Patents

Literature

32 results about "Finger cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

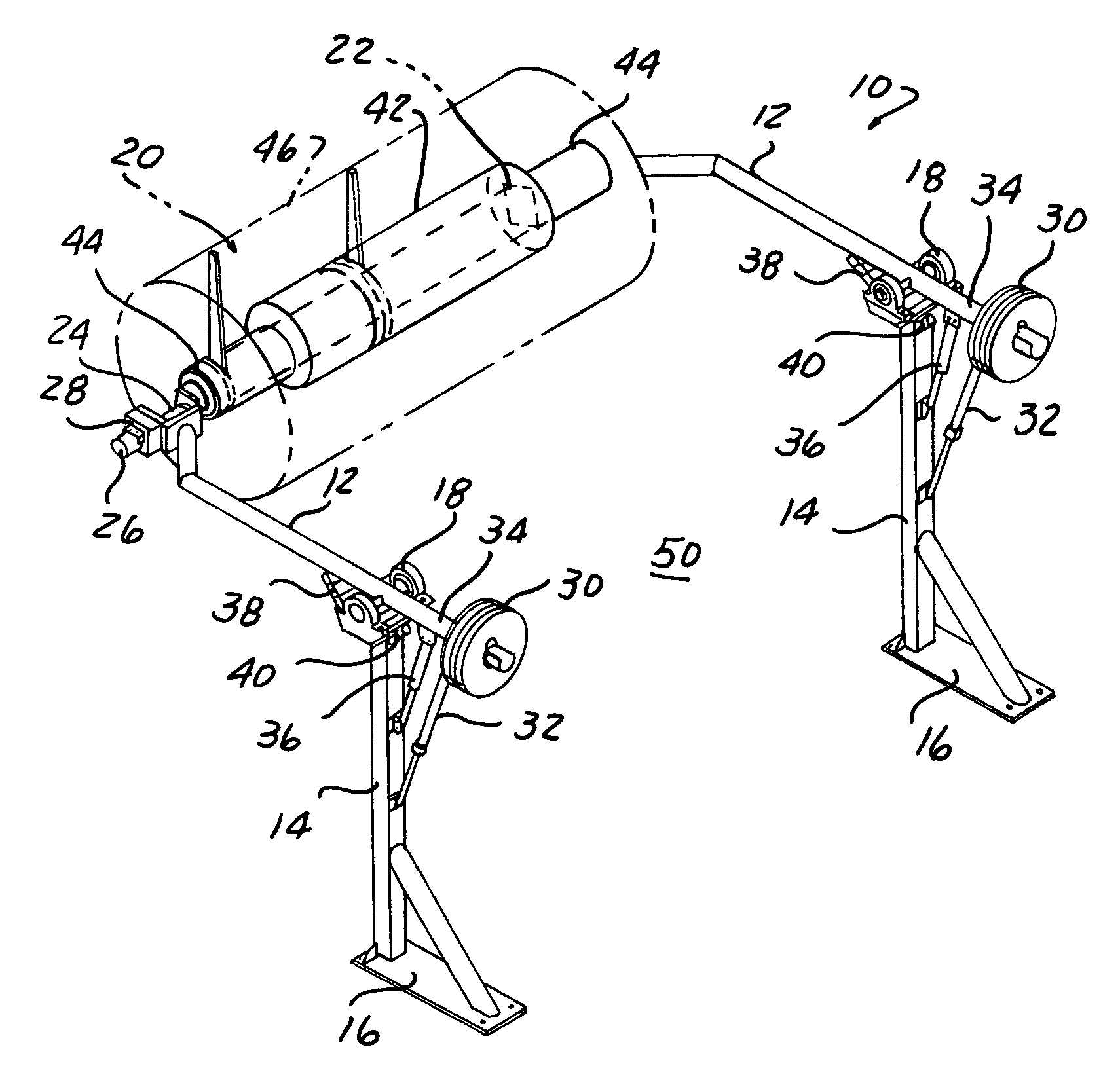

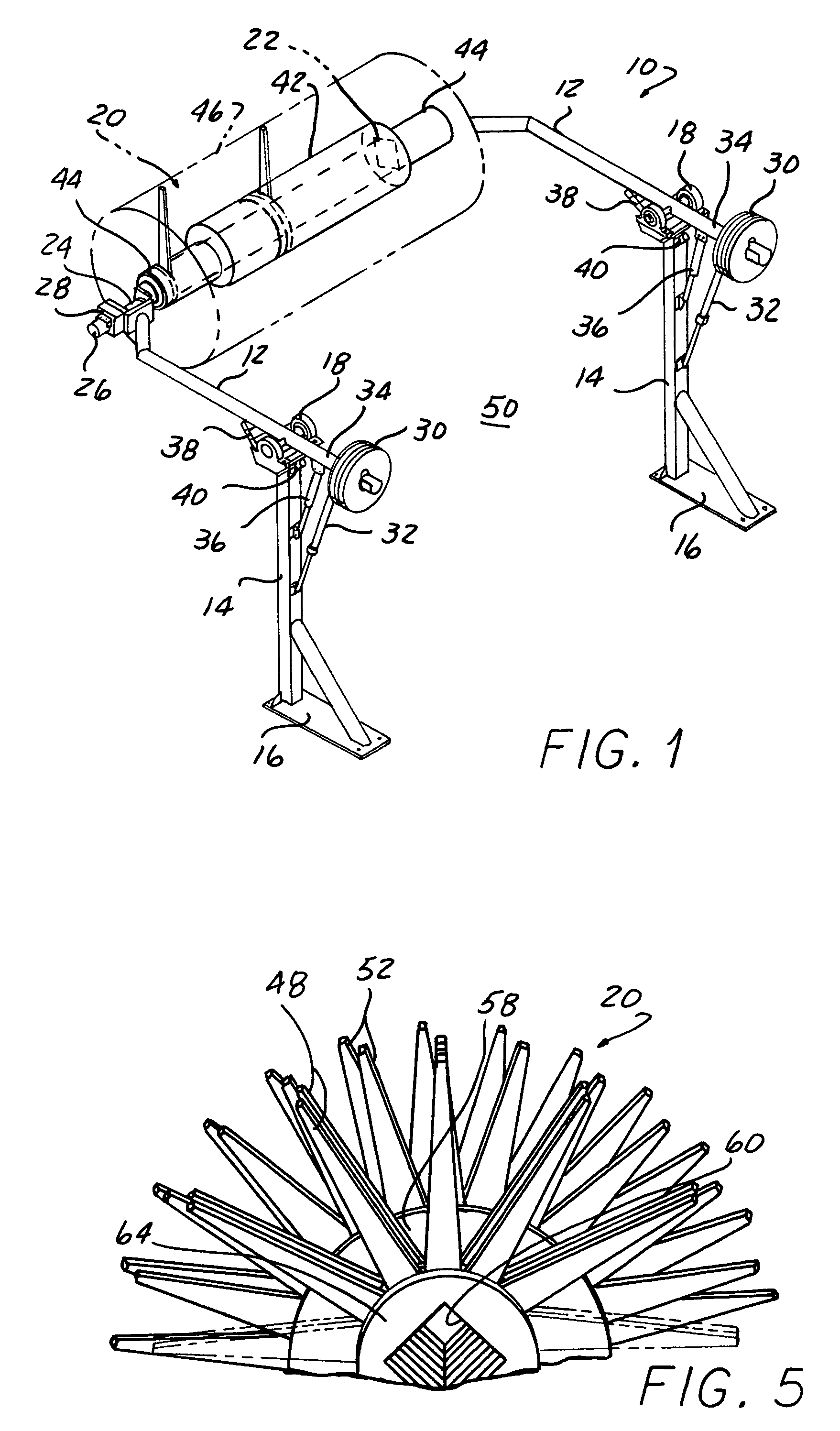

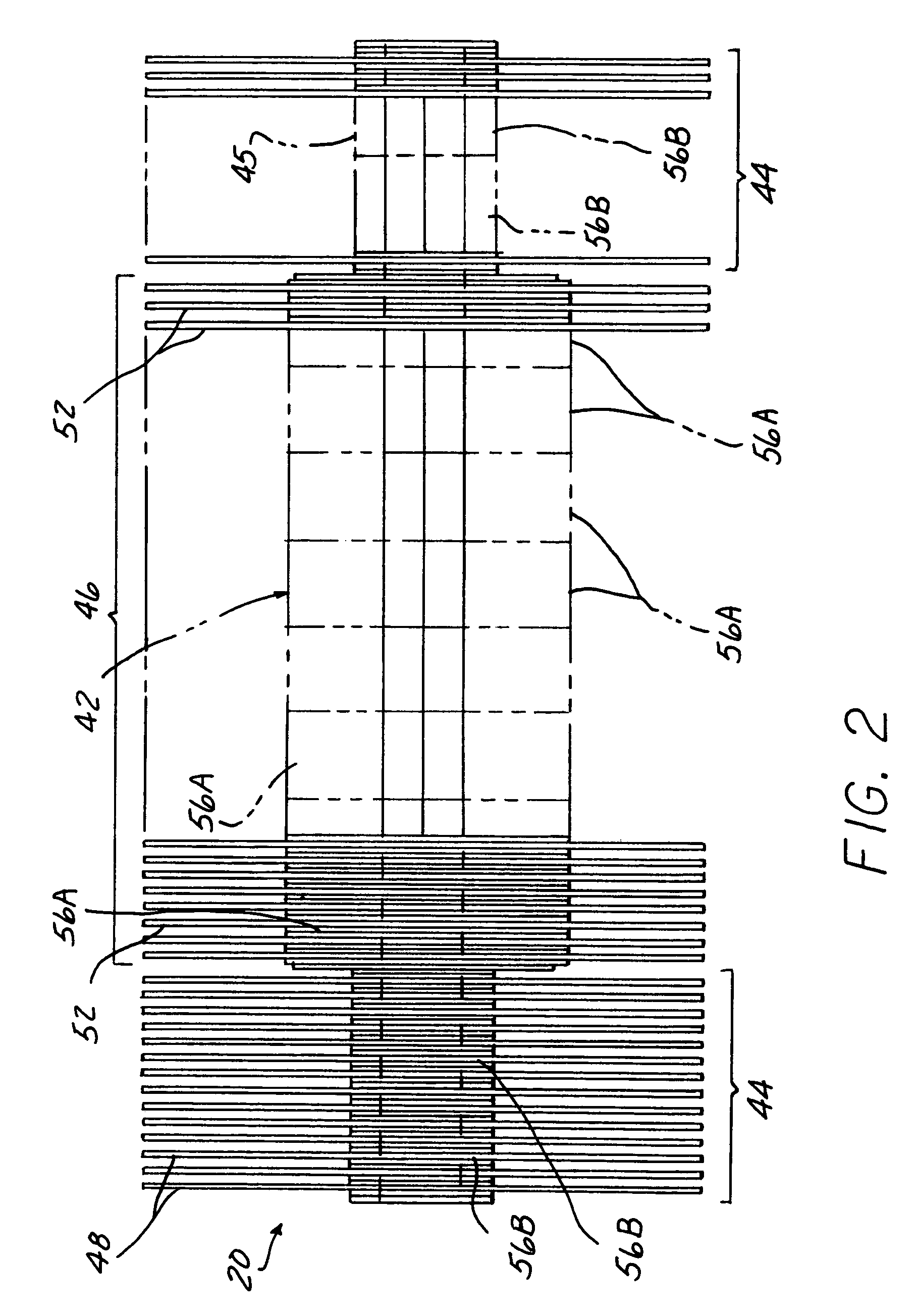

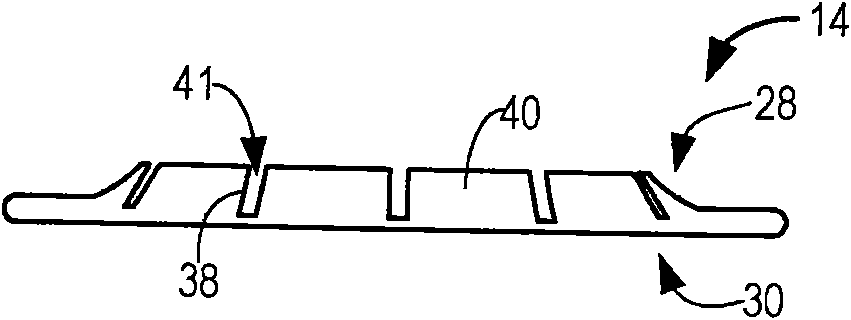

Brush and method for car wash

InactiveUS7219385B1Slow changeGreat tendencyLiquid surface applicatorsLiquid processingEngineeringMechanical engineering

A brush for a car wash has radial arrays of fingers cut from flat sheets of closed cell foam. The finger arrays are stacked atop each other with interposed spacer discs, bonded together to form sections of the brush. A top brush has a center section core formed by the spacer discs of a larger diameter than two smaller core diameter ends to provide a larger diameter center section core caused to roll when encountering a vehicle surface to pass over the some without damage, and smaller core diameter end sections able to accommodate antennas with less bending. The fingers of the scrubbing section of the brush are short, no longer than and are held sufficiently stiffly to support the brush on the side rails of pickup cargo beds at a high enough height as to avoid finger contact with the cargo bed bottom surfaces.

Owner:RIETSCH JR GILBERT J

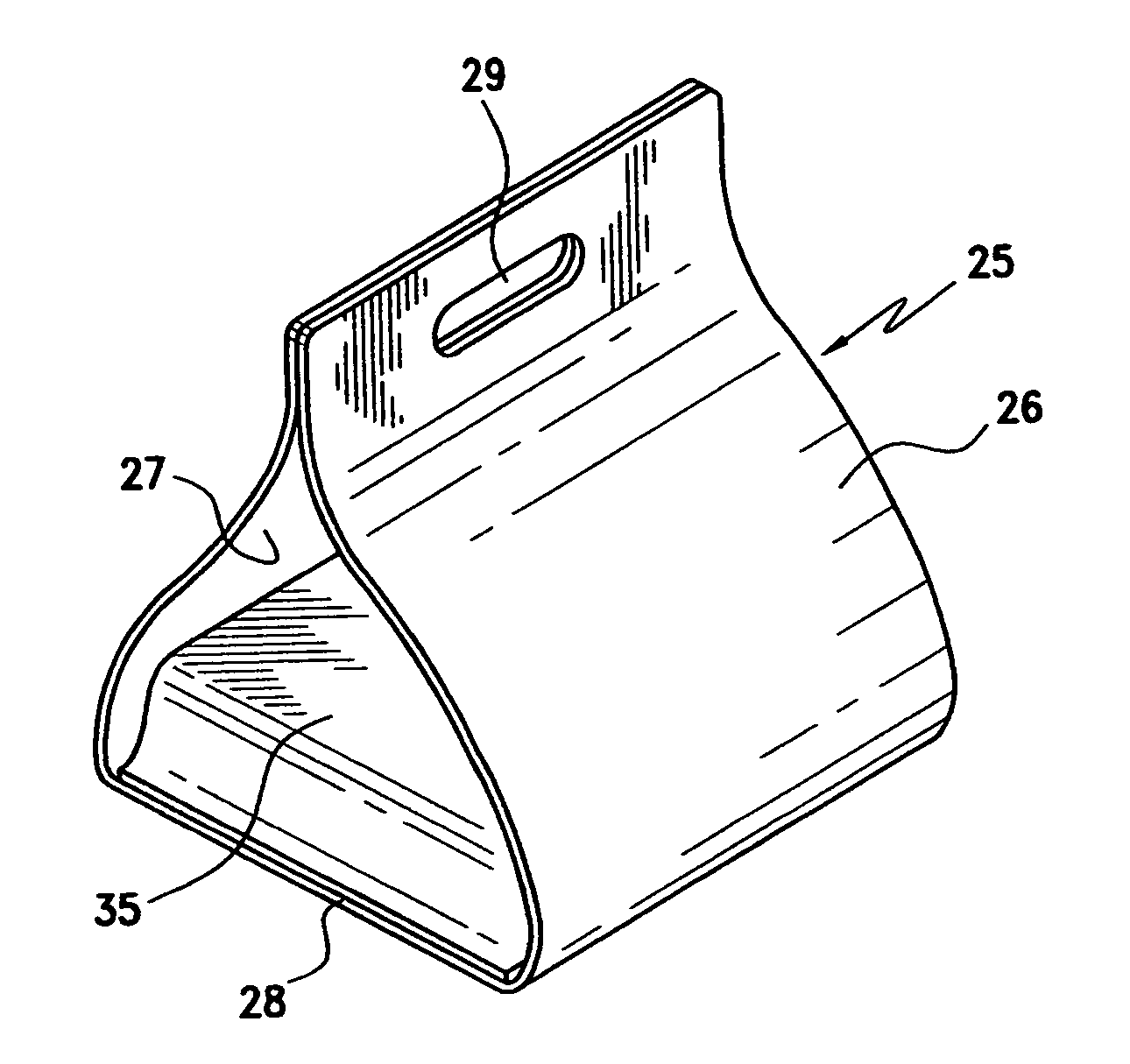

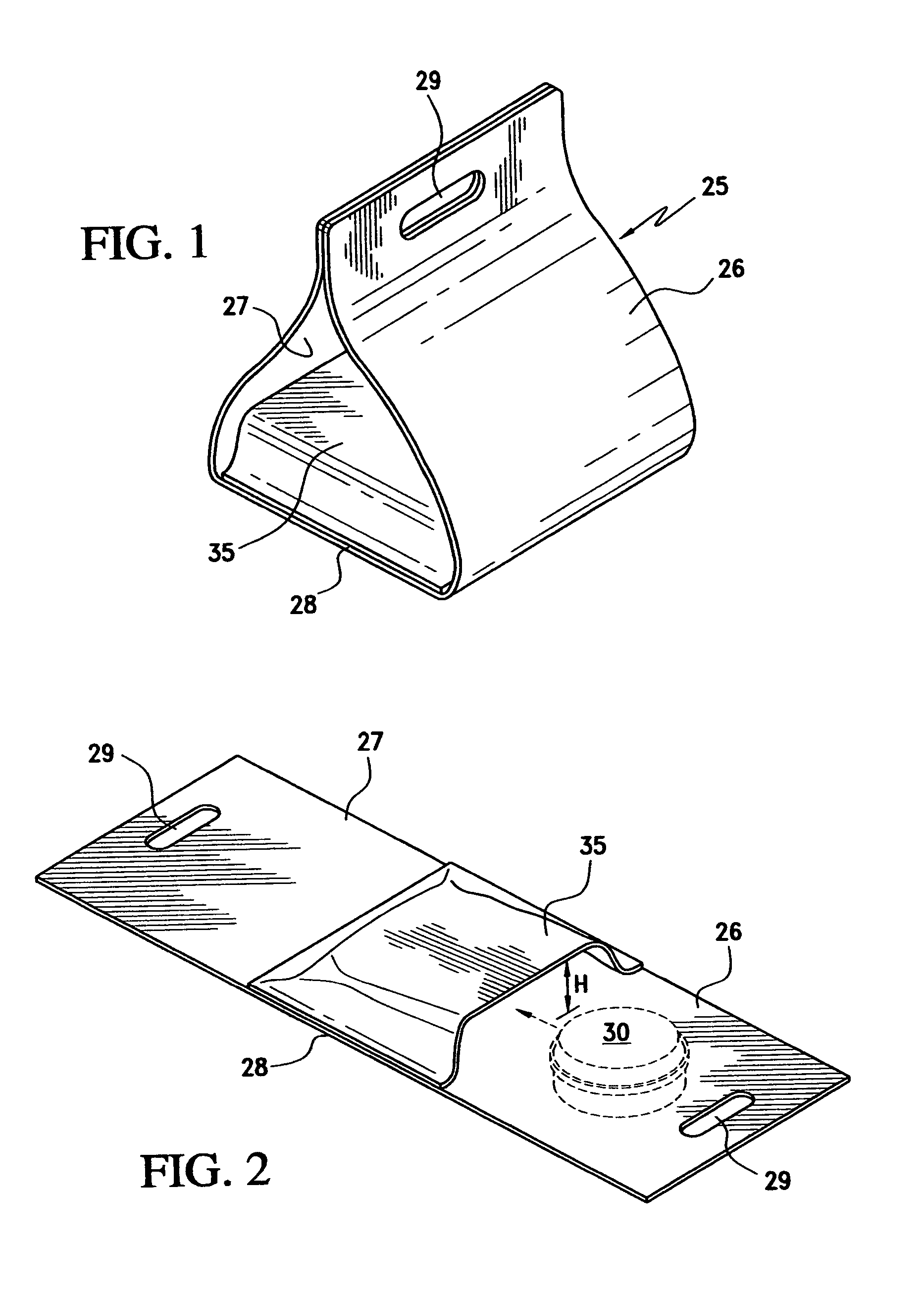

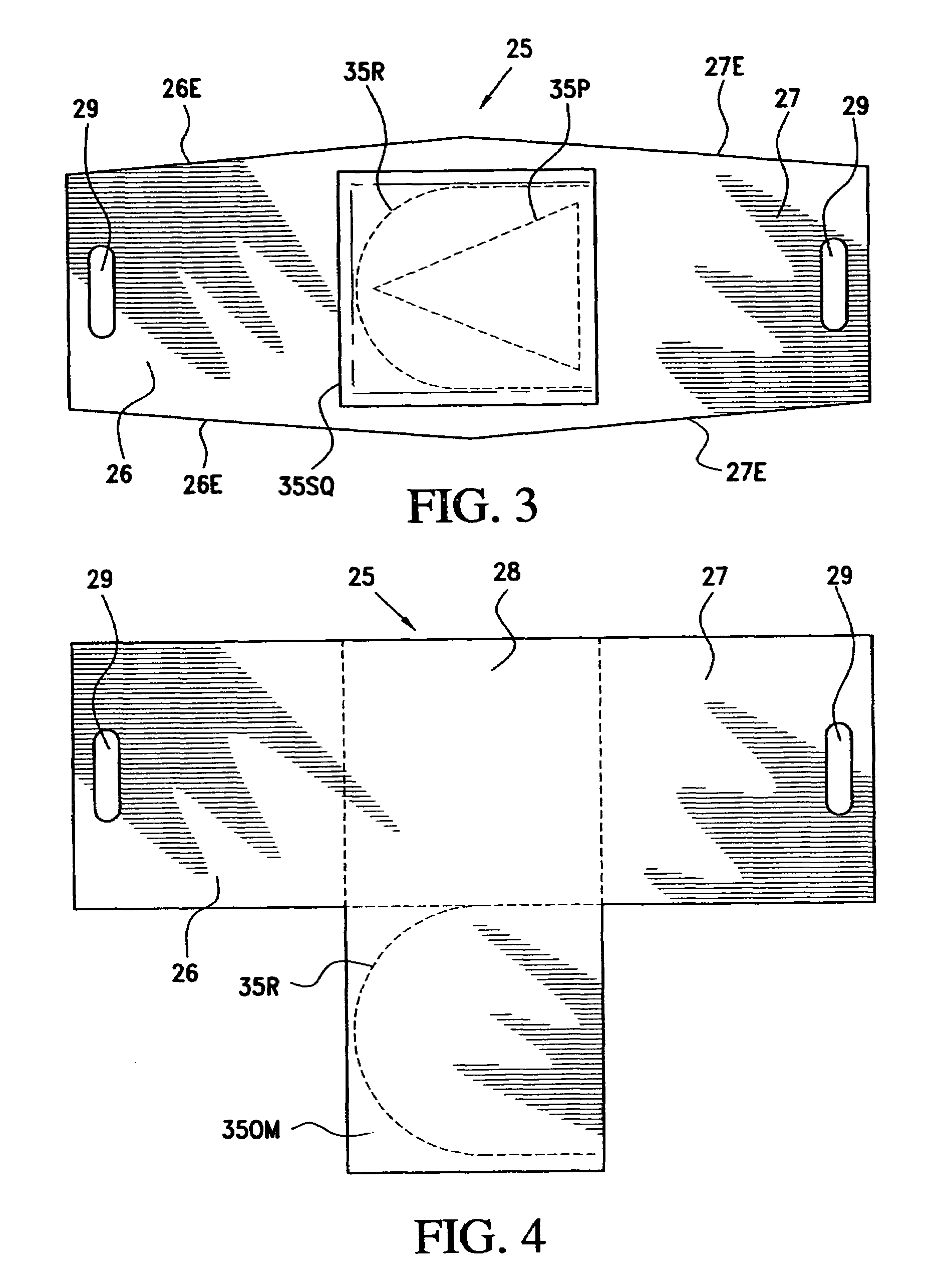

Up-right carry-out

InactiveUS7591496B1Reduce manufacturing costEasy to useTravelling carriersHoldersEngineeringMechanical engineering

A uniquely designed “sling type” container carrier which can be made from a variety of materials including paper, plastic, cloth or other suitable material. As noted above, it has a “sling type” design with a pocket positioned centrally on the “sling” in such a manner that when the pocket is filled with a product, i.e., a cake, pie, pizza or fast food container of food, the lengths of the two opposite sides of the sling are equal and serve to engage the opposite ends of the pocket and securely hold the container therein. Each end of the sling is provided with a finger cut-out which, when placed in close proximity with each other, serve as carrying handles, thus allowing a product that has been placed within the pocket, to be carried in an up-right position.

