Full-automatic support cutting machine for LED lamp bead support

An LED lamp bead, fully automatic technology, used in metal processing equipment, feeding devices, manufacturing tools, etc., to achieve the effect of high degree of automation, low labor cost, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

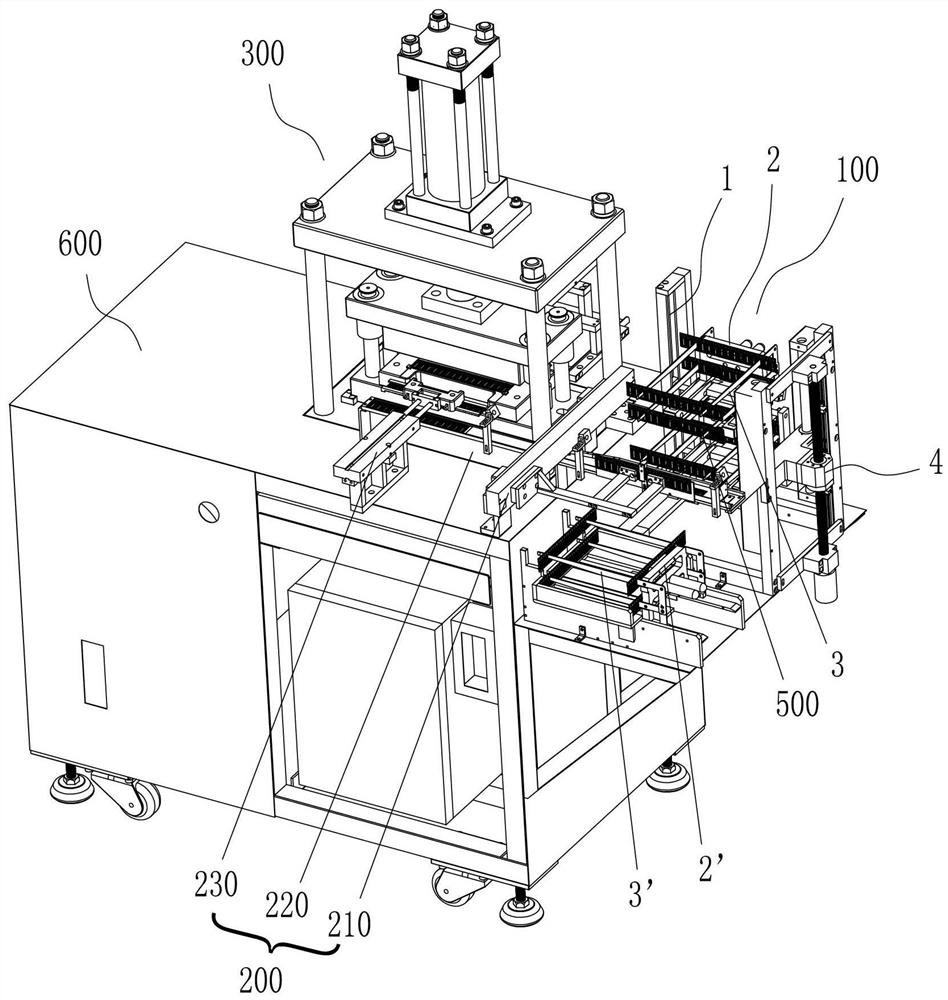

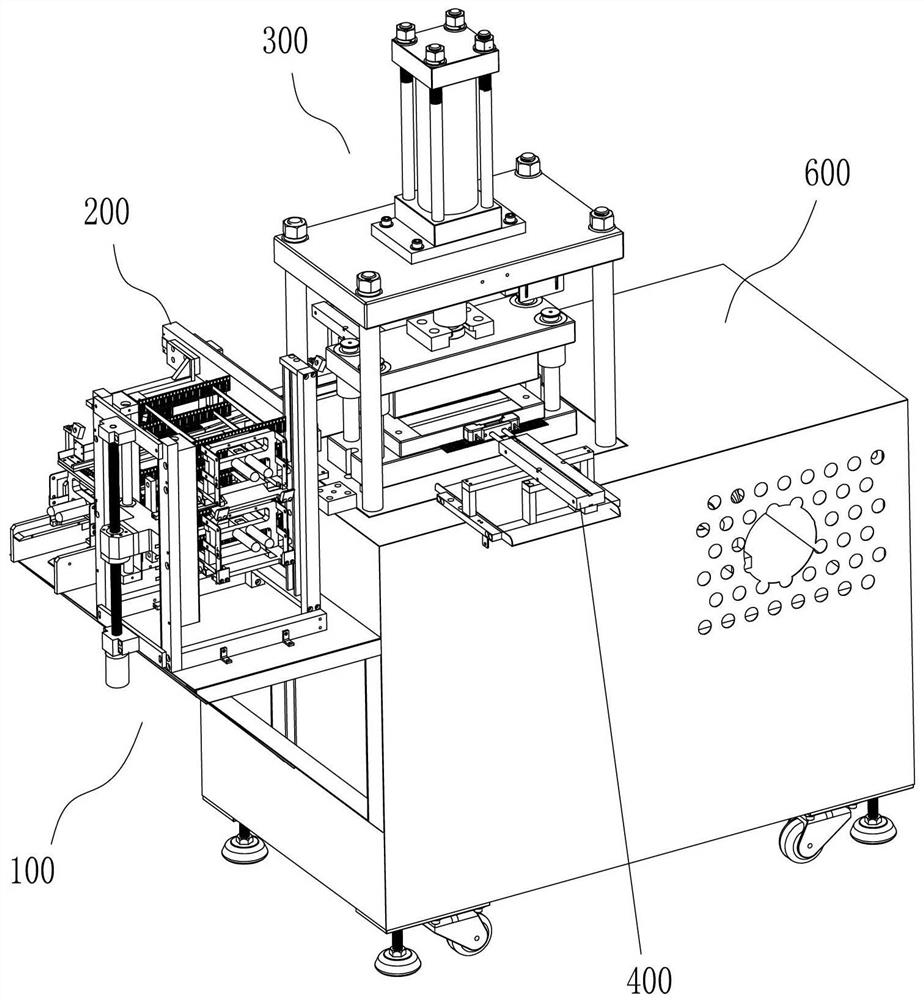

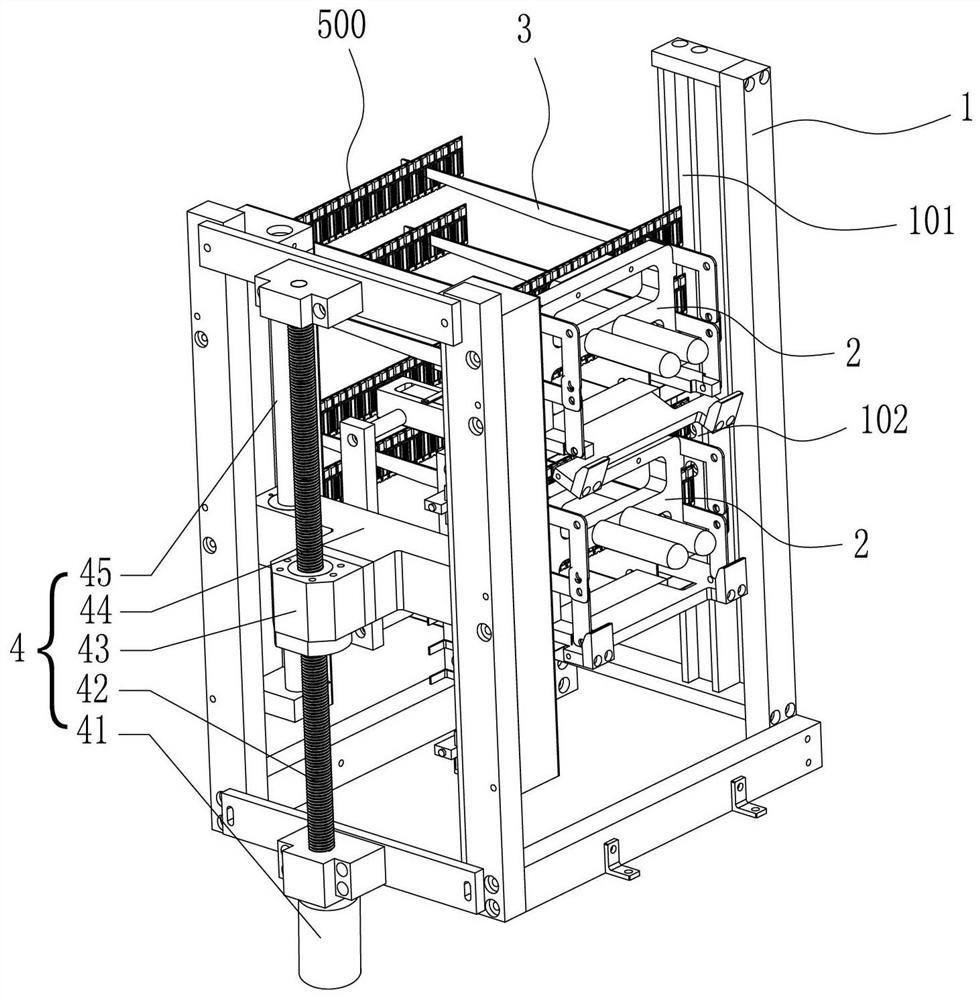

[0020] Such as Figure 1 to Figure 5 As shown, the present invention is a fully automatic bracket cutting machine for LED lamp bead brackets, comprising a machine 600 on which an LED lamp bead bracket storage device 100, an LED lamp bead bracket feeding device 200, and an LED lamp bead bracket are installed. The bracket cutting device 300 and the LED lamp bead bracket discharging device 400; the LED lamp bead bracket storage device 100 includes a vertical rod 1, a lifting seat 2, a hanging rod 3 and a lifting mechanism 4, and the vertical rod 1 is provided with a vertical The slide rail 101 of the slide rail 101 is installed with a slider 102 that can slide up and down, one end of the lift seat 2 is connected with the slide block 102, and the rear end of the hanging rod 3 is connected with the lift seat 2. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com