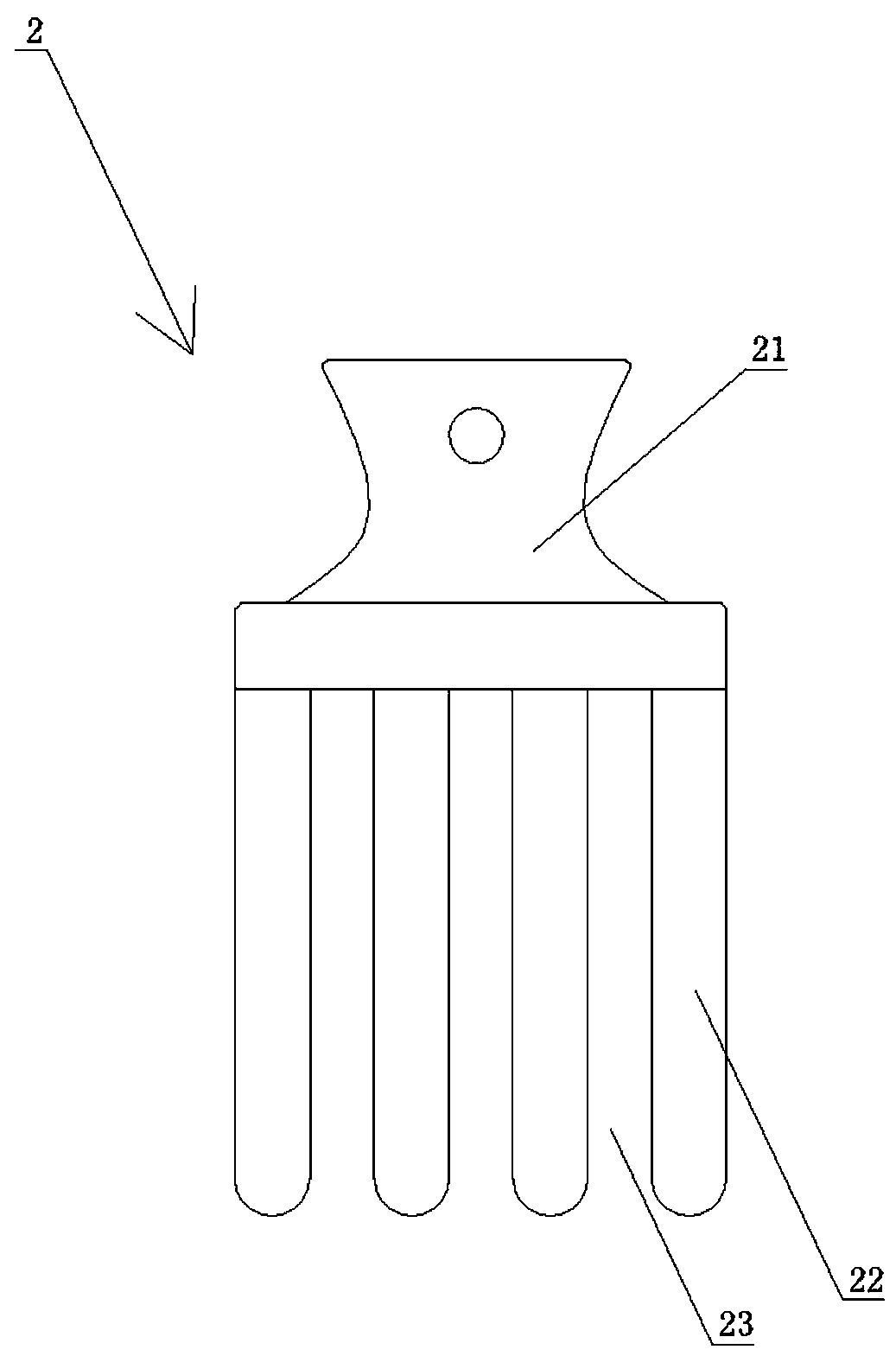

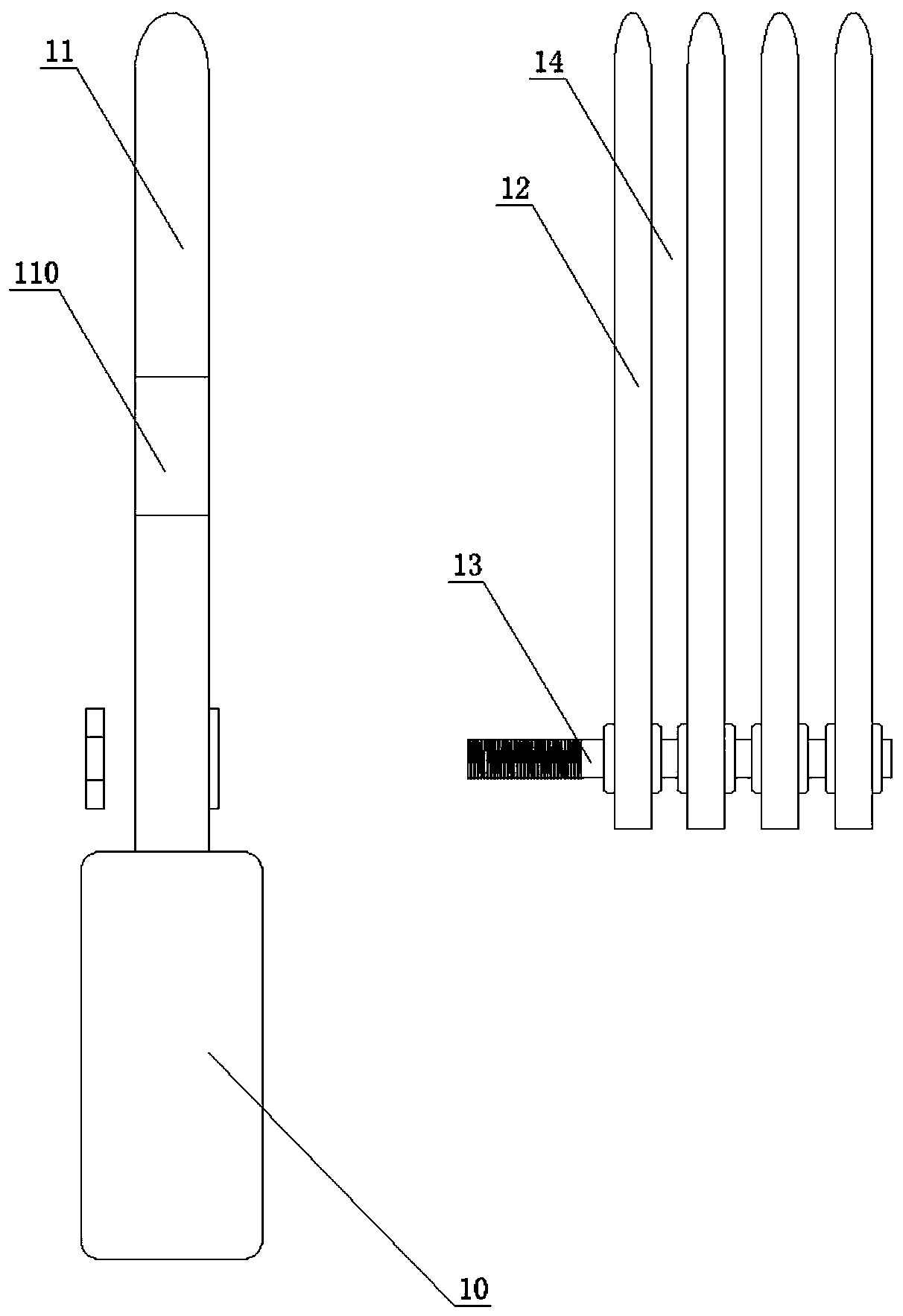

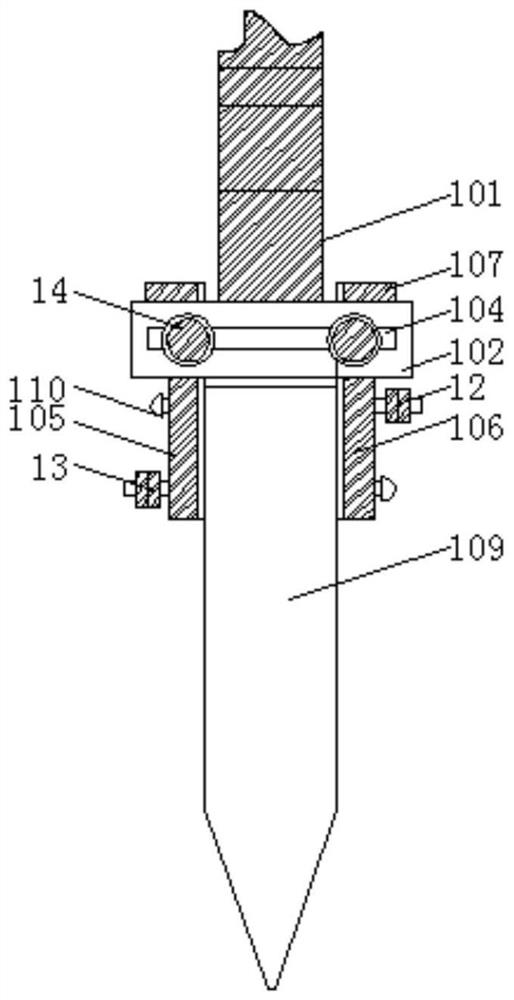

