Food material processing method, storage medium and vegetable cutting device

A processing method and technology for ingredients, applied in the kitchen field, can solve the problems of user injury, inability to accurately grasp the size, shape and thickness of ingredients, and achieve automation, improve efficiency, and improve the quality of dishes, and the effect of cooking science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] According to an embodiment of the present invention, a material processing method is provided, which can be applied to a controller of a vegetable cutting device, and the vegetable cutting device further includes an identification device and a material cutting device, wherein the identification device It is used for collecting image information of food to be processed, and the food cutting device is used for cutting the food to be processed.

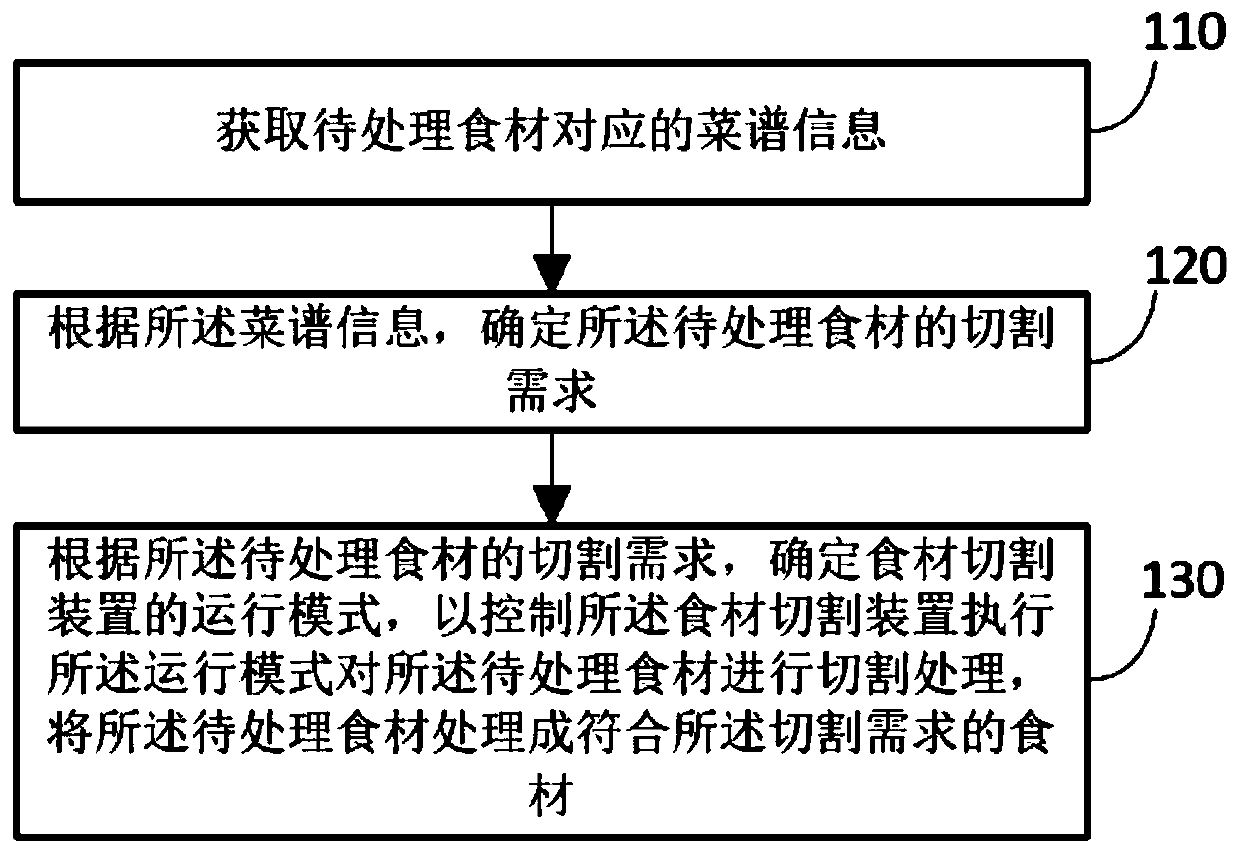

[0037] figure 1 It shows a schematic flow chart of a food processing method proposed in Embodiment 1 of the present invention, as shown in figure 1 As shown, the food processing method may include: step 110 to step 130 .

[0038] In step 110, the recipe information corresponding to the ingredients to be processed is acquired.