Owner:DE BECK THOMAS D

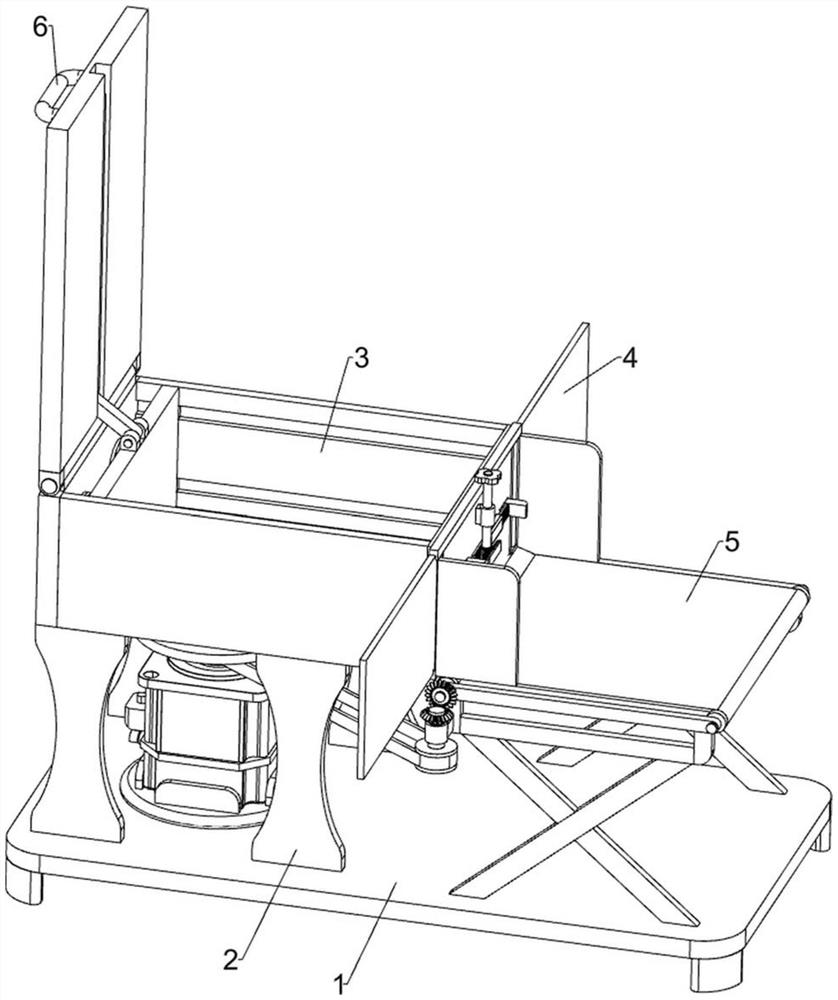

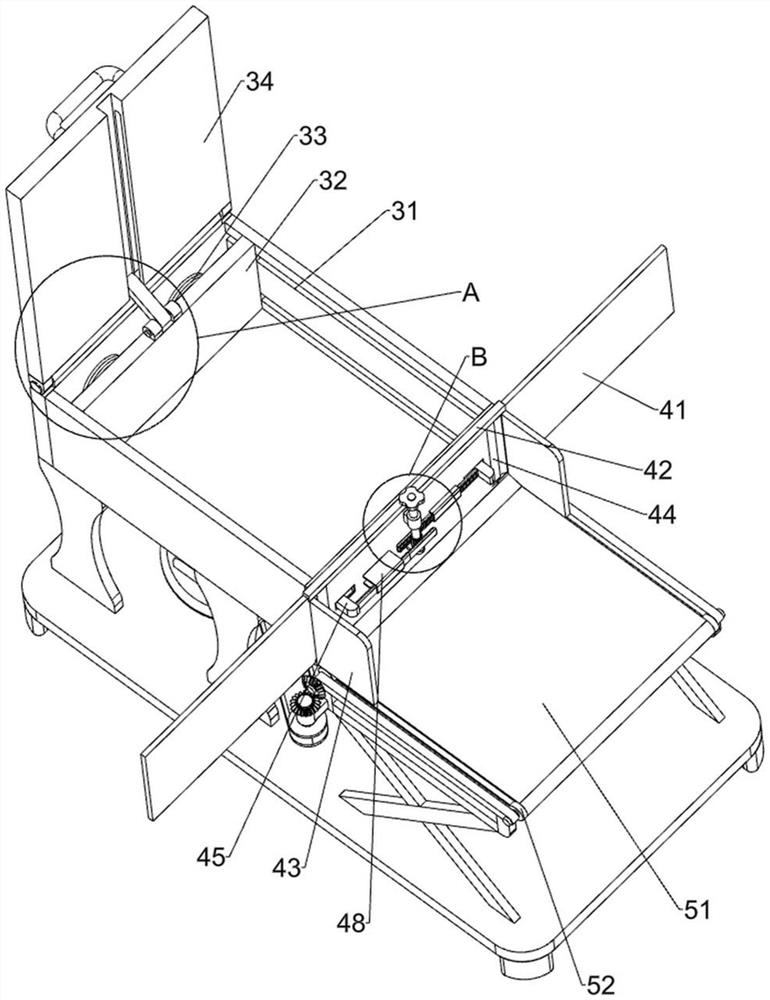

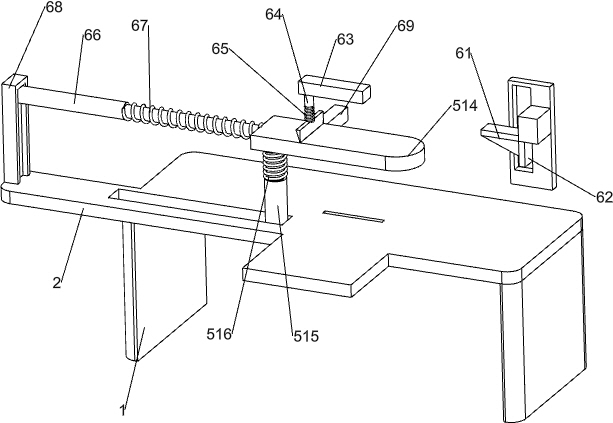

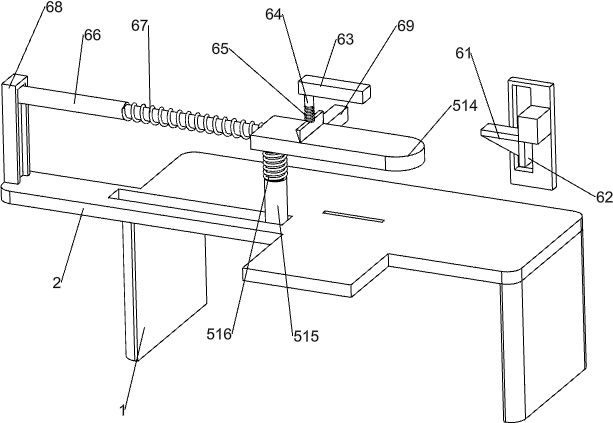

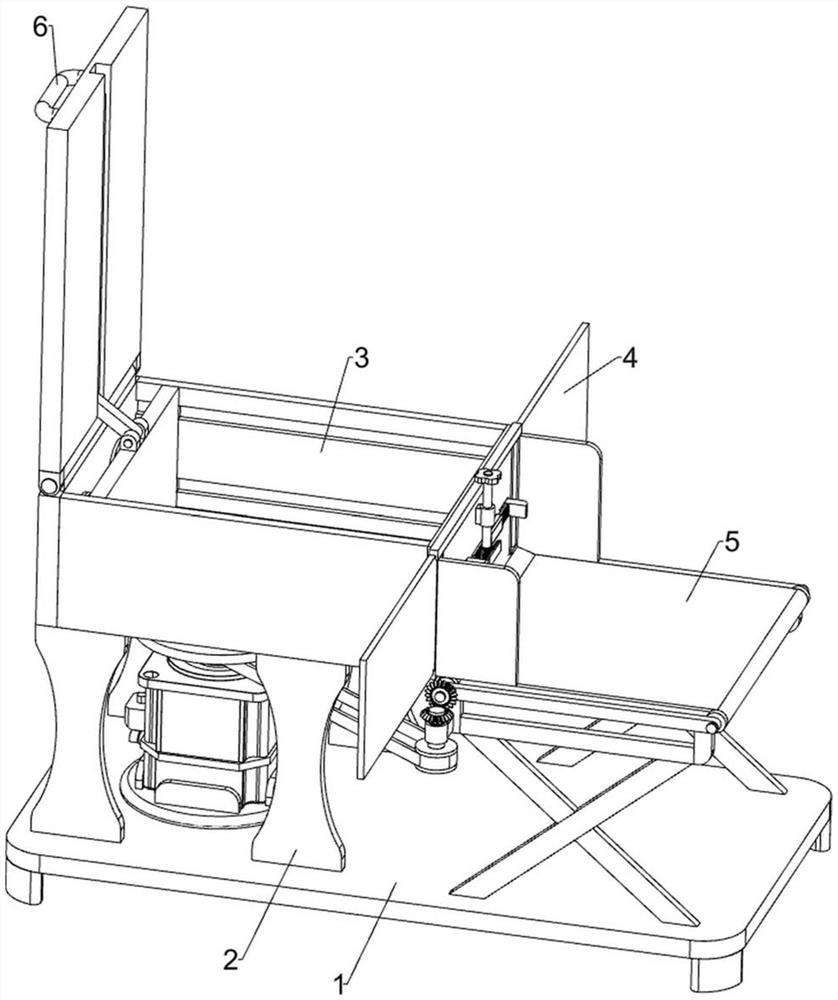

Meat product slicer for food processing

ActiveCN111844210AReduce laborAvoid sorenessMetal working apparatusMeat processing devicesProcess engineeringFood processing

The invention relates to a slicer for food processing, in particular to a meat product slicer for food processing. The meat product slicer for food processing can slice meat products without the needto manually hold a kitchen knife. The meat product slicer for food processing comprises a base, a pushing mechanism, and a slicing mechanism. The upper side of the base is symmetrically connected withfour supporting frames. The pushing mechanism is arranged between the supporting frames and the base. The slicing mechanism is arranged on the pushing mechanism. The pushing mechanism can push meat products to move to the right, and the slicing mechanism can slice the meat products moved to the right, so as to slice the meat products without manually holding a kitchen knife, thereby reducing thelabor of workers. The meat product slicer can prevent arm pain and cutting of fingers.

Owner:江西谷纬科技有限公司

Automatic shelling and flesh-taking manufacture equipment for building decorating material shells

InactiveCN107549283AEnsure safetySave time at workBivalves processingEngineeringUltimate tensile strength

The invention relates to an automatic peeling and meat-removing production equipment for building decoration material shells, which includes a conveying device, a cutting device and a meat-peeling device. rear side of the upper end. The present invention solves the problem that in the existing building decoration material shells peeling and meat removal, workers need to use tools to pry open the gaps in the two petal-shaped shells and then manually remove the meat. The process is cumbersome and complicated. During the process, fingers may be cut due to improper operation, causing potential safety hazards. At the same time, when manually peeling shells, the staff usually put the peeled shells and shell meat into the storage bucket and wait until the bucket is full before moving the storage bucket. To the designated location, the operation is complicated, the efficiency is low, the manual use of tools to pry open the shells is inefficient, time-consuming, labor-intensive and low-efficiency, etc., can realize the function of automatic shelling and meat removal of shells for building decoration materials.

Owner:俞樑兵

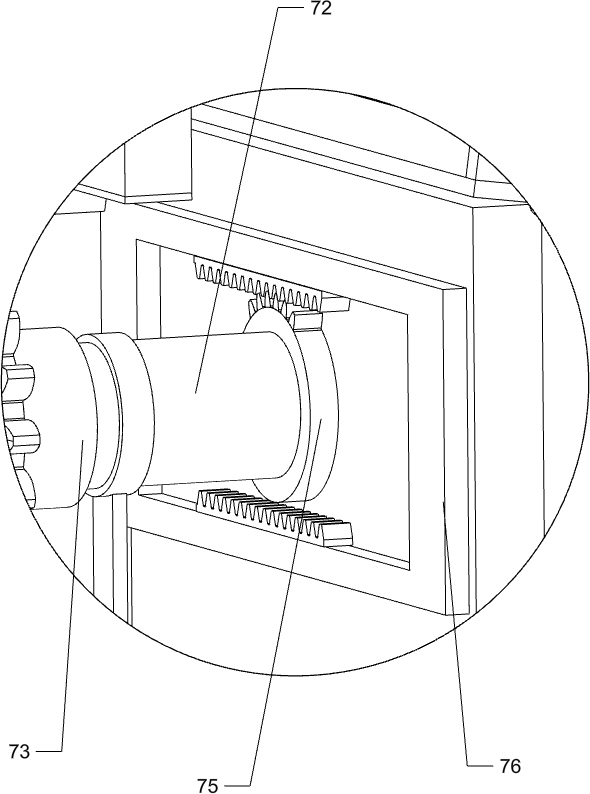

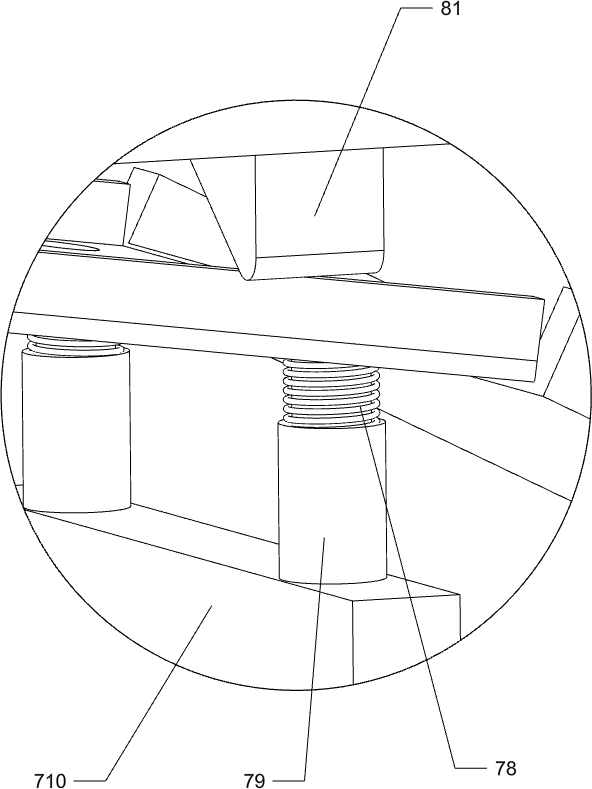

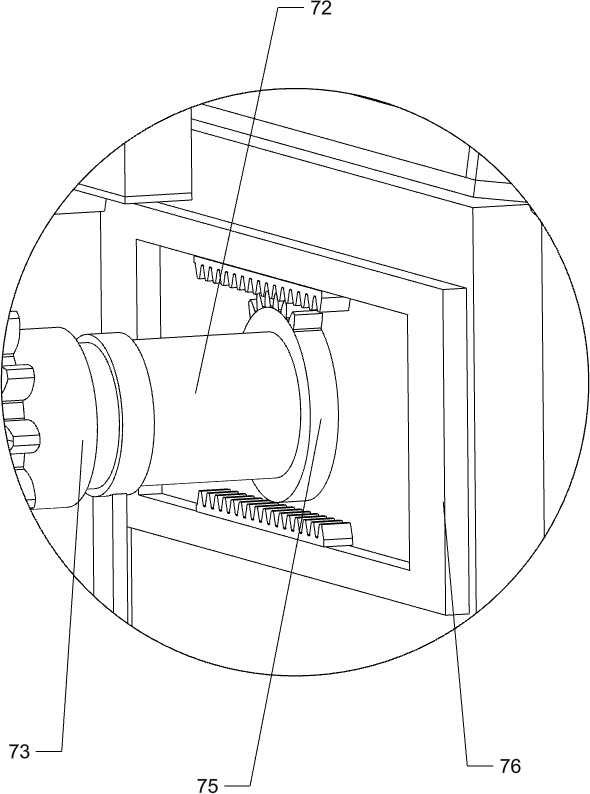

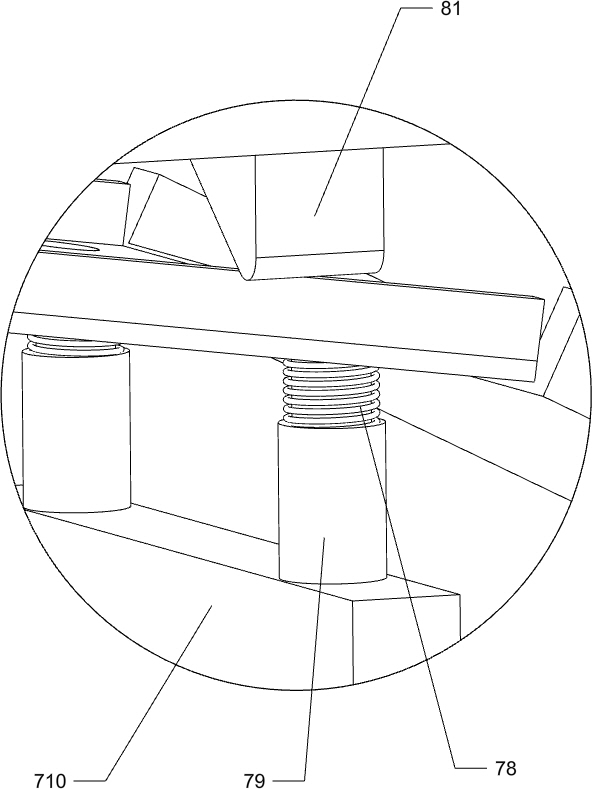

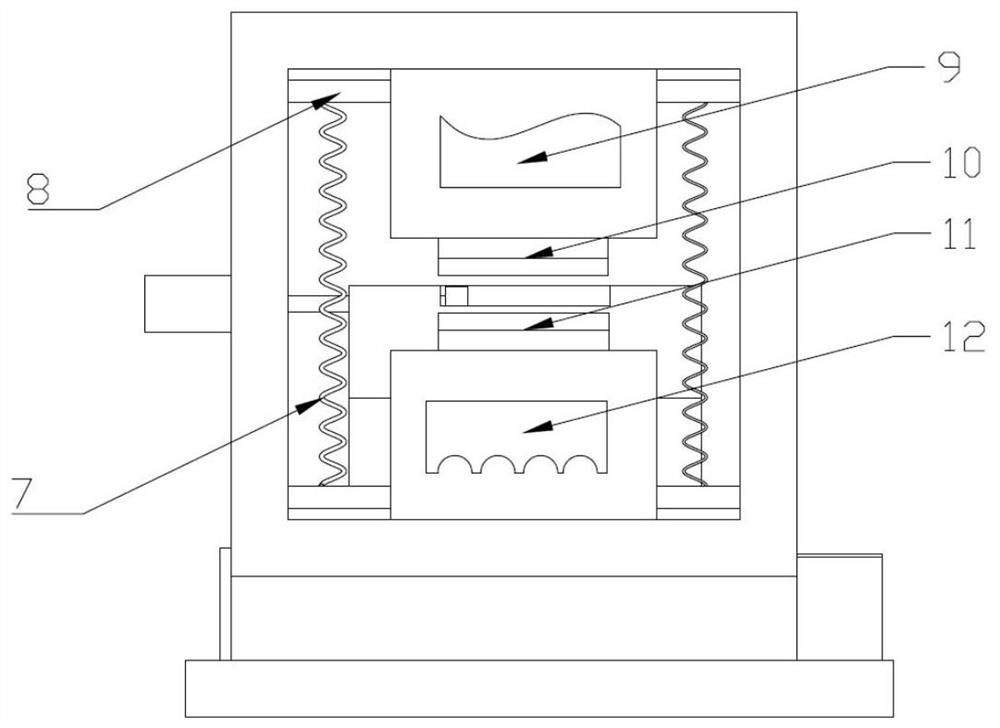

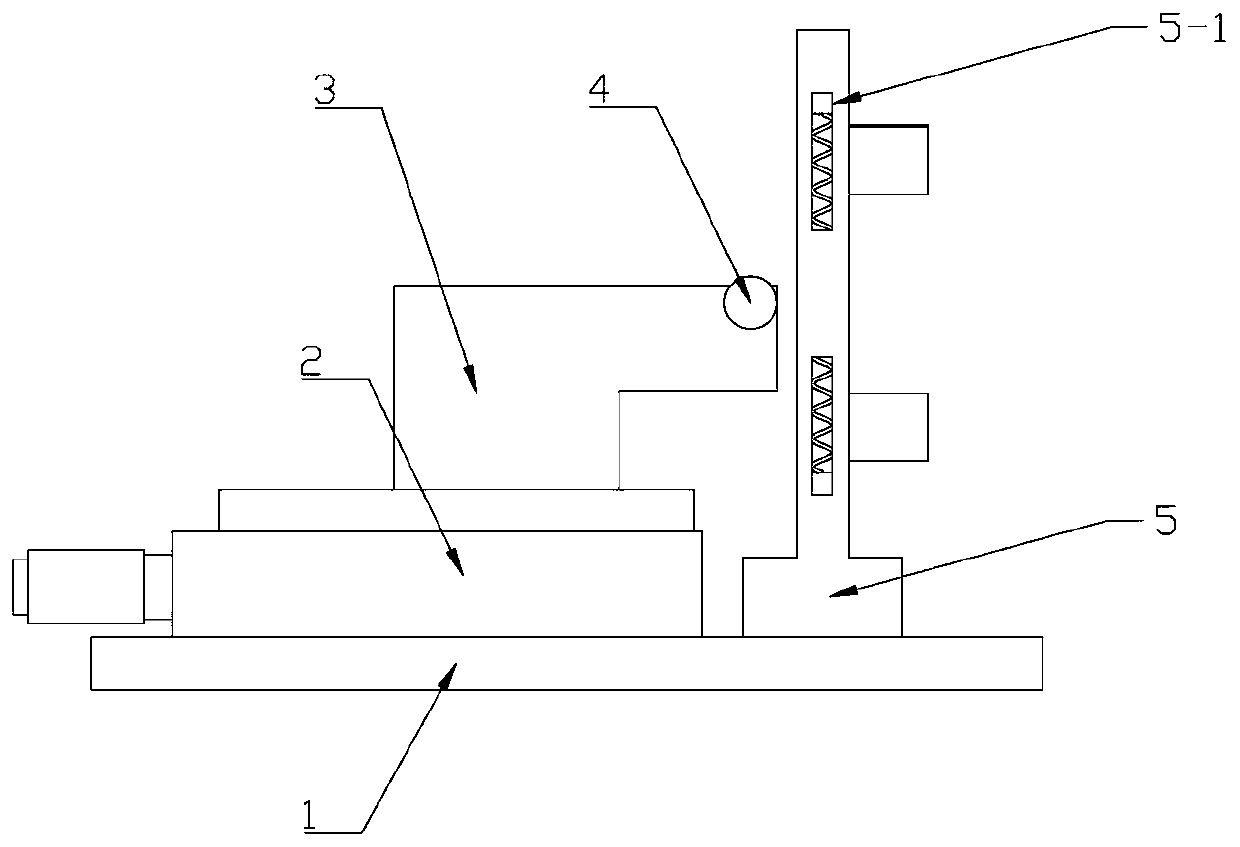

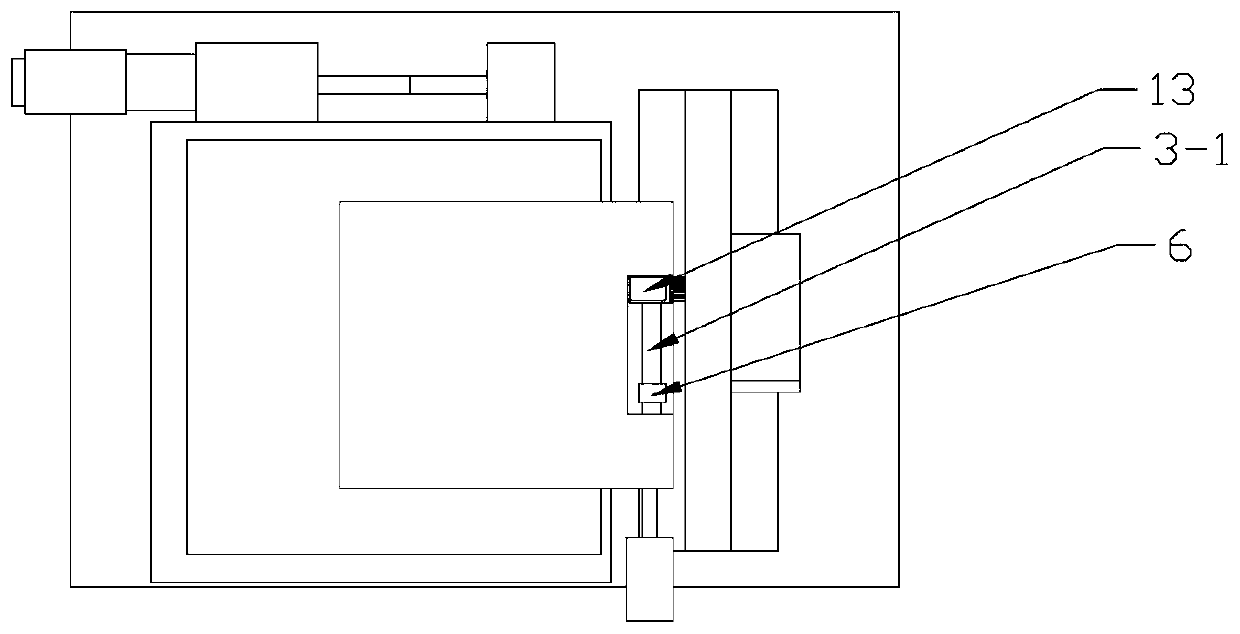

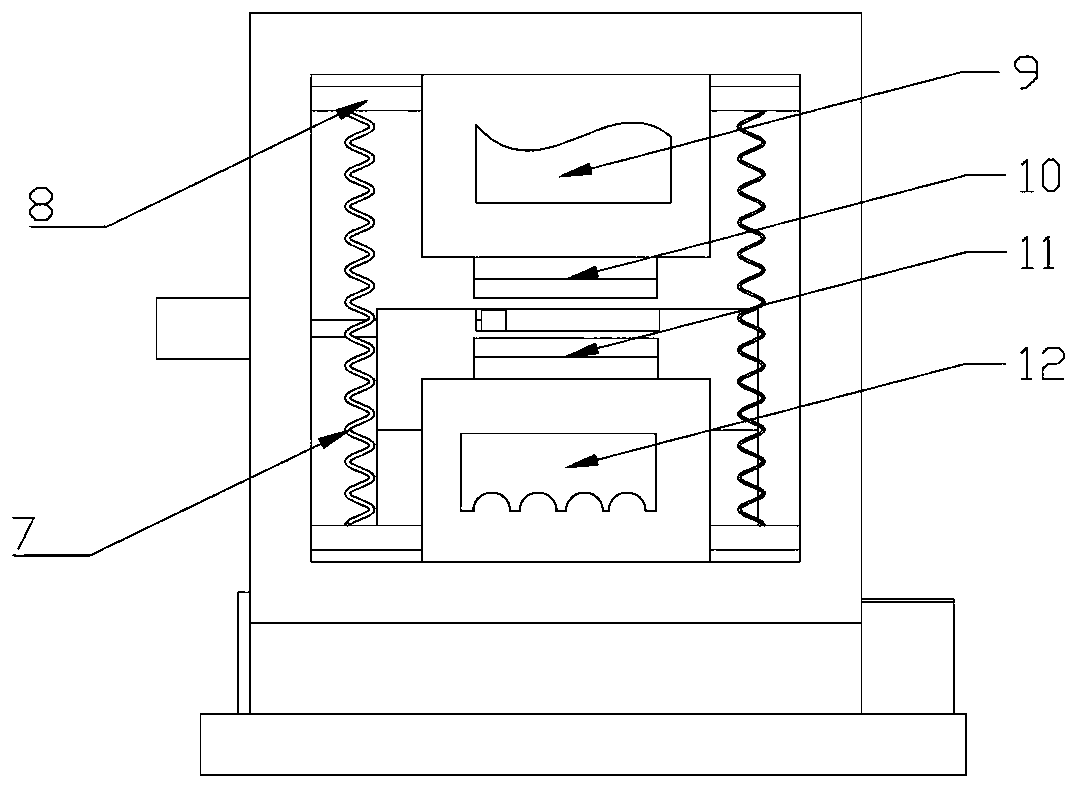

Graphite gasket equipment for slicing processing of graphite rod

ActiveCN111823413AEvenly slicedConsistent thicknessWorking accessoriesStone-like material working toolsGraphiteFinger cut

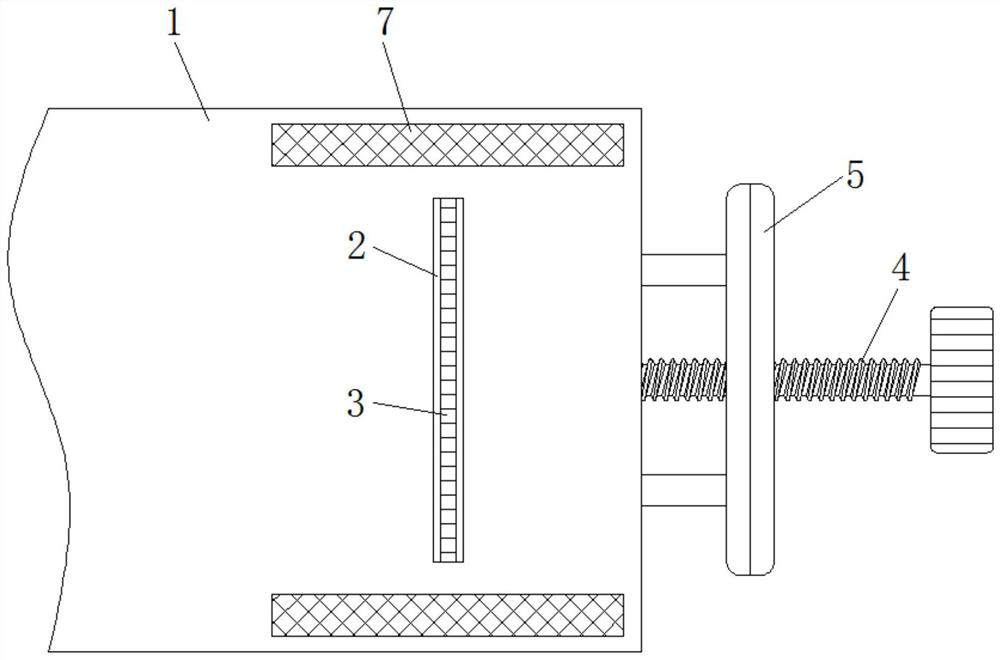

The invention relates to graphite rod processing equipment, in particular to graphite gasket equipment for slicing processing of a graphite rod. According to the graphite gasket equipment for slicingprocessing of the graphite rod, the graphite rod can be automatically and uniformly sliced. The graphite gasket equipment for slicing processing of the graphite rod comprises a working plate, an object placing plate, a mounting plate and a cutting mechanism, wherein supporting plates are both connected to the two sides of the bottom of the working plate; the object placing plate is connected to one side of the working plate; the mounting plate is connected to one side of the top of the working plate; and the cutting mechanism is arranged between the working plate, the object placing plate andthe mounting plate. According to the graphite gasket equipment, the graphite rod can be automatically and uniformly sliced through the cutting mechanism, the thicknesses of the slices are consistent,the error is reduced, the graphite rod is sliced without manually holding cutting equipment, the cut wound of the finger is prevented, and the labor intensity can be reduced.

