Patents

Literature

183results about How to "Material removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

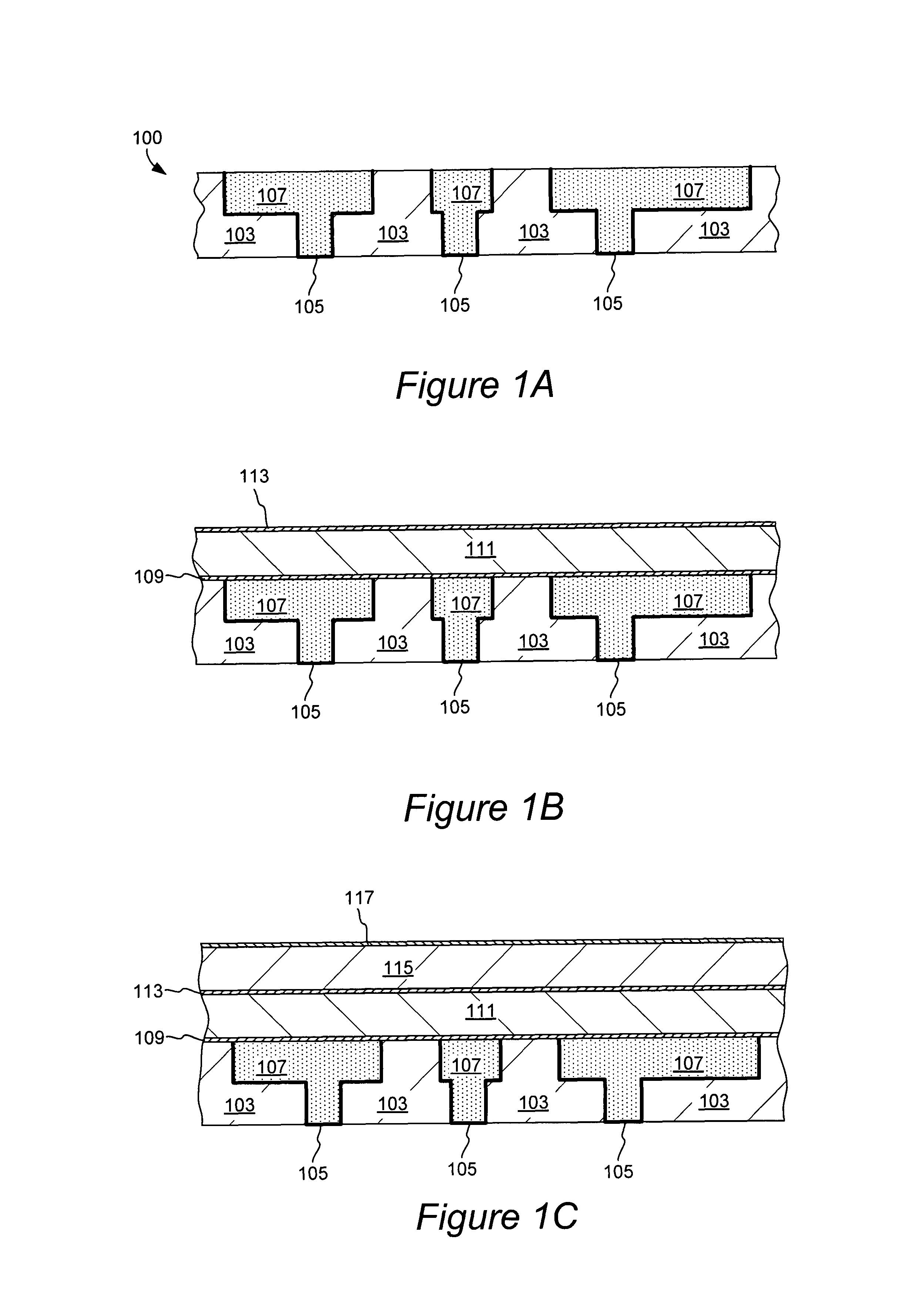

Dry-etch for silicon-and-nitrogen-containing films

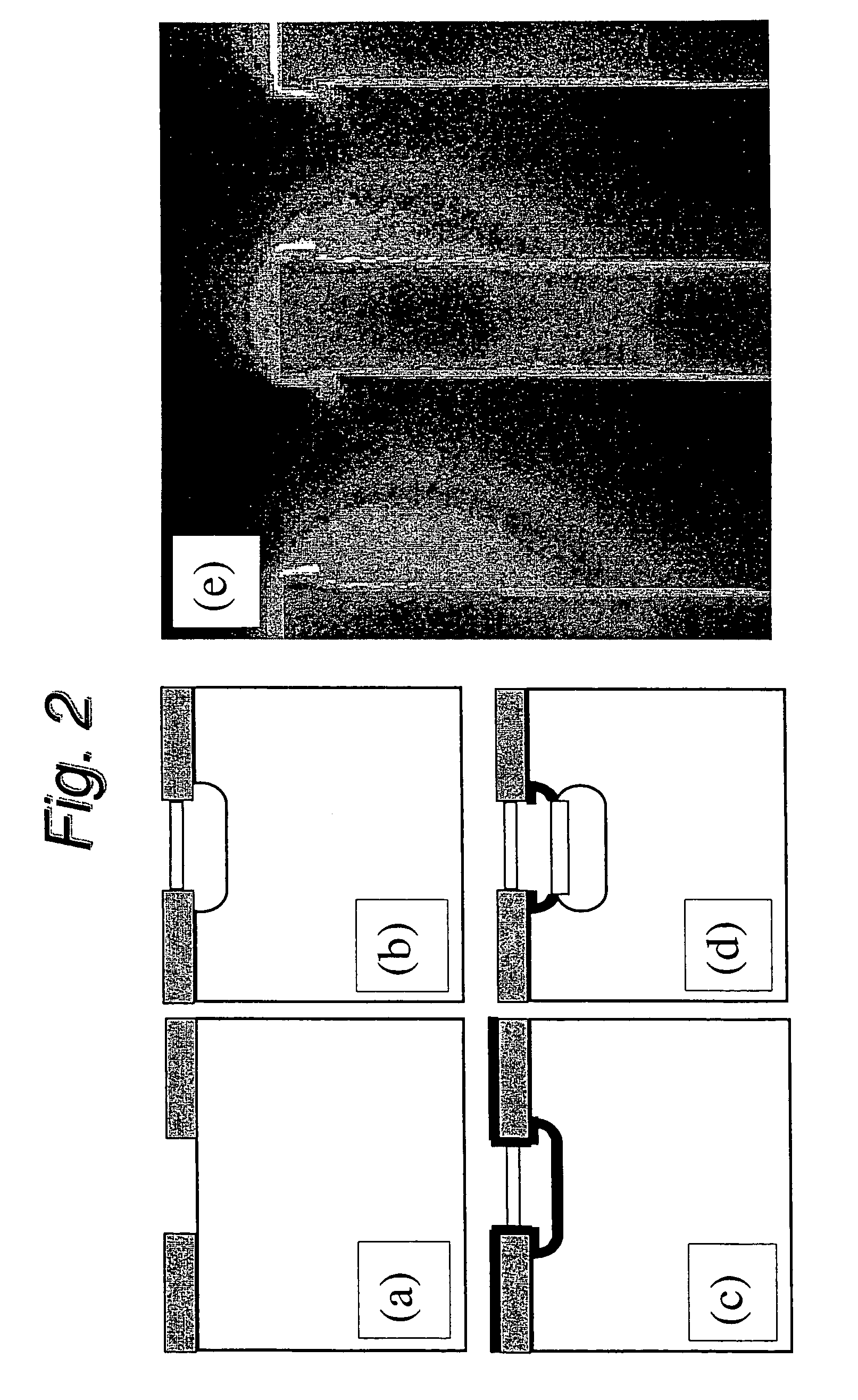

InactiveUS20130045605A1Reduces and substantially eliminates numberMaterial removalElectric discharge tubesSemiconductor/solid-state device manufacturingHeterojunctionRemote plasma

