Bunched cable manufacturing multi-function intelligent manipulator and automatic cabling system thereof

An intelligent machine, multi-functional technology, applied in the field of robotics, can solve the problems of less function of the robot hand, limited working range, difficult trajectory planning, etc., to achieve the effect of improving wiring efficiency and reliability, high degree of automation, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

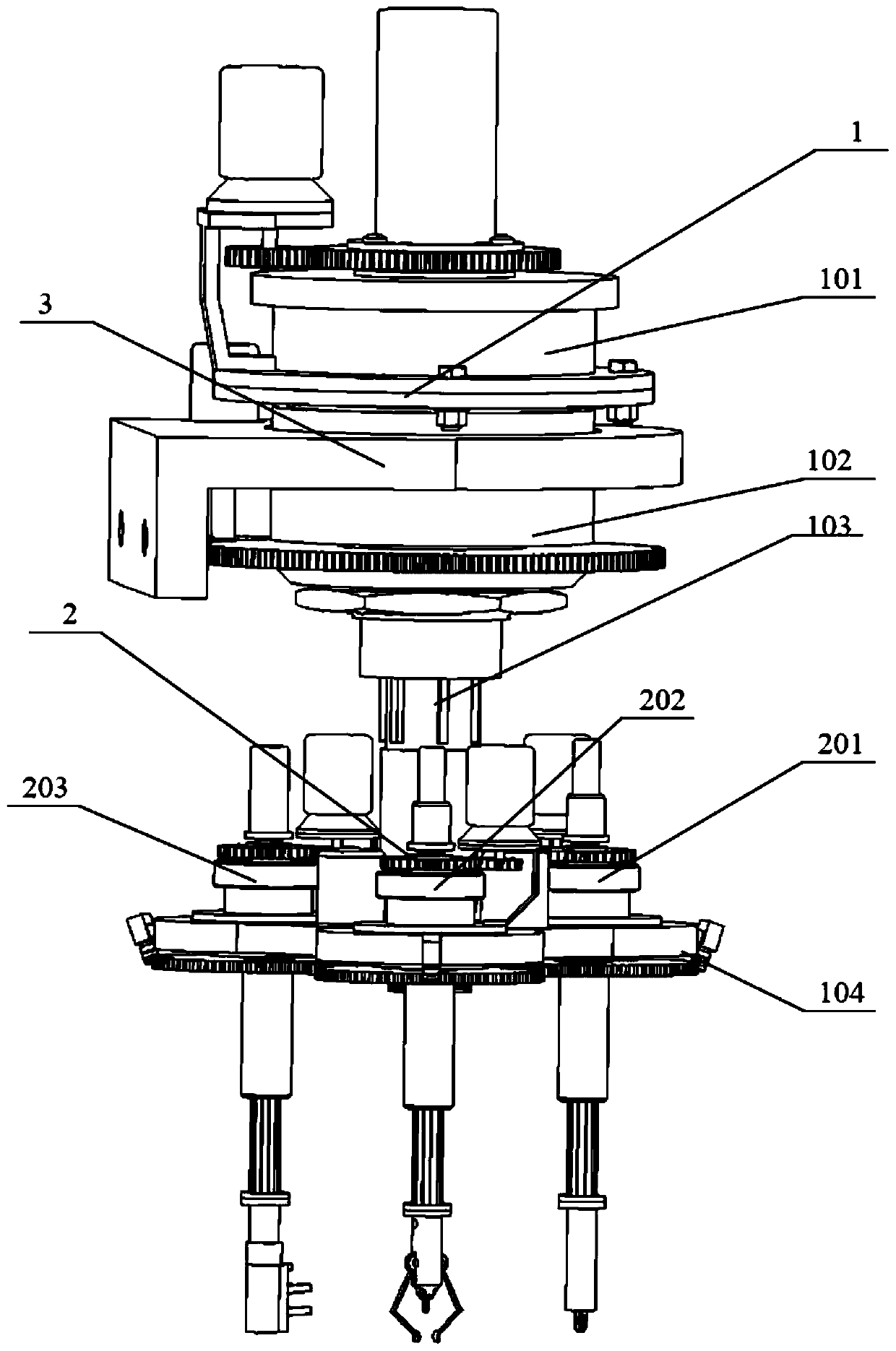

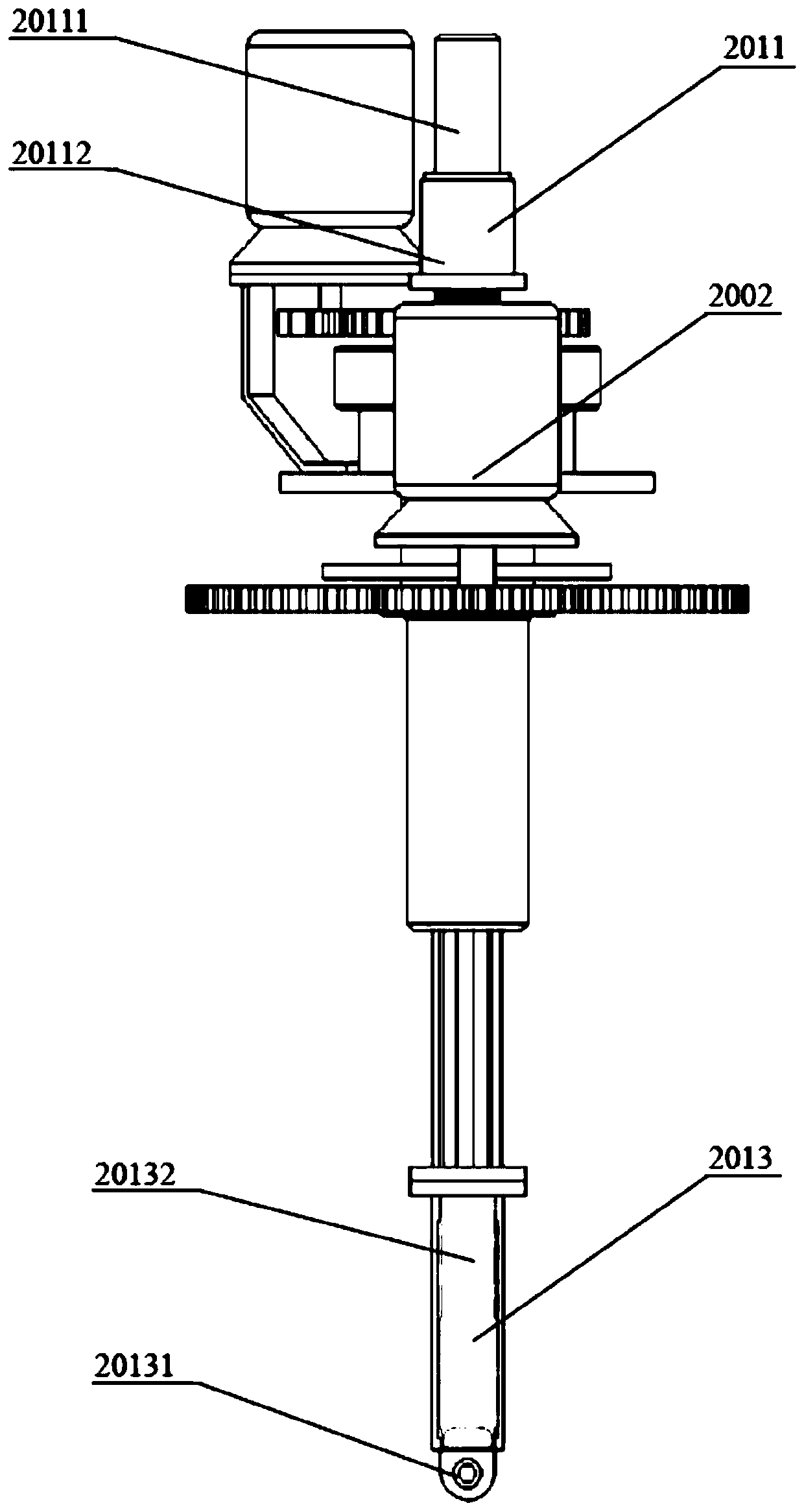

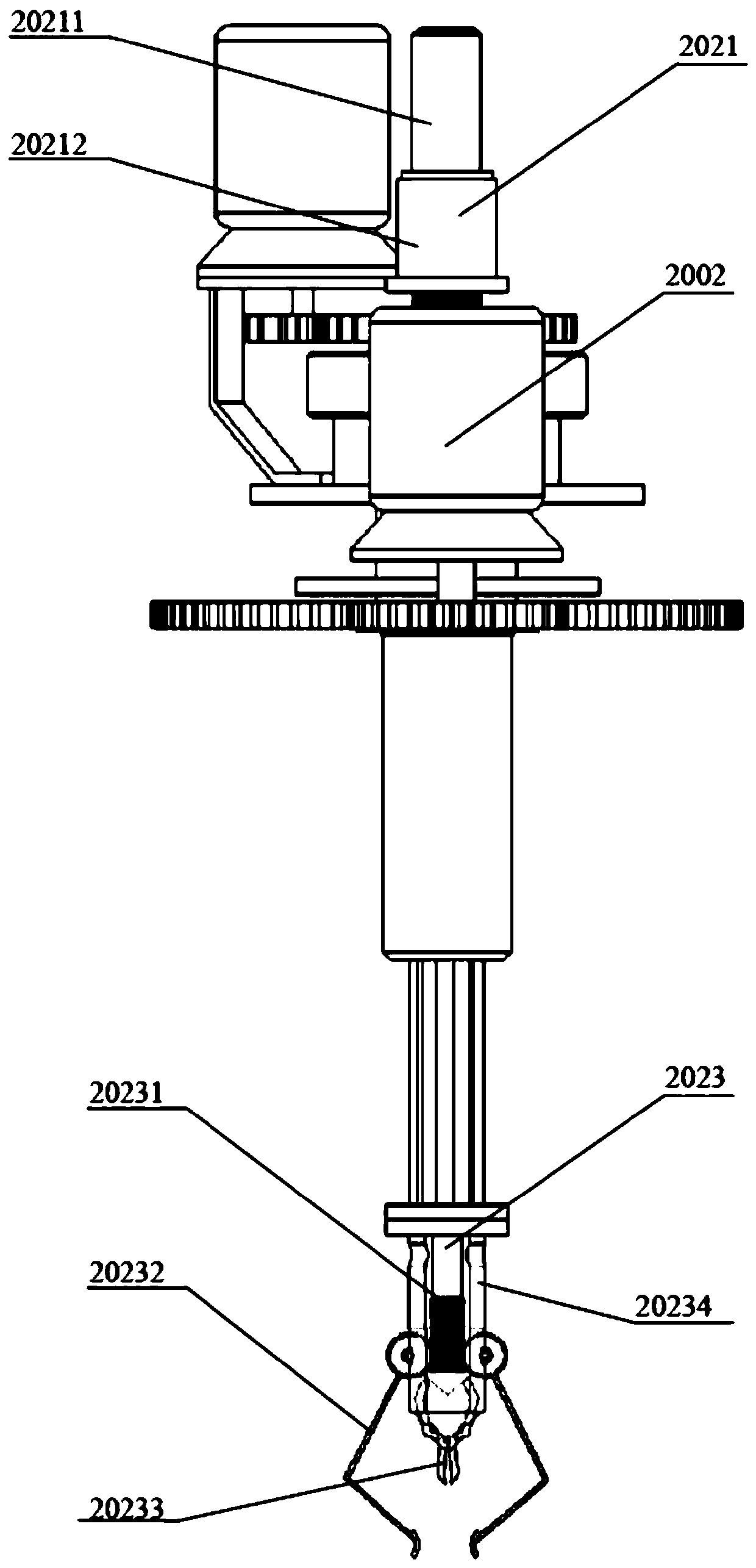

[0041] Such as figure 1 As shown, a multifunctional intelligent robotic hand manufactured by a bundled cable network includes a wrist system 1, a multifunctional finger system 2 and a motion mechanism 3. The wrist system 1 includes a wrist lifting mechanism 101, a wrist rotating mechanism 102, a main shaft 103 and The finger mounting plate 104, the lower end