Owner:山西博翔汇良新材料有限公司

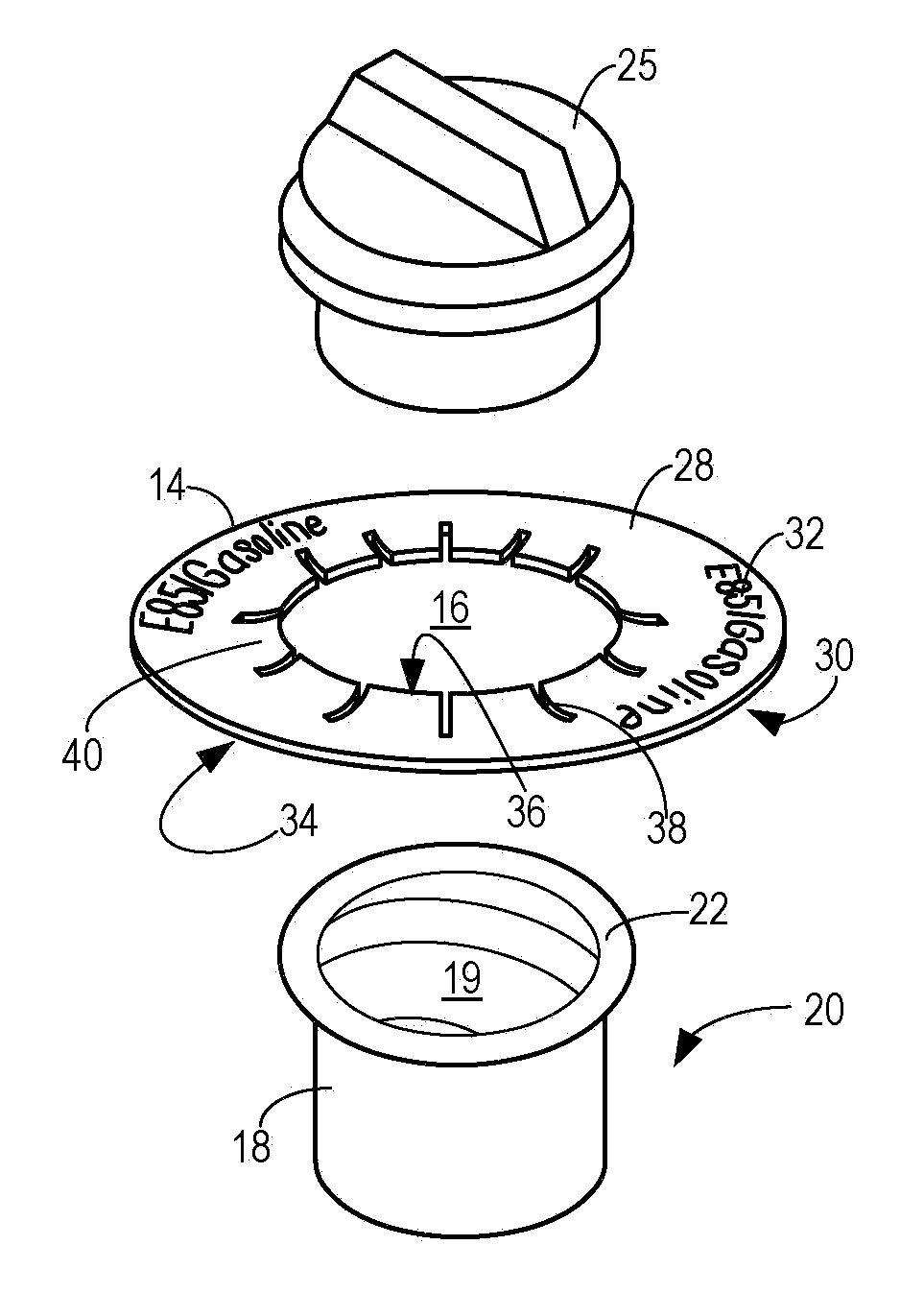

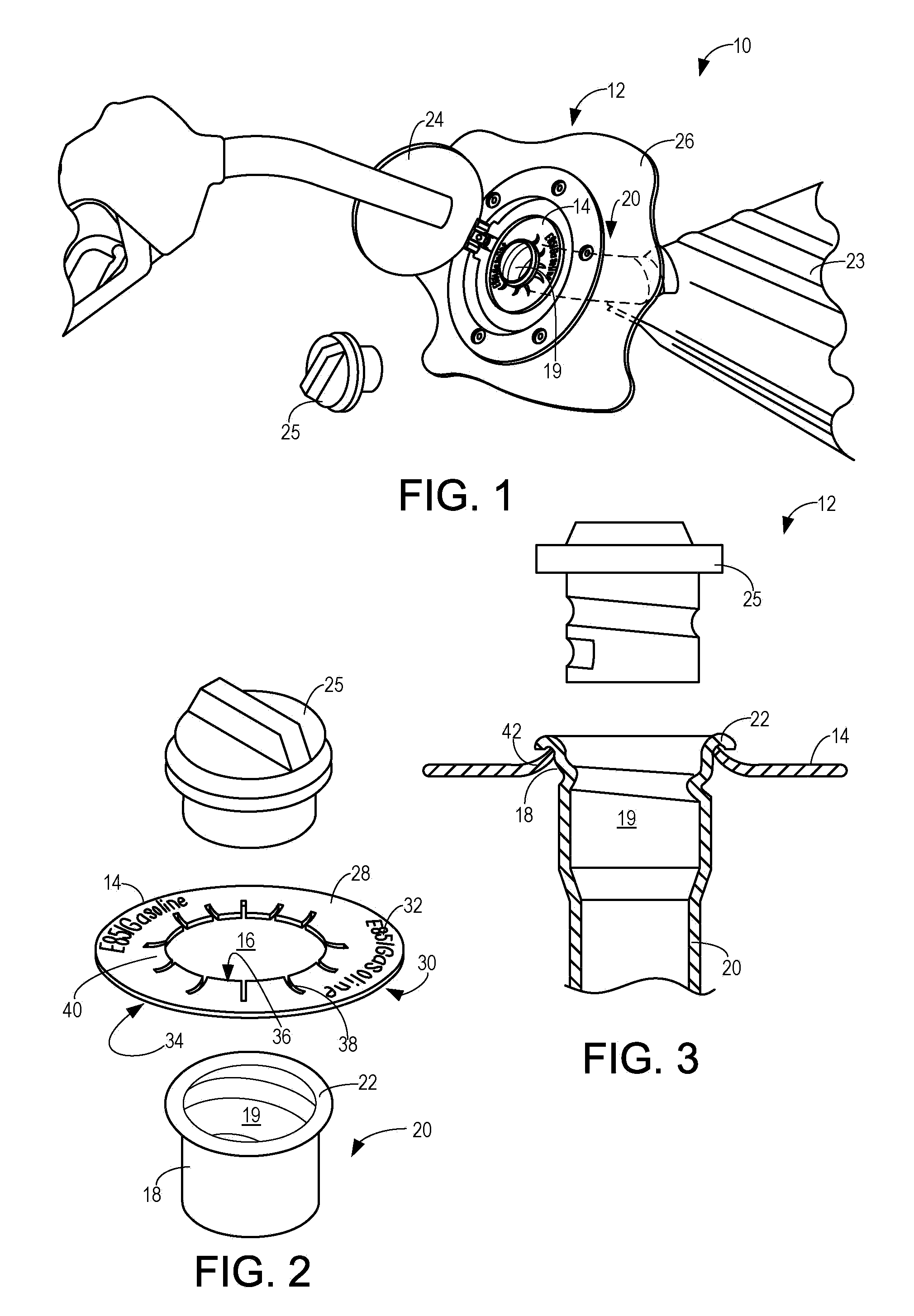

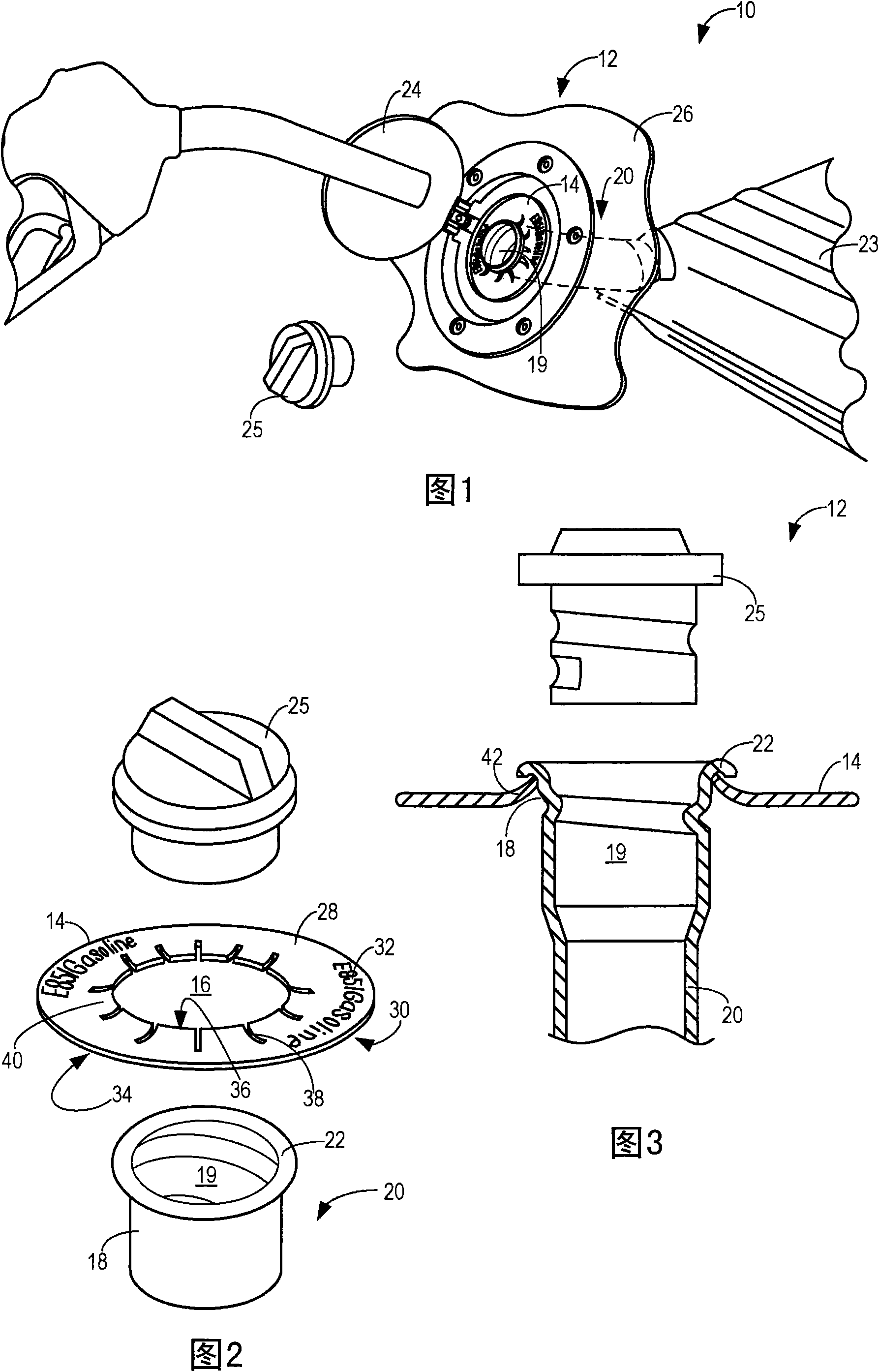

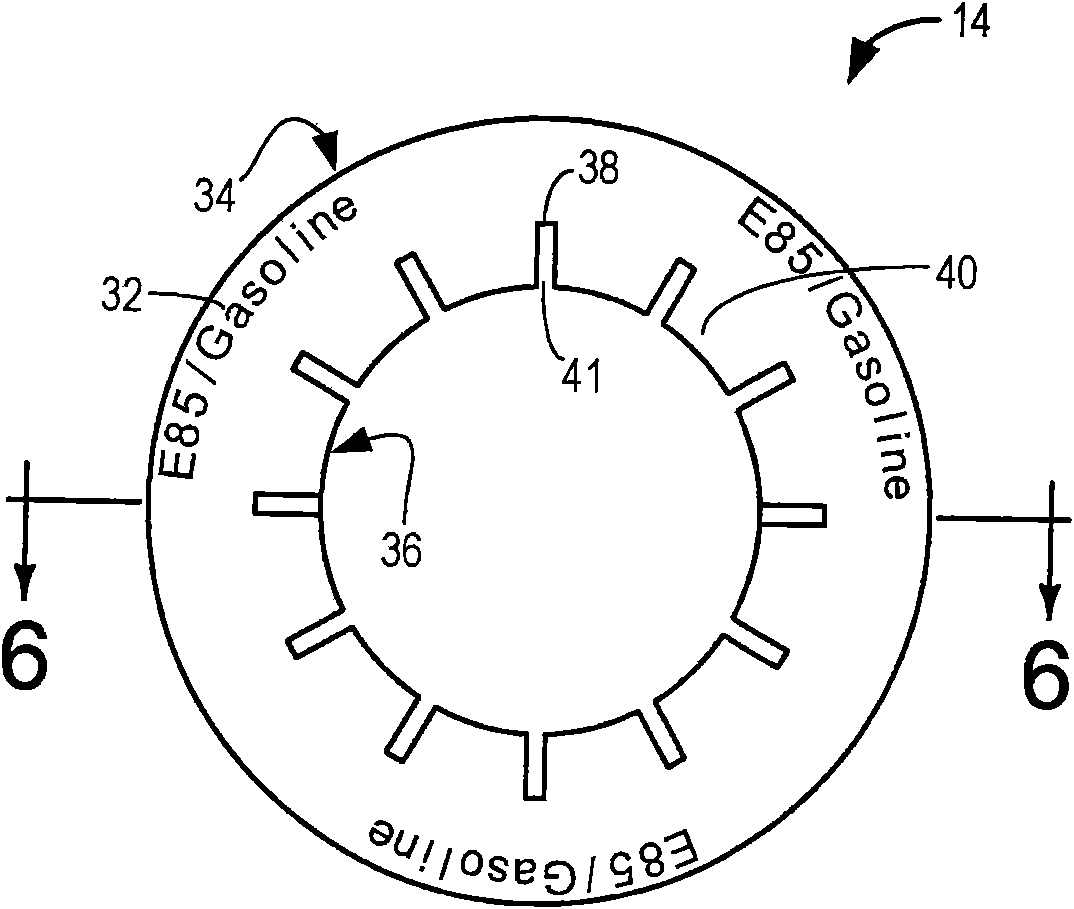

Fuel Filler Pipe Information Collar for Fuel Type Identification

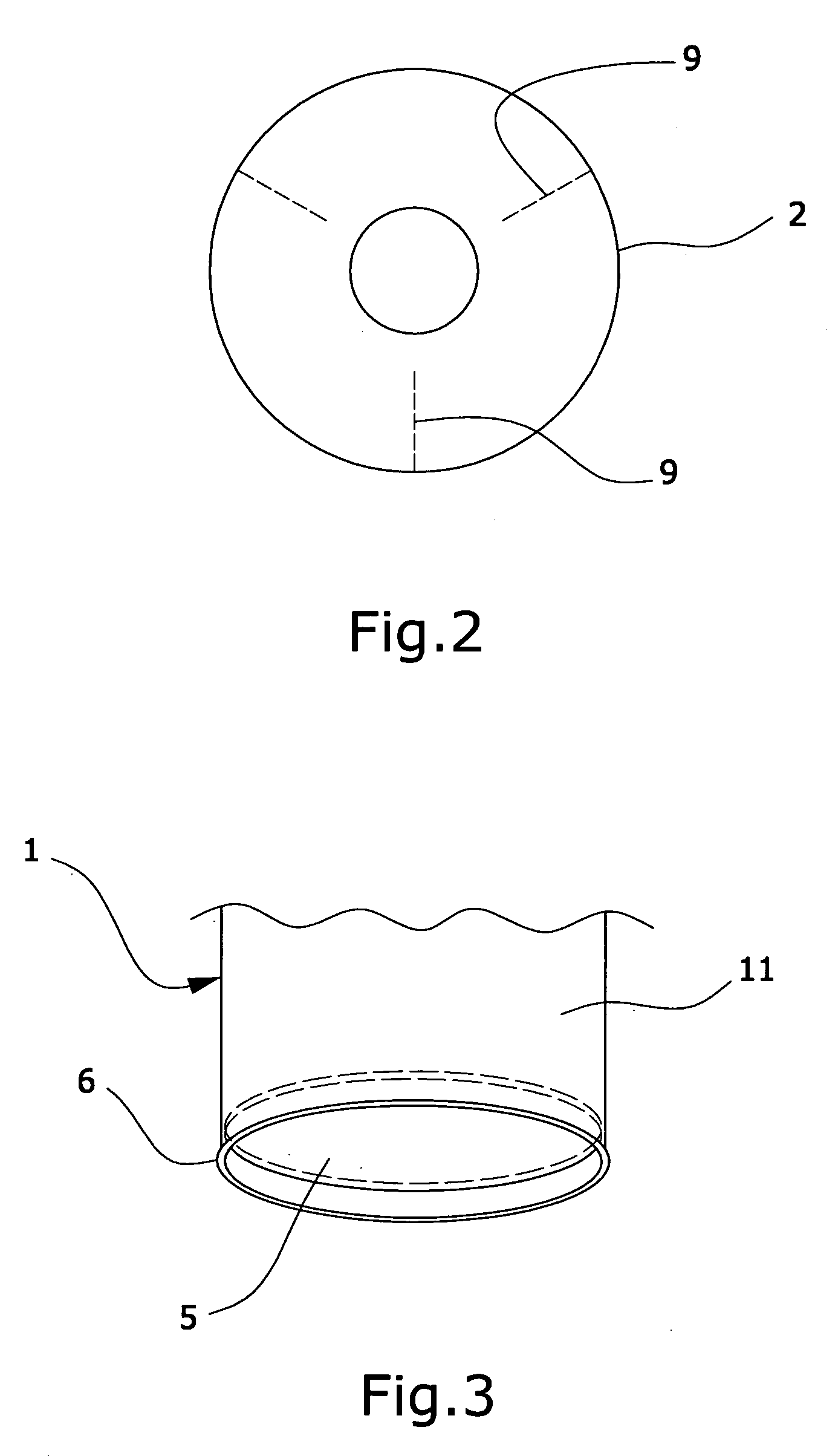

InactiveUS20090235567A1Easy to seeAvoid easy removalStampsMobile visual advertisingMobile vehicleFuel tank

A fuel type information collar is provided. The fuel type information collar is configured to engage an outer perimeter of a fuel tank filler pipe assembly of an automotive vehicle. It may include an inner perimeter defining an aperture configured to engage the outer perimeter of the fuel tank filler pipe assembly. It may additionally include a top surface including indicia of fuel type information for indicating type of fuel to be used by the automotive vehicle. It may further include a plurality of radial finger cuts angularly spaced around the inner perimeter, the plurality of radial finger cuts forming a plurality of fingers that engage the outer perimeter of the fuel tank filler pipe assembly.

Owner:FORD GLOBAL TECH LLC

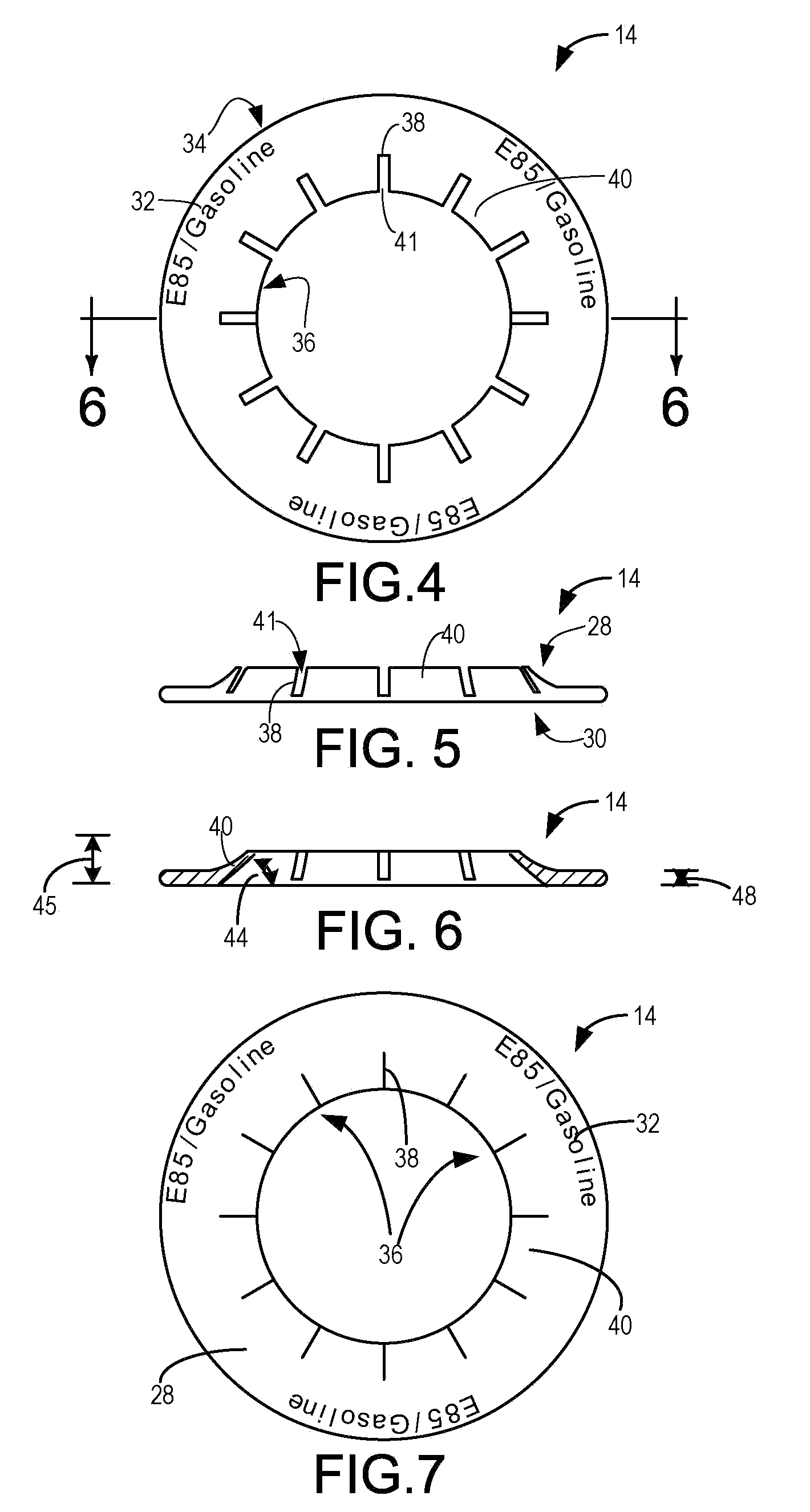

Optical module connecting finger cut-off position anti-electroplating ink pattern structure

PendingCN109195323AUse less materialReduce manufacturing costPrinted circuit aspectsElectrical connection printed elementsOptical ModuleEtching

A cut-off position anti-electroplating ink pattern structure of a connecting finger of an optical module comprises an anti-electroplating ink, wherein the anti-electroplating ink is arranged on the cut-off position of the connecting finger; Characterized by. The anti-electroplating ink is H-shaped and comprises a waist, a left part and a right part, wherein the left part and the right part are connected through the waist, the waist part is arranged at the cut position of the connecting finger, the left part and the right part are arranged at the spacing between the connecting finges, and the left part and the right part of the anti-electroplating ink are provided with grooves for improving the anti-electroplating ink developing ability. The invention utilizes H-type anti-electroplating inkpattern structure, the developing ability of the developing solution is improved. The invention reduces the abnormality of electroplating ink shedding and gold infiltration in the production and processing process of the cut connecting finger, improves the etching lead wire, solves the short circuit at the cut place of the connecting finger caused by the abnormality of the etching, improves the production yield of the product, and has simple design and good use effect.