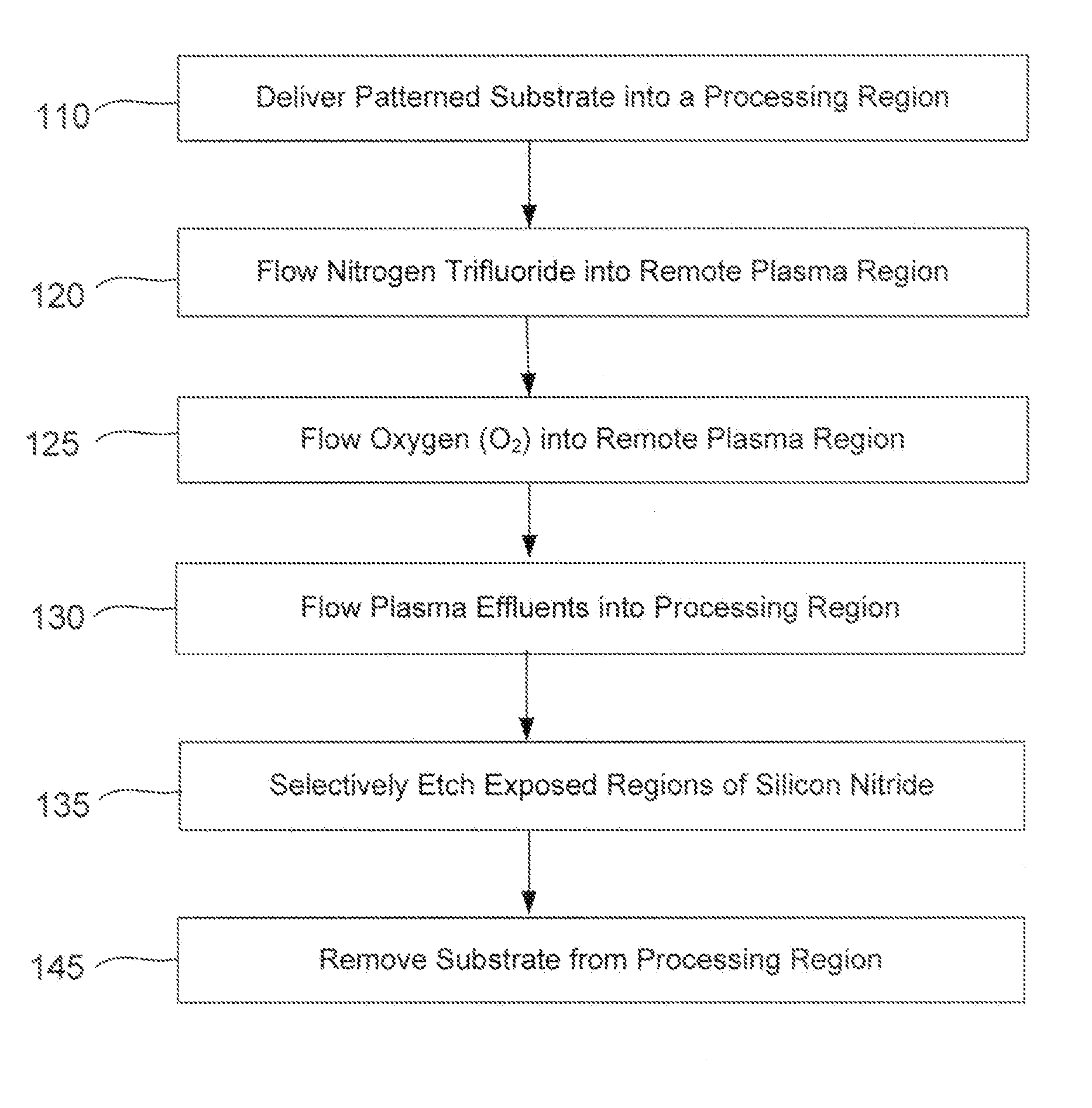

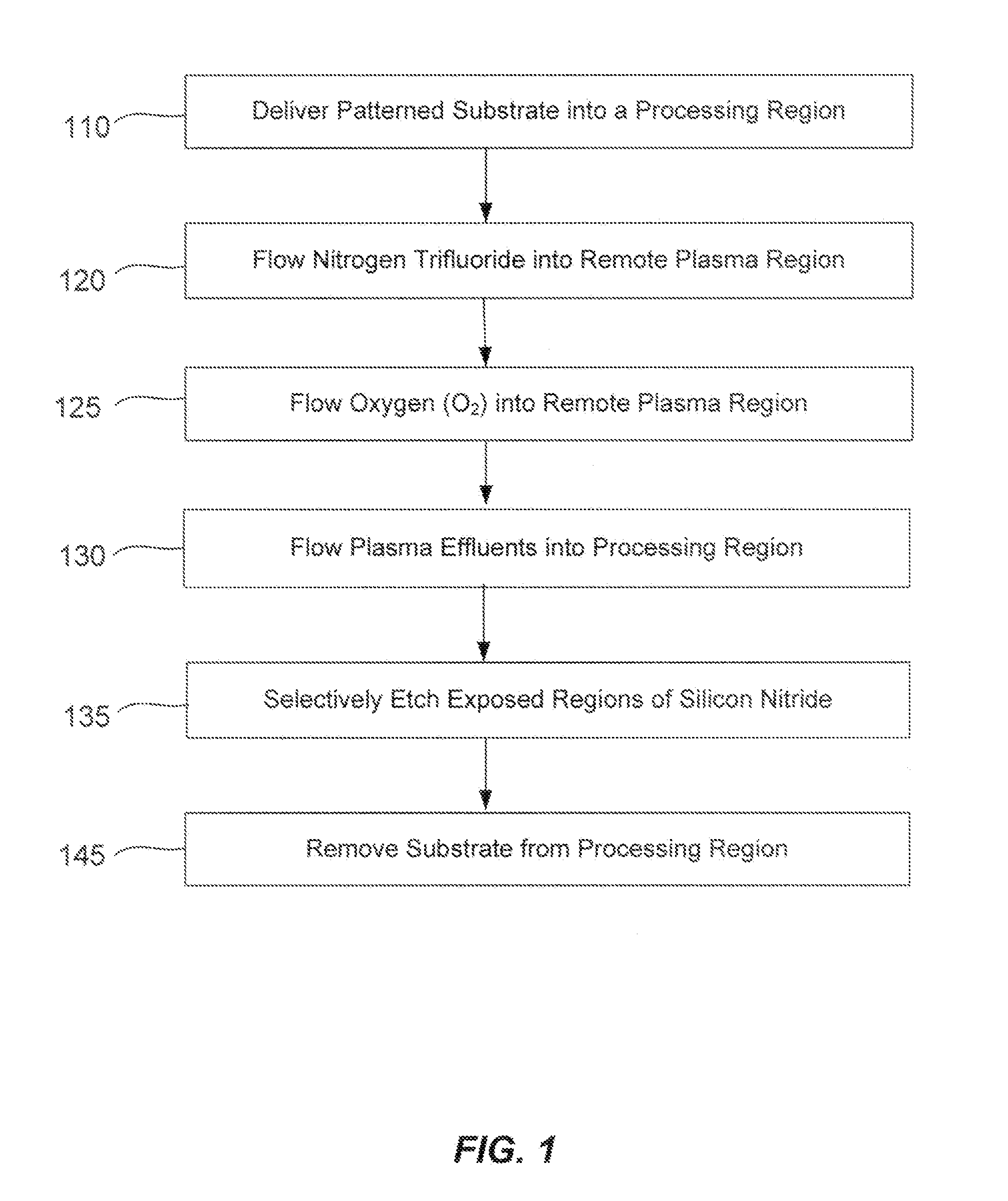

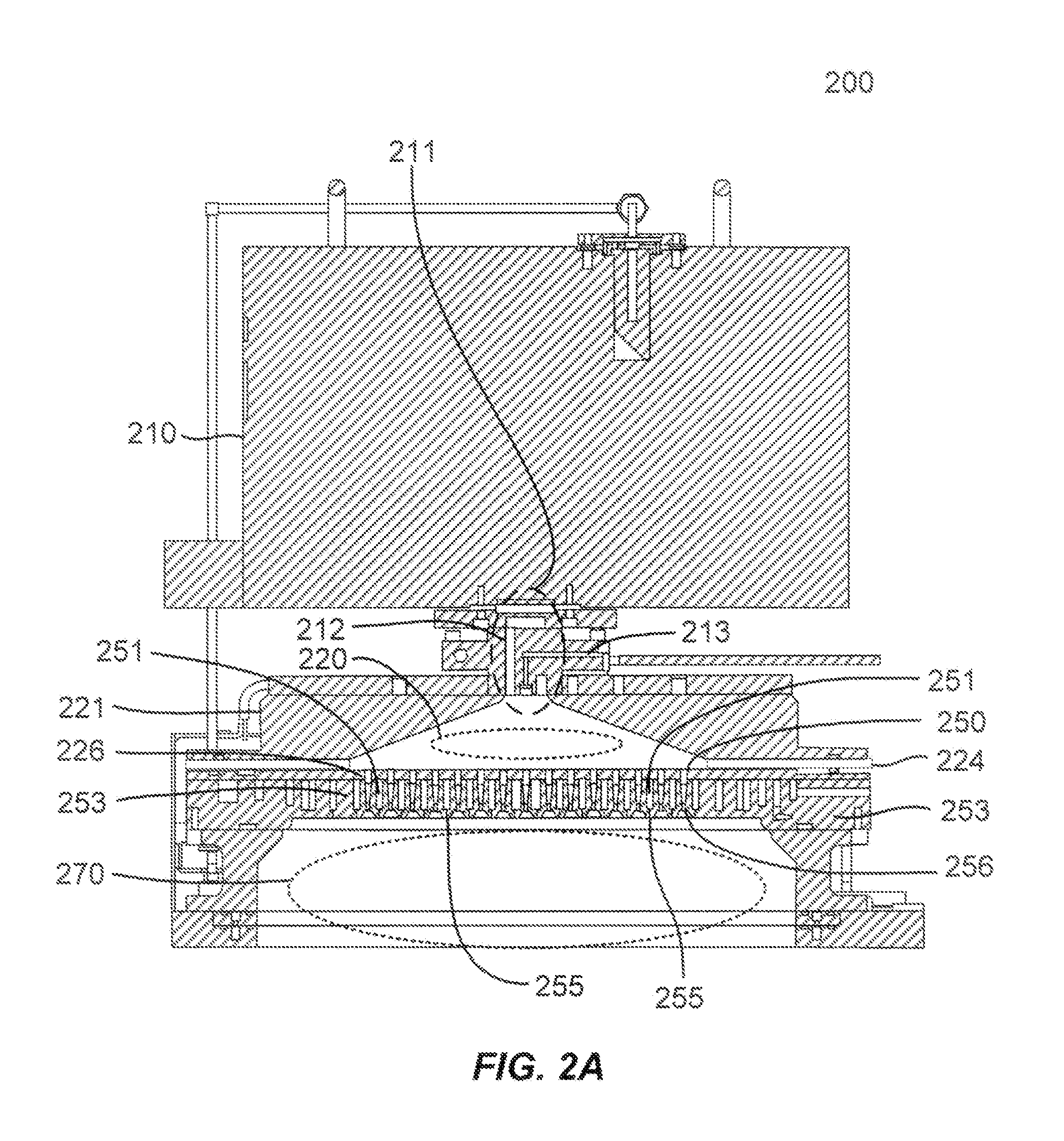

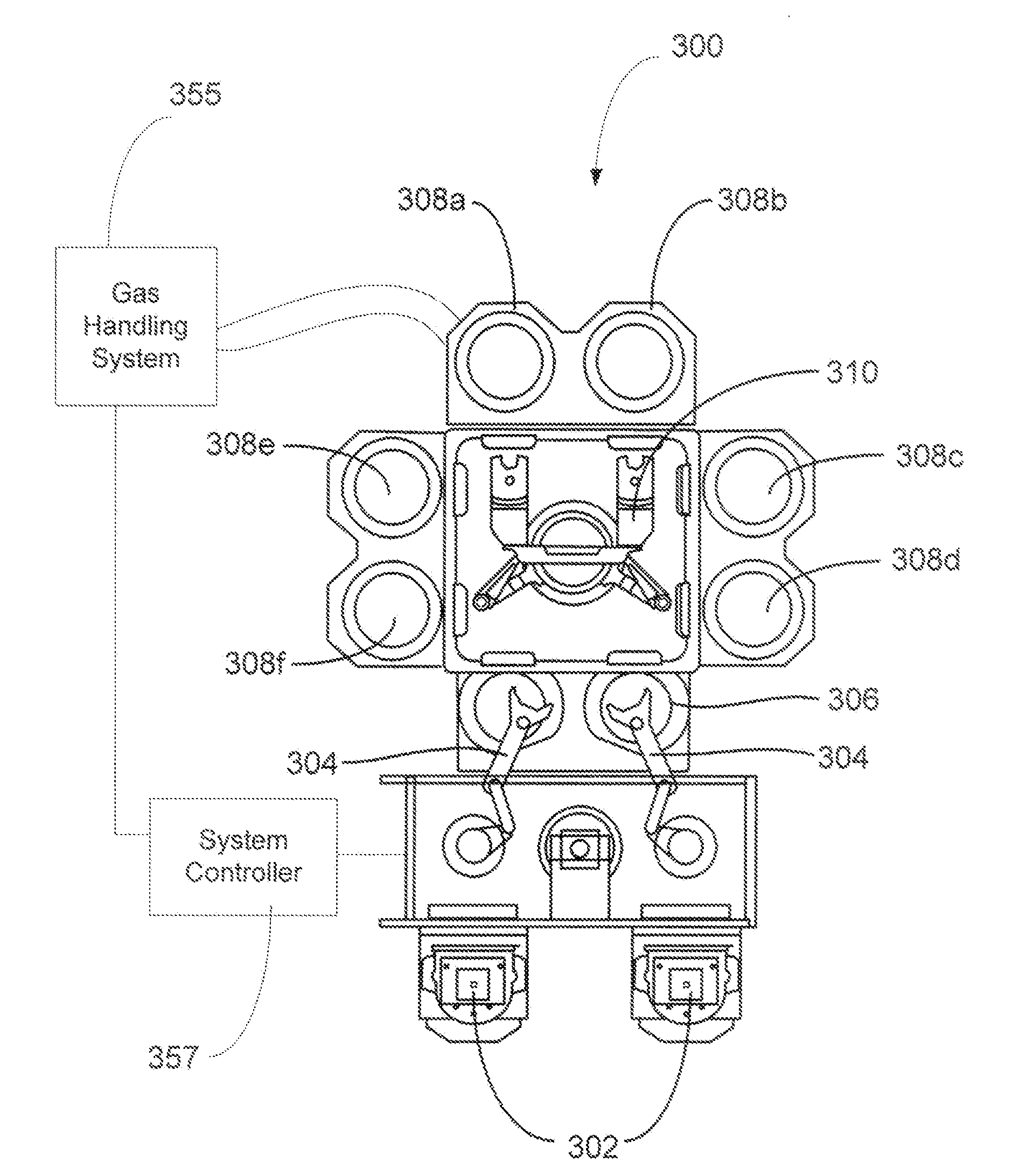

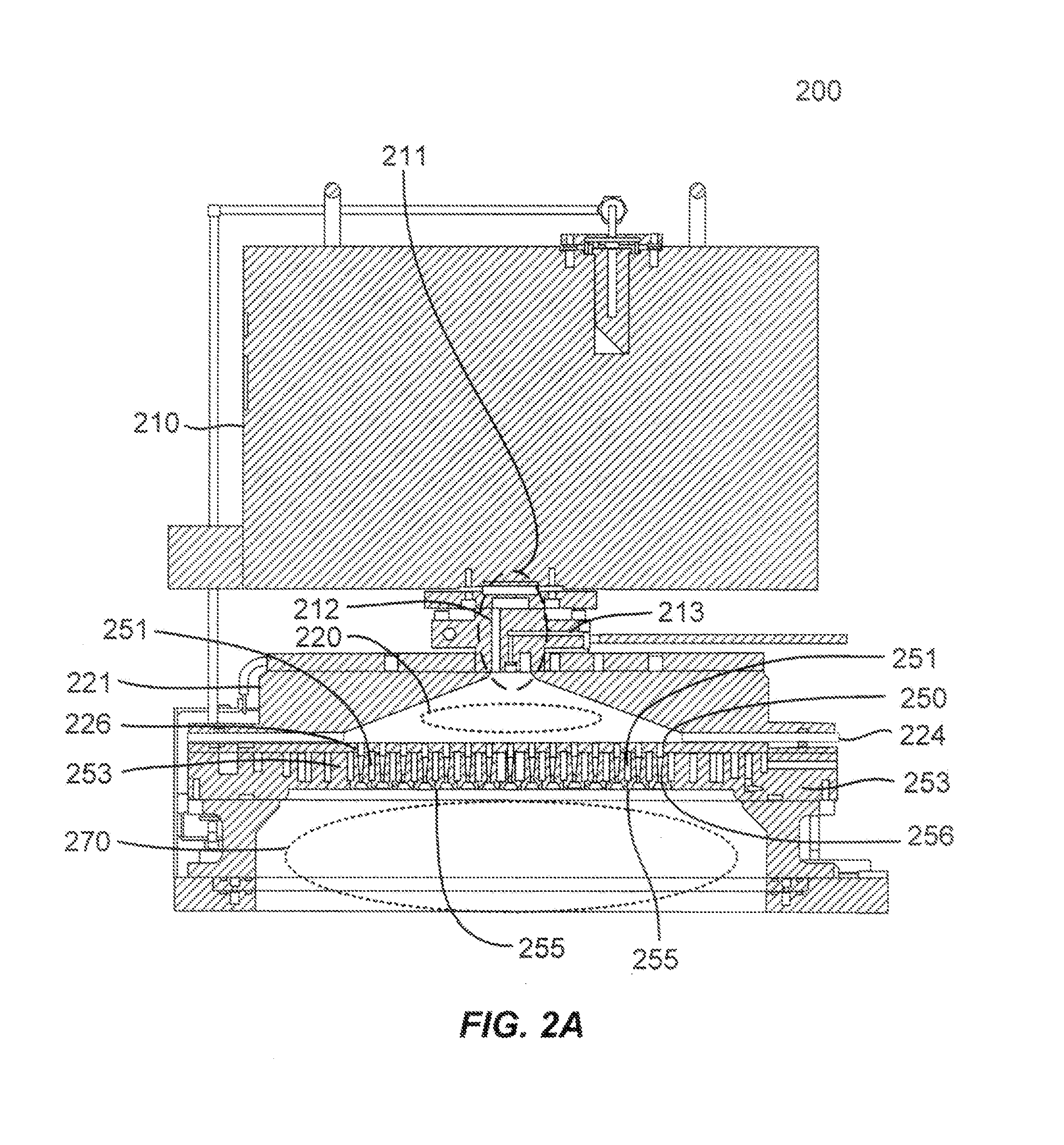

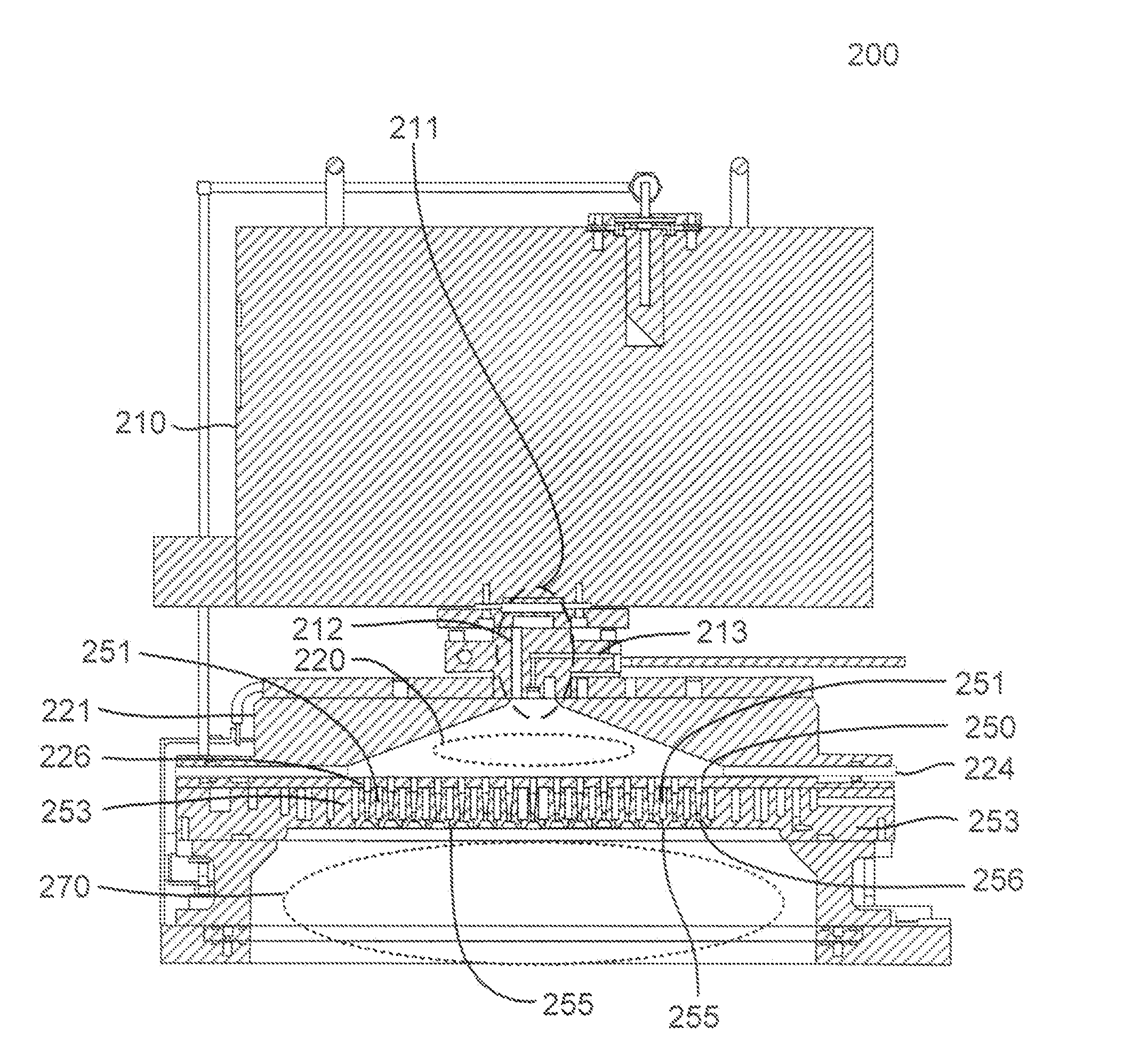

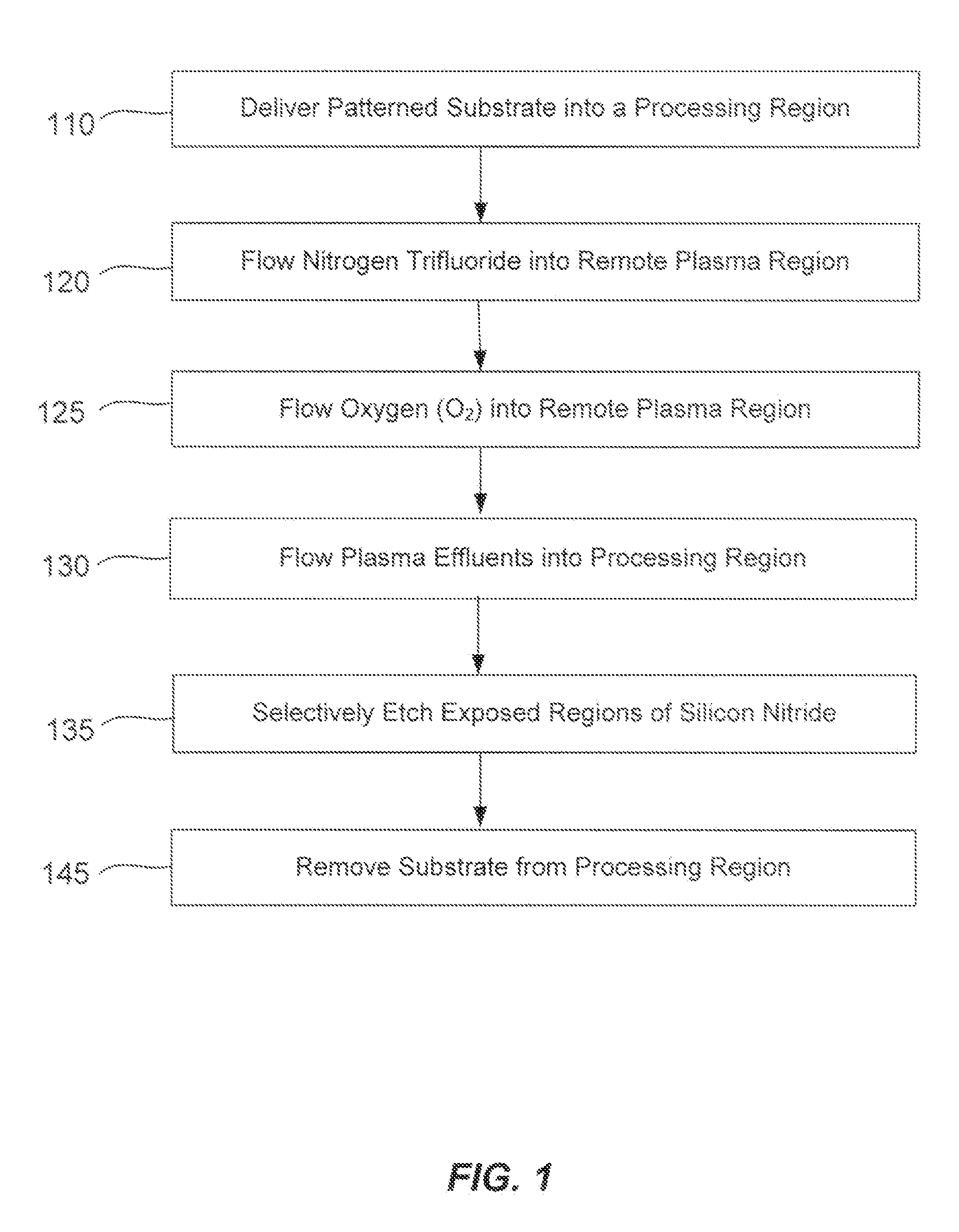

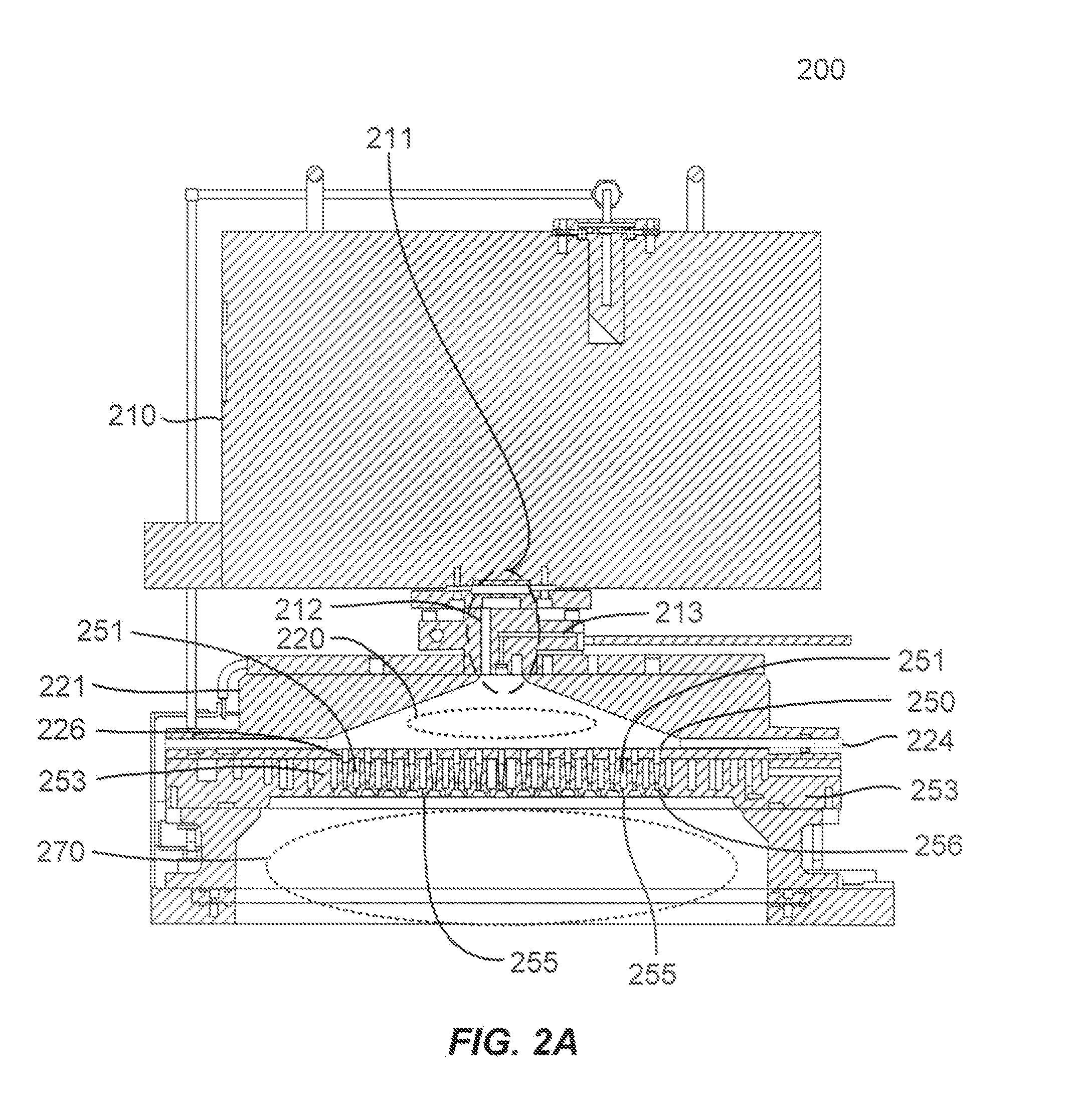