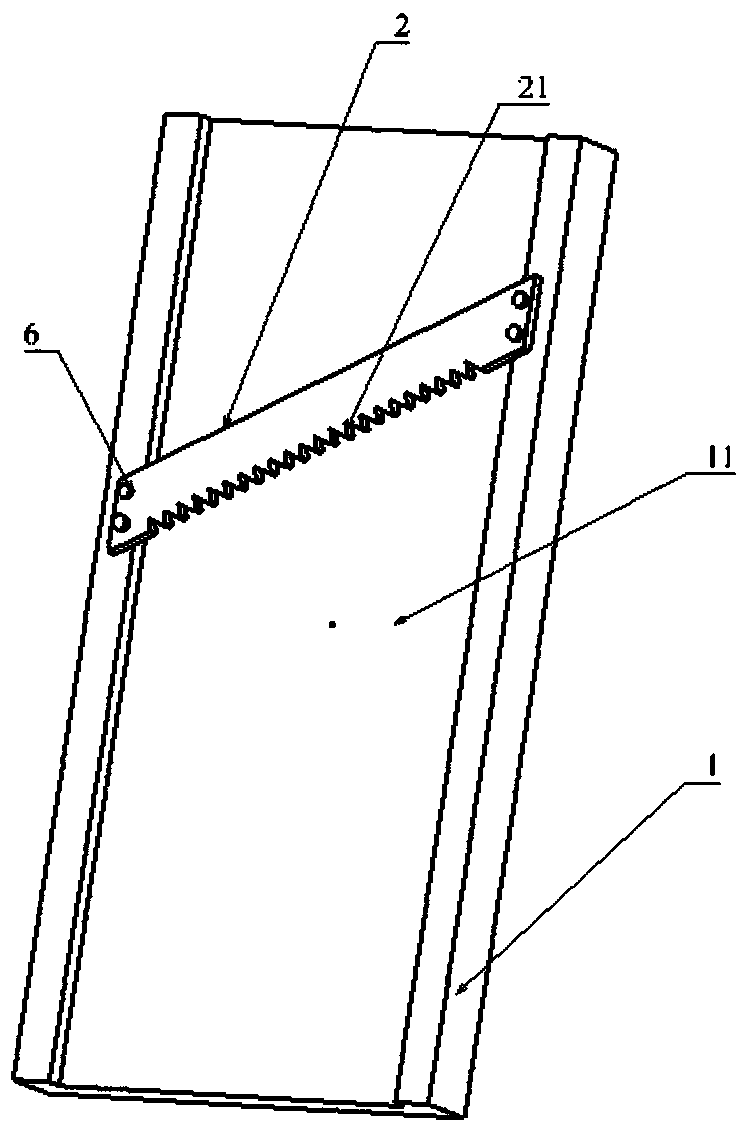

Cutter for vegetable cutter, anti-injury hand wood multifunctional vegetable cutter and using method thereof

PendingCN109366540AImprove vegetable cutting efficiencyTo achieve the segmentation effectMetal working apparatusSolid woodEngineering