Owner:深圳欣强智创电路板有限公司

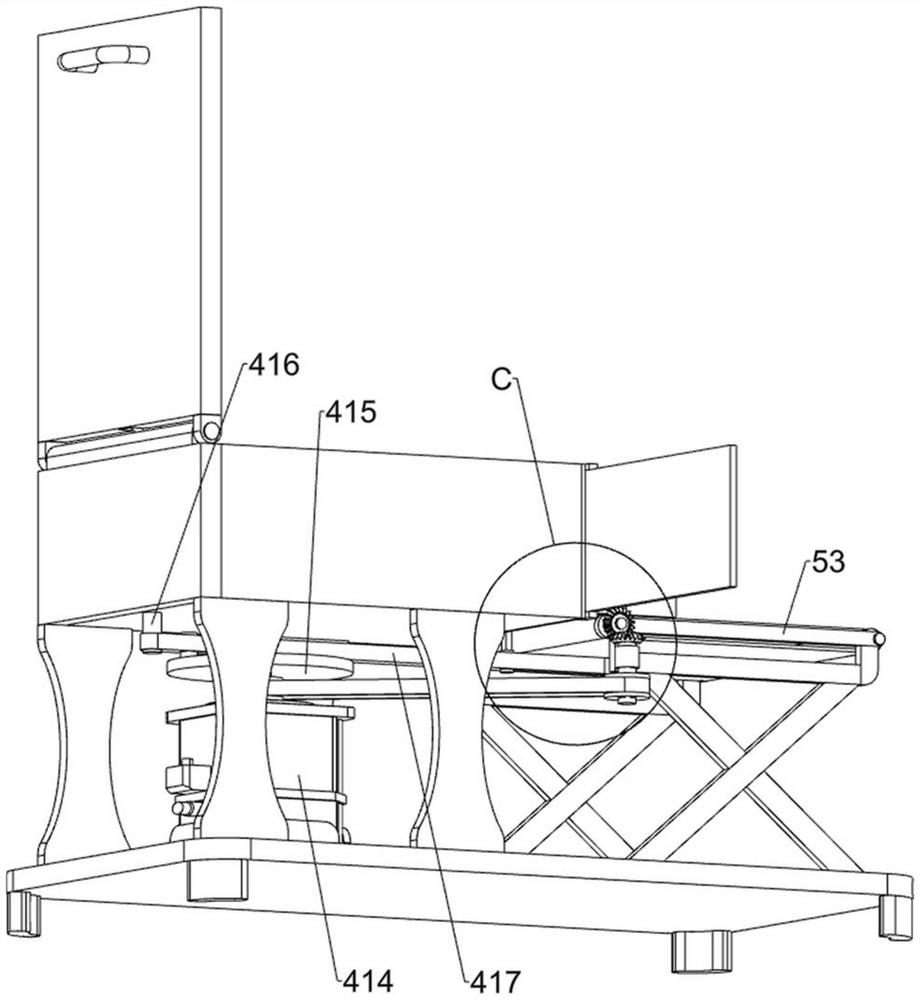

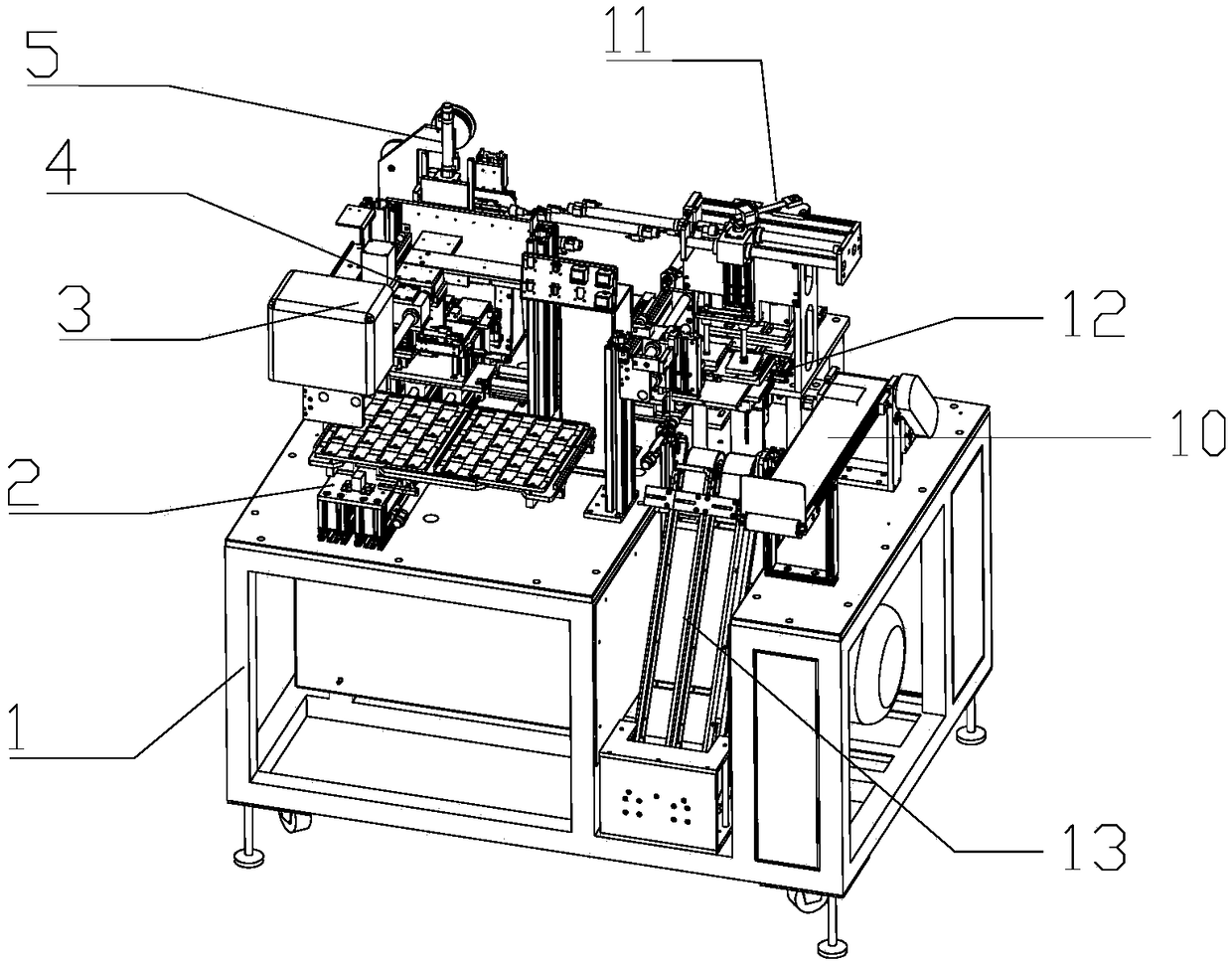

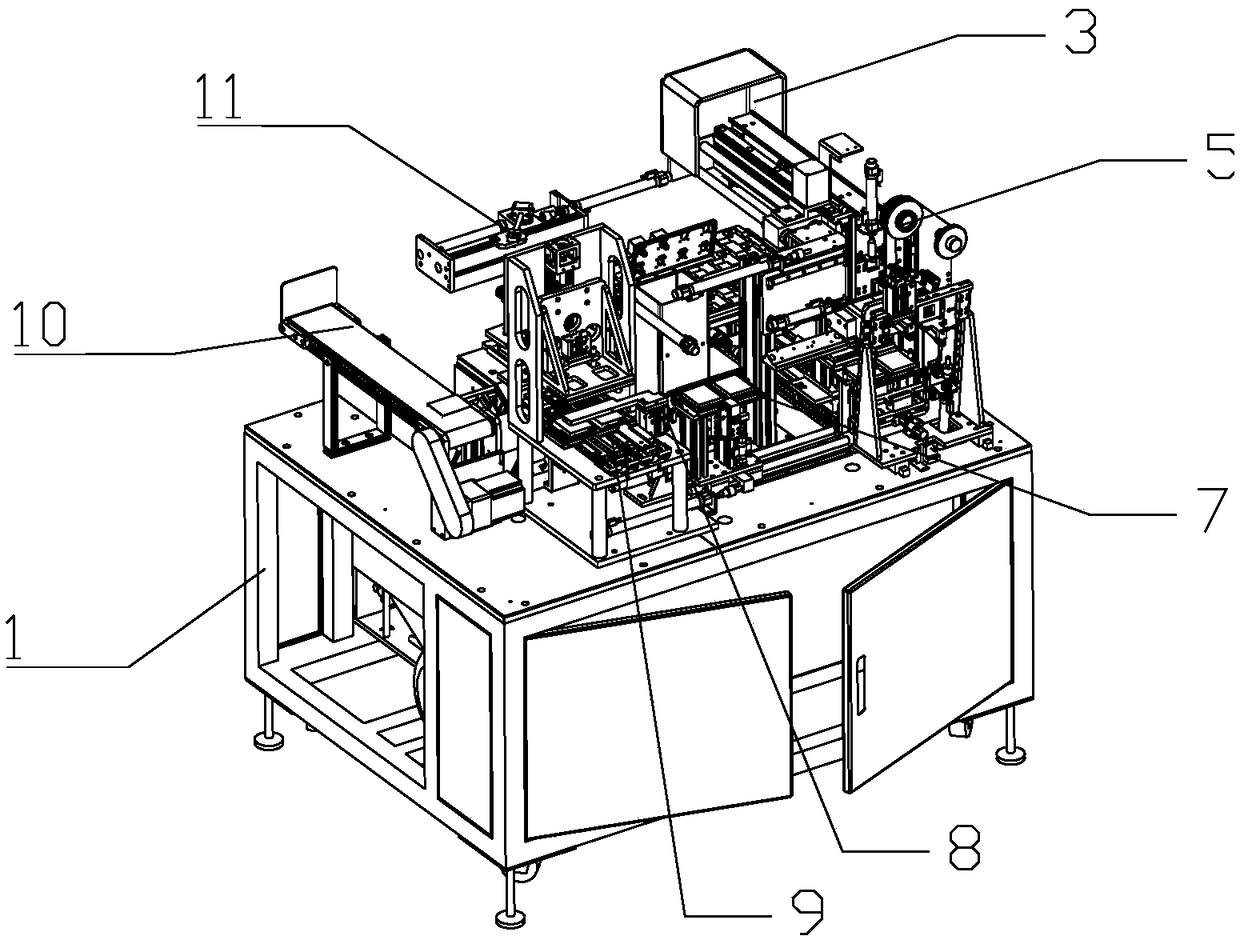

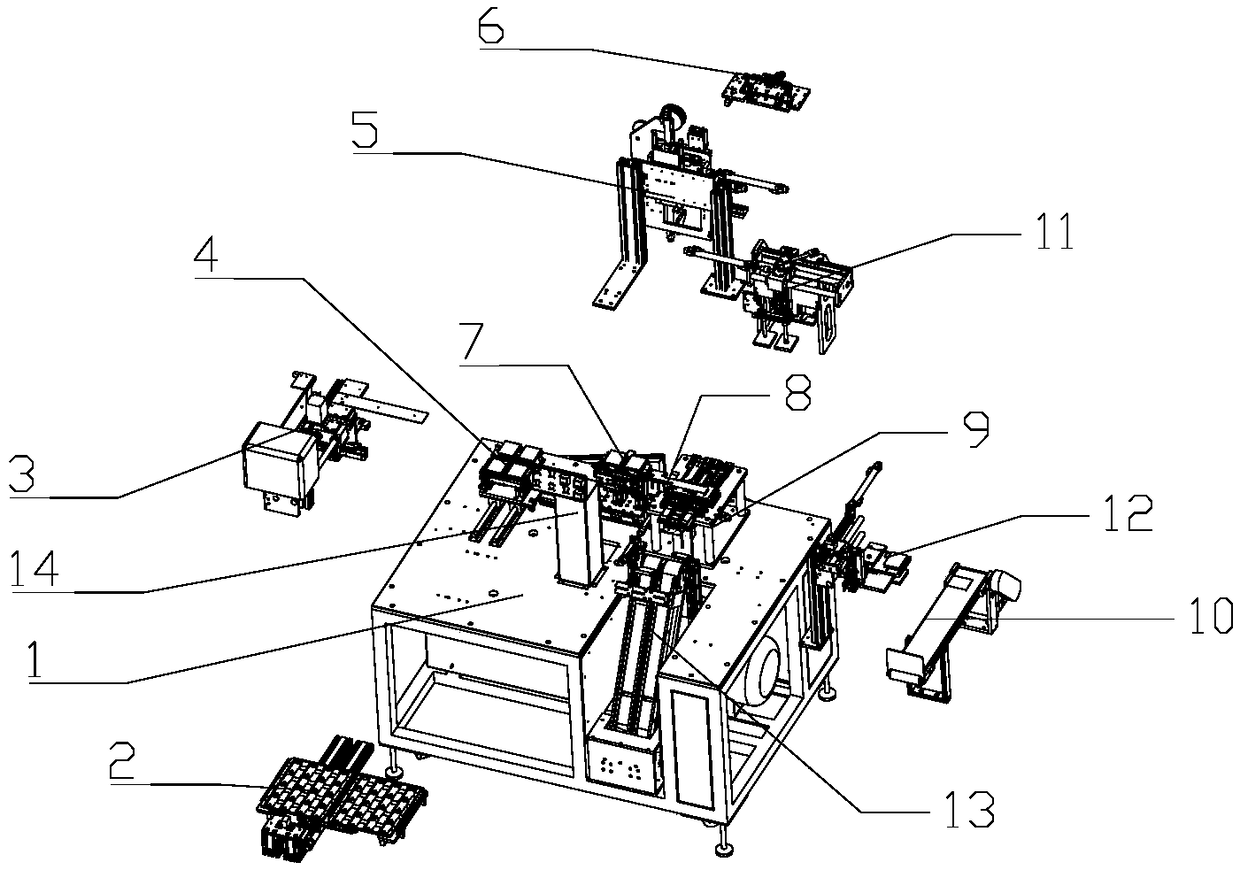

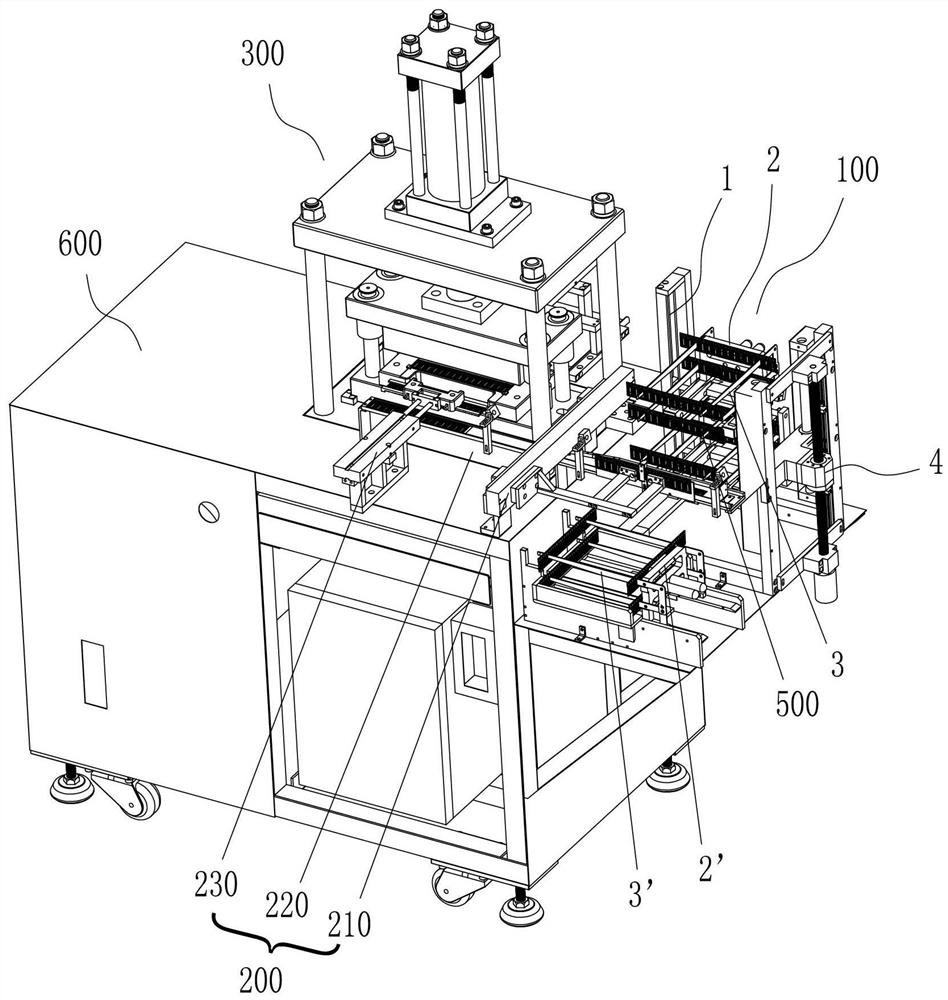

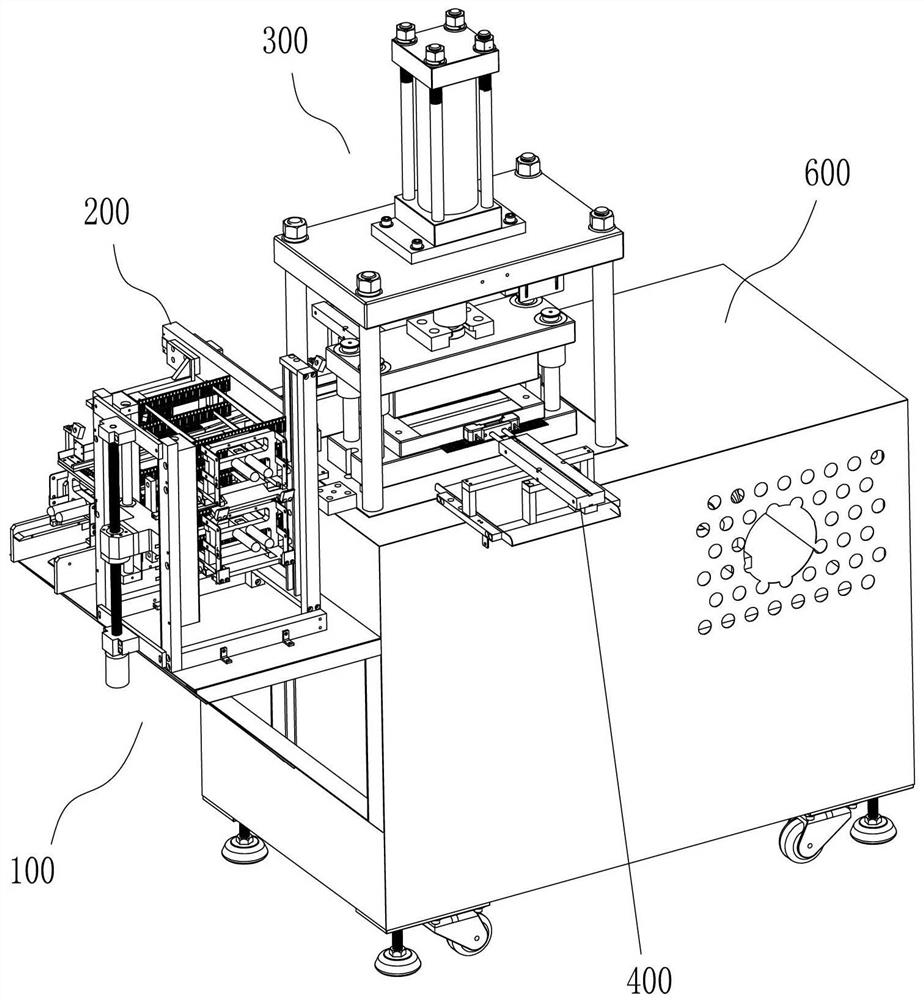

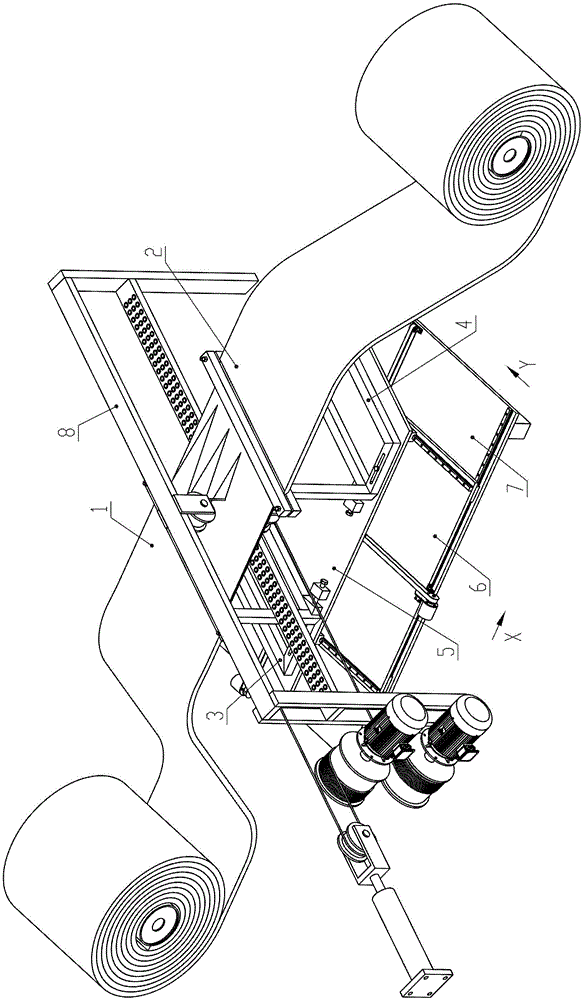

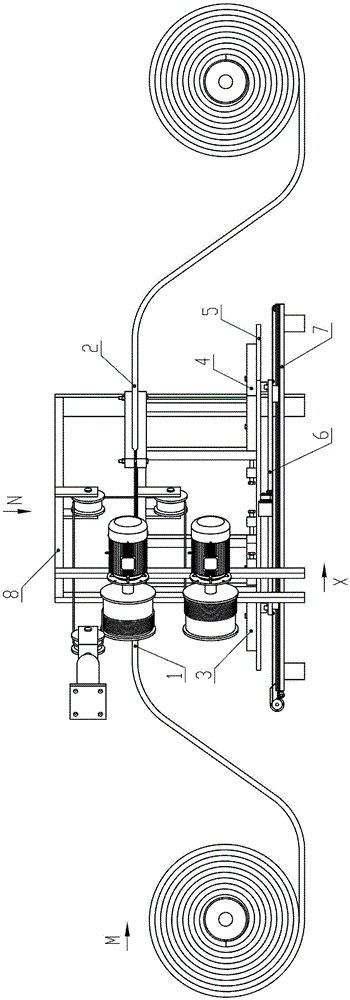

An automated method for adhesive packaging of new energy lithium battery cells

ActiveCN108306054BIntelligent productionIncrease the level of automationFinal product manufactureElectrolyte accumulators manufactureNew energyAutomated method

The invention relates to the field of new energy, in particular to an automatic method for adhesive packaging of new energy lithium battery cells. An automatic method for adhesive packaging of new energy lithium battery cells. The equipment used in the method includes a frame assembly, a cell material tray device, a cell handling device, a first workbench, an adhesive tape fixed-length cutting device, and an adhesive tape Adhesive device, translational transfer device, flip transfer device, second workbench, aluminum shell feeding device, aluminum shell handling device, battery unloading device, finished product blanking device and control assembly; this method simultaneously completes the square lithium-ion cell Paste the bottom adhesive tape and automatically put the battery cells into the aluminum shell, which improves the automation level and makes the production of square lithium batteries more intelligent.

Owner:扬州兴通锂电科技有限公司

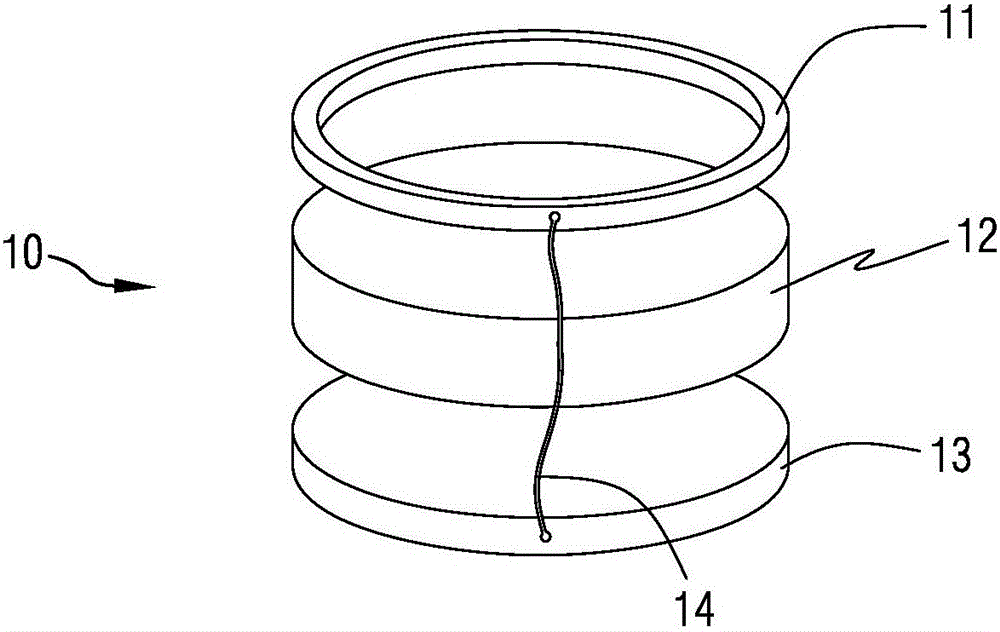

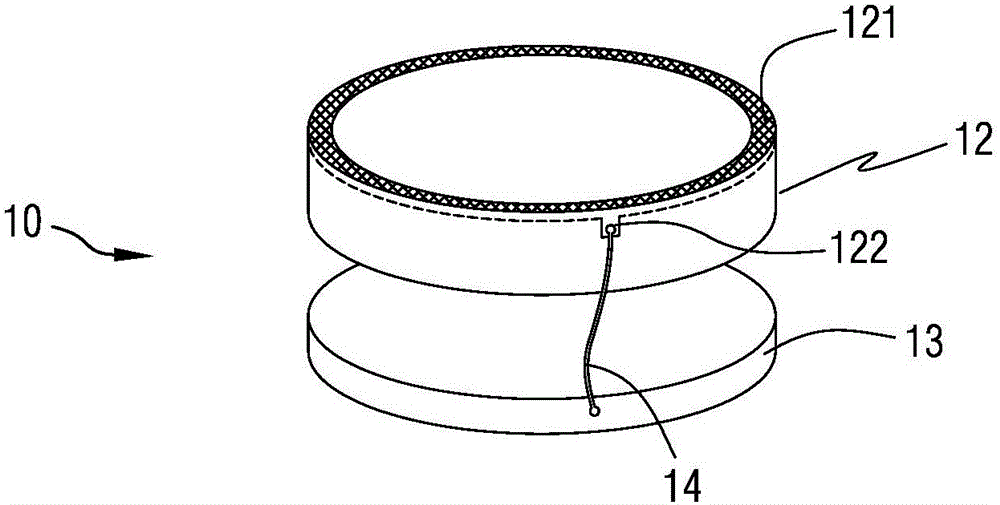

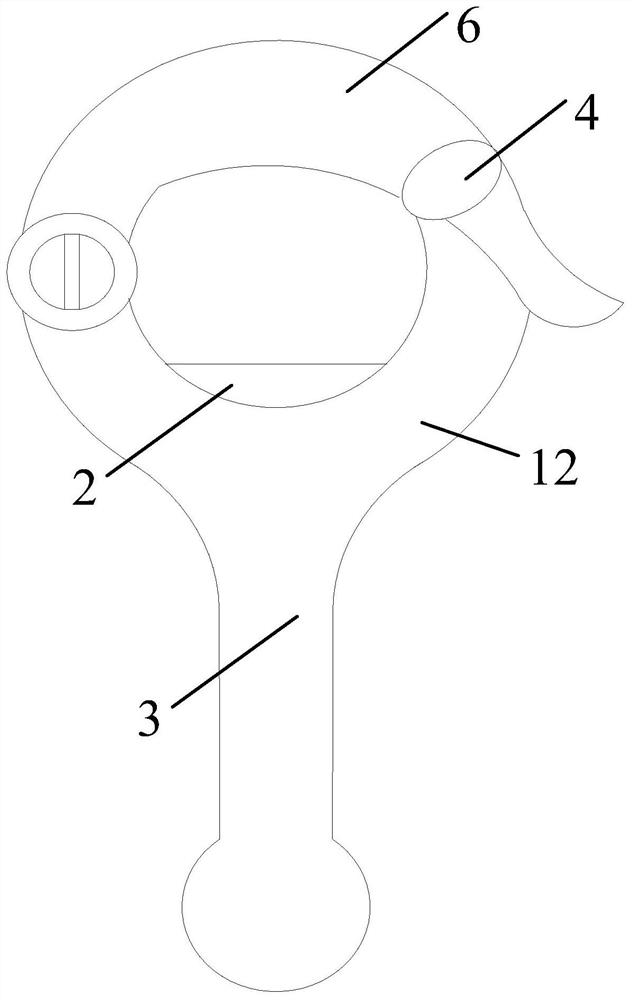

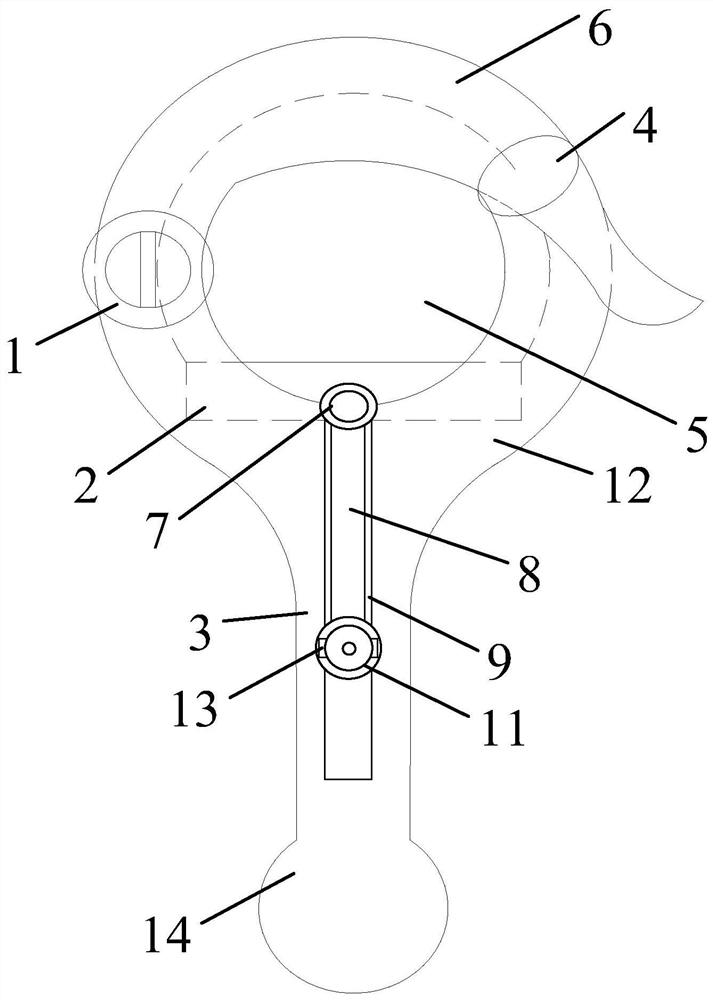

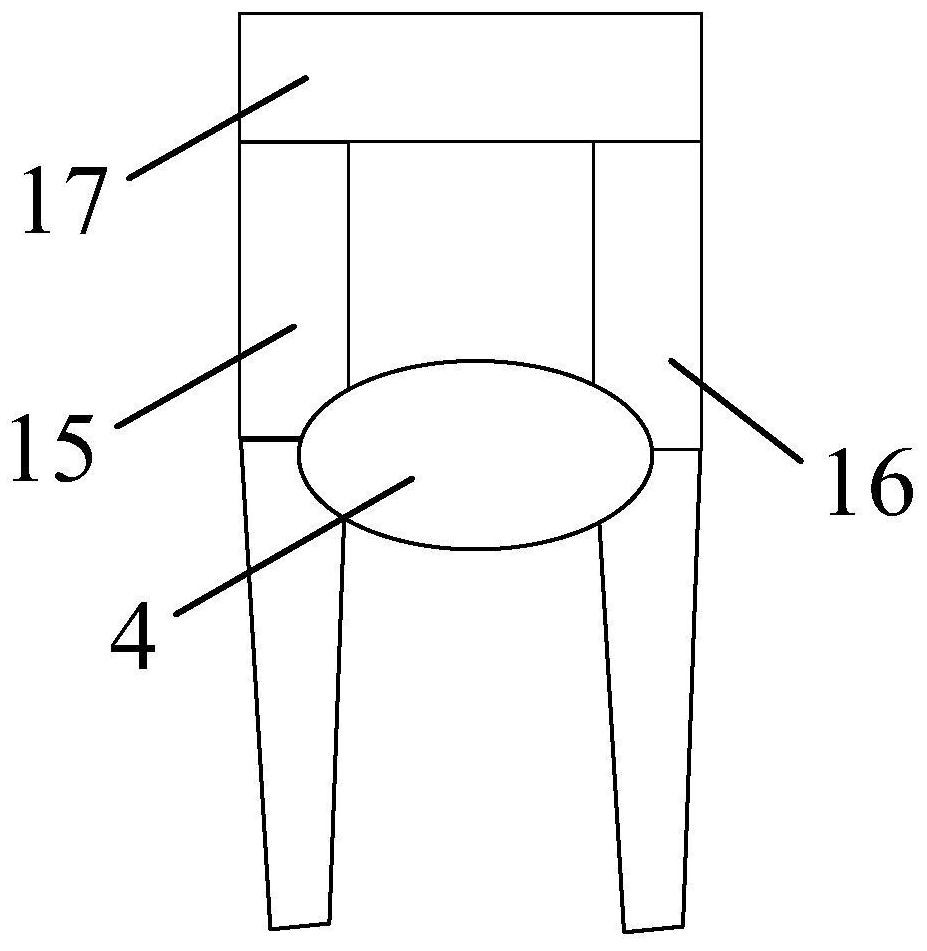

Fingerprint identification module

ActiveCN105069422AAvoid height differenceFew structural partsCharacter and pattern recognitionHeight differenceEngineering

The present invention provides a fingerprint identification module. The fingerprint identification module (10) comprises a ceramic cover plate (12) and a fingerprint identification chip (13) which are arranged from top to bottom. An annular conductive part (121) is integratedly formed at the outer edge of the upper surface of the ceramic cover plate (12). The annular conductive part (121) and the fingerprint identification chip (13) are connected through a conductive wire (14). According to the fingerprint identification module, through integratedly forming the annular conductive part (121) with a conductive function at the outer edge of the upper surface of the ceramic cover plate, the annular conductive part can substitute a metal ring to realize the function of the metal ring, the problem of a height difference brought by the existence of the metal ring is avoided completely, the problems of finger cut by protruding edges and dust dead corners do not exist, structural parts are reduced, the problem of an assembly error is completely avoided, and the product precision is improved while the cost is saved.