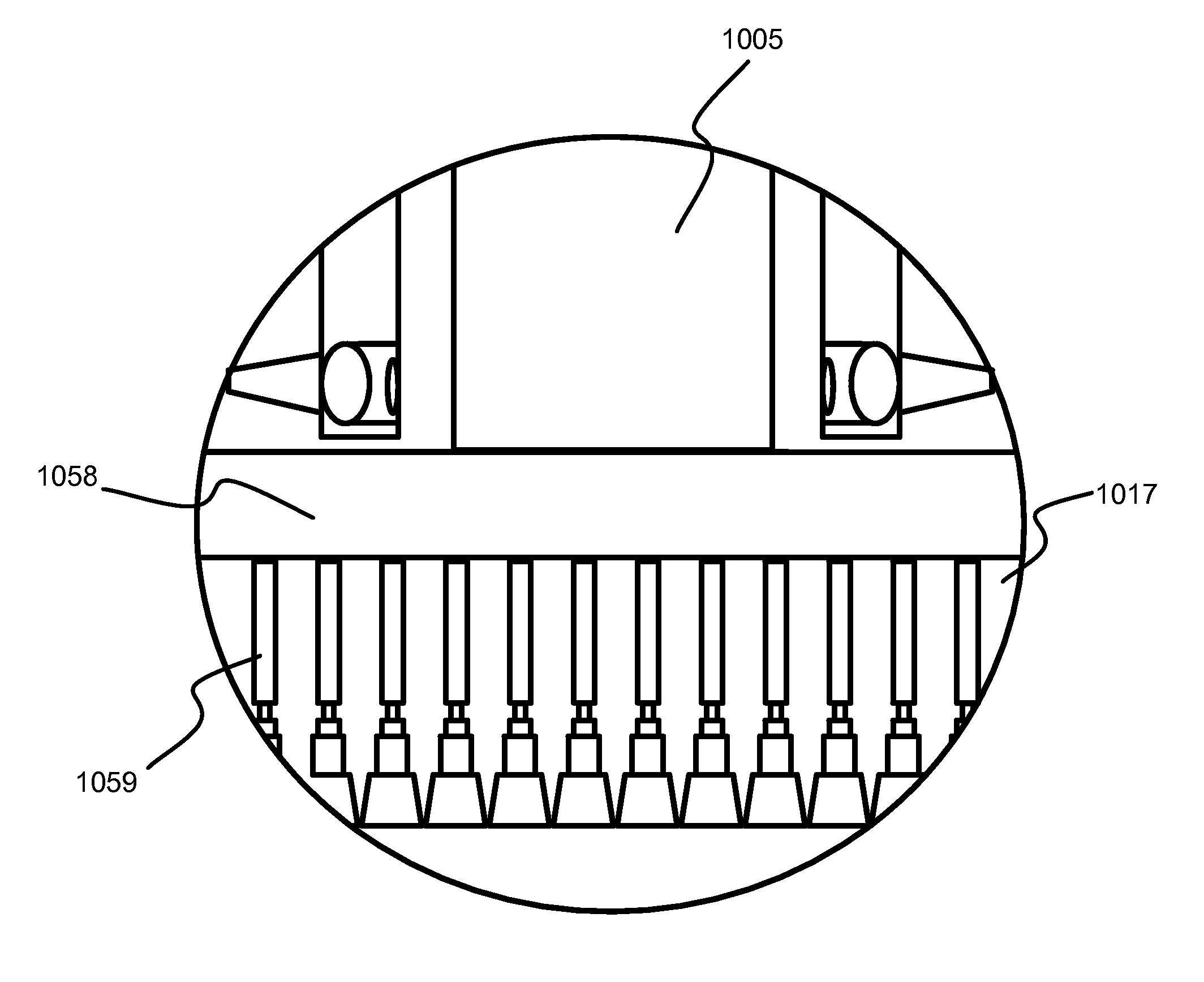

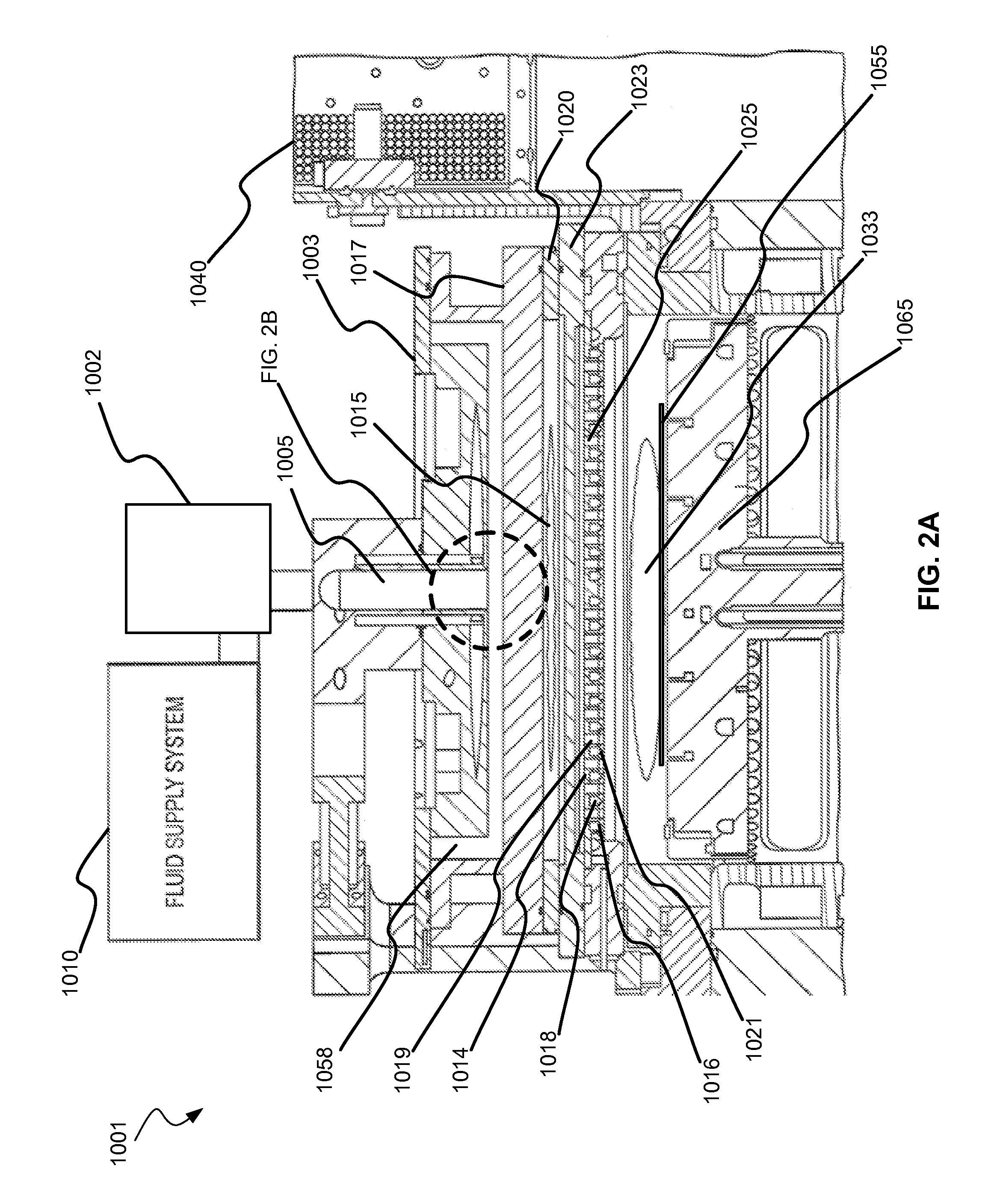

A method of etching exposed silicon-and-nitrogen-containing material on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor and an oxygen-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the exposed regions of silicon-and-nitrogen-containing material. The plasmas effluents react with the patterned heterogeneous structures to selectively remove silicon-and-nitrogen-containing material from the exposed silicon-and-nitrogen-containing material regions while very slowly removing other exposed materials. The silicon-and-nitrogen-containing material selectivity results partly from the presence of an ion suppression element positioned between the remote plasma and the substrate processing region. The ion suppression element reduces or substantially eliminates the number of ionically-charged species that reach the substrate. The methods may be used to selectively remove silicon-and-nitrogen-containing material at more than twenty times the rate of silicon oxide.