The invention discloses a cutter for a vegetable cutter and the vegetable cutter and a using method of the vegetable cutter. The cutter is provided with blades, first cutting edges are arranged on thefront sides of the blades, the front sides of the blades are further connected to a plurality of cutter teeth, the cutter teeth extend from top to bottom, and second cutting edges are arranged at thefront ends of the cutter teeth. Compared with an existing vegetable cutter, the vegetable cutter provided has the following advantages that (1) the blades are sharp, the vegetable cutting efficiencyis high, positioning points of the cutter teeth are used for positioning and puncturing food material like needles, so that the longitudinal section of the food material is cut left and right; then aplurality of first cutting edges are used for cutting the transverse section of the food material up and down; and after the longitudinal and transverse cross sections are cut, the rear ends of the first cutting edges and the rear ends of the second cutting edges are used for cutting the food material in a three-dimensional cross section, so that the food materials can be broken in sequence one byone and a connection-free effect is achieved; (2) the cutter teeth of the vegetable cutter are downward, hands are prevented from being hurt, and a hand protector does not need to be used; and (3) the whole vegetable cutter rest is of an integrated structure, the whole vegetable cutter rest integrated structure is a solid wood board type process and is more stable and more durable.

Owner:王瑞华

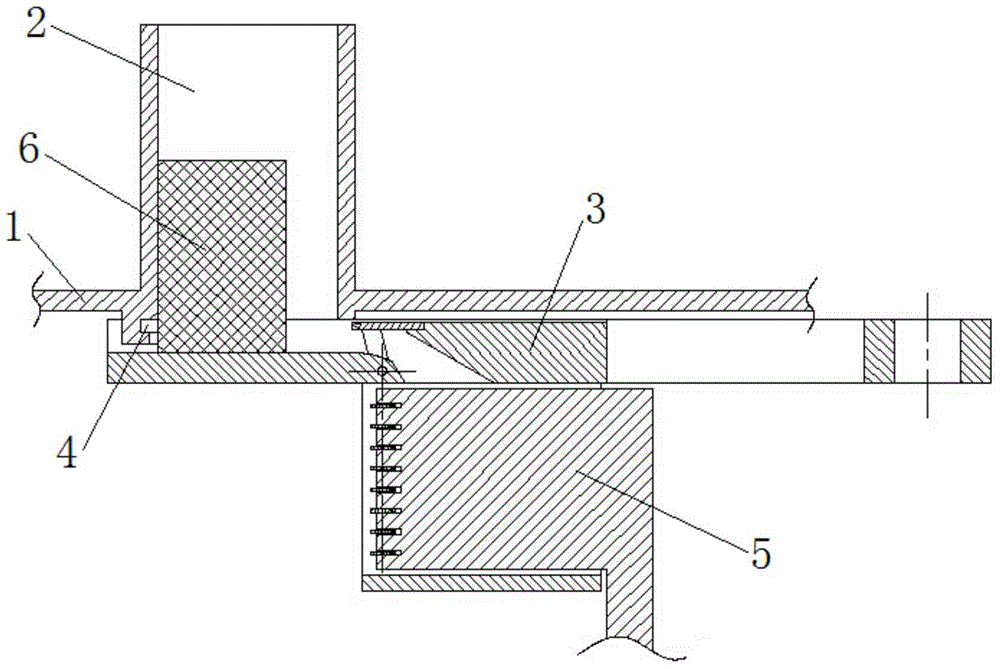