Owner:CERMATEC MATERIAL TECH

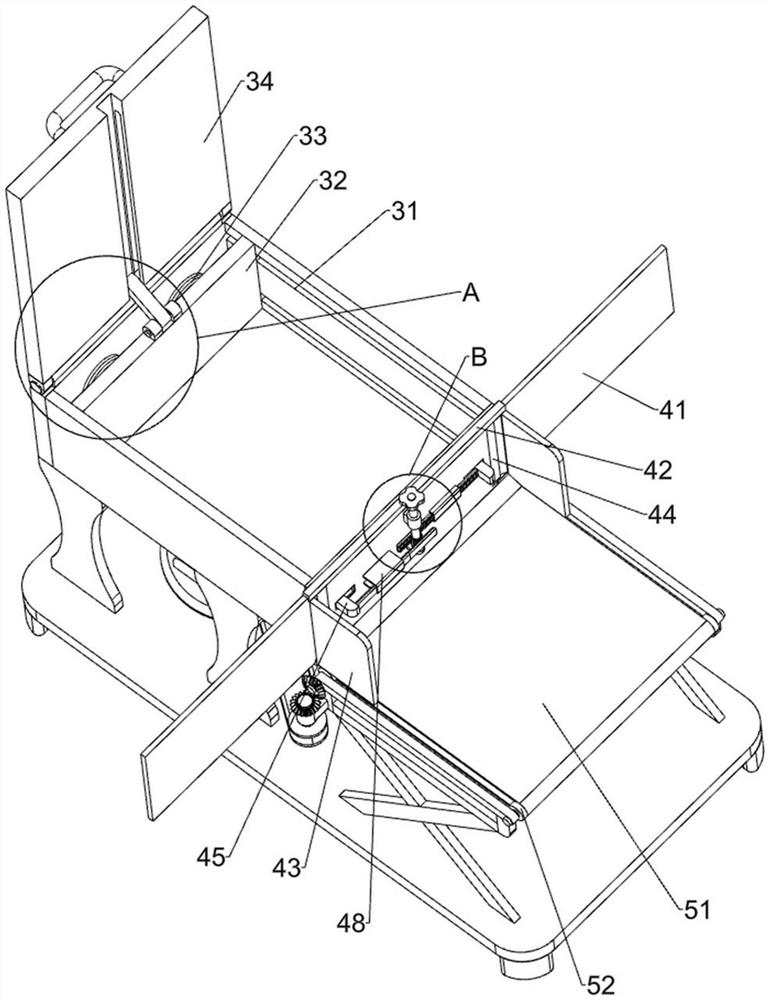

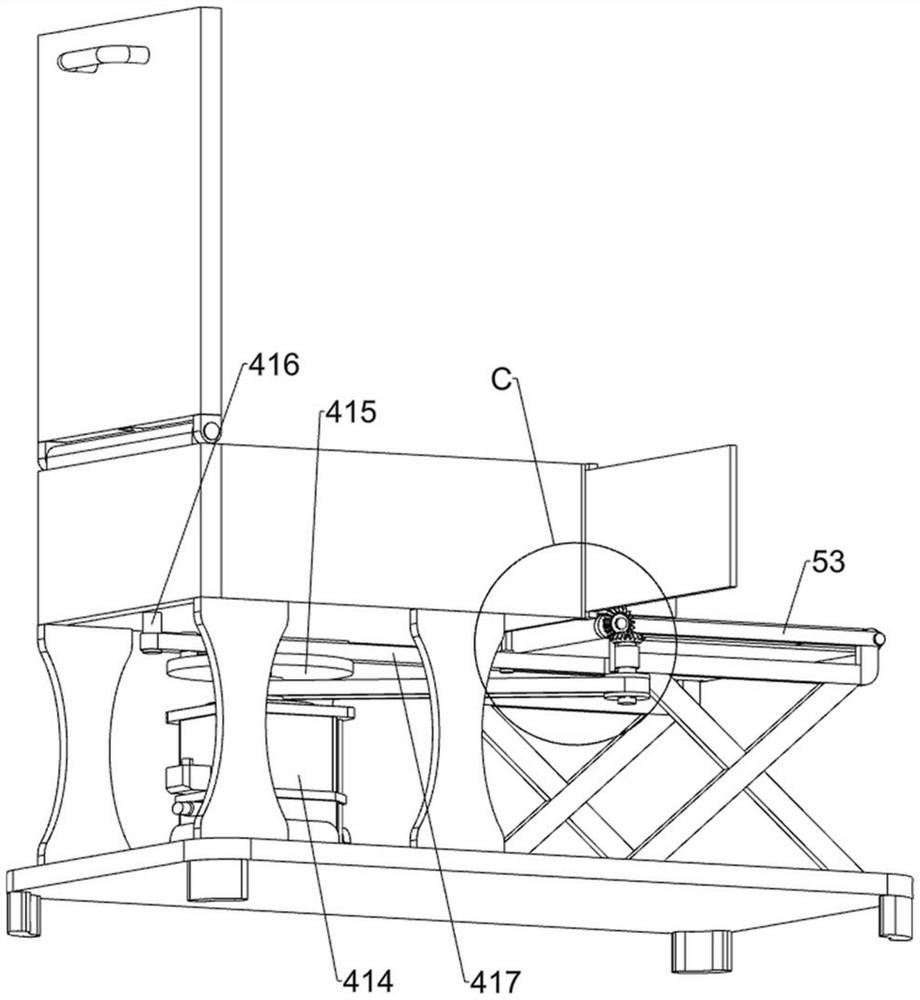

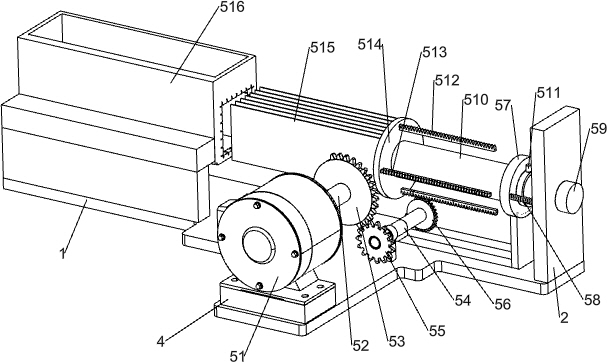

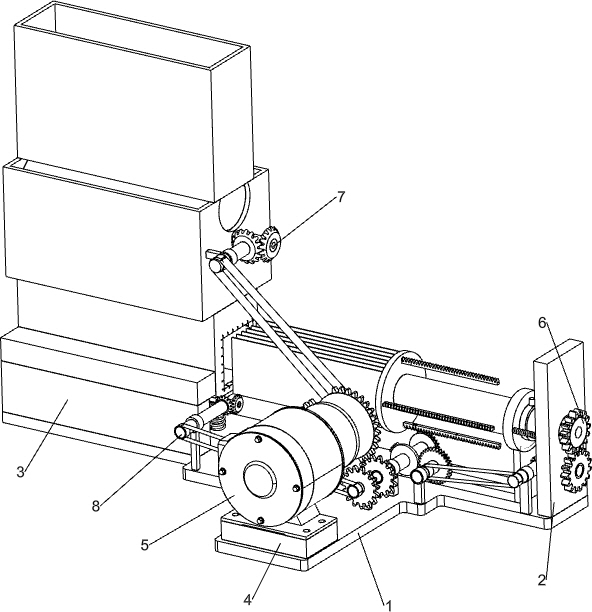

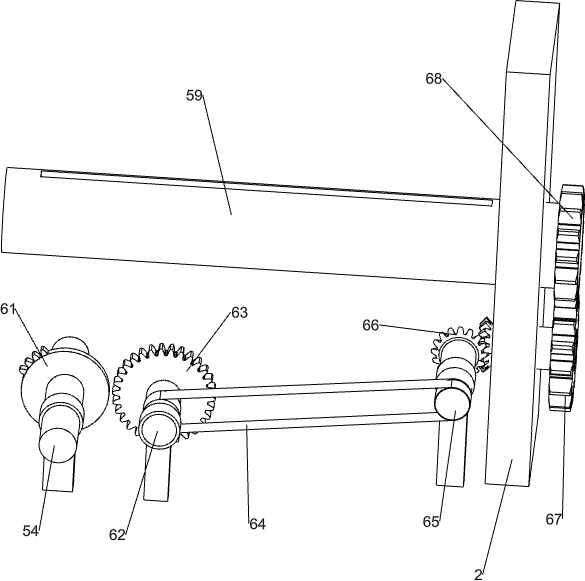

A graphite rod slice processing graphite gasket equipment

ActiveCN111823413BEvenly slicedConsistent thicknessWorking accessoriesStone-like material working toolsEngineeringGraphite

The invention relates to graphite rod processing equipment, in particular to graphite rod slice processing graphite gasket equipment. The invention provides a graphite rod slicing processing graphite gasket equipment capable of automatically and uniformly slicing graphite rods. The invention provides such a graphite rod slicing processing graphite gasket equipment, comprising: a working plate, the bottom two sides of which are connected with support plates; a storage plate, one side of the working plate is connected with a storage plate; The side is connected with a mounting plate; a cutting mechanism is installed between the operation plate, the storage plate and the mounting plate. The invention can automatically slice the graphite rod through the cutting mechanism, and can uniformly slice the graphite rod, so that the thickness of the slice is consistent, and the error is reduced, so that manual hand-held cutting equipment is not required to slice the graphite rod, and the fingers can be prevented from being cut. , can reduce labor intensity.

Owner:山西博翔汇良新材料有限公司

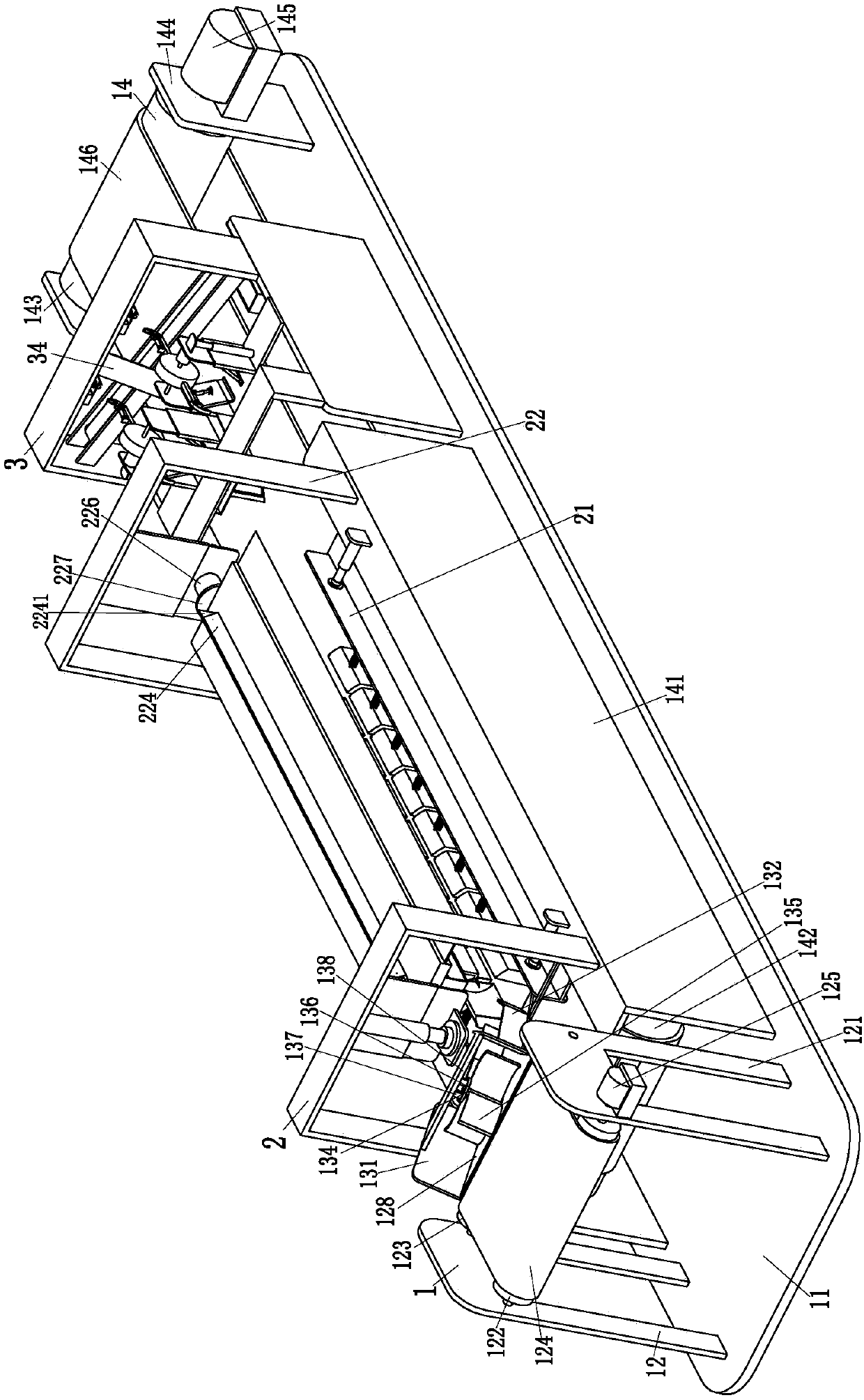

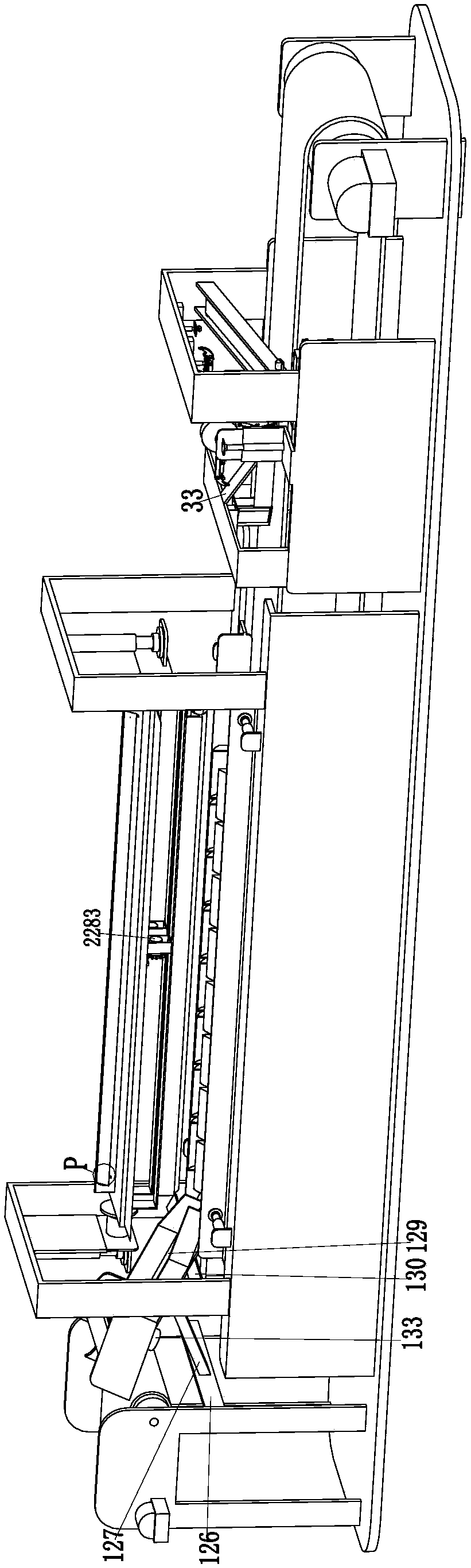

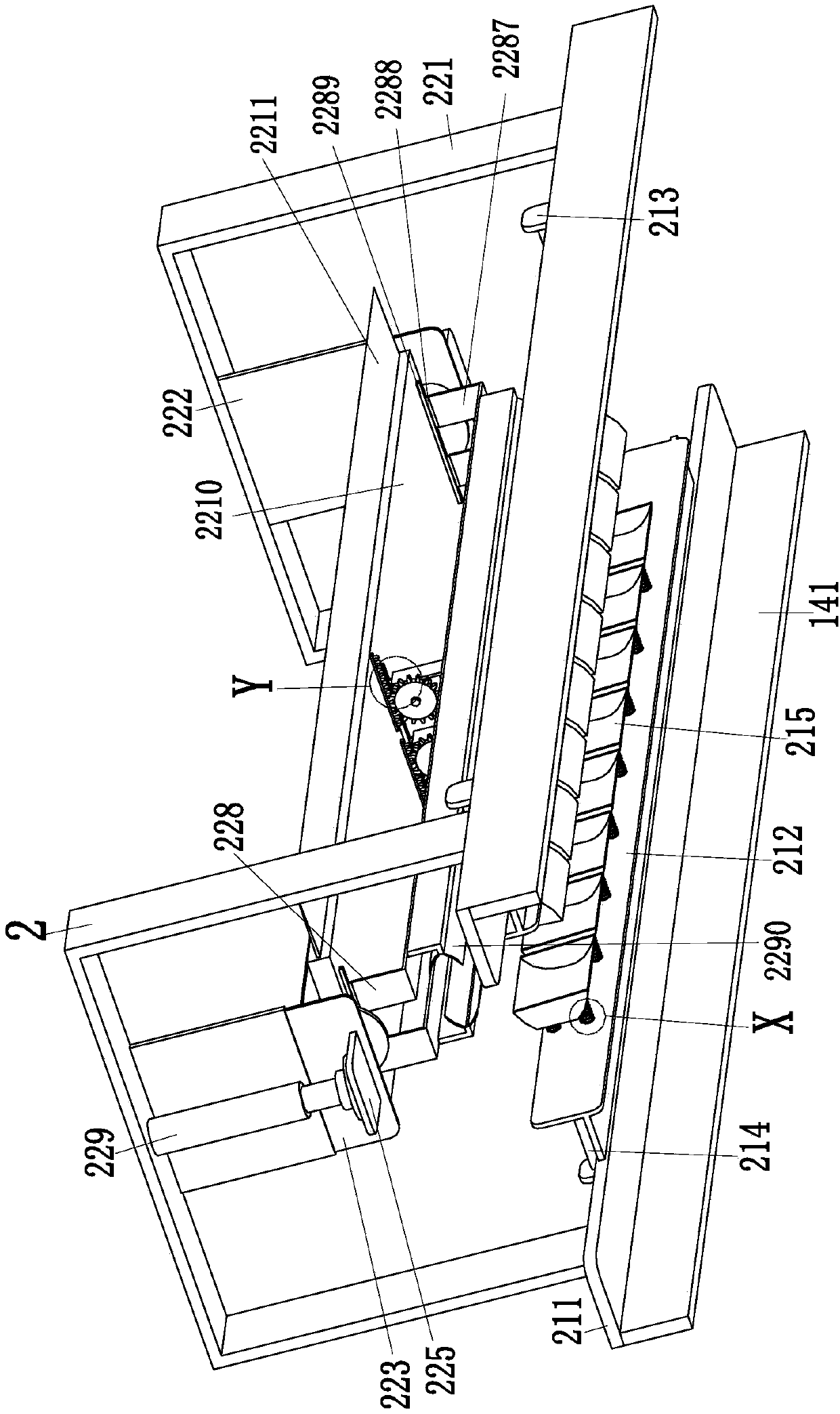

Meat slicer for food processing

ActiveCN111844210BReduce laborAvoid sorenessMetal working apparatusMeat processing devicesProcess engineeringFood processing

The invention relates to a slicer for food processing, in particular to a meat slicer for food processing. The invention provides a meat product slicer for food processing which does not need to manually hold a kitchen knife to slice meat products. The invention provides such a meat product slicer for food processing, comprising: a base, four support frames are symmetrically connected to one side of the base; a material pushing mechanism is installed between the support frame and the base; a slicing mechanism, A slicing mechanism is installed on the pushing mechanism. The present invention can push the meat products to move to the right through the pushing mechanism, and can slice the meat products moving to the right through the slicing mechanism, so that there is no need to manually hold a kitchen knife to slice the meat products, thereby reducing the labor load of workers and preventing the arm Soreness, to prevent cutting fingers.

Owner:江西谷纬科技有限公司

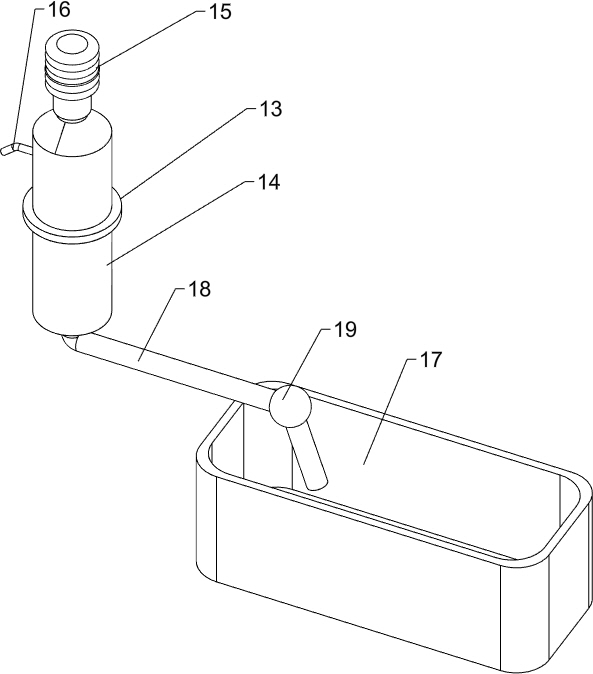

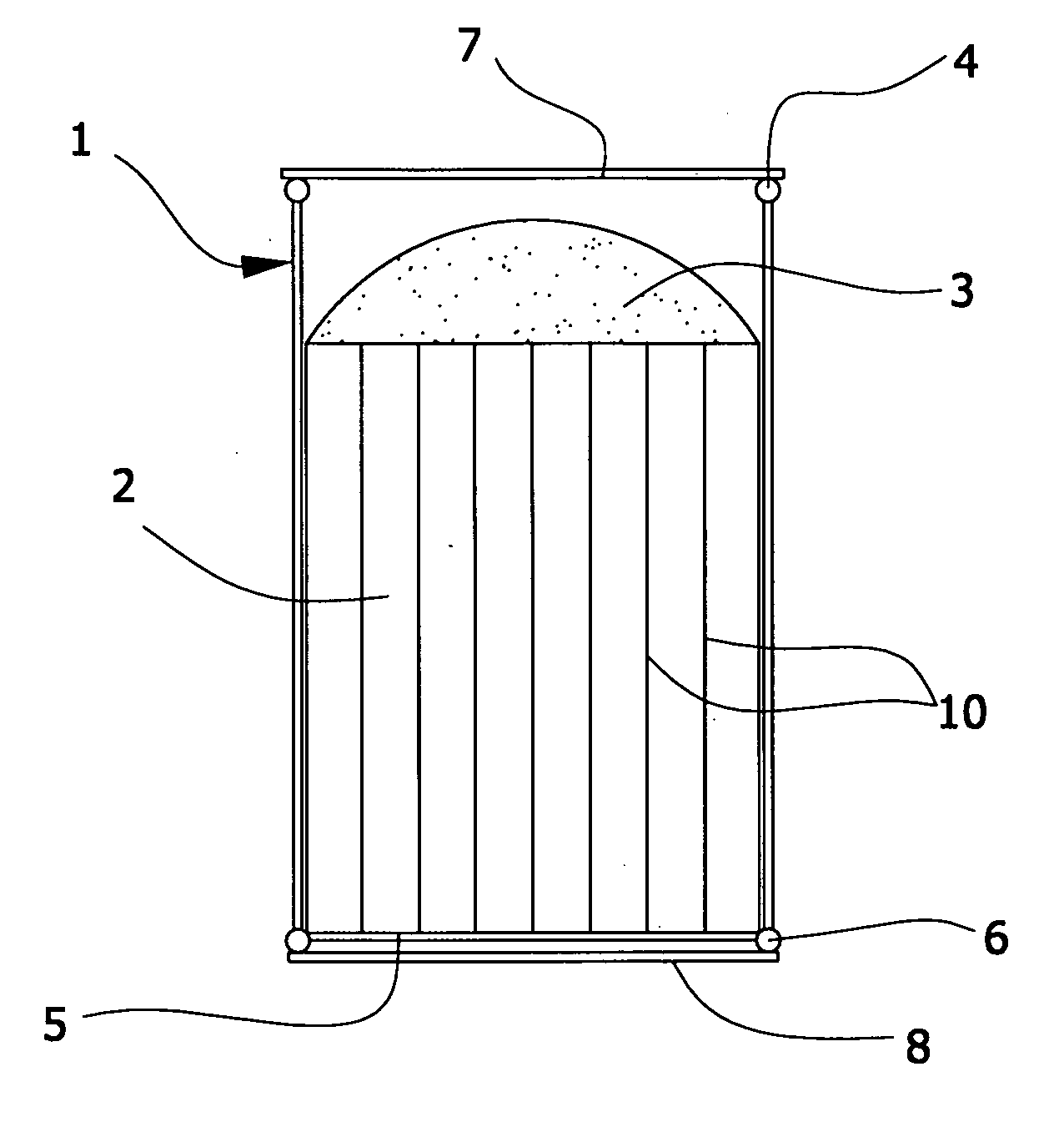

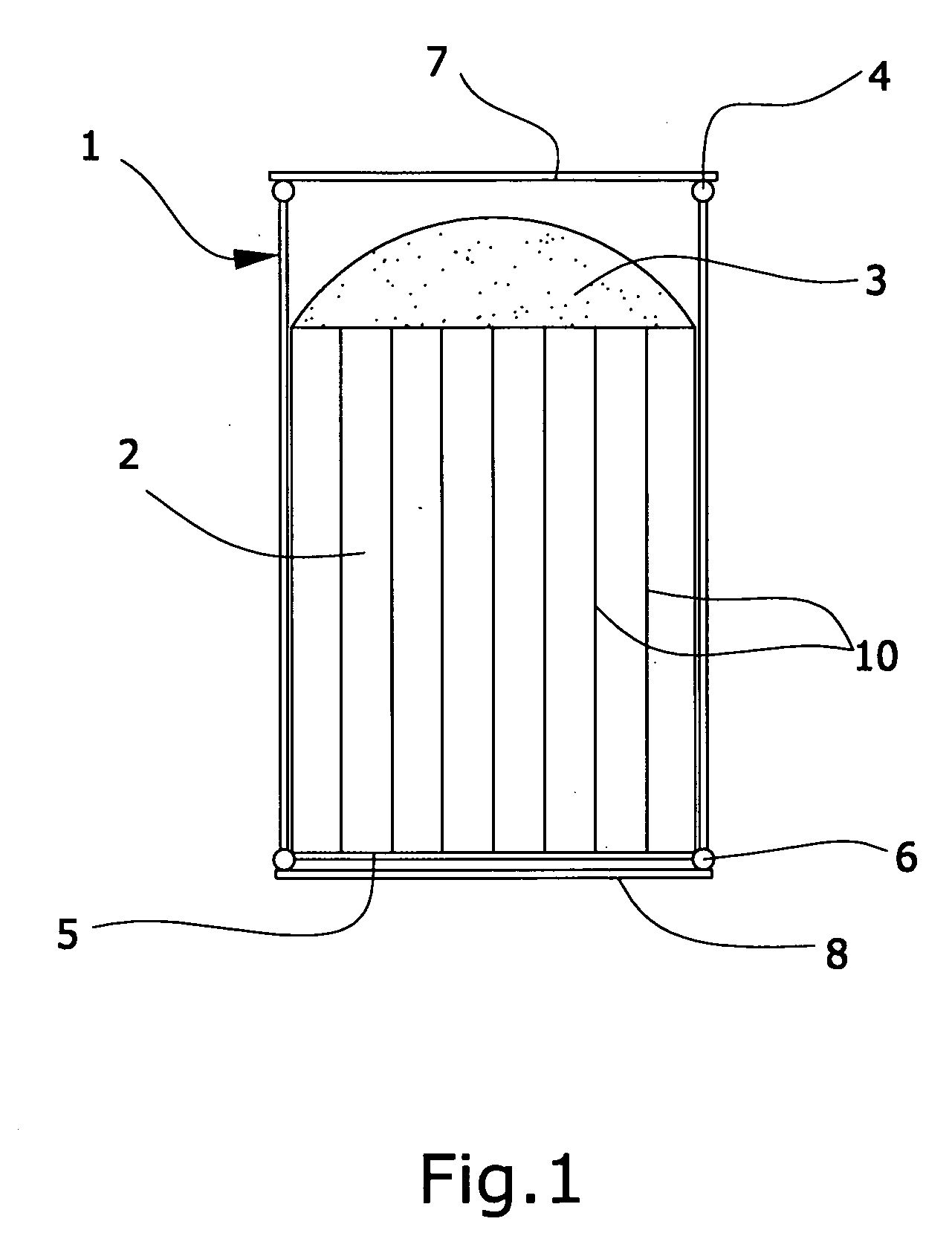

Plantain core slicing device

The invention relates to a slicing device, in particular to a plantain core slicing device. The technical aim to be achieved by the invention is to provide the plantain core slicing device capable ofprotecting fingers of people and preventing the fingers from being cut. In order to achieve the technical aim, the plantain core slicing device provided by the invention comprises a bottom plate, a fixing plate, a collecting box, a cutting device and a feeding device, a supporting column is connected onto the bottom plate, the fixing plate is connected onto the supporting column, and the side, close to the supporting column, of the bottom plate is connected with the collecting box; the cutting device is mounted on one side of the fixing plate; and the feeding device is mounted at the end partof the fixing plate. By means of the feeding device, plantain cores can move rightwards, the cutting device can slice the plantain cores moving rightwards, and therefore the plantain cores do not needto be sliced manually with a kitchen knife, and the effects of protecting the fingers of people and preventing the fingers from being cut are achieved.

