Mechanical arm clamping device

A technology of clamping device and mechanical arm, applied in the field of mechanical arm, can solve the problems of complex structure, reduced reliability of rigidity index, high manufacturing and maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

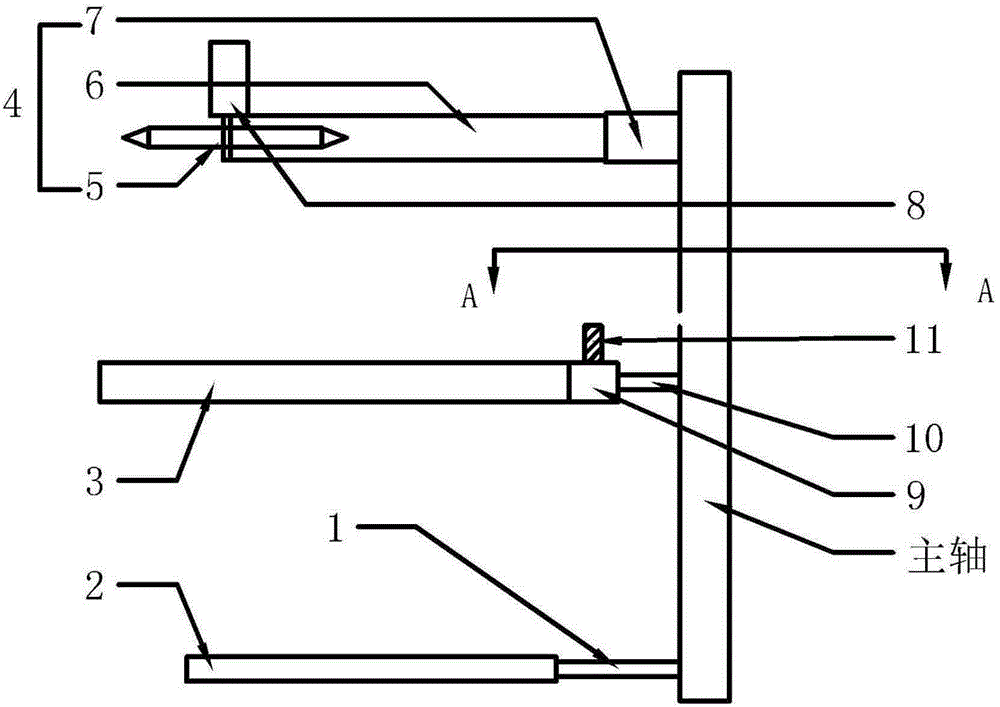

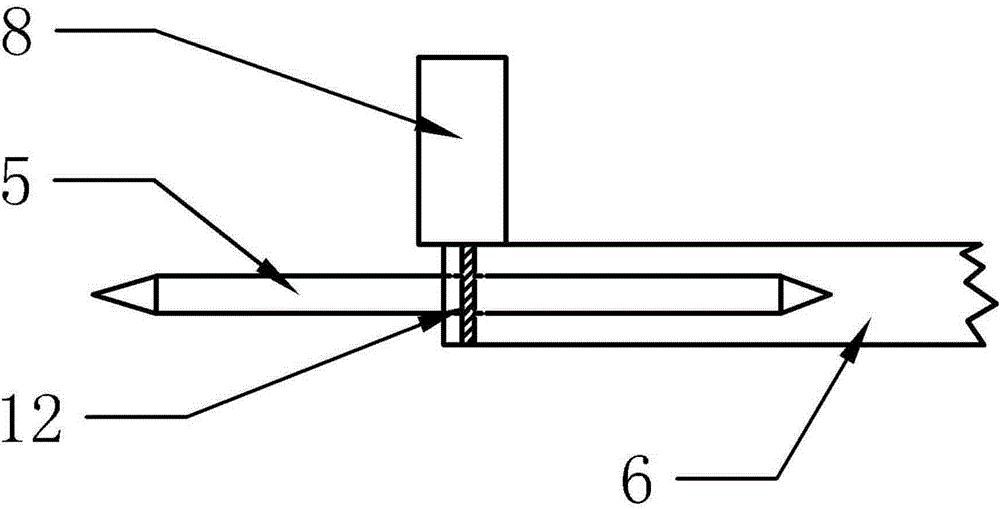

[0019] refer to Figure 1-3 , a specific embodiment of the present invention includes a main shaft and a cutting finger 4 , a clamping finger and a tray 2 installed sequentially from top to bottom. The cutting finger 4 has a cutting arm 6, one end of the cutting arm 6 is connected to the main shaft, the other end is equipped with a cutting wheel 5, the center of the cutting wheel 5 has a rotating shaft 12, and a cutting motor is detachably connected above the rotating shaft 12 8. The cutting arm 6 is connected to the main shaft through the hydraulic drive 7, so that the cutting wheel 5 can move horizontally.

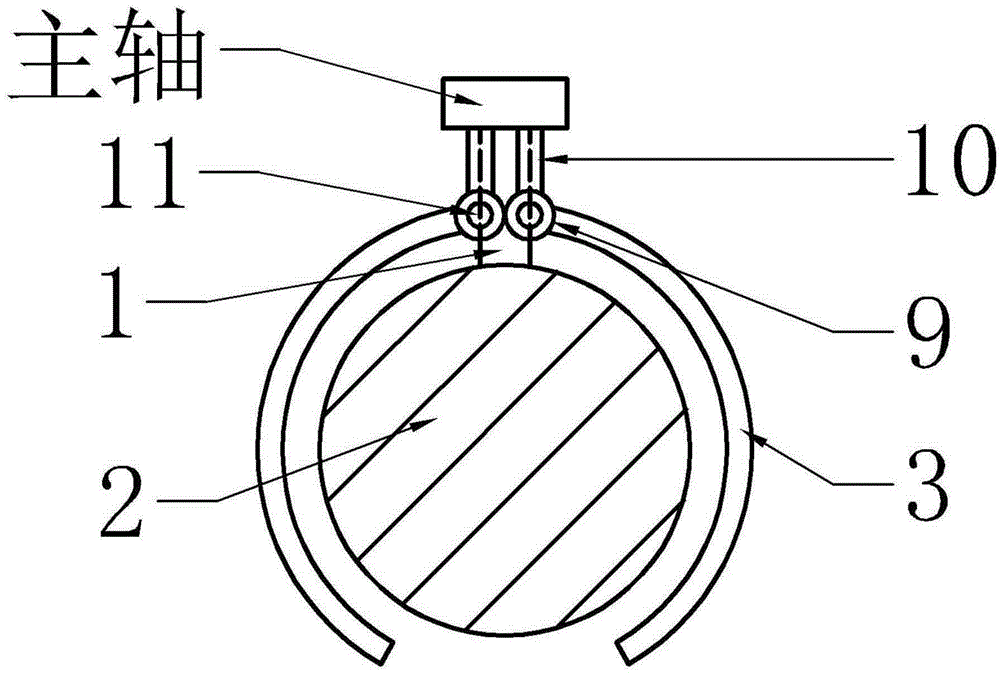

[0020] The clamping finger has two arc-shaped finger bodies 3 , and the ends of the finger bodies 3 close to the main shaft are respectively connected to the rotating shaft 9 and connected to the main shaft through the clamping finger connecting rod 10 . The clamping finger has a pressure sensing device, which is used to adjust the strength of the clamping finger and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com