Owner:APPLIED MATERIALS INC

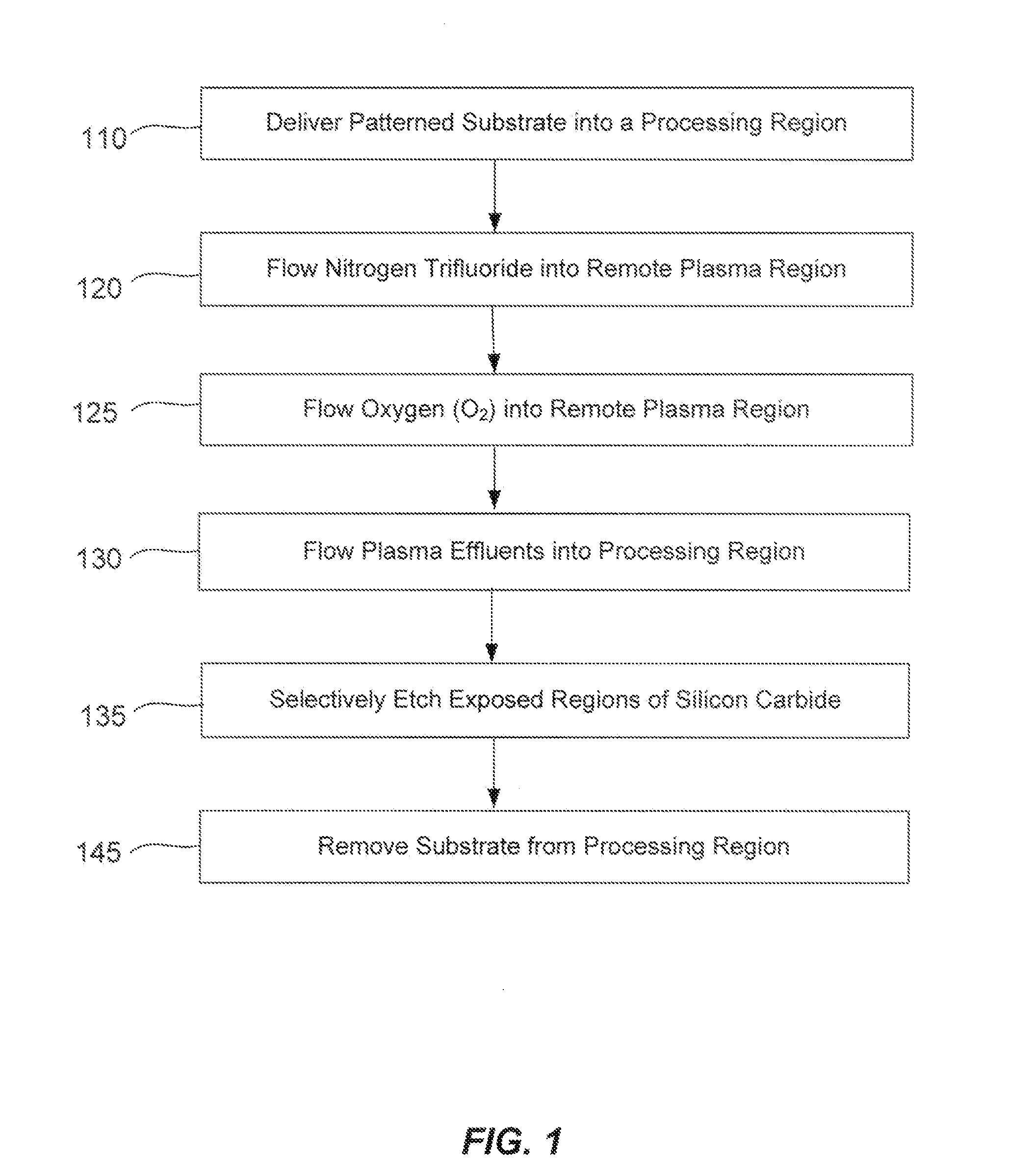

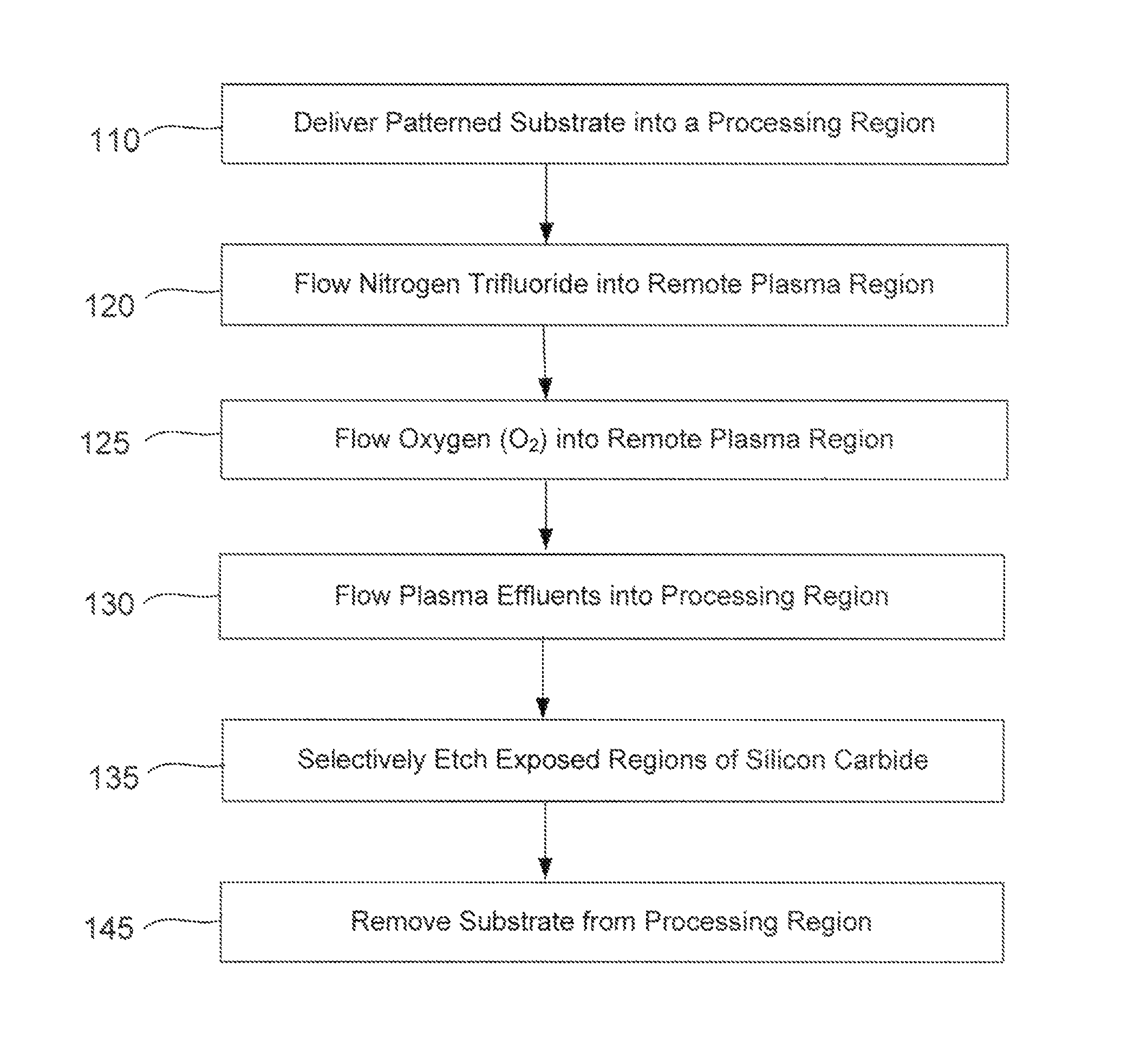

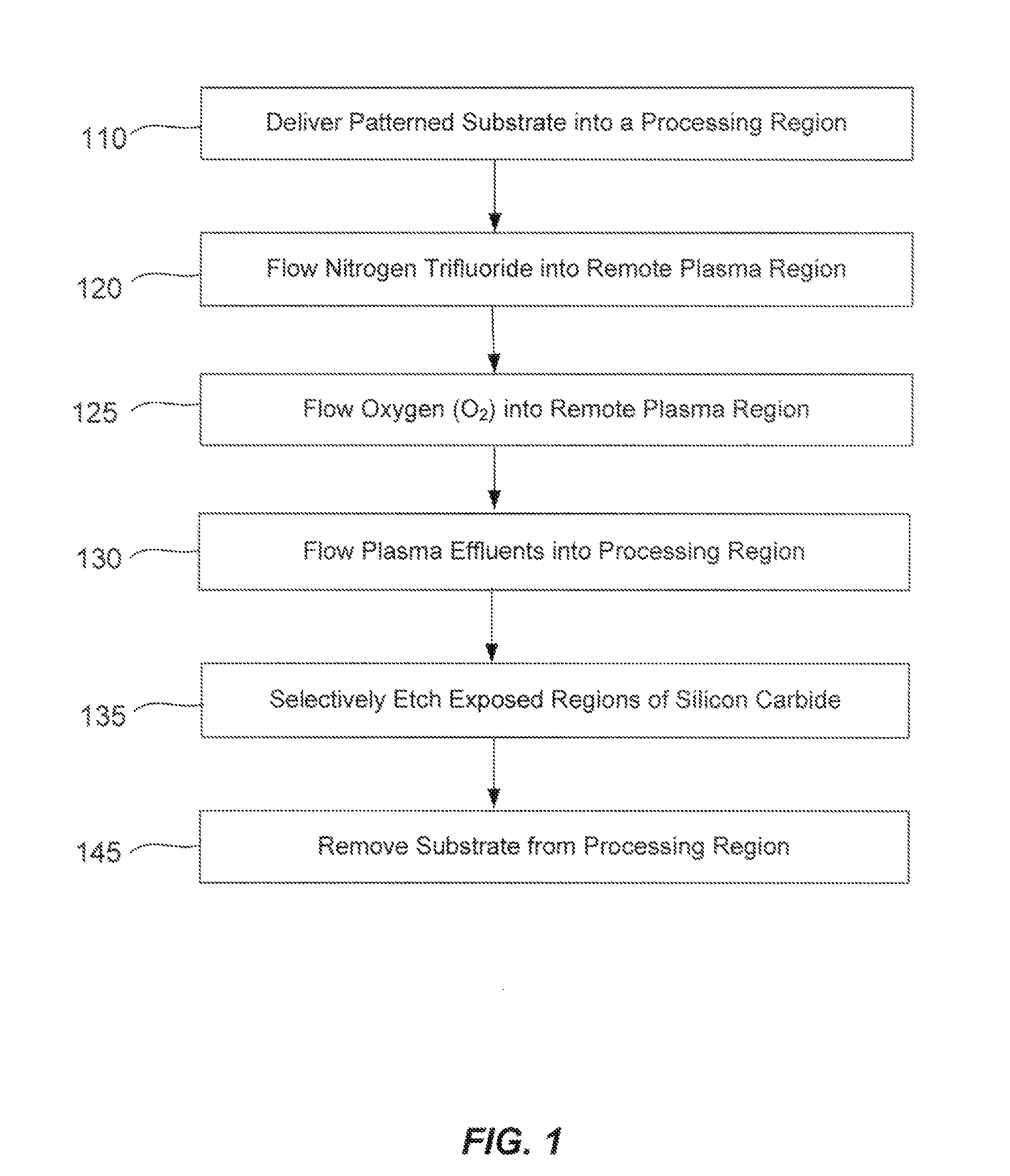

Dry-etch for silicon-and-carbon-containing films

InactiveUS20130034968A1Reduces and substantially eliminates numberMaterial removalSemiconductor/solid-state device manufacturingRemote plasmaSilicon oxide

A method of etching exposed silicon-and-carbon-containing material on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor and an oxygen-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the exposed regions of silicon-and-carbon-containing material. The plasmas effluents react with the patterned heterogeneous structures to selectively remove silicon-and-carbon-containing material from the exposed silicon-and-carbon-containing material regions while very slowly removing other exposed materials. The silicon-and-carbon-containing material selectivity results partly from the presence of an ion suppression element positioned between the remote plasma and the substrate processing region. The ion suppression element reduces or substantially eliminates the number of ionically-charged species that reach the substrate. The methods may be used to selectively remove silicon-and-carbon-containing material at more than twenty times the rate of silicon oxide.

