Vegetable cutting device

The technology of a vegetable cutting device and a slicing device, which is applied in the field of kitchen utensils, can solve the problems of increasing the workload of operators, inconsistent vegetable cutting size, and low vegetable cutting efficiency, so as to improve the vegetable cutting efficiency and avoid the risk of cutting fingers. Guaranteed cutting size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with drawings and embodiments.

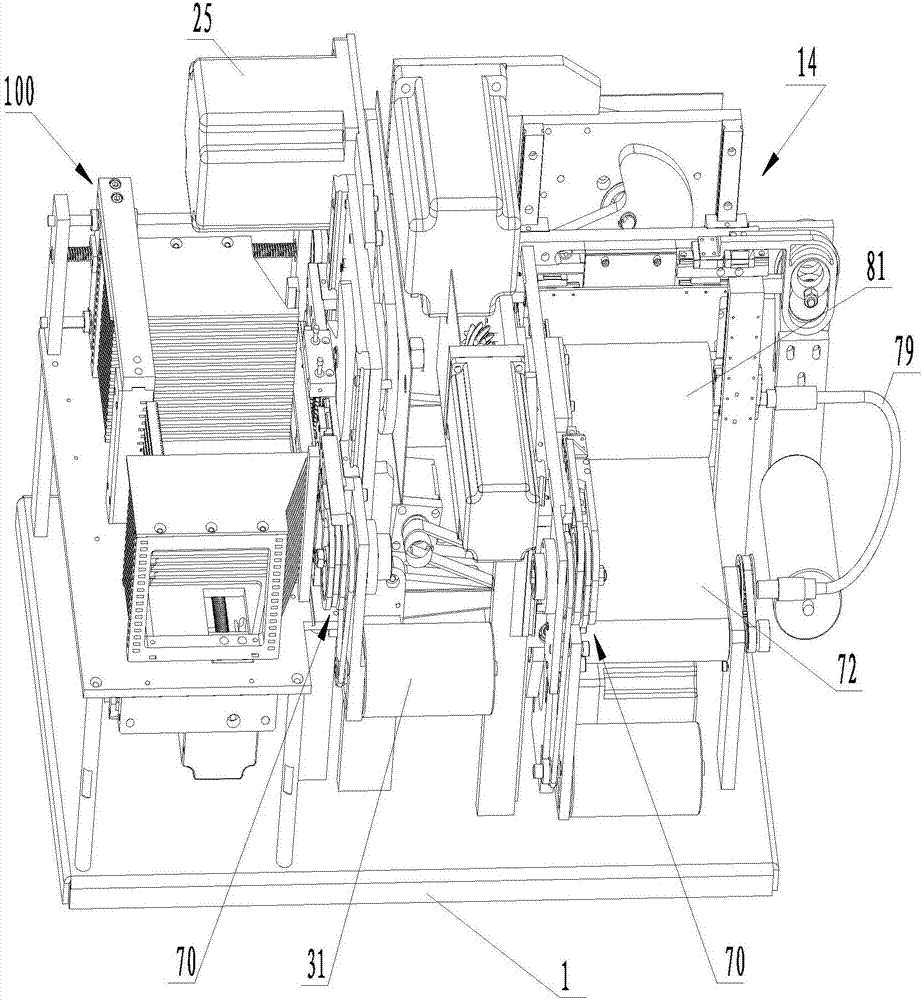

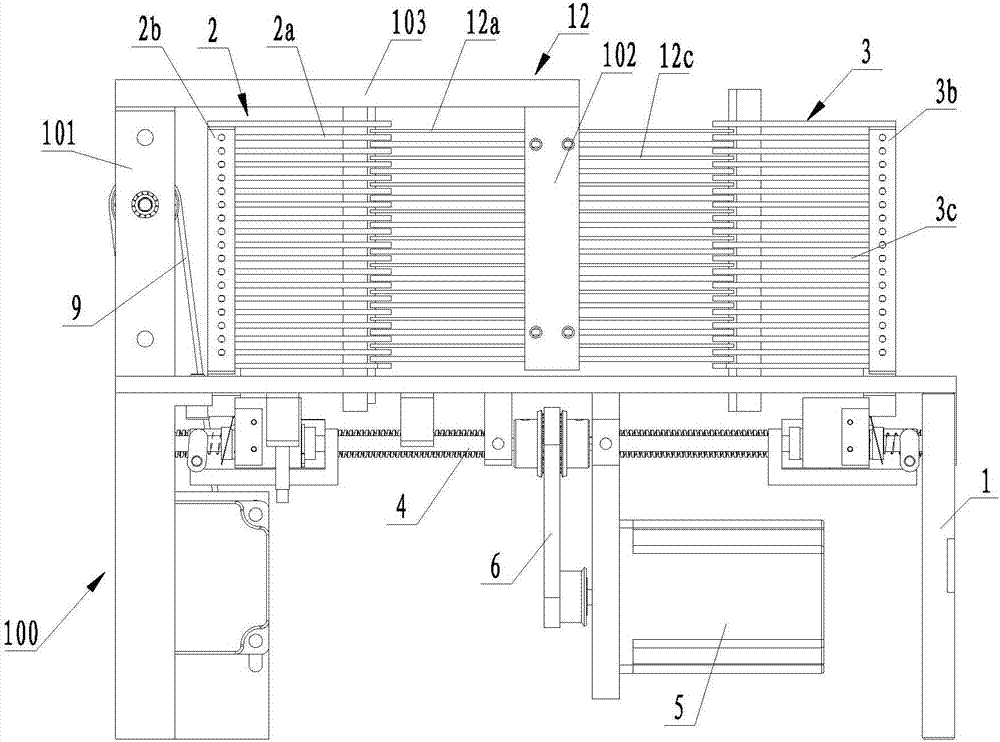

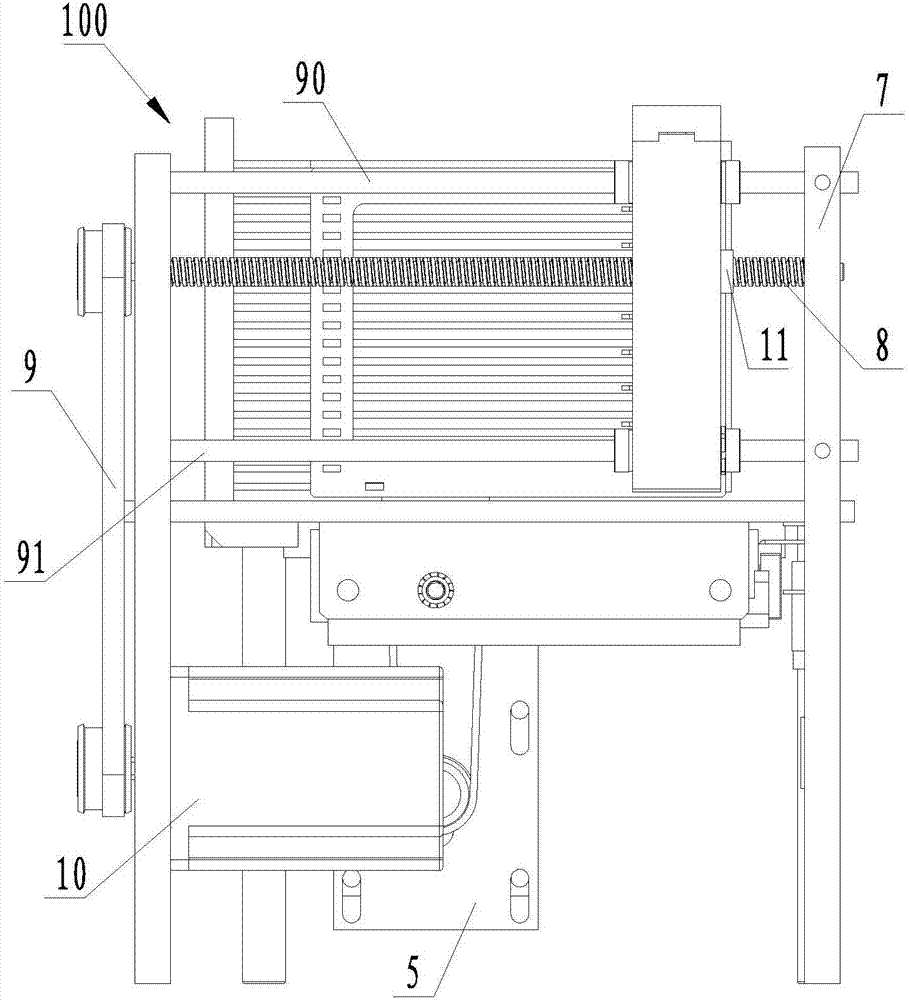

[0038] as follows Figure 1 to Figure 11 As shown; a vegetable cutting device, including a frame 1, the frame 1 is sequentially provided with a clamping device 100, a slicing device 13, a first limiting device 60, a shredding device 70, and a second limiting device 71 and dicing device 84.

[0039] The clamping device 100 includes a first clamping frame 2 and a second clamping frame 3 which are symmetrical to each other. The first clamping frame 2 includes a plurality of first clamping plates 2a, and each first clamping plate 2a is spaced apart from top to bottom. It is provided that the outer sides of the first clamping plates 2a are connected by the first connecting plate 2b, and the second clamping frame 3 has the same structure as the first clamping frame 2 . The bottoms of the first clamping frame 2 and the second clamping frame 3 are in clearance fit with the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com