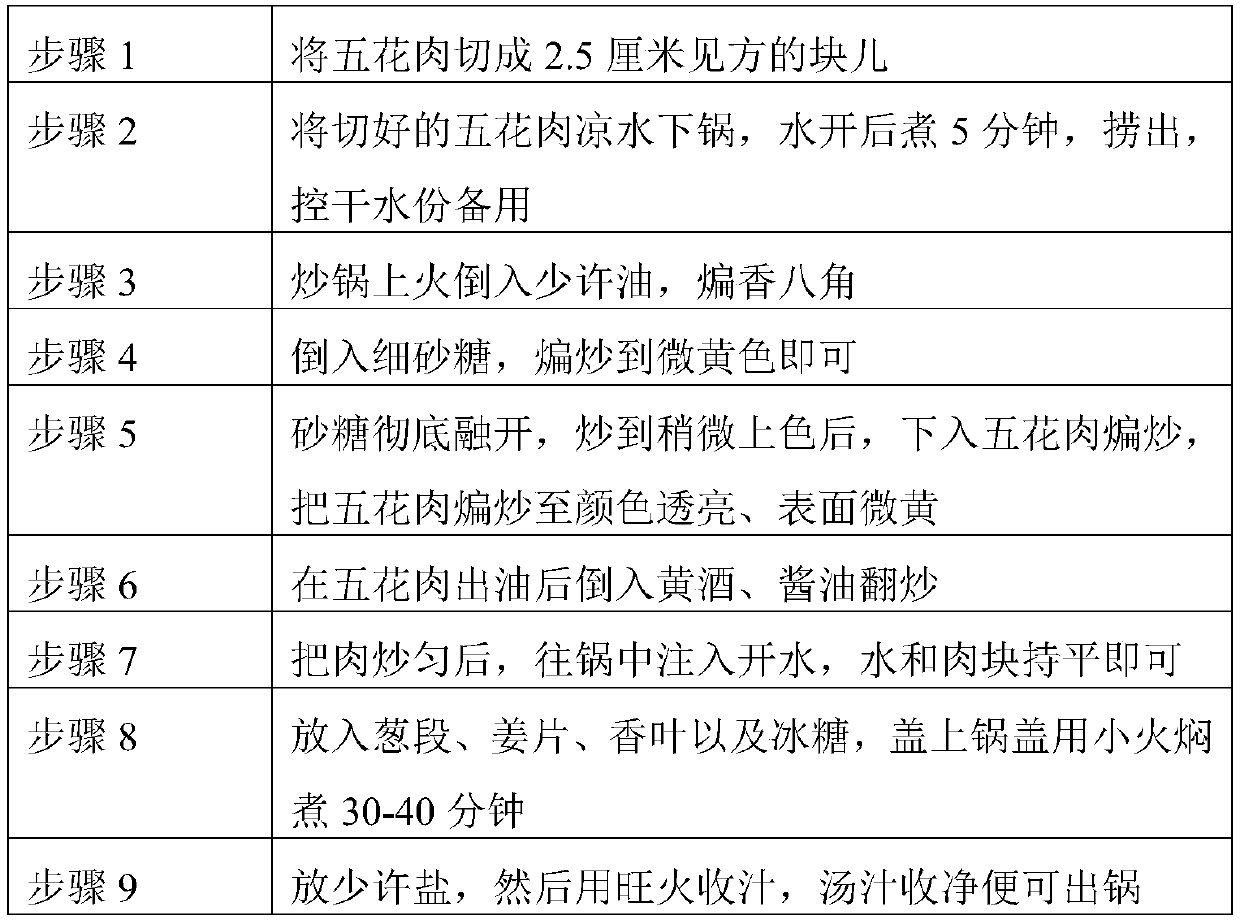

[0039] Here, the food to be processed refers to the food to be cut by the user. For example, if the user wants to cut pork belly to obtain a 2.5 cm square pork belly, the food to be processed is pork bell...