of the main shaft 103 passes through the wrist lifting mechanism 101 and the wrist rotating mechanism 102 in turn, and is connected with the finger mounting plate 104, the upper part of the main shaft 103 is connected with the wrist lifting mechanism 101, and the wrist lifting mechanism 101 drives the main shaft 103 to lift to realize finger mounting The disk 104 lifts, the lower part of the main shaft 103 is connected with the wrist rotation mechanism 102, and the wrist rotation mechanism 102 drives the rotation of the main shaft 103 to realize the rotation of the finger mounting disk 104. The wrist lifting mechanism 101 i...

Embodiment 2

[0047] Such as Figure 6As shown, an automatic wiring system for manufacturing a multifunctional intelligent robot based on a bundled cable network includes a cable collection platform 6, a positioning column shuttle box storehouse 7, a cable material storehouse 8, a crimping machine storehouse 9, and a control unit 10. Including the above-mentioned multifunctional intelligent manipulator 4, the motion mechanism is an X-Y direction movement mechanism 5, the X-Y direction movement mechanism 5 is a floor type double-sided drive type, and the multifunctional intelligent manipulator 4 is installed on the X-Y direction movement mechanism 5, The control unit automatically optimizes the placement position of the positioning column 20333 and the wire crimping device on the cable collection platform 6 according to the imported cable network graphics, the model and length of each branch cable, and gives the coordinates of the corresponding holes. After the instruction sent by 10, the mu...

Embodiment 3

[0049] Such as Figure 7 As shown, this embodiment is basically the same as Embodiment 2, except that the X-Y direction movement mechanism 5 is a floor type single cantilever driven type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com