Vibration-reducing and anti-blocking vegetable cutting device

A vegetable cutting device and anti-clogging technology, applied in the field of kitchen utensils, can solve the problems of not taking into account the splashing and clogging of the vegetable section and the vibration of the knife handle, unable to be removed smoothly, clogging, etc., so as to improve the vegetable cutting efficiency and have a simple structure. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

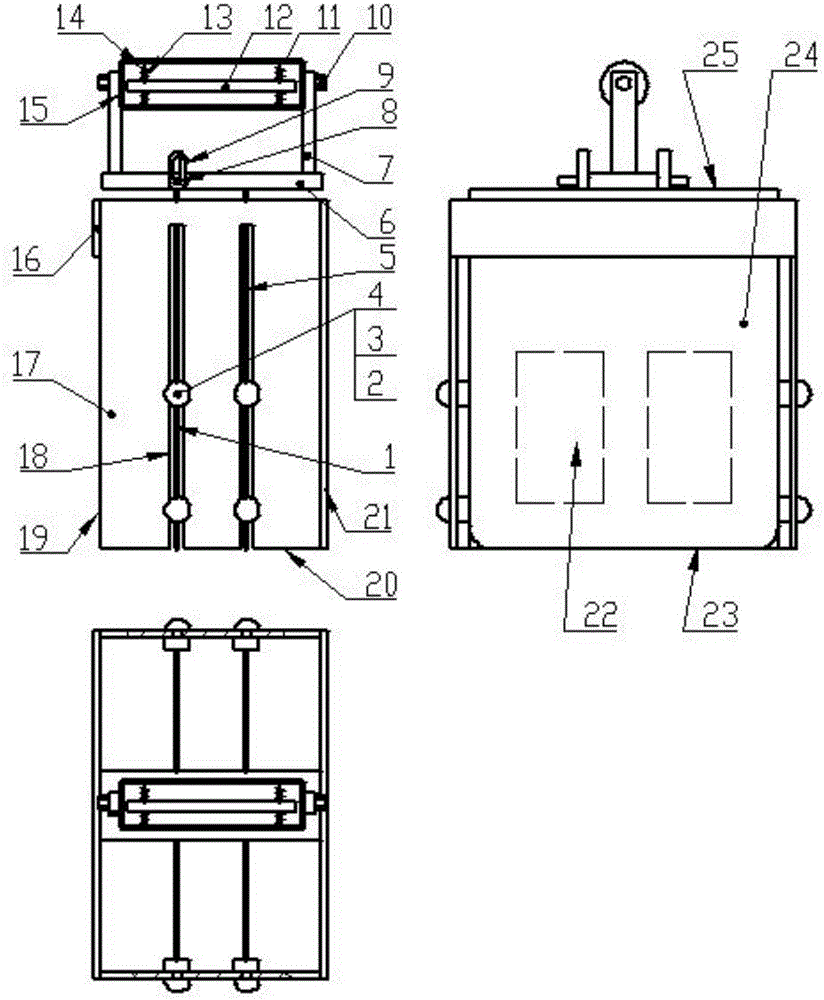

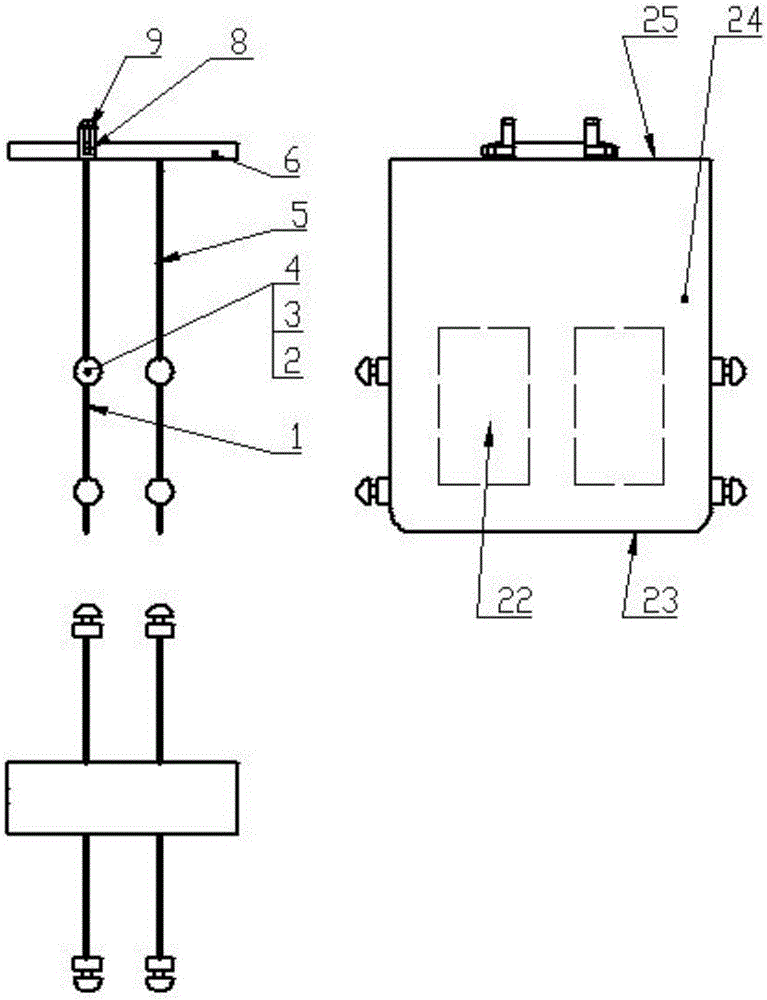

[0027] Such as figure 1 As shown, a vibration-reducing and anti-clogging vegetable cutting device includes: a blade A1, a hemispherical shaft end 2, a short shaft A3, a cylindrical shaft end 4, a blade B5, a connecting plate 6, a support 7, a short shaft