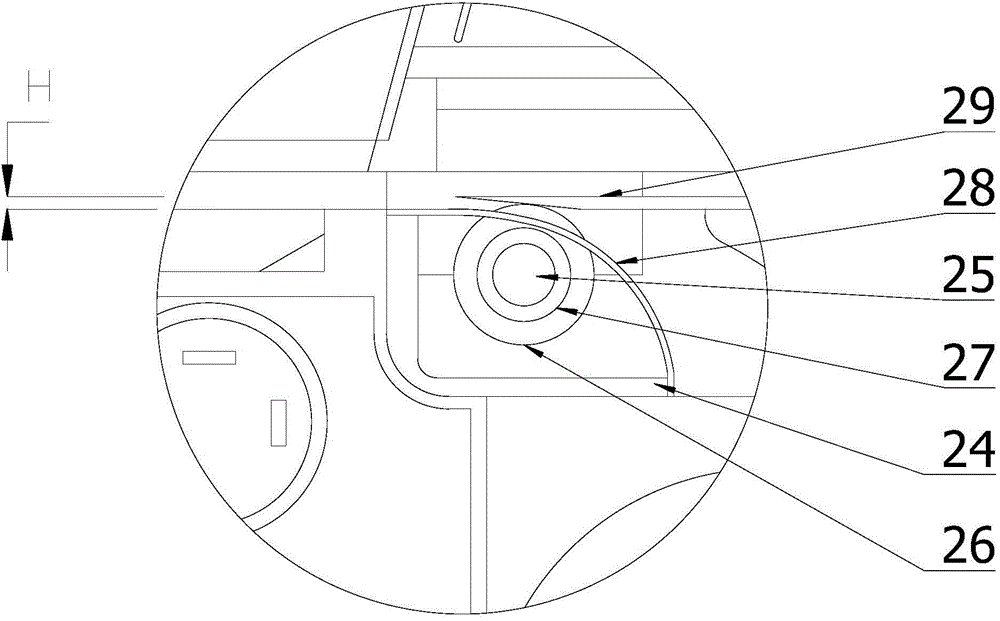

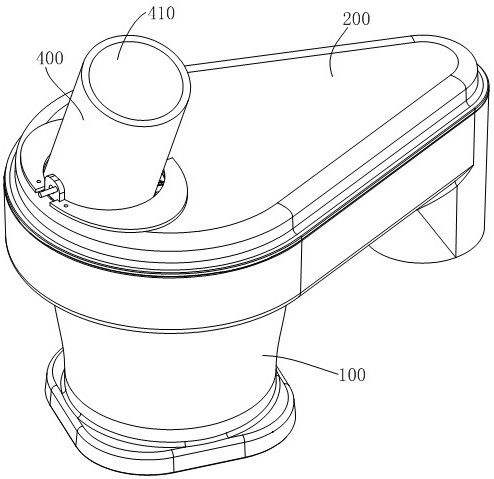

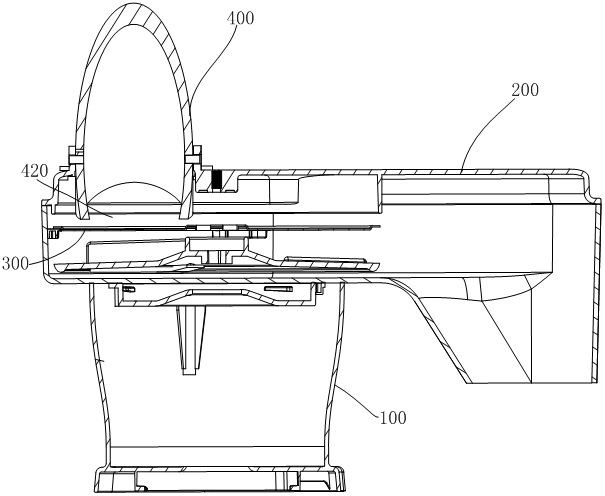

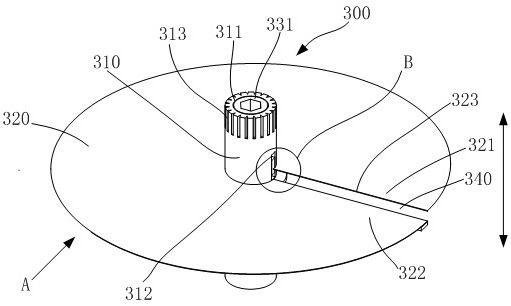

Food processing knife and food processing cup

The invention discloses a food processing knife and a food processing cup, so that the slicing thickness can be adjusted without disassembling, use is safe, operation is convenient, and the vegetablecutting efficiency can be improved. The food processing knife comprises a rotating shaft, a spiral knife disc and an adjusting assembly; the spiral knife disc spirally surrounds the rotating shaft bya circle, a cutting edge extending in the radial direction is arranged at the first end, the first end is suspended above the second end, a discharging gap is formed between the first end and the second end, the second end is fixedly connected with the rotating shaft, and the first end is parallel to the second end, or the second end inclines upwards relative to the first end; and the adjusting assembly is used for driving the first end of the spiral knife disc to move up and down, so that the height of a discharging gap in the direction parallel to the axial direction of the rotating shaft isadjustable. By arranging the spiral knife disc and operating the adjusting assembly, the height of the discharging gap in the direction parallel to the axial direction of the rotating shaft can be adjusted, and then the slicing thickness of the food processing knife can be adjusted, so that the use risk of a user is reduced, the use safety is improved, operation is convenient, and the vegetable cutting efficiency can be improved.