Owner:APPLIED MATERIALS INC

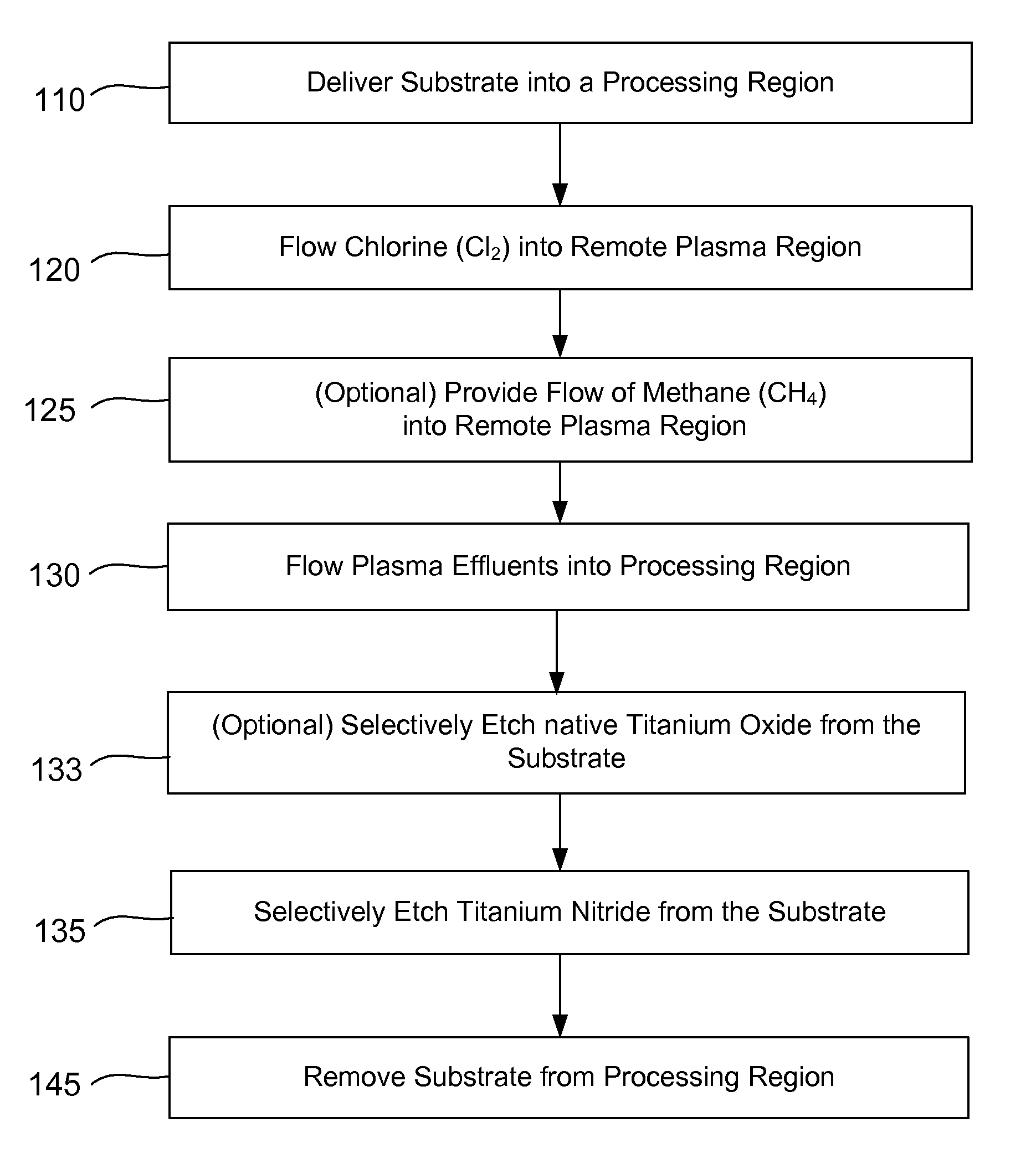

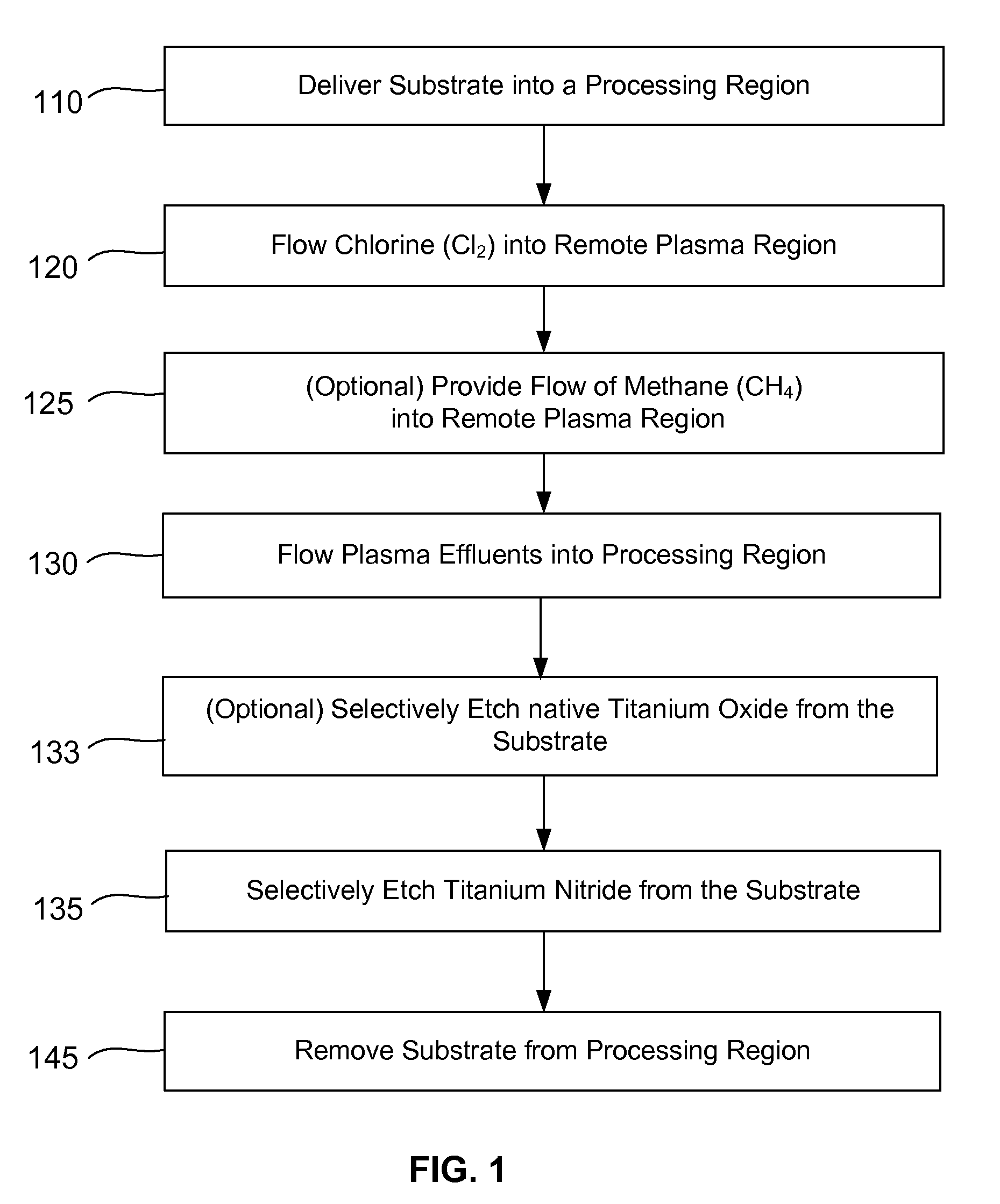

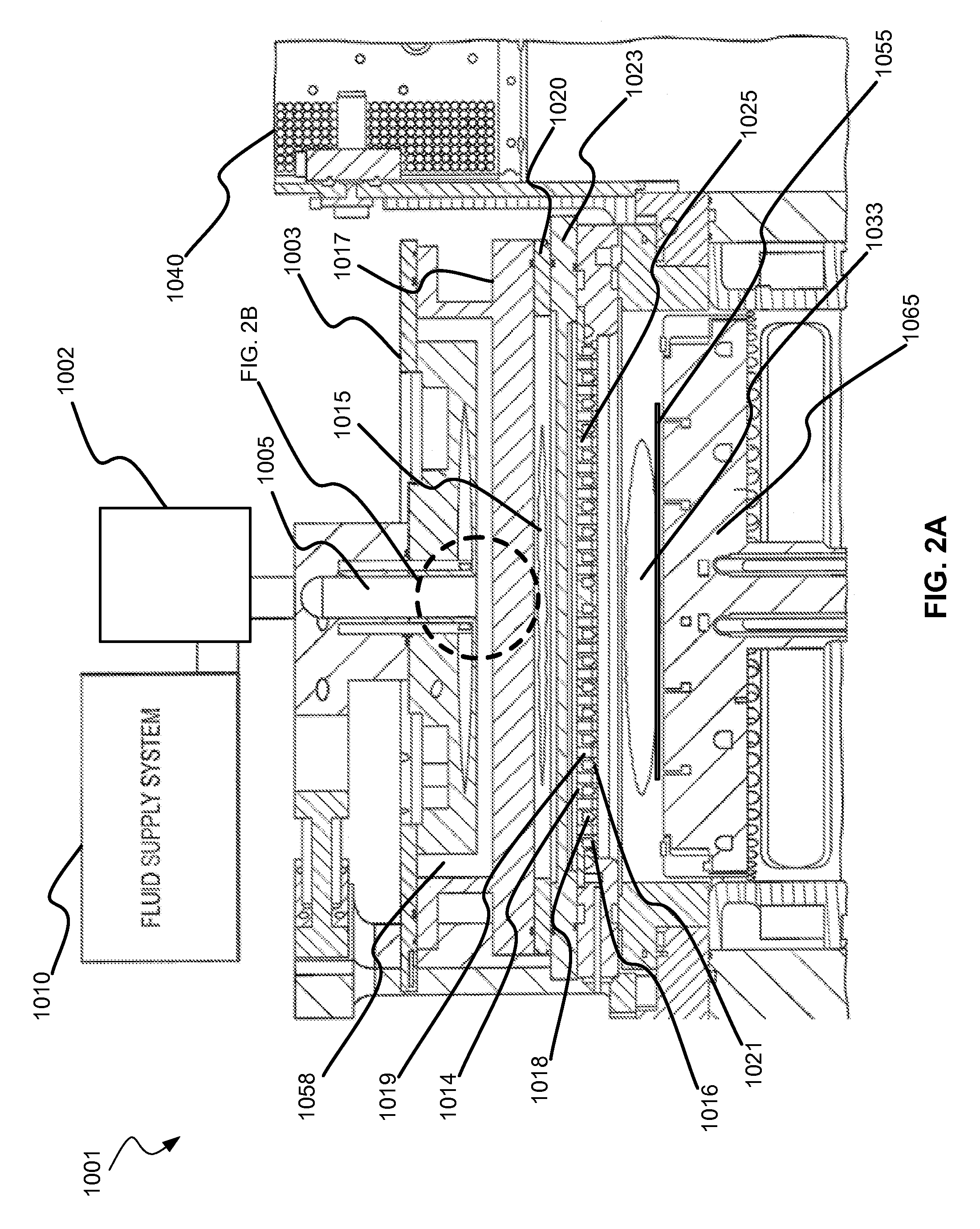

