Fabricated energy-saving building

An energy-saving house and prefabricated technology, which is applied to roofs, building components, and building insulation materials, can solve problems such as unsatisfactory thermal insulation performance and fire safety, complicated light steel structure houses, and unsatisfactory thermal insulation effects. Rust is difficult to remove, good heat preservation effect, easy to remove repeatedly

Inactive Publication Date: 2019-01-29

DONGGUAN DACHANG REFRIGERATION ELECTRICAL & MECHANICAL ENG

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the small houses in our country are mainly brick-concrete structures, and light steel structures are also promoted at present, but the existing brick-concrete structure houses have a long construction period, the insulation effect is not ideal, and more construction waste is generated. The construction process of the main structure of the house, cement floor level-building steel structure-wall filling-wall inner and outer hanging panels, etc. At present, the temporary resettlement houses for disaster relief in China are mainly tents and ordinary board houses, which are not ideal for thermal insulation performance and fire safety.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0047] The difference from the first embodiment above is that in this example, the outer color steel plate 11 of the wall panel unit 1 can also be replaced by a solid wood board.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

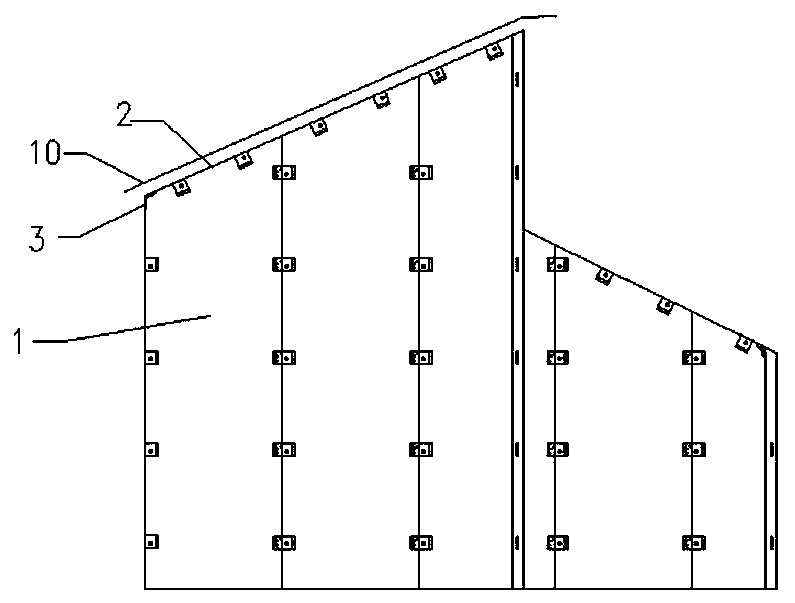

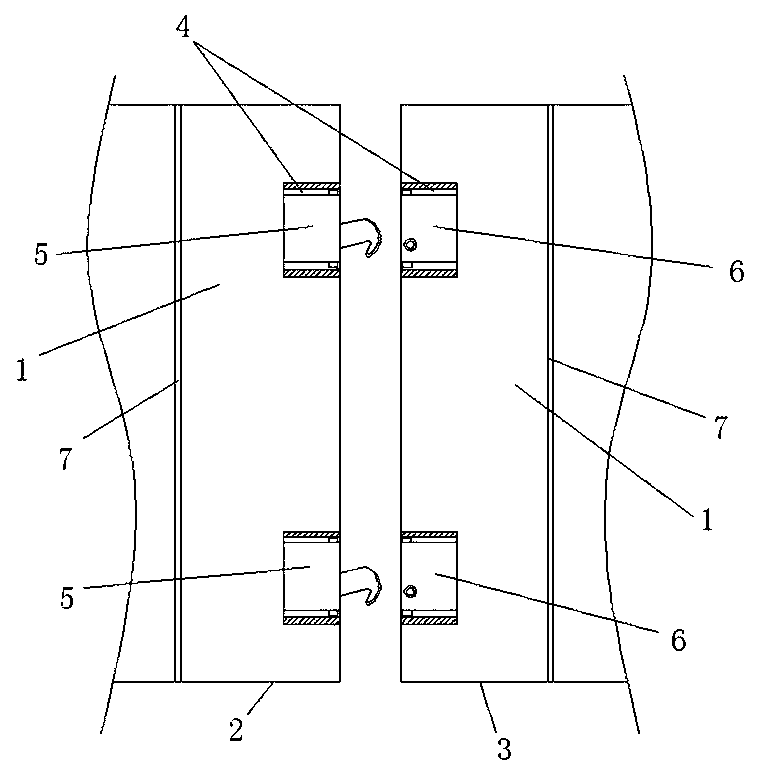

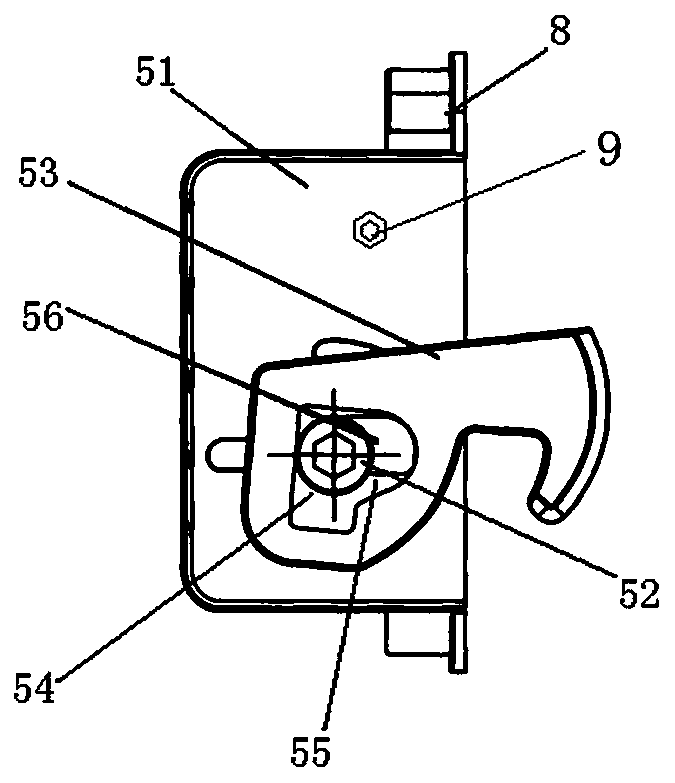

The invention discloses a fabricated energy-saving building, and relates to the field of energy-saving board rooms. The fabricated energy-saving building comprises wall body plate units, roof plate units and a locking mechanism. The wall body plate units close to a roof are fixedly connected with the roof plate units by steel angle fixing pieces. The locking mechanism comprises mounting grooves respectively formed in vertical faces of the