Supporting frame of wood roof

A technology for supporting frames and wooden houses, which is applied to roofs, truss structures, joists, etc., can solve problems such as insufficient slope, roof leakage, and wooden roof damage, and achieve the effect of using less material, large span and strong supporting capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

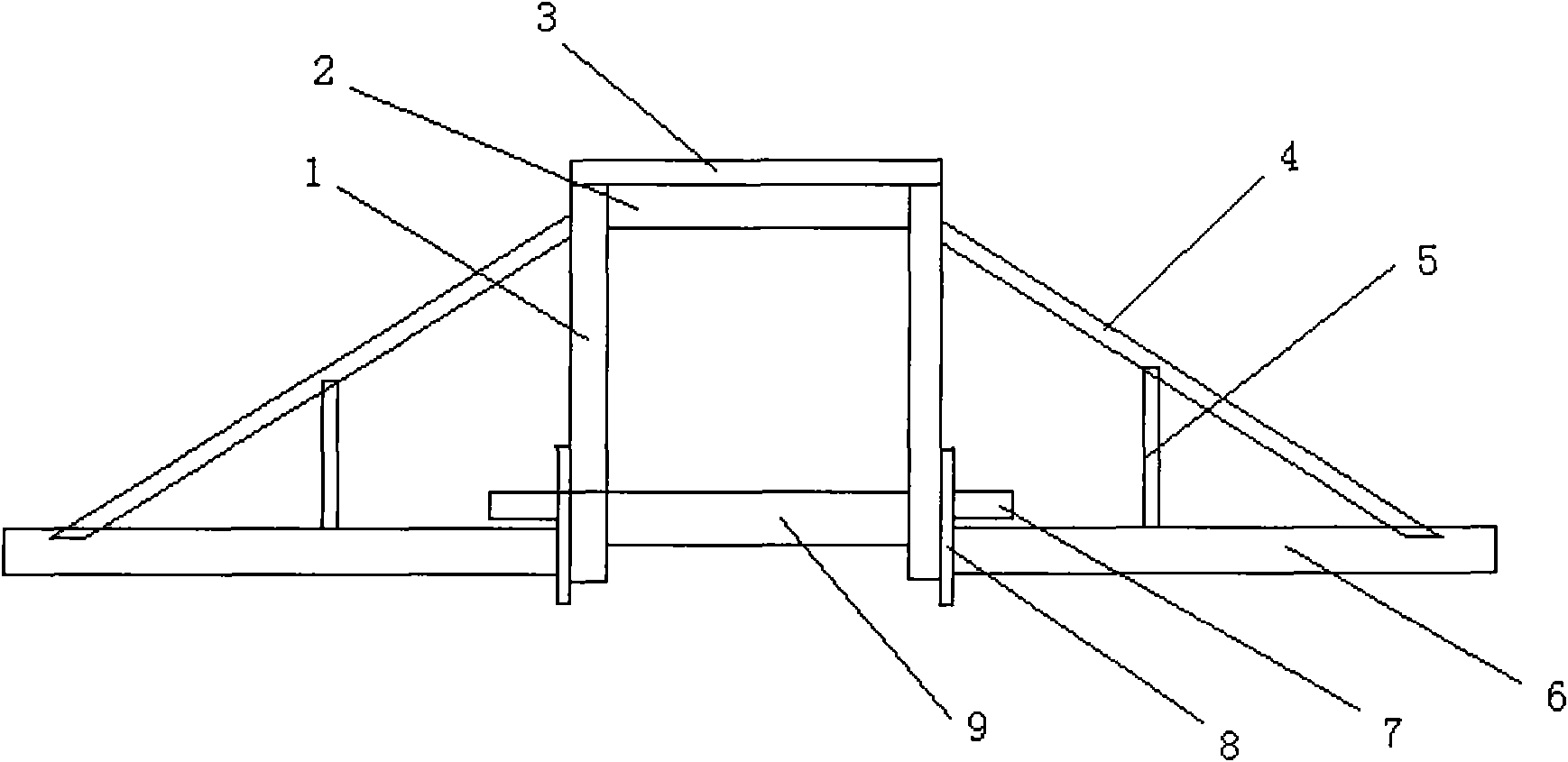

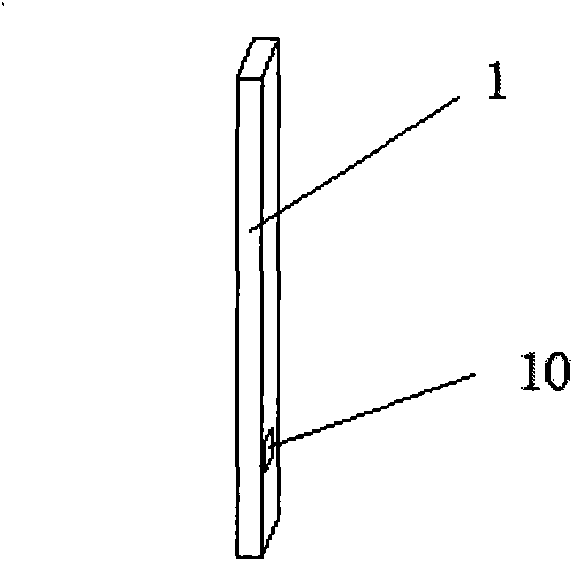

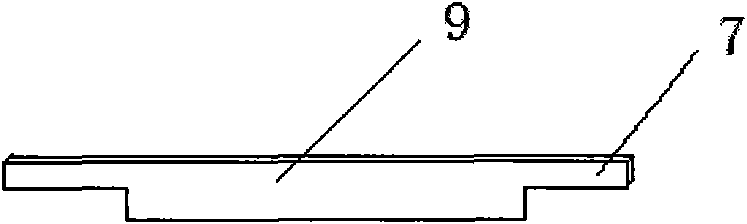

[0012] Such as figure 1 As shown, the wooden roof support frame of the present invention includes two gables supporting the upper beam 2, and a ridge purlin 3 is installed above the upper girder 2, and the structure of the girder is basically the same as that of the prior art. The lower part of the column 1 is connected with a bottom beam 9 for connecting and stabilizing the herringbone frame. The tenon pins 7 at both ends of the bottom beam 9 pass through the tenon hole 10 at the bottom of the middle column 1 and the upper tenon hole 12 of the extension joint 8, so that the extension joint 8 Hang on the mortise pin 7 and fix it on the center column through connecting pieces such as screws or bolts, the extension joint 8 is connected with the extension beam 6 through the lower tenon hole 11, the end of the extension beam 6 is connected with the roof frame, and connected with the herringbone An extended inclined beam 4 is connected between the tops of the middle columns of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com