Optical module connecting finger cut-off position anti-electroplating ink pattern structure

A graphic structure and anti-plating technology, applied in electrical components, printed circuits, printed circuits, etc., can solve the problems of gold finger penetration, ink shedding, and dirty etching, etc., to reduce shedding, reduce production costs, and improve etching leads Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

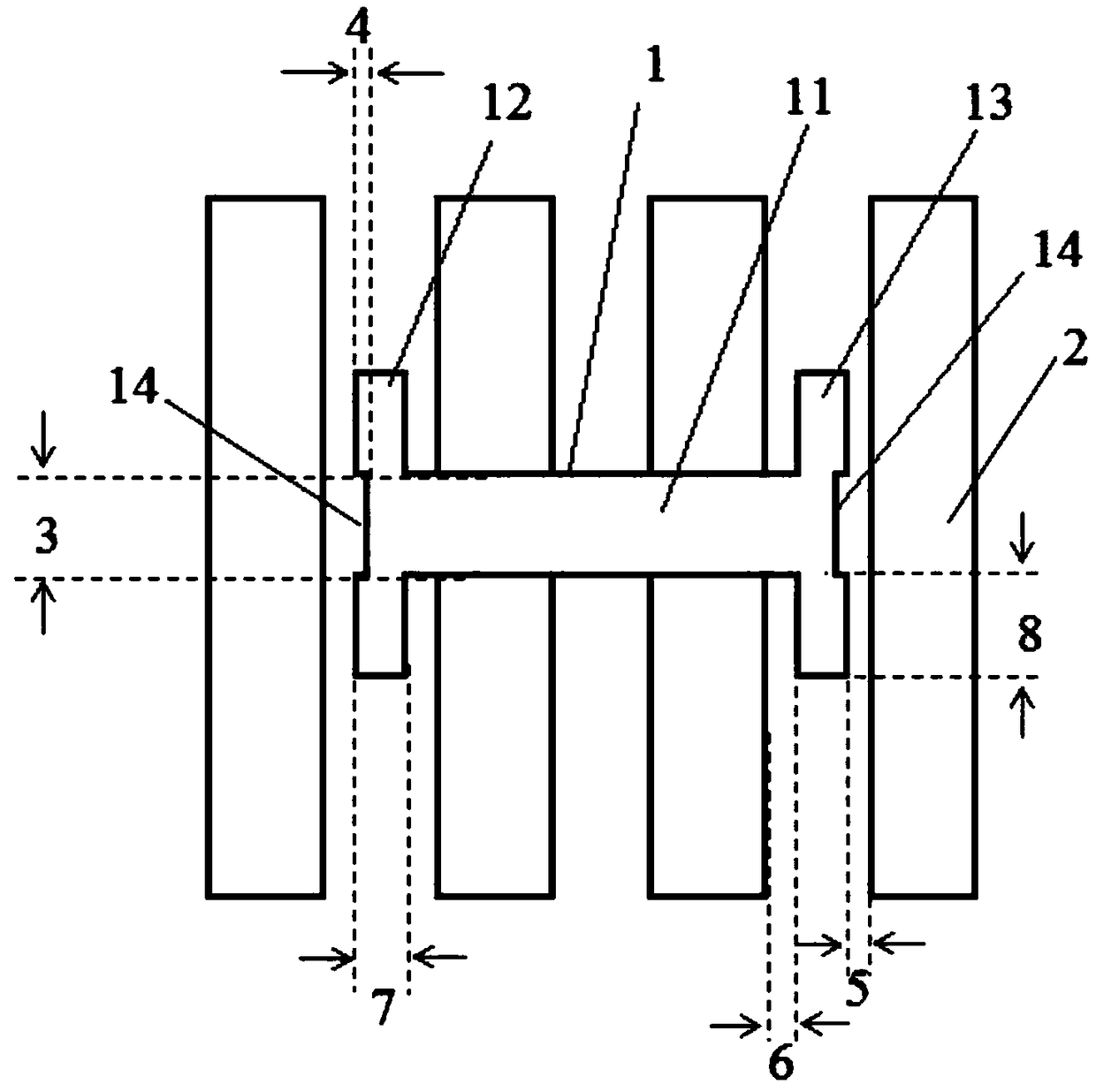

[0020] Example: refer to figure 1 .

[0021] An anti-plating ink graphic structure of a truncated position of an optical module gold finger, which includes an anti-plating ink 1, and the anti-plating ink 1 is arranged on the truncated position of the gold finger 2; the anti-plating ink 1 is H-shaped, including a waist 11, The left part 12 and the right part 13, the left part 12 and the right part 13 are connected by the waist part 11, the waist part 11 is arranged on the cut-off position of the golden finger 2, and the left part 12 and the right part 13 are arranged at the distance between the golden fingers 2 Above, the left part 12 and the right part 13 of the electroplating ink 1 are provided with grooves 14 for improving the development ability of the electroplating ink 11 . Set the H-type anti-plating ink 1 at the truncated position of the gold finger 2, so that the anti-plating ink 1 is not easy to fall off and deviate from the upper plate, and the design of the groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com