adjacent wall body plate units and roof plate units, and female hook bodies and male hook bodies in the mounting grooves. Flow guide plates are arranged at the connecting seams between the adjacent roof plate units. Each flow guide plate comprises two inclined plates with the planes being manually obliquely. The inclined plates are fist inclined plates and second inclined plates. The inclination angle of the first inclined plates is the same as that of the roof plate units. The ends of the second inclined plates are inserted below the first inclined plates. The fabricated energy-saving building has excellent heat preservation effect, has good water resisting and fire resisting performance, has a certain of shock resisting ability, and is suitablefor post-disaster disaster relief housing.

Description

technical field [0001] The invention relates to the field of energy-saving board houses, in particular to a prefabricated energy-saving house. Background technique [0002] At present, the small houses in our country are mainly brick-concrete structures, and light steel structures are also promoted at present, but the existing brick-concrete structure houses have a long construction period, the insulation effect is not ideal, and more construction waste is generated. The construction process of the main structure of the house is cement floor leveling - steel structure building - wall filling - wall hanging panels inside and outside the wall, etc. At present, the temporary resettlement houses for disaster relief in China are mainly tents and ordinary board houses, which are not ideal for thermal insulation performance and fire safety. [0003] In order to reduce the cost of small houses, solve construction waste disposal, and reduce energy consumption during living, it is urg...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04B1/61E04B2/00E04B7/00E04B1/76E04B1/94E04B1/68

CPCE04B1/612E04B1/68E04B1/76E04B1/94E04B2/00E04B7/00

Inventor 易春阳赵秀钱

Owner DONGGUAN DACHANG REFRIGERATION ELECTRICAL & MECHANICAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com