B8, and an O-shaped slideway 9. Screw 10, cylinder 11, mass rod 12, guide column 13, spring 14, end cover 15, reinforcement plate 16, guide support plate 17, rectangular groove 18, vegetable inlet 19, vegetable outlet 20, vegetable retaining board 21. Rectangular through hole 22, blade A23, blade body A24, blade back A25, blade B26, blade body B27 and blade back B28.

[0028] Such as figure 2 As shown, the blade A1, the pulley A, the O-shaped slideway 9, the blade B5, the pulley B and the connecting plate 6 form a combined blade structure.

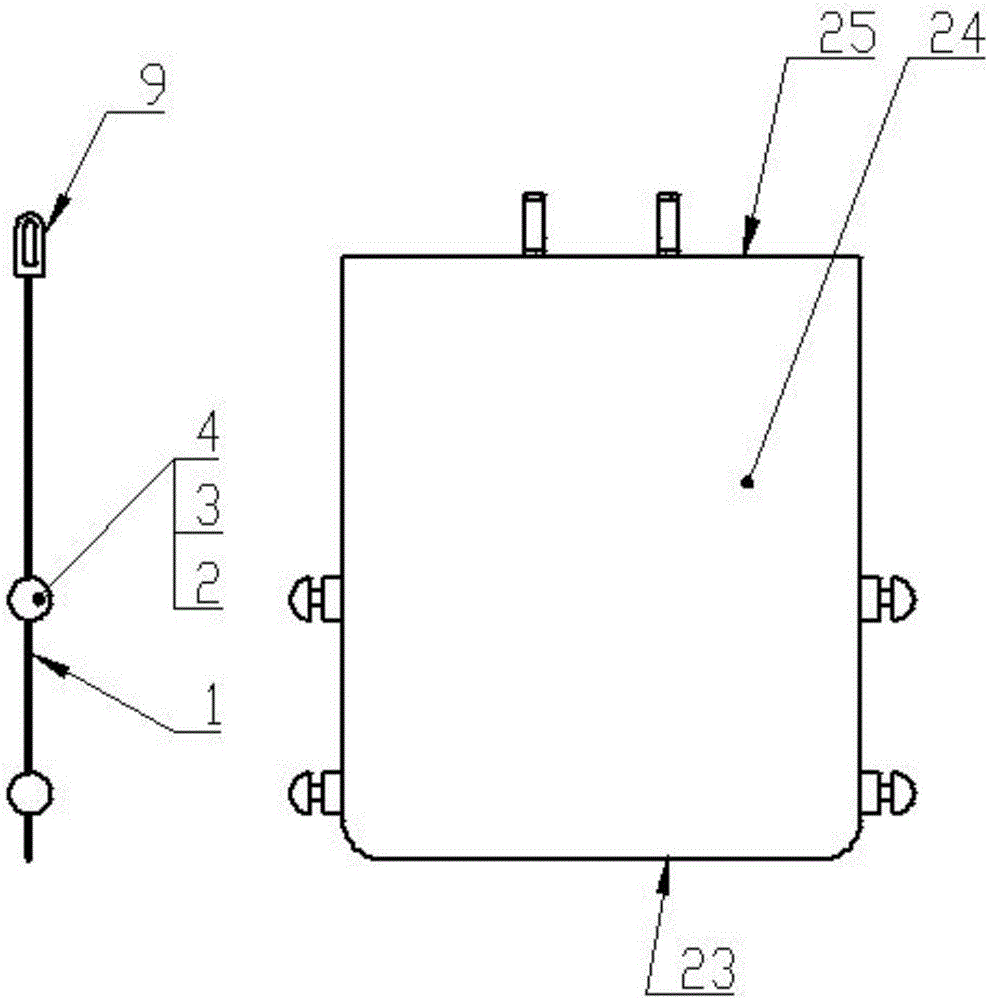

[0029] Such as image 3 As shown, the blade A1 is composed of a blade A23, a blade body A24 and a blade back A25. The blade A1 is made of stainless steel as a whole, and its overall sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com