Finger-shaped connector of aramid fiber conveying belt and preparation method of finger-shaped connector

A finger joint and conveyor belt technology, applied in the field of aramid conveyor belt finger joint and its preparation, can solve the problems of conveyor belt extraction, etc., and achieve the effect of increasing the extraction force and improving the uniformity of the force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

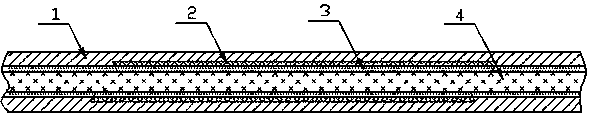

[0042] Embodiment 1 The method for preparing a finger joint of an aramid conveyor belt comprises the following steps:

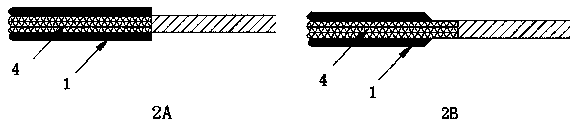

[0043] 1 Peeling of cover glue

[0044] Peel off the upper and lower cover glue on the joint, and the cutting part of the cover glue is a 45-degree slope, and polish the slope.

[0045] 2 Cleaning of residual glue

[0046] Use a utility knife to cut off the remaining rubber on the surface of the skeleton material, use an angle grinder to roughen the surface of the skeleton material and the rubber around the groove, clean it with a brush, blow away fine particles with a hair dryer, and dry the surface of the skeleton .

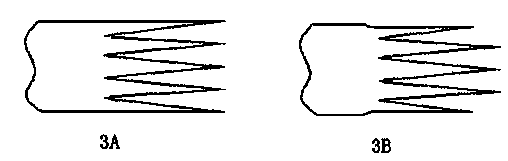

[0047] 3 finger cut

[0048] Align the two ends of the two belts that need joints, draw a vertical line on the longitudinal surface of the conveyor belt, use a marker pen to mark every other finger-width unit on both sides of the vertical line, and cut along the drawn line with a utility knife. Always follow the principle of removing more ...

Embodiment 2

[0057] Example 2 A joint test was carried out on a 1600N / mmDPP aramid canvas core conveyor belt, including the following steps:

[0058] (1) Peeling off the cover glue

[0059] Peel off the upper and lower cover glue on the joints of the aramid canvas conveyor belt.

[0060] (2) Cleaning of residual glue

[0061] Remove the remaining glue on the surface of the skeleton material, roughen the surface of the skeleton material and the rubber around the groove, clean it, remove fine particles, and dry the surface of the skeleton.

[0062] (3) Finger cutting

[0063] 1. Draw a line

[0064] Make a straight line that intersects with both sides of the conveyor belt width as xx , , the length is x, then take 1 / 2x as point O, and point O as the reference point; take O as the fixed point, L as the length (L≥2m), and take y, y on the two sides of the bandwidth , , connect to yy , ; xy and yy , vertical, x , the y , with yy , vertical, such as Figure 4 shown.

[0065] 2. Fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com