Owner:青岛海氏烘焙电器有限公司

Transportation limiting device

The invention discloses a transportation limiting device. The transportation limiting device comprises a rack, and a second conveyer belt is arranged on the rack; the second conveyer belt transmits vegetables through a first rotating shaft and a second rotating shaft; a seventh power device is arranged at the bottom of the rack; an output shaft of the seventh power device is connected with one end of the second rotating shaft through a seventh belt; a first guide rod is arranged on the rack; and a longitudinal guide rail is arranged on the first guide rod. According to the transportation limiting device, food materials which are cut into blocks and strips can be transported to a slitting or dicing device to be continuously cut, and a limiting function is achieved while cutting, so that on one hand, vegetable cutting efficiency is effectively improved, the food materials are arranged trimly, vegetable cutting quality is guaranteed, and size uniformity of cut vegetables can be guaranteed, on the other hand, workload of operators is effectively reduced, and further, the risk of cutting fingers is effectively reduced.

Owner:FUYANG WANRUI ELECTRONICS LOCKS CO LTD

Kitchen Appliances

InactiveCN106584563BFully automatedImprove vegetable cutting efficiencyMetal working apparatusEngineeringElectrical equipment

The invention relates to a kitchen appliance. The kitchen appliance comprises a conveying assembly, a cutting assembly and a containing body. The conveying assembly comprises a motor and a conveying belt. The cutting assembly comprises a bearing plate, a plurality of cutting wires and a driving part. The bearing plate is connected with the conveying belt. A plurality of narrow cutting grooves are formed in the bearing plate at intervals. A cutting space is formed between the multiple cutting wires and the bearing plate. A containing cavity is formed in the containing body. The containing body comprises a base body part and a connecting part formed on one side of the base body part. A guiding oblique plane is formed on the connecting part. The containing cavity is formed in the base body part. The kitchen appliance is high in vegetable cutting efficiency and safe.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Vegetable cutting machine conveying limit device

ActiveCN107009423BOrderly rowsReduce workloadMetal working apparatusEngineeringMechanical engineering

The invention discloses a conveyance limiting device for a vegetable cutter. The conveyance limiting device comprises a rack, a first swing arm and a second swing arm. The two sides of the rack are hinged to the front end of the first swing arm and the front end of the second swing arm correspondingly. A limiting rotary shaft is arranged between the rear end of the first swing arm and the rear end of the second swing arm, and the two ends of the limiting rotary shaft are connected with the first swing arm and the second swing arm in a rotating mode. One ends of conveying belt rotary shafts are provided with a fourth belt, and the conveying belt rotary shafts are connected through the fourth belt and a fifth power device. The fifth power device is arranged at the bottom of the rack. The limiting rotary shaft is attached to the upper surface of a first conveying belt. By the adoption of the conveyance limiting device, food materials cut to be in a block shape and a bar shape can be conveyed to a slitting or dicing device to be cut continuously, and a limiting effect can be achieved while cutting is conducted. On one hand, vegetable cutting efficiency is effectively improved, the food materials can be arrayed neatly, vegetable cutting quality is guaranteed, and the dimensional consistency in vegetable cutting can be ensured; and on the other hand, workloads of operators are effectively reduced, and the danger of cutting the fingers is effectively avoided.

Owner:广德山水环境工程有限公司

Vegetable cutting device

InactiveCN110883809ASimplify choppingImprove vegetable cutting efficiencyMetal working apparatusAgricultural engineeringStructural engineering

The invention discloses a vegetable cutting device. The vegetable cutting device mainly comprises a kitchen knife, a separation cavity, a sliding rail and a cover plate, wherein the kitchen knife comprises a knife handle and a knife body; the separation cavity comprises an upper inlet and a lower outlet, and the knife body can penetrate through the upper inlet and penetrate out of the lower outlet; and the sliding rail is positioned at the upper part of a support, an inner cavity of the support is used for placing to-be-cut objects to be cut, and the separation cavity moves in parallel along the sliding rail. During work, the to-be-cut objects are placed in the inner cavity of the support and covered by the cover plate to be fixed, the separation cavity moves from the head to the tail of the to-be-cut objects, the kitchen knife repeatedly penetrates out of the lower outlet in the process to complete the cutting operation of the to-be-cut objects, and finally, the vegetable cutting operation can be simplified, the vegetable cutting efficiency can be improved, and the vegetable cutting process can be safer.

Owner:余敏区

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com