Food processing knife and food processing cup

A knife plate and blanking technology, applied in the field of cooking cups, can solve the problems of affecting vegetable cutting efficiency, inconvenient operation, danger, etc., and achieve the effects of reducing use risk, convenient operation, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

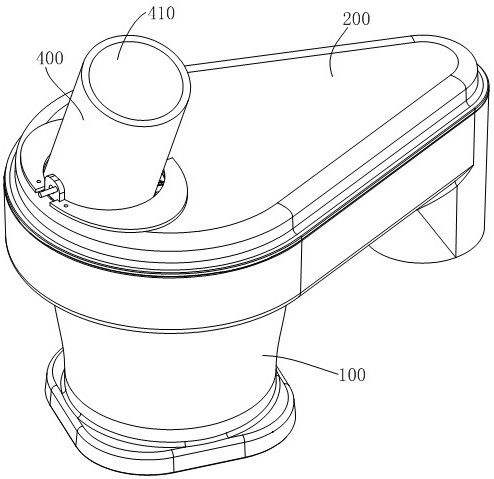

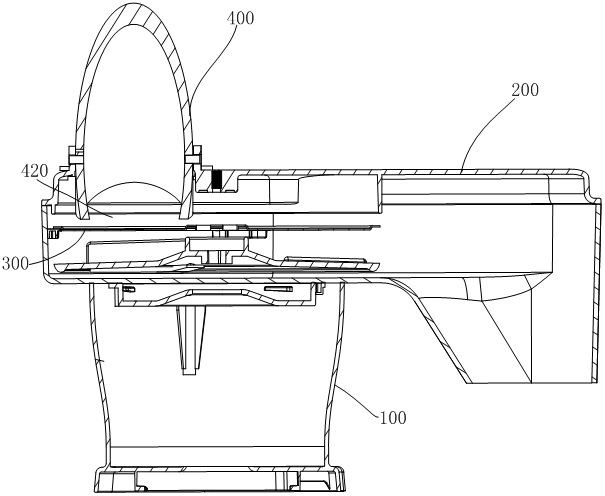

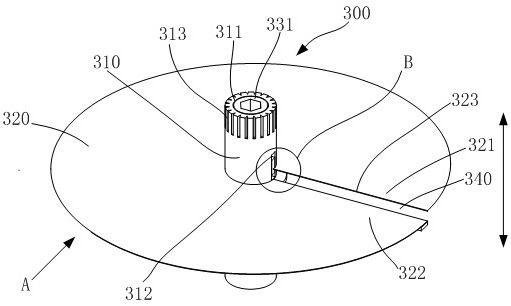

[0036] refer to Figure 1 to Figure 4 , a cooking cup in this embodiment, comprising a cup body 100, a cup cover 200, a cooking knife 300 and a feeding barrel 400, the cooking knife 300 is rotatably arranged in the cup body 100, and the cup cover 200 is provided with a mounting hole (viewing angle reason, not shown in the figure), the feeding tube 400 is installed on the cup cover 200 and extends into the cup body 100 through the installation hole, the feeding tube 400 is located above the cooking knife 300 and has a feeding port 410 above the cup cover 200 And the discharge port 420 located above the cooking knife 300; the food material is put into the space above the cooking knife 300 in the cup body 100 through the feeding tube 400, and the food material is close to the bottom of the cooking knife 300 und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com