Owner:王发云

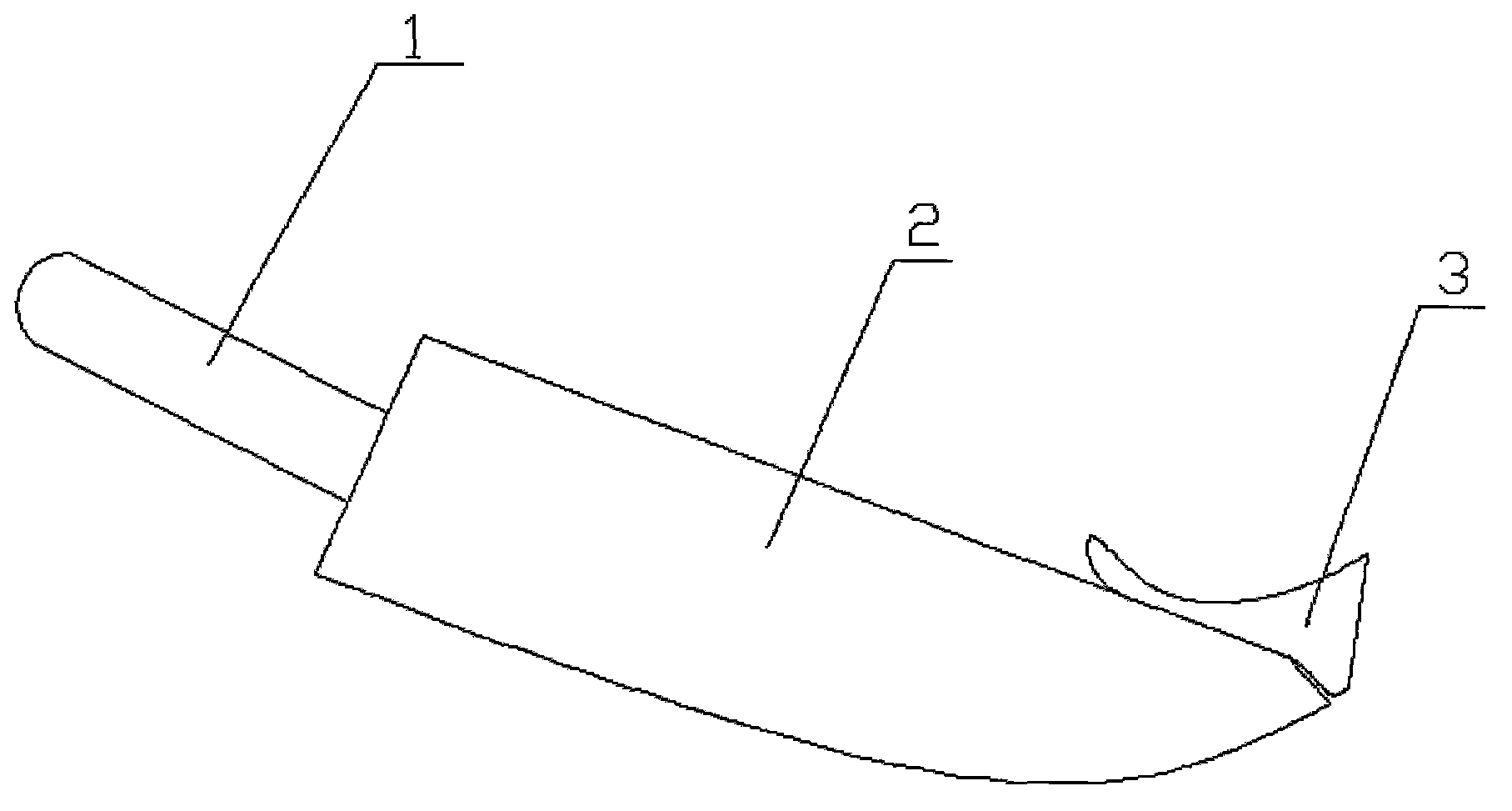

Novel kitchen knife

The invention relates to a novel kitchen knife which comprises a knife body, a knife handle and a retaining plate. One end of the knife body is connected with one end of the knife handle, The retaining plate is located on the side of the other end of the knife body. The retaining plate is arc-shaped. The novel kitchen knife has the advantages that the kitchen knife is simple in structure and easy in batch production; during use, fingers can be placed into the retaining plate, and accidental finger cut caused by fast chopping or other accidents can be avoided effectively.

Owner:牟道娜

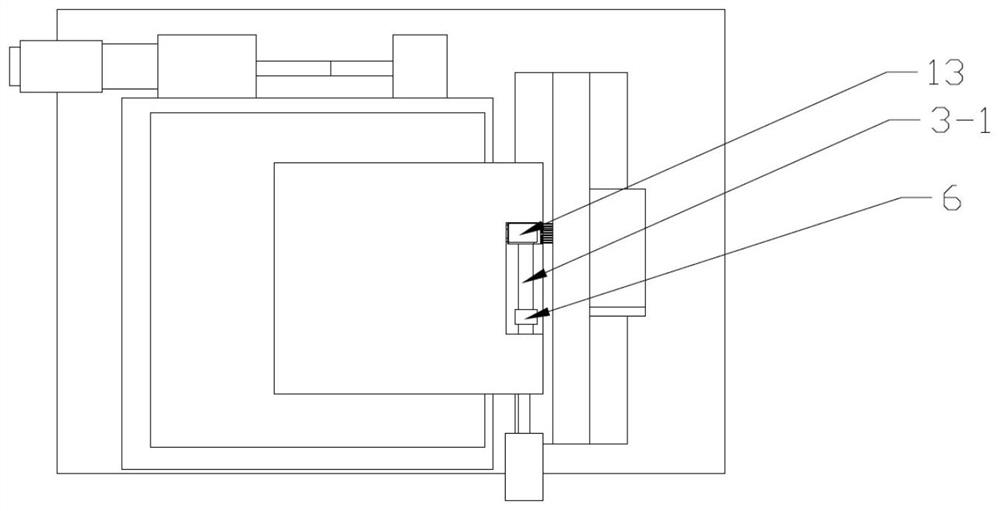

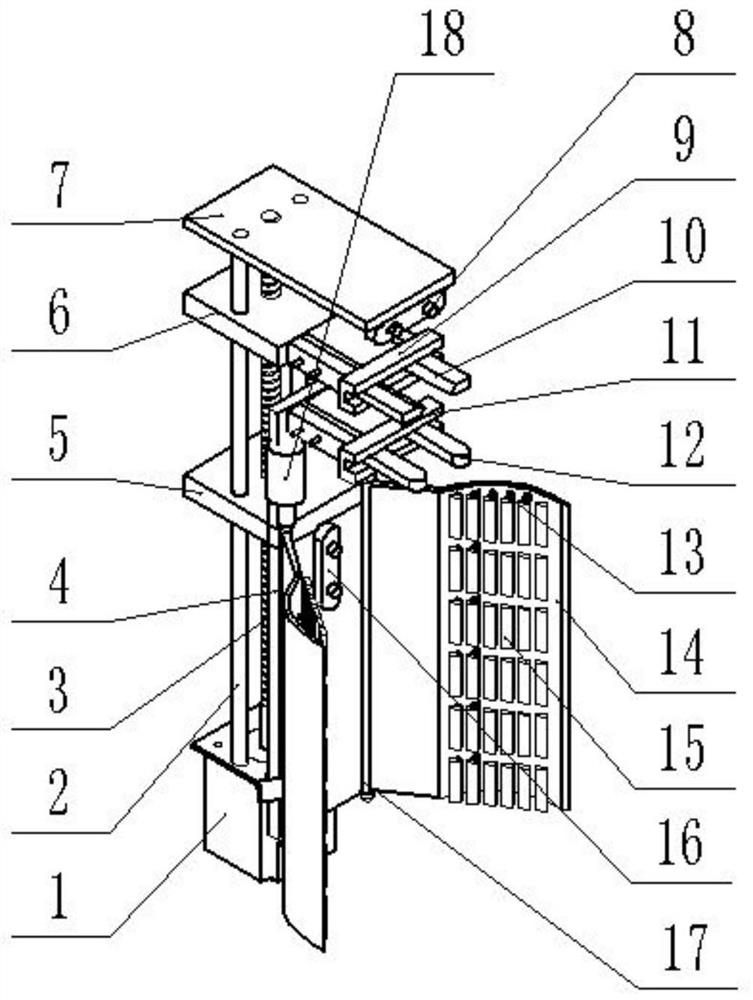

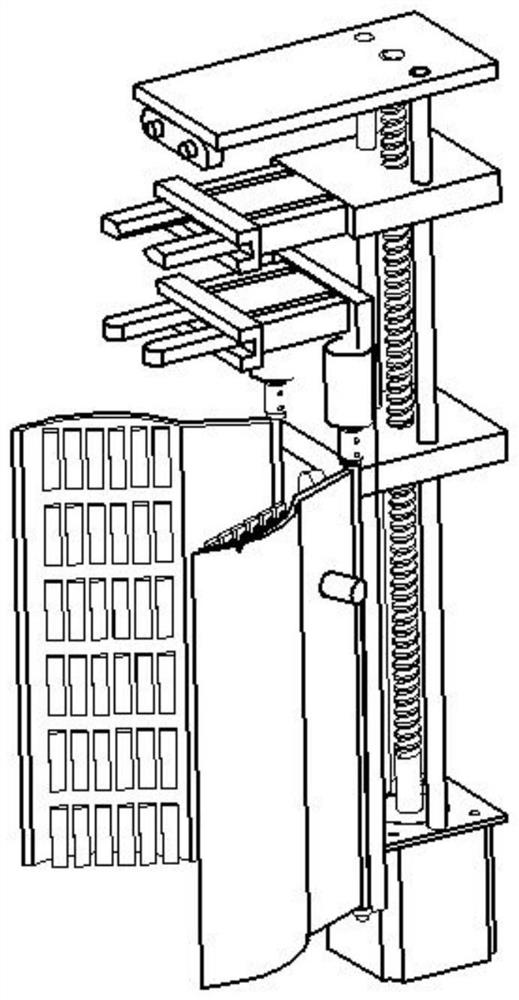

A tube shell golden finger cutting device

ActiveCN111215683BAvoid scrappingIncrease flexibilityShearing machinesShearing machine accessoriesEngineeringOptical communication

The invention belongs to the technical field of optical communication, and particularly relates to a tube shell golden finger cutting device. The device comprises a fixing base, an X-axis manual displacement fine adjustment platform, a clamp, a screwing wire, a bracket, a locking block, return springs, sliding blocks, an upper cutter handle, an upper cutter, a lower cutter and a lower cutter handle; tube shells to be processed are placed in a groove of the clamp, the screwing wire is rotated and then fixed through the locking block, and the X-axis manual displacement fine adjustment platform is used for adjusting the position; and during operation, the upper cutter handle and the lower cutter handle control the upper cutter and the lower cutter to move along sliding grooves of the slidingblocks of the bracket to cut golden fingers of the tube shells. According to the device, the plurality of tube shells can be cut simultaneously, and the production efficiency is improved; the length of the reserved parts of the golden fingers is determined by controlling the X-axis manual displacement fine adjustment platform, so that products have higher consistency; and by matching with the different clamps, one or more products are processed, and the flexibility of processing quantity is greatly improved.

Owner:大连优欣光科技股份有限公司

RPT remaining piece pull ring easy-open cover

The invention relates to an easy-open covers, in particular to an RPT remaining piece pull ring easy-open cover. The RPT remaining piece pull ring easy-open cover comprises a cover body and a pull ring body; an open area which is defined by an annular cutting line is formed on the cover body; the edge part, close to one side of the centre of the cover body, of the open area is connected with the pull ring body through a riveting piece; a remaining piece which is defined by a finger hole area is arranged on the pull ring body; symmetrical punched holes are formed between the left edge as well as the right edge of the remaining piece and the pull ring body; a cutting line is formed between one of the upper edge and the lower edge of the remaining piece and the pull ring body. According to the RPT remaining piece pull ring easy-open cover, the edge of the pull ring body can be flanged into a curled shape through a flanging mould by punched parts between the pull ring body and the remaining piece; when a finger enters the finger hole area to open the easy-open cover forcibly, the inner edge of a pull ring can prevent a finger cutting phenomenon because of curled structure of the punched parts; only a small section of cutting line is reserved between the remaining piece and the pull ring body, so that the remaining piece is convenient to overturn.

Owner:遵化艾尔投资管理中心(有限合伙)

Bread paper container

InactiveUS20060222742A1Improve shortcomingsLightweight materialFruit and vegetables preservationRigid containersPulp and paper industryContamination

It is therefore a primary object of the invention to provide a bread paper container that improves shortcomings of metal can, to apply lighter and safer material, the processes of filling, ferment, toasting etc. is finished in succession in this paper container, no contamination issue during whole process. To apply paper as material of the container, the issues of garbage process and environmental protection also better than the metal can. In order to achieve the objective set forth, a bread paper container in accordance with the present invention applies thermostability paper as material that is lighter than metal, the paper container weight only 1 / 4 of traditional metal can, no finger cutting issues by metal can.

Owner:KOMATSU SHOJI

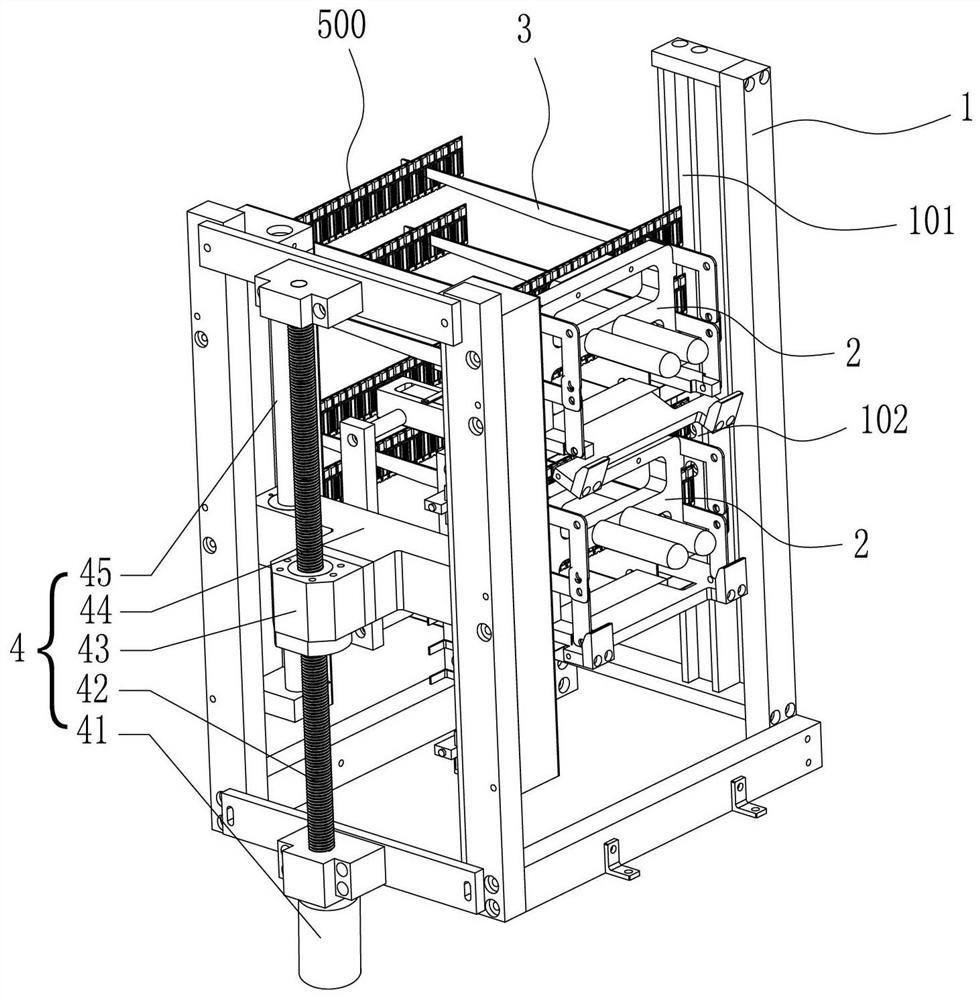

Full-automatic support cutting machine for LED lamp bead support

PendingCN114101456AHigh degree of automationImprove securityMetal-working feeding devicesPositioning devicesLED lampMechanical engineering

The full-automatic support cutting machine comprises an LED lamp bead support storage device, the LED lamp bead support storage device comprises a vertical rod, a lifting seat, a hanging rod and a lifting mechanism, the vertical rod is provided with a vertical sliding rail, a sliding block is installed in the sliding rail, one end of the lifting seat is connected with the sliding block, the rear end of the hanging rod is connected with the lifting seat, and the front end of the hanging rod transversely extends forwards; the hanging rod is used for hanging an LED lamp bead support, and the lifting mechanism is connected with the other end of the lifting base. The LED lamp bead support feeding device is used for transferring the LED lamp bead supports hung on the hanging rod to the LED lamp bead support cutting device one by one; the LED lamp bead bracket cutting device is used for cutting and processing; and the LED lamp bead bracket discharging device is used for taking out the processed LED lamp bead bracket. The automatic finger cutting machine is high in automation degree, good in safety, high in machining efficiency, low in labor cost and high in feeding and discharging accuracy, the problem that fingers are cut manually is solved, one person can operate a plurality of machines, operation and production can be conducted in rest time such as noon, and the like.

Owner:DONGGUAN BRIGHT LED ELLECTRONICS LTD

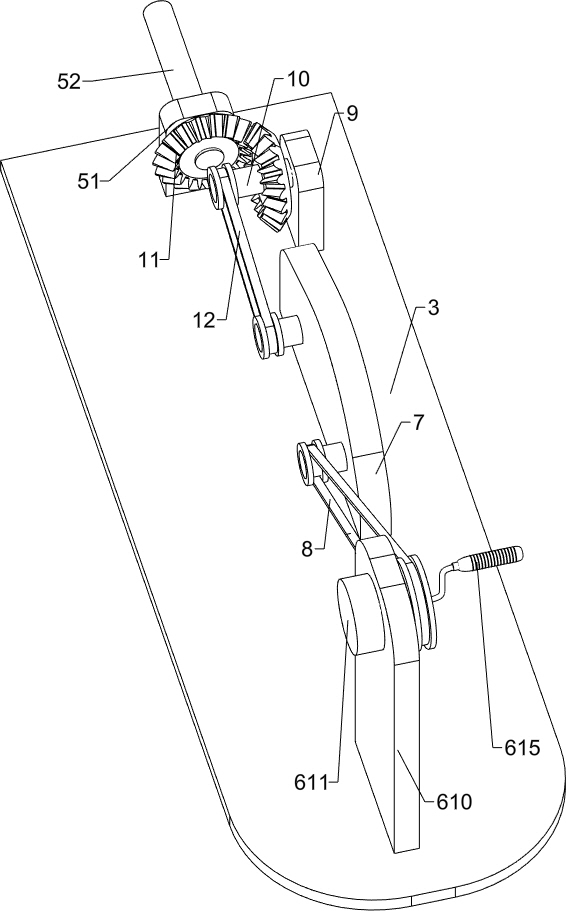

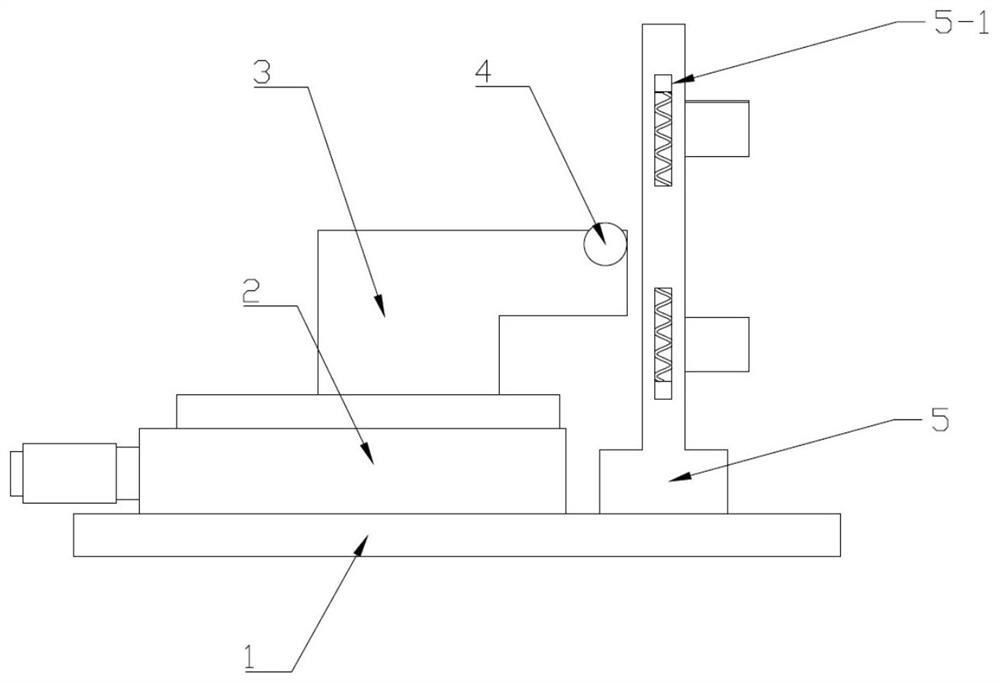

A radish cutting device for food processing

ActiveCN111923104BAvoid cutsReduce workloadClimate change adaptationMetal working apparatusEngineeringMechanical engineering

The invention relates to a strip cutting device, in particular to a radish strip cutting device for food processing. The present invention provides a radish slicing device for food processing which can automatically slice radishes. A radish cutting device for food processing, comprising: a bottom plate, on which a mounting plate is connected on one side; a support plate, on which the other side of the bottom plate is connected with a support plate; a storage plate, on which the other side of the bottom plate is connected with a storage plate; In the mechanism, a cutting mechanism is arranged between the bottom plate, the mounting plate, the support plate and the object storage plate; the rotating mechanism, a rotating mechanism is connected between the bottom plate and the mounting plate, and the rotating mechanism is connected with the cutting mechanism by transmission. Through the cooperation of the cutting mechanism and the rotating mechanism, the present invention can automatically cut the radish into strips, thereby eliminating the need to manually cut the radish with a kitchen knife, thereby reducing workload, saving time and effort, and preventing fingers from being cut.

