Electric silkworm cocoon cutting machine for silkworm egg production

A technology of using electric silkworms and silkworm seeds, applied in animal husbandry and other directions, can solve the problems of cutting silkworm chrysalis, need large, easy to cut fingers, etc., and achieve the effect of reducing labor intensity and improving the speed of cocoon cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

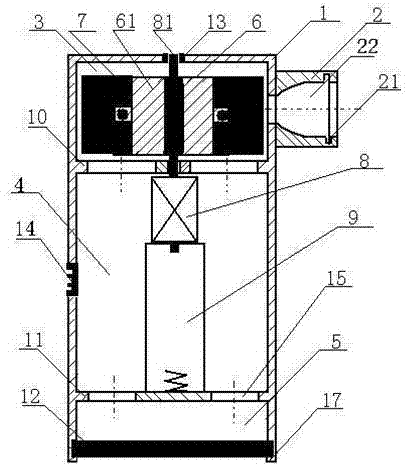

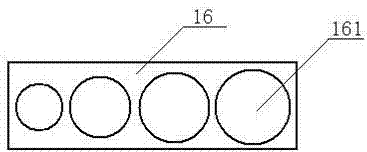

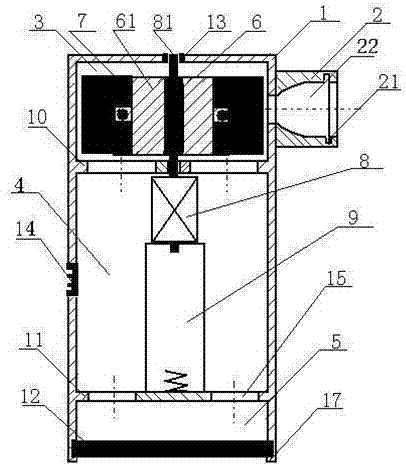

[0019] The present invention as figure 1 As shown, the housing 1 is provided with a feeding chamber 3, a blanking chamber 4, and a storage chamber 5, and an A partition 10 is arranged between the feeding chamber 3 and the blanking chamber 4, and the blanking chamber 4 and the storage chamber 5 is provided with a B partition 11, the shape of the A partition 10 and the B partition 11 matches the cross section of the shell 1, and they are arranged in parallel; the A partition 10 and the B partition 11 are symmetrically provided with four blanking hole 15; a knife seat 6 is arranged in the feeding chamber 3, and the knife holder 61 arranged on it is connected with the cutting knife 7; The channel 22 is a "conical" cavity, which is "folded" inwards. Its shape matches the shape of the silkworm cocoon and communicates with the feeding cavity 3 in the housing 1. The cocoon enters the channel 22 on the opposite side wall. A card slot 21 is arranged symmetrically, such as figure 2 Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com