Embodiment 2

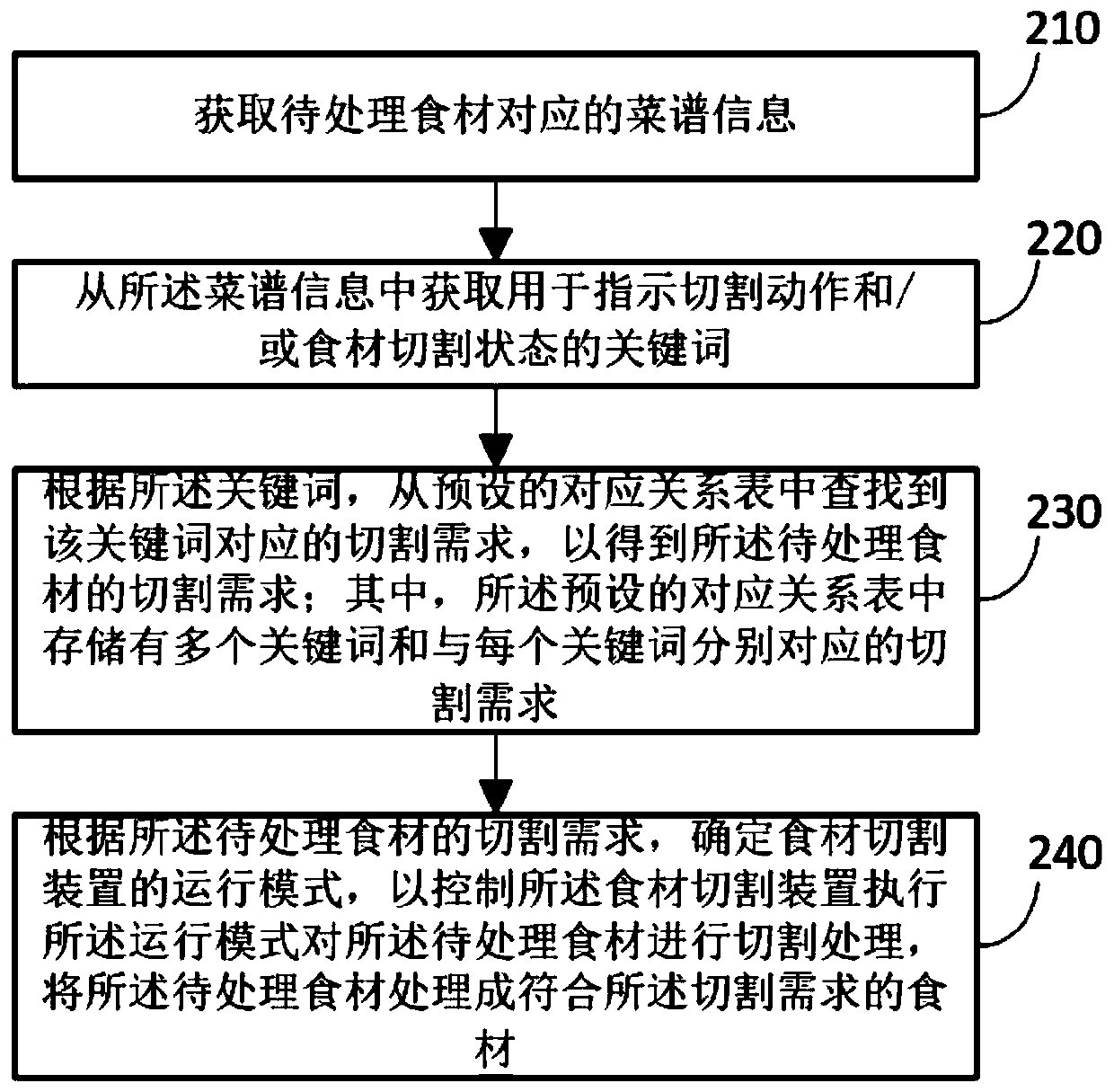

[0046] On the basis of the foregoing embodiments, Embodiment 2 of the present invention may further provide a food processing method. figure 2 It shows a schematic flow chart of a food processing method proposed in Embodiment 2 of the present invention, as shown in figure 2 As shown, the food processing method may include: step 210 to step 240 .

[0047] In step 210, the recipe information corresponding to the ingredients to be processed is acquired.

[0048] Here, the food to be processed refers to the food to be cut by the user. For example, if the user wants to cut pork belly to obtain a 2.5 cm square pork belly, the food to be processed is pork belly. Get recipes related to pork belly. Wherein, the recipe information corresponding to the food to be processed may be a recipe determined by the user in advance. For example, the recipes to be cooked by the user include braised pork recipes and double pepper beef recipes. When the food to be processed is pork belly, the cor...

Embodiment 3

[0095] According to an embodiment of the present invention, a storage medium is further provided, and a program code is stored on the storage medium. When the program code is executed by a processor, the food processing method as described in any one of the above-mentioned embodiments is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com