Owner:厨中鲜餐饮集团有限公司

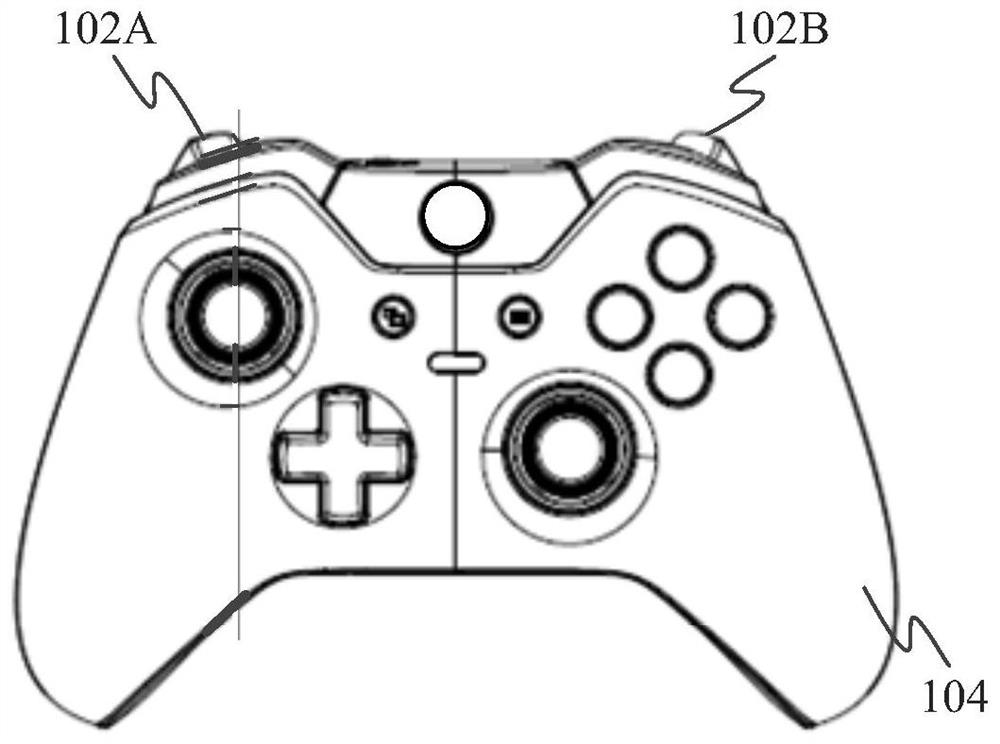

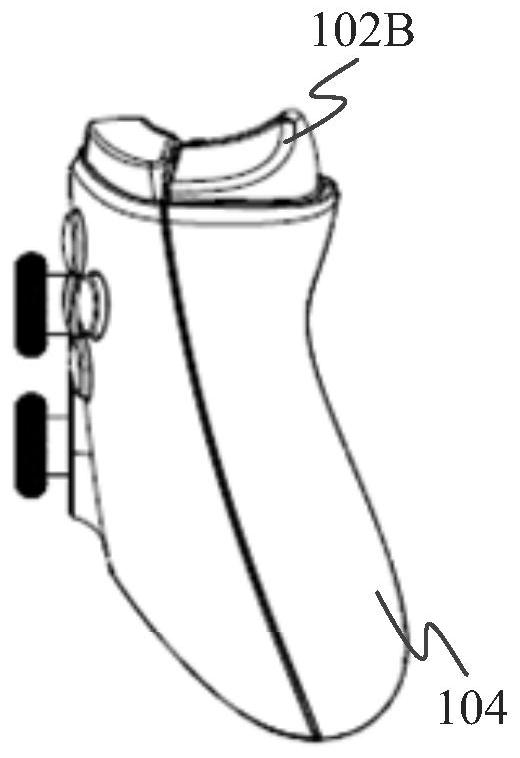

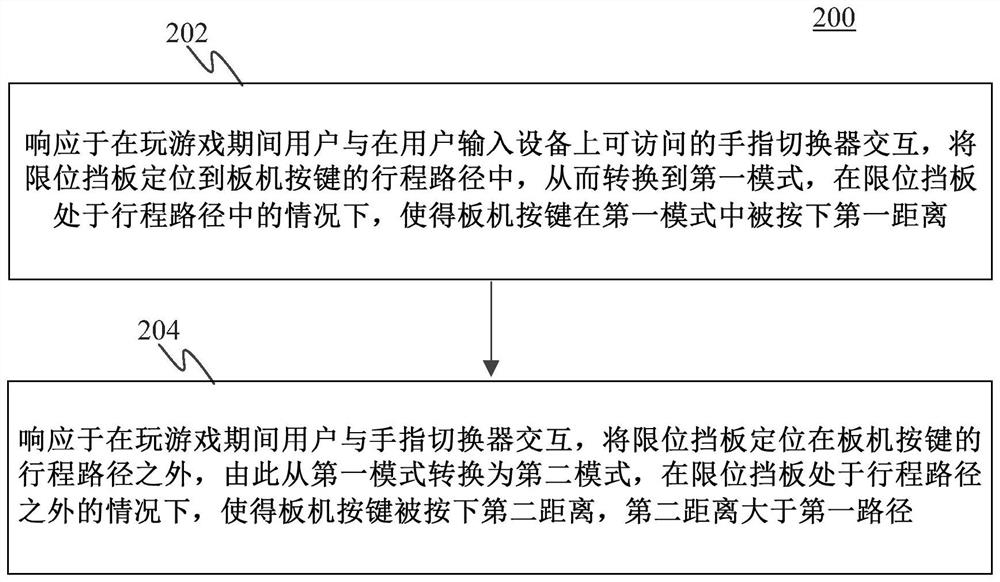

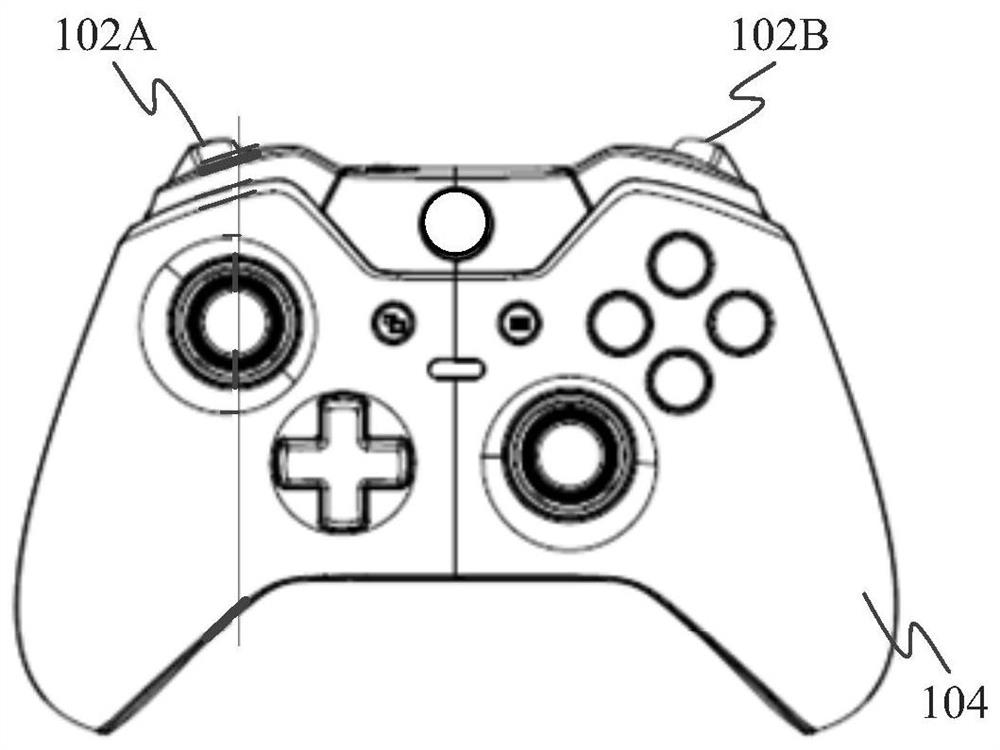

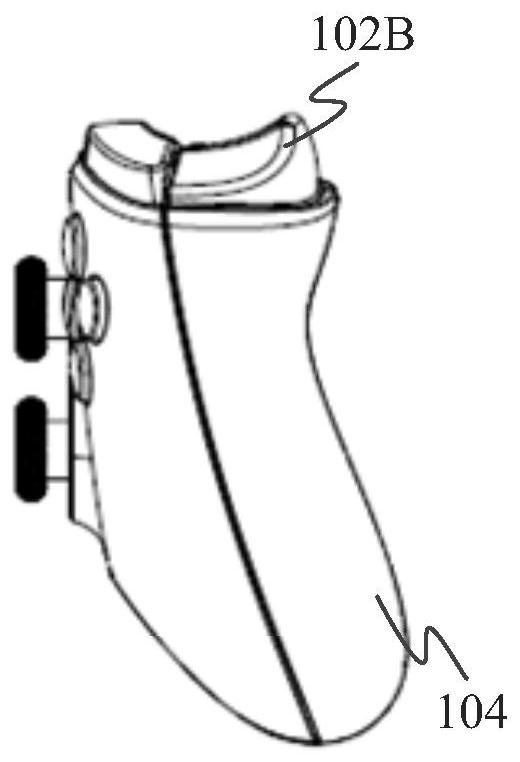

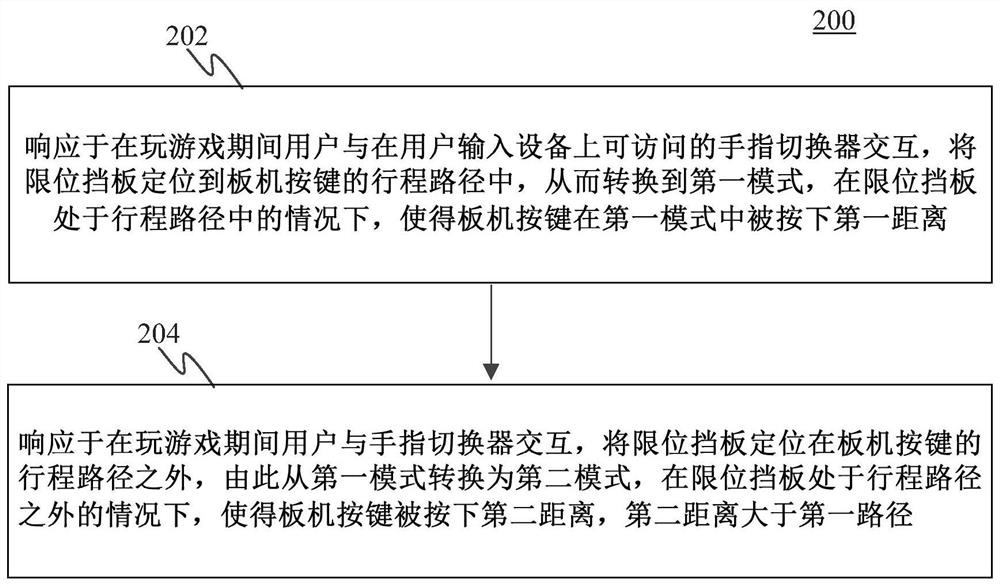

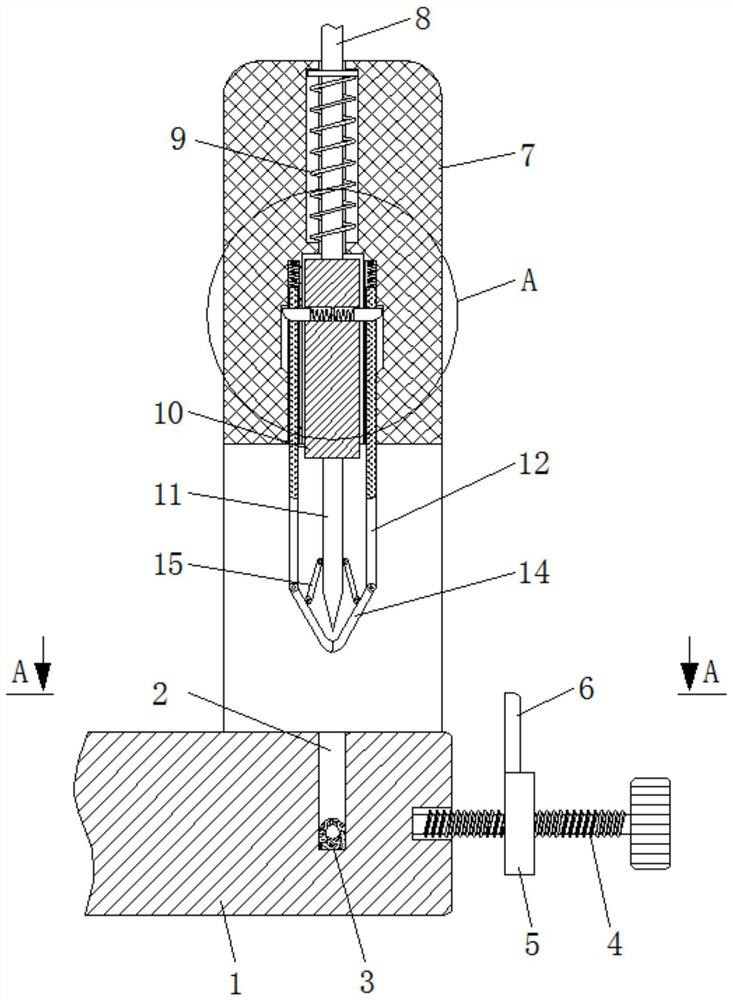

Micro-force trigger travel limit with on-demand switching

Methods, systems, apparatus and computer program products for user input devices, such as game controllers, are provided. The user input device includes a finger-depressible trigger key, a trigger travel path adjustment assembly residing within an interior cavity of a housing of the user input device, and configured (eg, during game play) to switch between a plurality of selectable Finger switcher for real-time switching between locations. The first selectable position of the finger switch causes the trigger key to be pressed a first distance. The second selectable position of the finger switch causes the trigger button to be pressed a second distance greater than the first distance.

Owner:MICROSOFT TECH LICENSING LLC

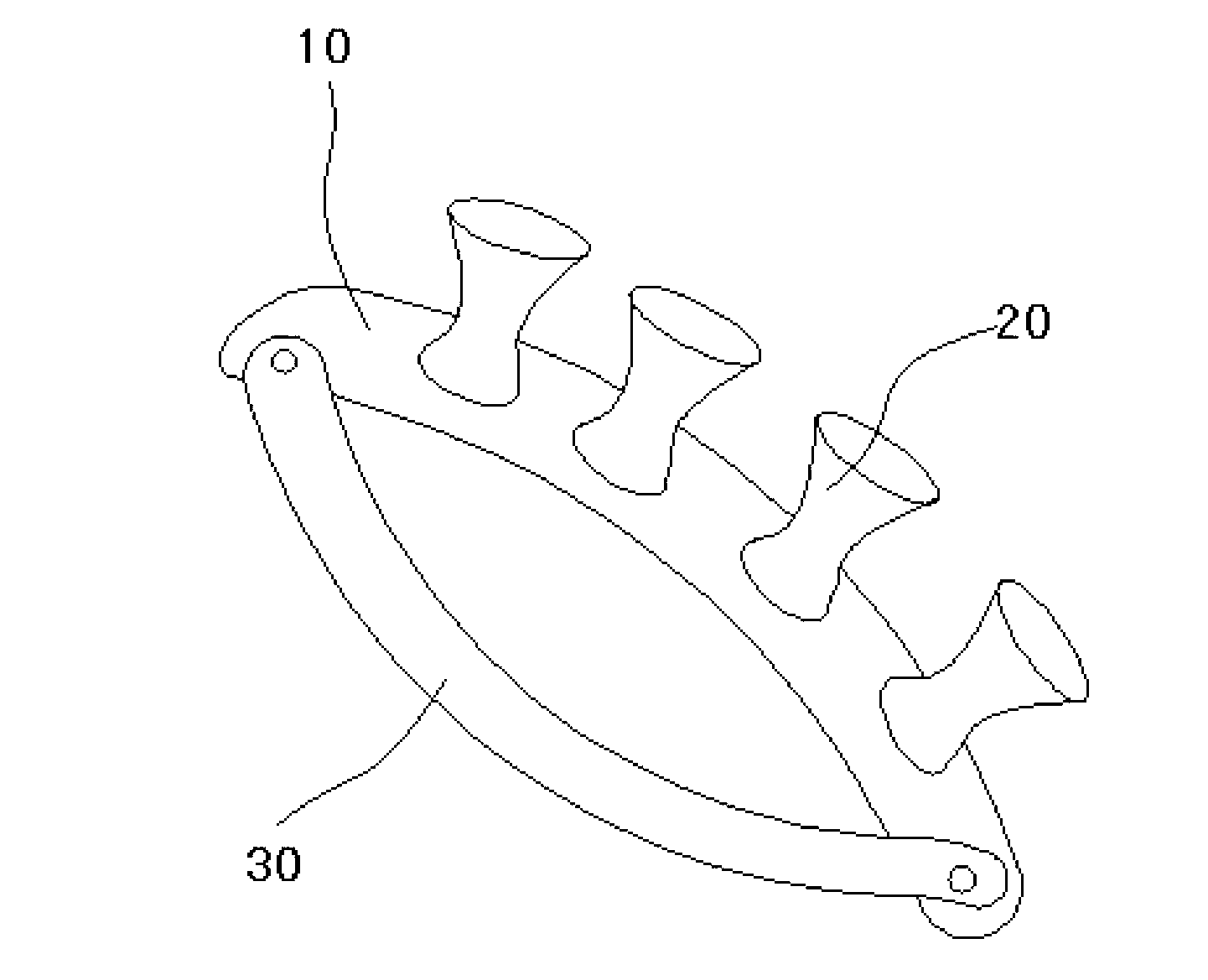

Hand protector for cutting vegetables

The invention discloses a hand protector for cutting vegetables. The hand protector comprises a hand protector main body, four finger protecting struts and an elastic band, wherein the hand protector main body is made of hard plastics; the hand protector main body is a semicircular annular structure; mounting holes are formed in the two ends of the hand protector main body; the finger protecting struts are uniformly distributed on the hand protector main body; the finger protecting struts are hard plastic struts which are thick at two ends and thin in the middle; and the elastic band is connected with the mounting holes at the two ends of the hand protector main body. The hand protector has the advantages of simple structure, convenience in use and no influence on normal vegetable cutting; moreover, finger cutting accidents during cutting the vegetables can be effectively reduced, and the safety in use is enhanced.

Owner:THE SECOND FOREIGN LANGUAGE SCHOOL AFFILIATED TO SHANGHAI NORMAL UNIV

Tube shell golden finger cutting device

ActiveCN111215683AAvoid scrappingIncrease flexibilityShearing machinesShearing machine accessoriesEngineeringStructural engineering

Owner:大连优迅科技股份有限公司

Fuel filler pipe information collar for fuel type identification

This invention relates to fuel filler pipe information collar for fuel type identification, a fuel type information collar is provided. The fuel type information collar is configured to engage an outer perimeter of a fuel tank filler pipe assembly of an automotive vehicle. It may include an inner perimeter defining an aperture configured to engage the outer perimeter of the fuel tank filler pipe assembly. It may additionally include a top surface including indicia of fuel type information for indicating type of fuel to be used by the automotive vehicle. It may further include a plurality of radial finger cuts angularly spaced around the inner perimeter, the plurality of radial finger cuts forming a plurality of fingers that engage the outer perimeter of the fuel tank filler pipe assembly.

Owner:FORD GLOBAL TECH LLC

A secondary cable lateral stripping tool

ActiveCN108899814BEven by forceReduce manufacturing costApparatus for removing/armouring cablesStructural engineeringKnife blades

The invention provides a secondary cable transverse sheath pulling tool, which comprises an upper half ring and a lower half ring, wherein the upper half ring and the lower half ring are hinged; a handle is connected to the outer ring wall of the lower half ring; an upper semicircular shape is defined by the inner ring wall of the upper half ring; a lower semicircular shape is defined by the innerring wall of the lower half ring; a cutter blade is arranged in the lower semicircular shape; the cutting edge of the cutter blade faces the opening part of the lower semicircular shape; the upper semicircular shape and the lower semicircular shape define a complete sheath pulling placement circle; a cable wire requiring the transverse sheath pulling is arranged in the sheath pulling placement circle; the cable or the sheath pulling tool rotates so that the cutting edge of the cutter blades cuts the sheath of the cable wire. The existing longitudinal cutting mode is changed; a transverse cutting mode is used; the problems of small cutting surface area, non-uniform stress in the cutting process and the like can be solved; the probability of cable damage and finger cut injury is reduced. The secondary cable transverse sheath pulling tool has the advantages that the cutting area is increased; the cutting work can be more easily performed; the transverse cutting mode is used; the force intensity can be more easily controlled, so that the stress of the cable is uniform.

Owner:ZOUPING POWER SUPPLY CO

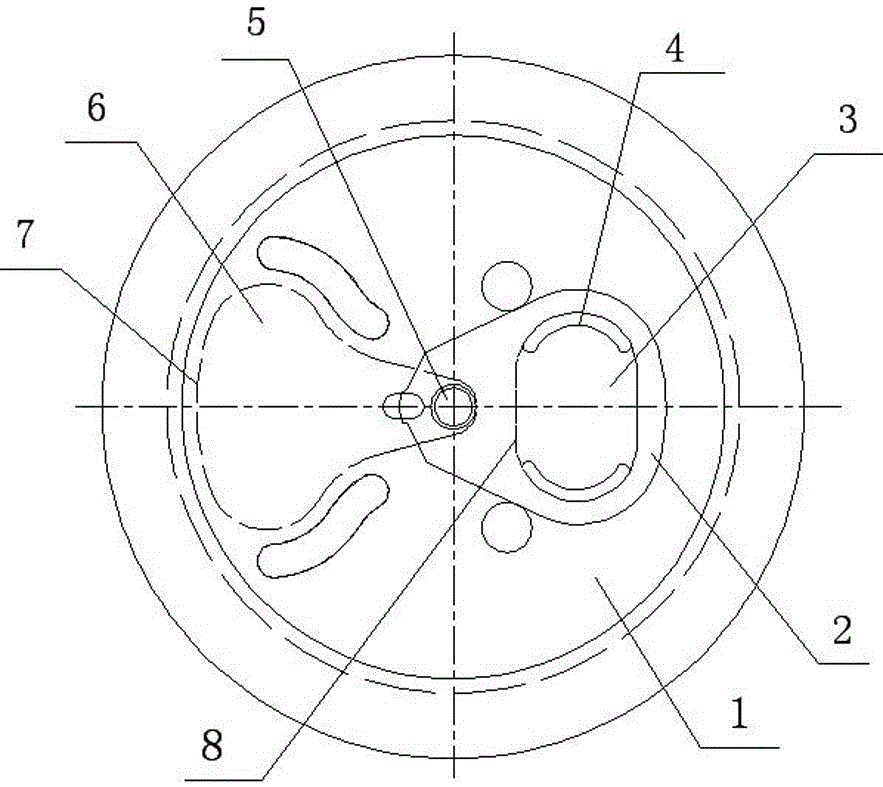

Rotating disc type feeding machining mechanism

The invention discloses a rotating disc type feeding machining mechanism. The rotating disc type feeding machining mechanism comprises a feeding table, a supporting rotating disc, a material arranging rotating disc, a pneumatic finger support, a feeding finger, a foot cutting moving finger, an embossing moving finger, a discharging moving finger, a foot cutting die, a first material fixing finger, a second material fixing finger, a discharging table, a third material fixing finger, an embossing die, a material head cutting die, a limiting groove, a material size adjusting baffle, a material in-place signal detection device, a material length positioning pneumatic device, an adjusting dovetail, a pneumatic vertical moving mechanism and a stepping horizontal moving mechanism. Compared with the prior art, the rotating disc type feeding machining mechanism has the advantages that another product is researched and developed on the basis of an original servo multifunctional feeding and discharging automatic assembling machine, and the machining speed of the product is more suitable for a punching machine to complete the whole feeding and machining; due to the complete mechanical process, glasses temples can be machined on the premise that unmanned operation is achieved, and the glasses temples are quite fast and convenient to machine.

Owner:王如红

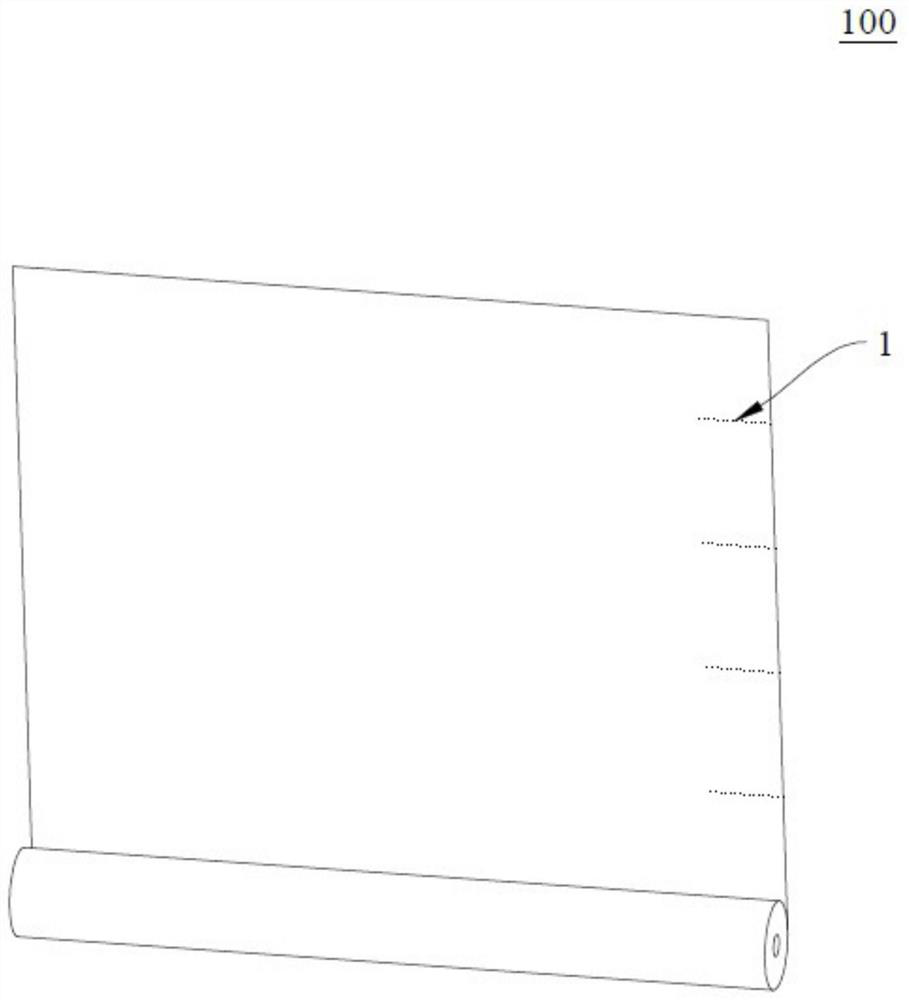

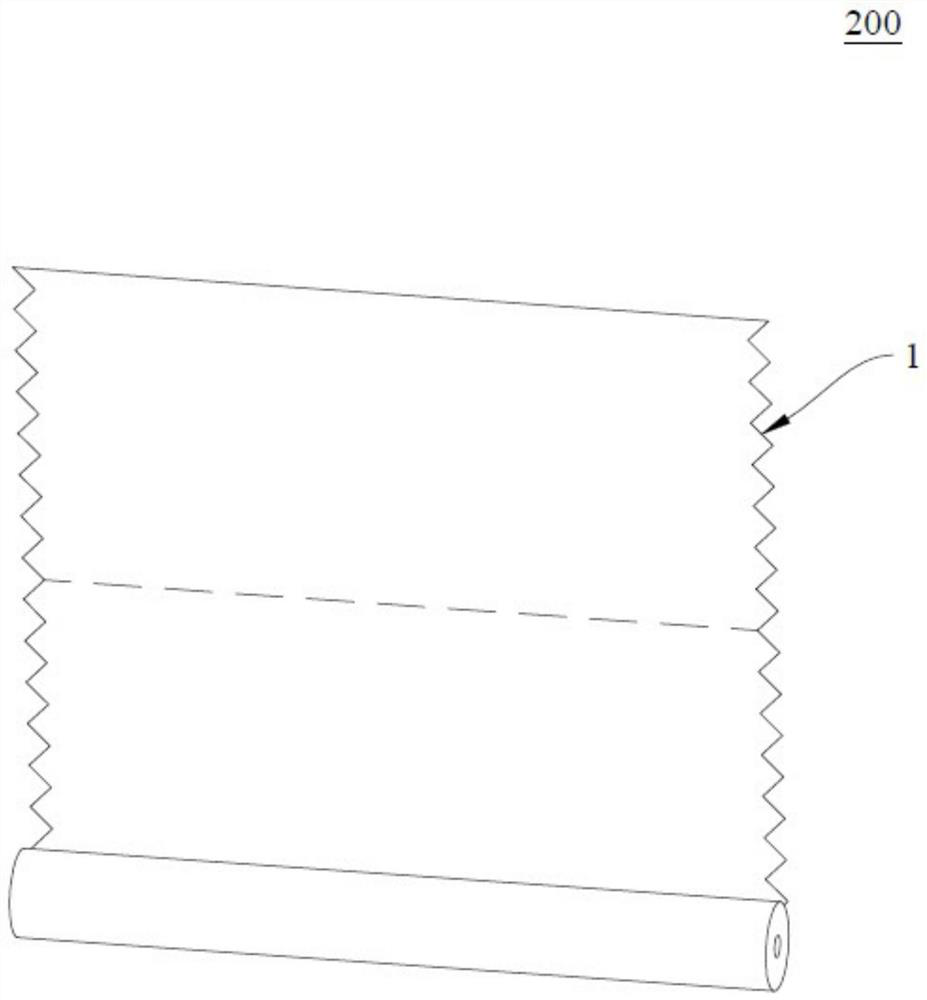

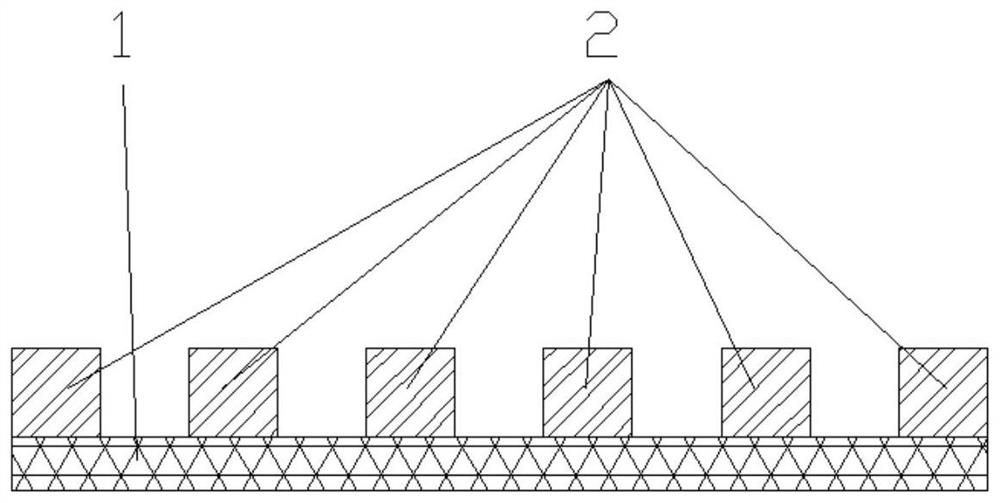

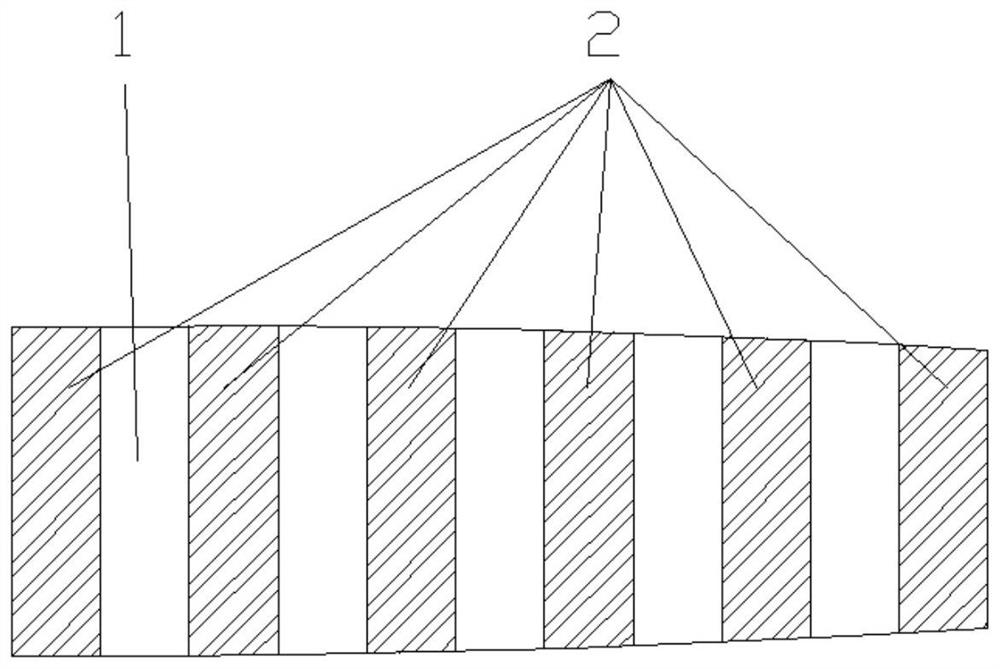

Plastic wrap and plastic wrap dispenser thereof

ActiveCN112573017AHas linear tearing propertiesWith linear tearabilityFlexible coversWrappersEngineeringStructural engineering

The present invention relates to a plastic wrap and a plastic wrap dispenser thereof. The plastic wrap comprises a plurality of preset tear structures, and the plurality of preset tear structures areconfigured on a single edge or two opposite edges of the wrap film, which benefits the plastic wrap to be torn off. In addition, the plastic wrap contains a polymer having linear tearing property, sothat when the plastic wrap can be torn straightly. The plastic wrap dispenser includes a box, a cutter, and the plastic wrap of the present invention, wherein cutter of the plastic wrap dispenser is ashort cutter or a retractable cutter, which benefits the user from being finger cut when using the plastic dispenser.

Owner:顺昶塑料股份有限公司

A gold finger laser cutting method and system for circuit boards

ActiveCN109940284BWill not cause pyrolysis and carbonizationWill not cause micro short circuitLaser beam welding apparatusLaser processingLaser cutting

The invention relates to a gold finger laser cutting method and system for circuit boards. The method comprises: projecting the inter-finger insulating layer clearing laser beam and the golden finger cutting laser beam to the area to be cut of the circuit board for scanning processing, and the laser peak value of the projected light spot of the inter-finger insulating layer clearing laser beam on the inter-finger insulating layer to-be-cut area The power density is less than the laser processing threshold of the gold finger material, and greater than or equal to the laser processing threshold of the inter-finger insulating layer material, and the laser peak power density of the projected spot of the gold finger cutting laser beam on the gold finger to be cut area is greater than or equal to the laser processing of the gold finger material Threshold: The inter-finger insulation layer removal laser beam is used to process and form a hole in the inter-finger insulation layer to be cut area, and the golden finger cutting laser beam is used to process and form a slit on the circuit board. Outer side edge. The technical scheme of the invention can solve the micro-short circuit problem generated on the golden finger when the circuit board is cut by laser.

Owner:WUHAN EXCEL SCI & TECH LTD EST

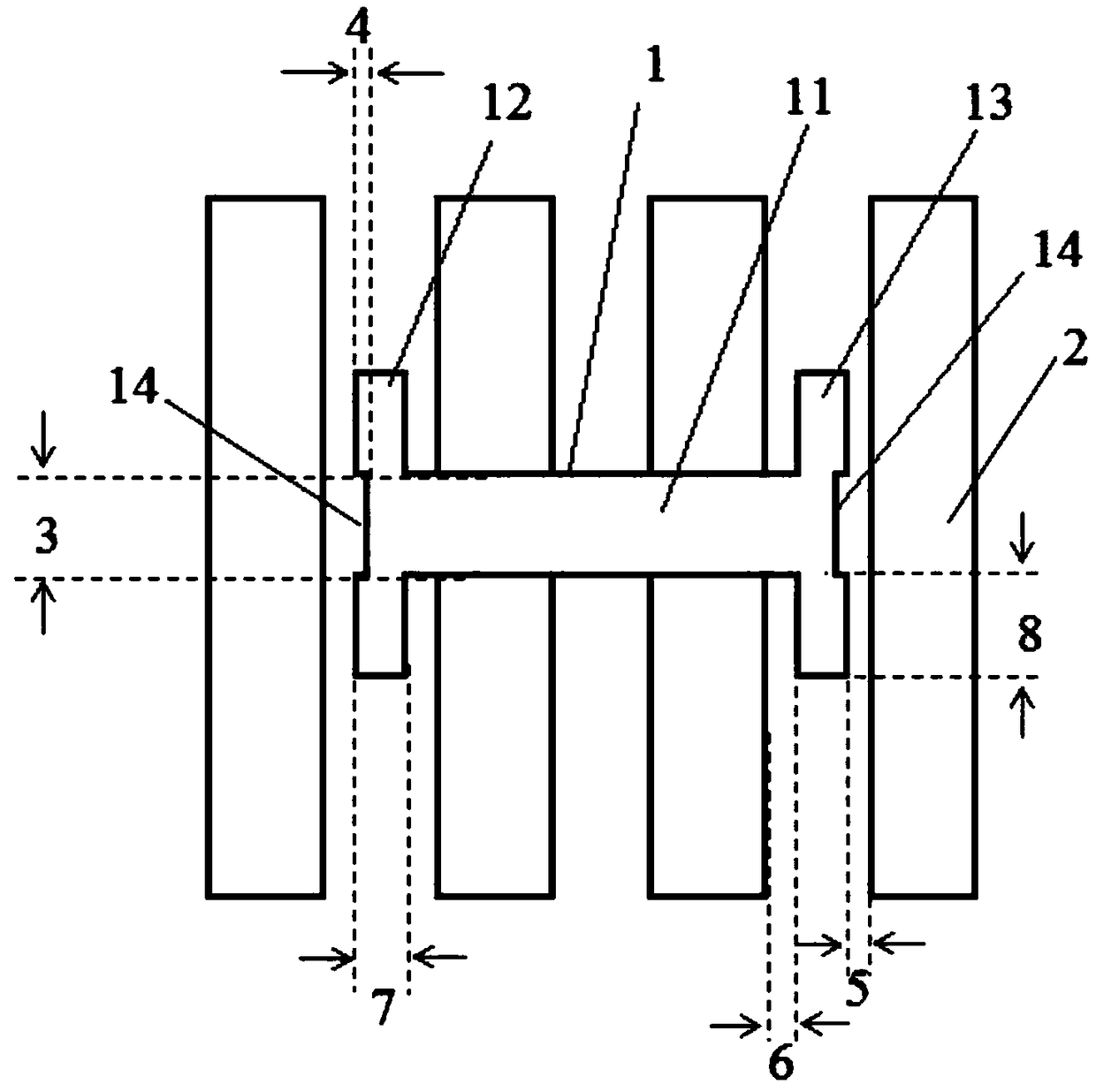

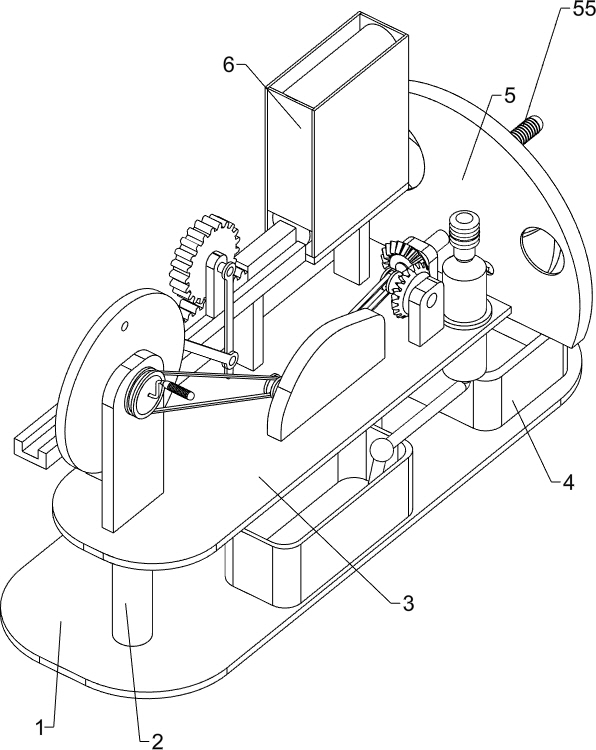

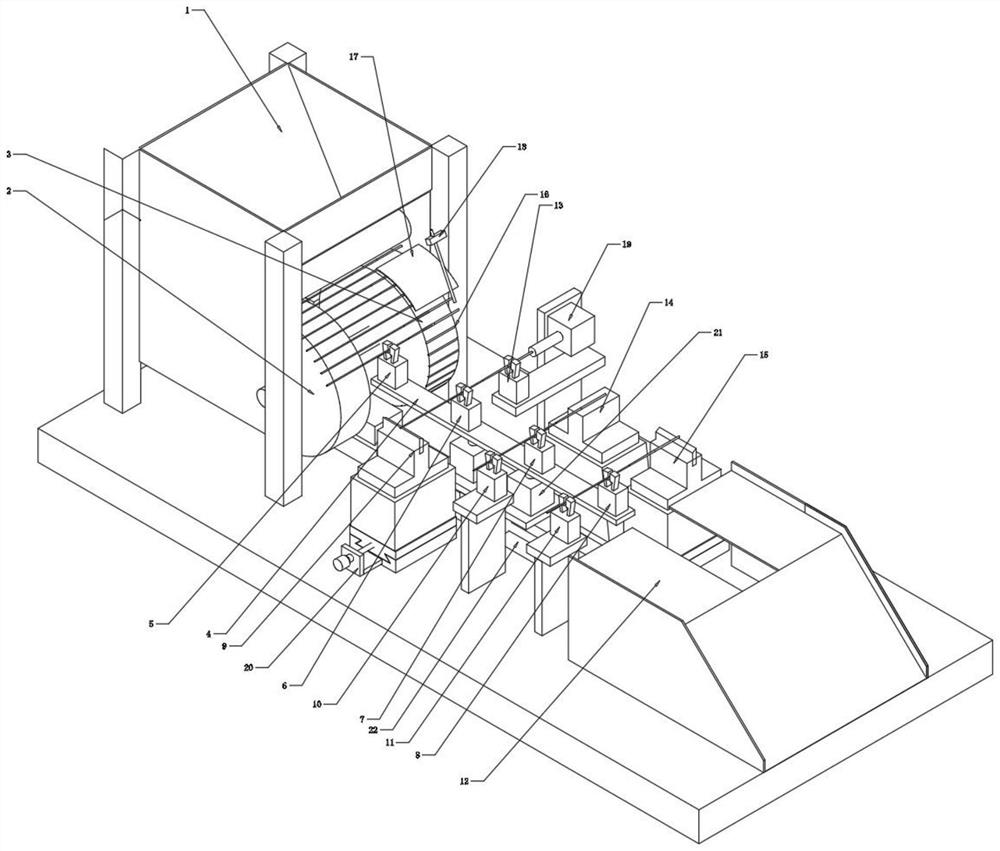

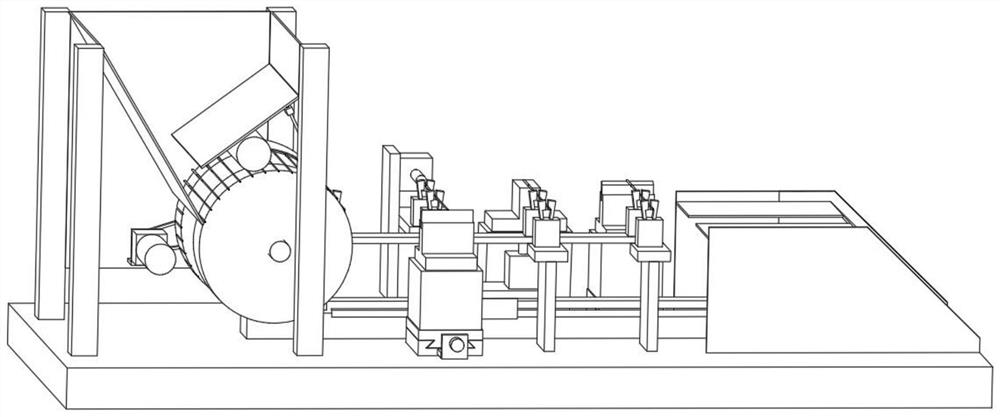

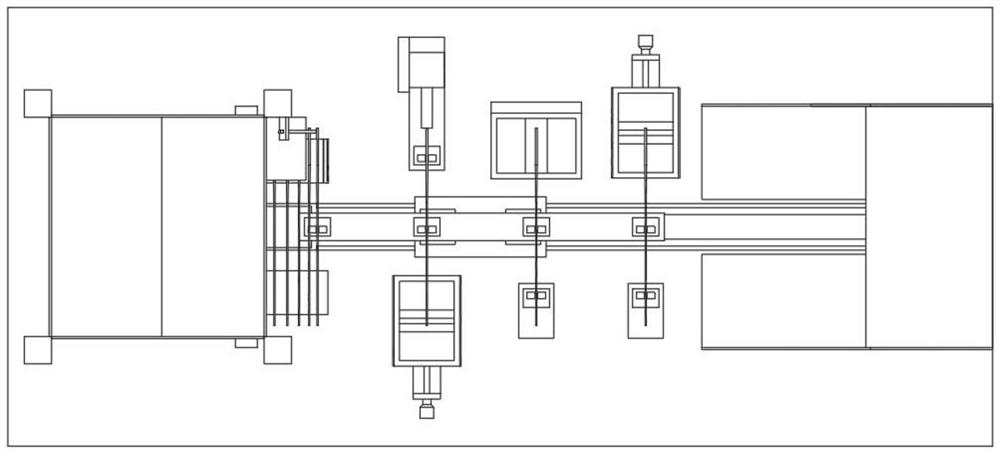

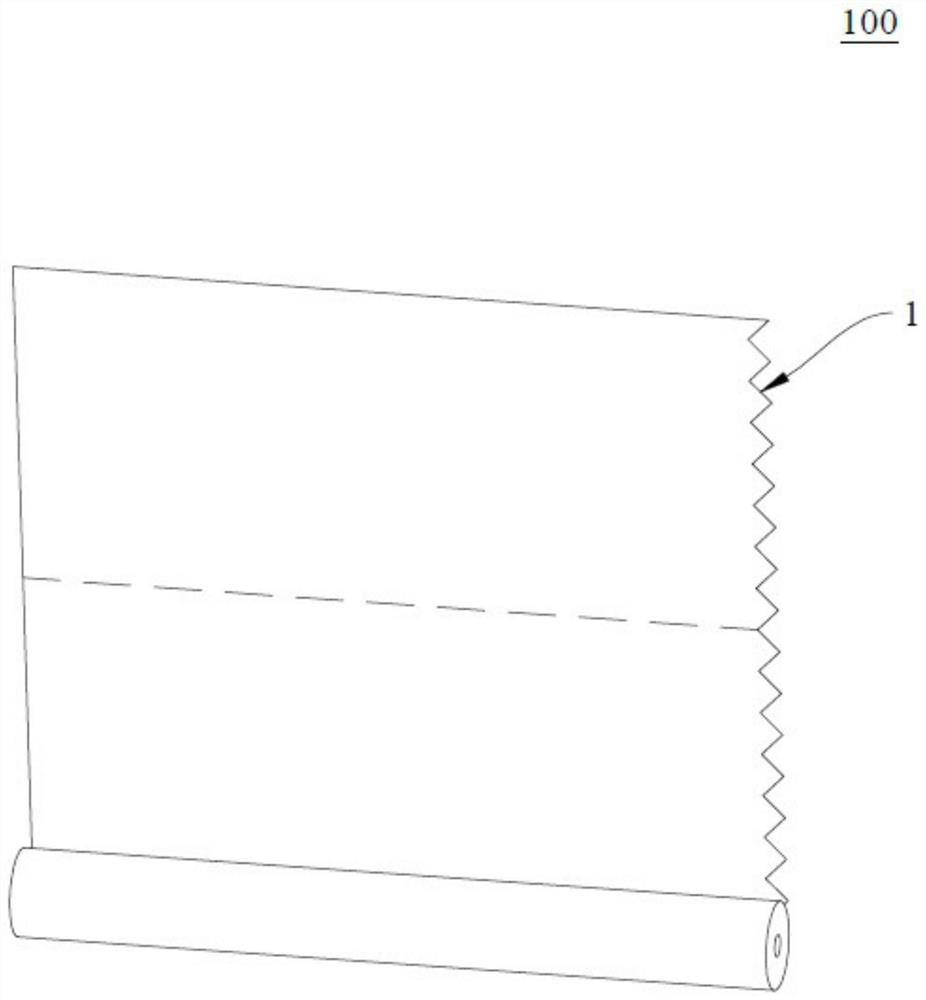

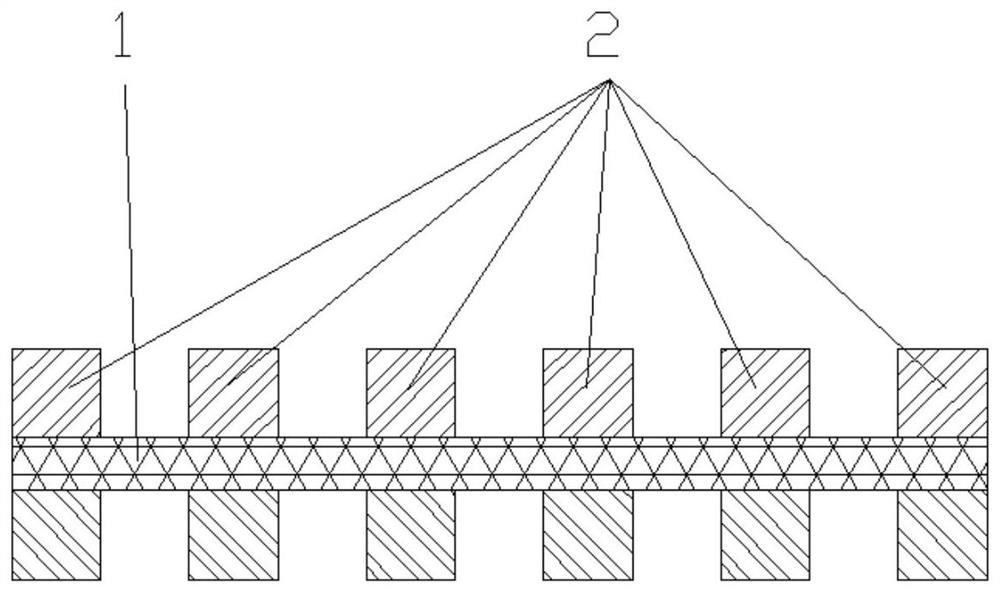

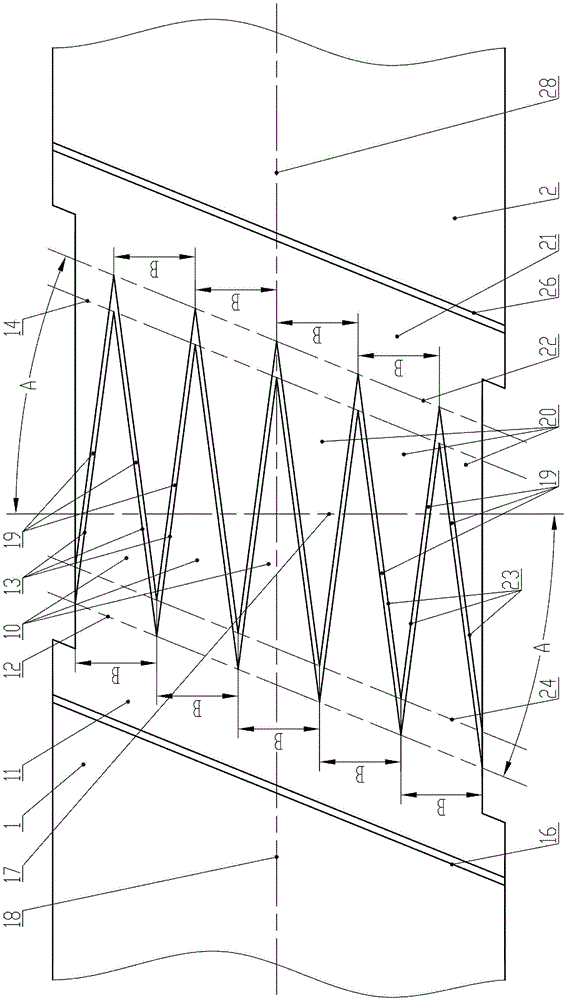

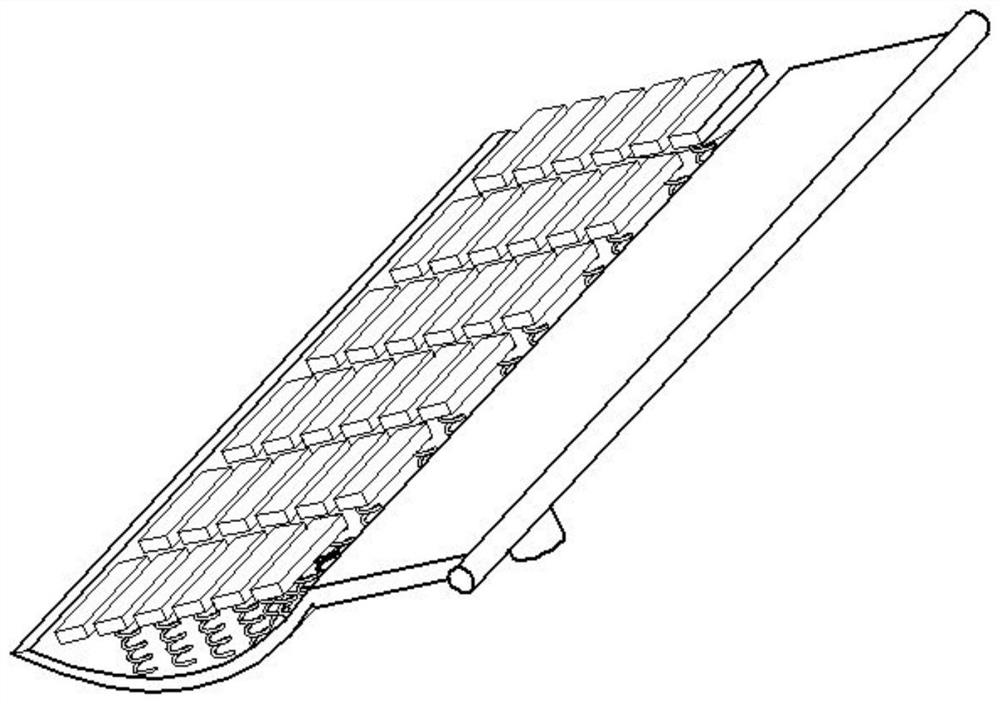

Finger Cutting Equipment

InactiveCN104552404BImprove continuitySave labor timeMetal working apparatusDiamond cuttingMotor drive

The invention belongs to the technical field of rubber belt manufacturing equipment, and relates to a device for manufacturing a connector, in particular to a finger-shaped cutting device. The finger-shaped cutting device comprises a cutting device, a diamond cutting line and a mobile platform component, wherein the diamond cutting line performs cutting movement, a belt end 1 and a belt end 2 which are superimposed together are fixed on an upper tray component, a stepping motor drives the upper tray component to move horizontally along a finger-shaped line track, and finally the belt end 1 and the belt end 2 are simultaneously cut into finger shapes. The finger-shaped cutting device manufactures the finger shapes accurate in size, saves labor time, enables sizing material to achieve good continuity in a vulcanizing process, does not generate a fault in the middle of the sizing material, enables tensile strength of the belt connector to reach prospective strength, and is difficult to break during the use process, safe and reliable to use, high in production efficiency, and low in labor intensity.

Owner:STATE GRID CORP OF CHINA +1

Hair trigger travel stop with on-demand switching

Methods, systems, apparatuses, and computer program products are provided for a user input device, such as a game controller. The user input device includes a finger depressible trigger button, a trigger travel path adjustment assembly that resides in an internal cavity of a housing of the user input device, and a finger switch configured to be switched between a plurality of selectable positionsin real-time (e.g., during game play). A first selectable position of the finger switch enables the trigger button to be depressed a first distance. A second selectable position of the finger switch enables the trigger button to be depressed a second distance that is greater than the first distance.

Owner:MICROSOFT TECH LICENSING LLC

A certificate photo cutting device for photo studios based on connecting rod transmission

ActiveCN111873002BAdjustable positionQuality improvementMetal working apparatusPhototypeStructural engineering

The invention provides a certificate photo cutting device for photo studios based on connecting rod transmission, and relates to the technical field of photo cutting. The certificate photo cutting device for photo studios based on connecting rod transmission includes a placement seat, a cutting groove is opened on the top of the right side of the placement seat, and a light strip is fixedly connected to the bottom end of the cutting groove, and the placement seat The right end of the right end is rotatably connected with a threaded rod, the periphery of the threaded rod is threadedly connected with a slide block, and a baffle is fixedly installed on the top of the slide block. The ID photo cutting device for photo studios based on connecting rod transmission can stably limit the position of the photo, and at the same time, the cutting line can be observed on the surface of the photo, and then the position of the photo can be adjusted more accurately, which improves the efficiency of photo cutting. Quality, avoiding the cutting of fingers during use, and automatically wrapping the blade of the cutter after use, avoiding scratches on the human body and improving the safety of the cutting device.

Owner:海宁王骏新材料有限公司

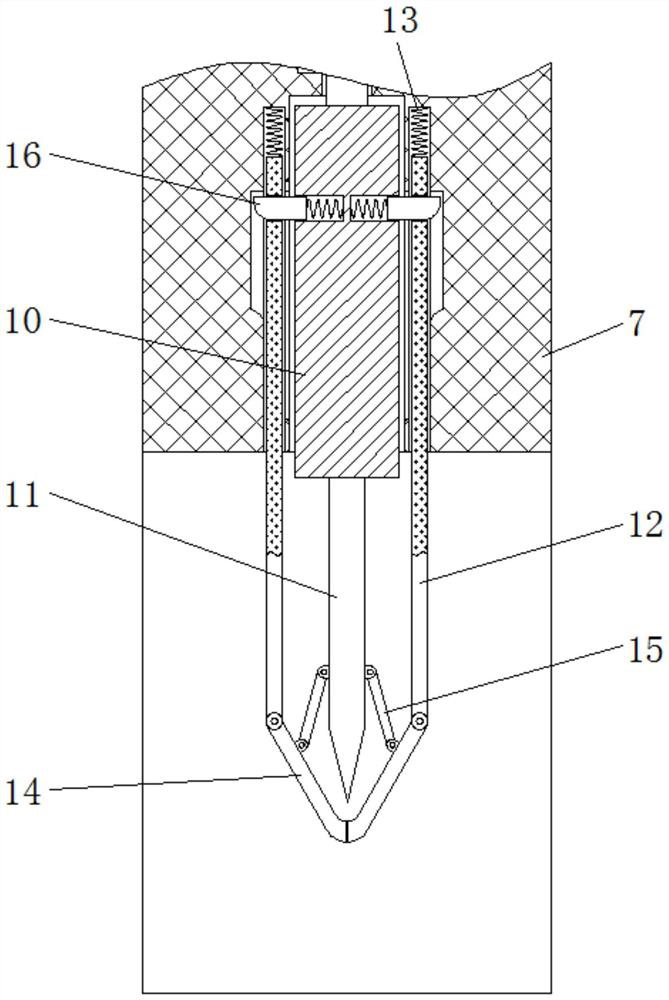

A cucumber flexible picking manipulator end effector and picking method

ActiveCN107696047BStabilize the middle and lower sectionsAvoid breakingGripping headsHarvestersRobot handControl engineering

The invention provides a cucumber flexible picking manipulator end executor and a picking method and relates to the field of agricultural picking robots. The cucumber flexible picking manipulator endexecutor is composed of a stepping motor, polished shafts, a lead screw, a mounting plate, a supporting plate, a nut slide block, an ejector plate, a visual sensor, a cutting cylinder, cutting fingers, a clamping cylinder, clamping fingers, springs, flexible clamping walls, silica gel keys, a laser sensor, a clamping arm rotating shaft and a rotary motor. The cucumber flexible picking manipulatorend executor is characterized in that the flexible clamping walls are installed on the two sides of the mounting plate through clamping wall rotary shafts, the silica gel keys are connected with the flexible clamping walls through the springs, and the working processes of aligning at cucumbers, moving close to the cucumbers, clamping the upper sections of the cucumbers, flexibly clamping the middle lower sections of the cucumbers and cutting off stems are completed. By adoption the picking manners that the flexible clamping walls clamp the middle sections and the lower sections of the cucumbers, the clamping fingers clamp the upper sections of the cucumbers, and the cutting fingers cut off the stems, the technical problems that the cucumber picking efficiency is low and cucumbers are proneto being damaged during clamping and are liable to break off due to shaking are solved.

Owner:新昌县大菠萝农业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com