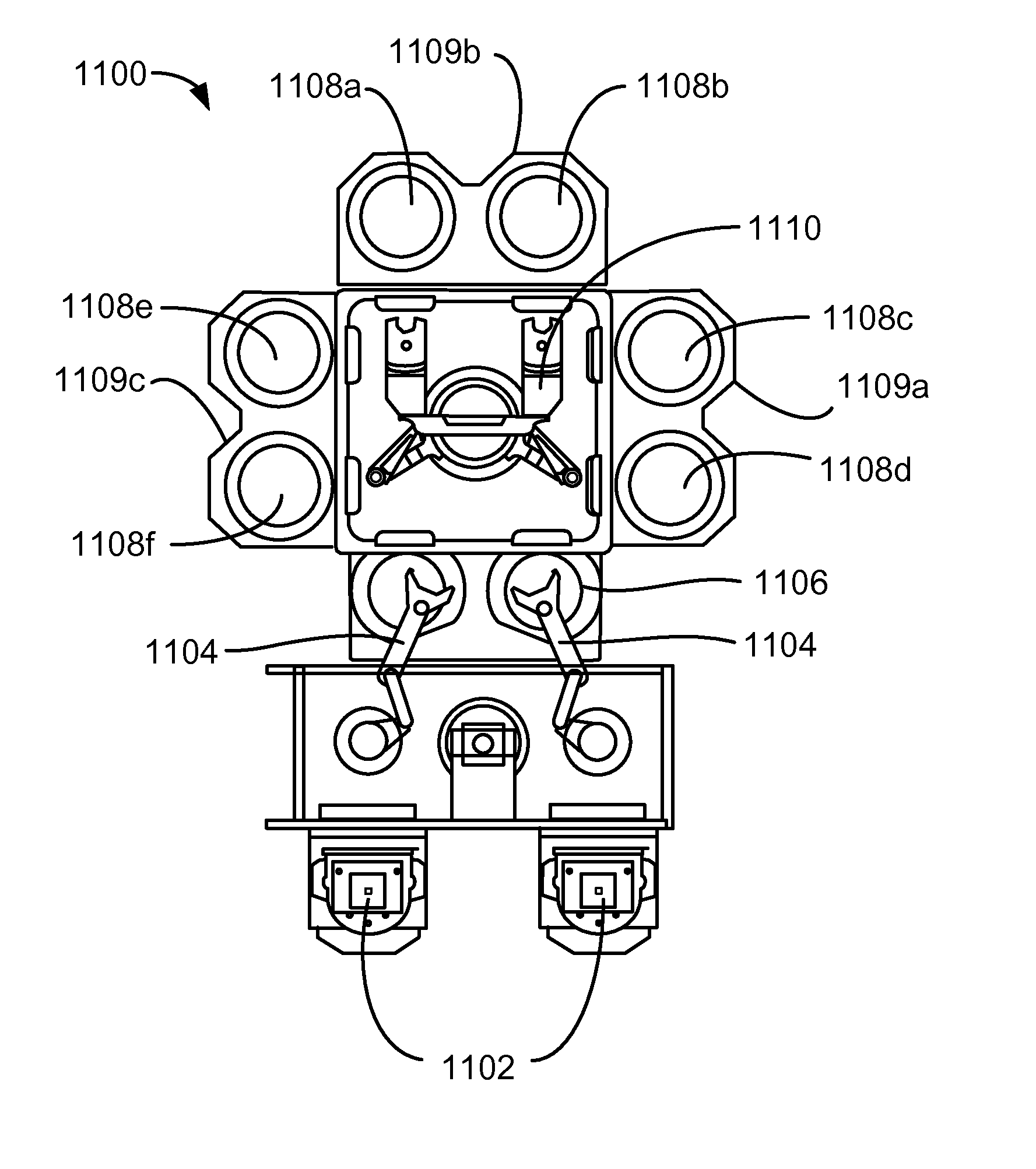

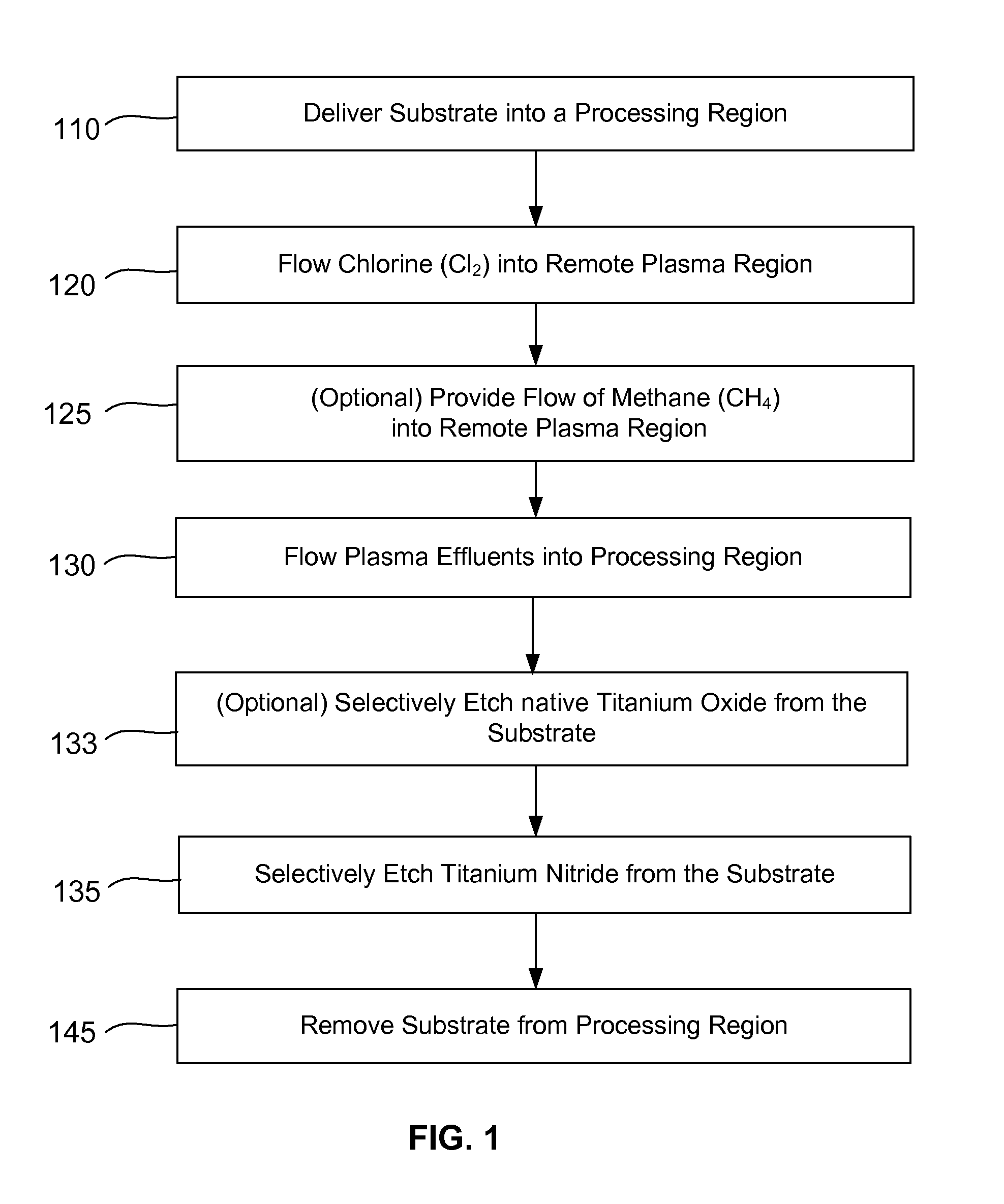

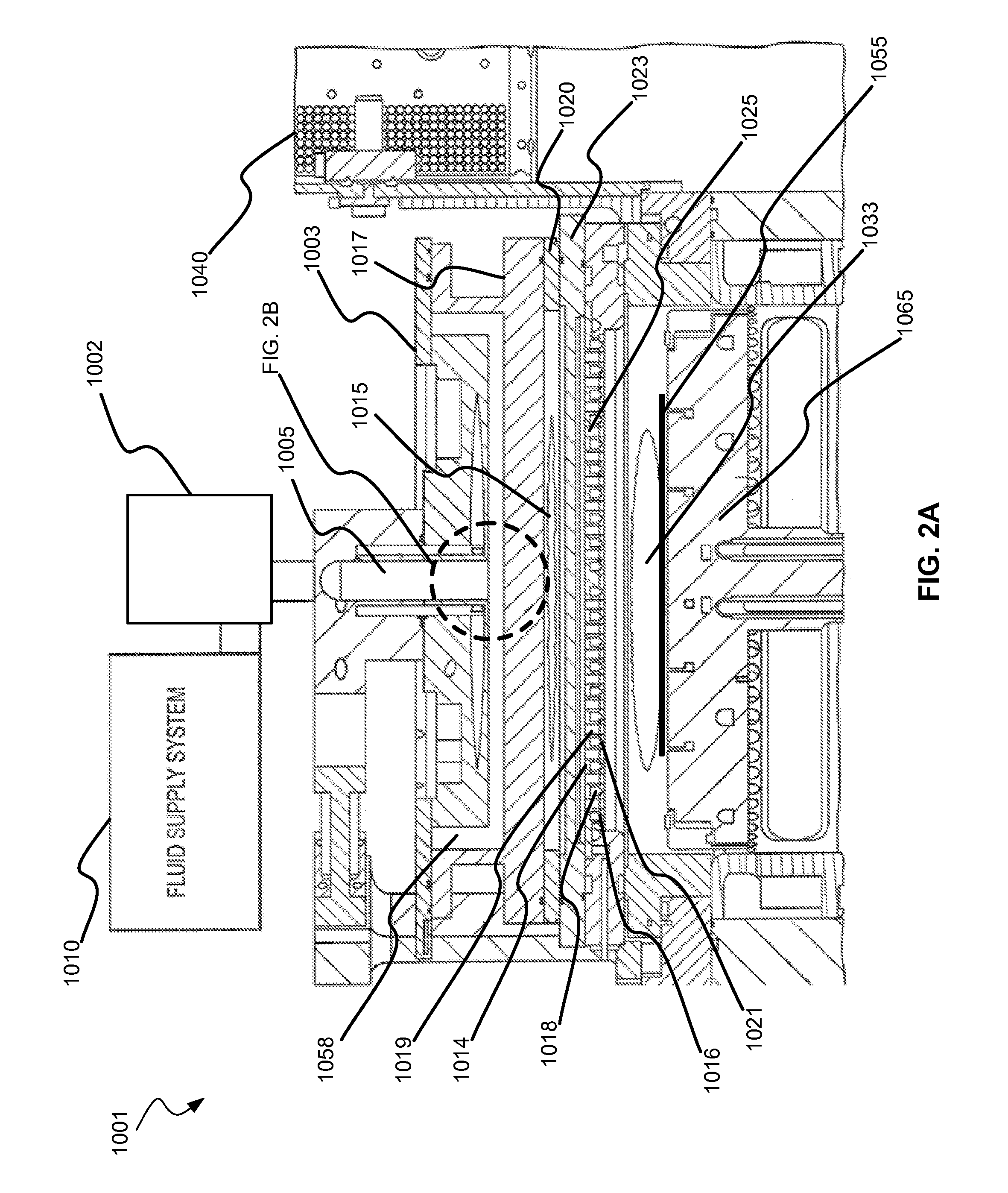

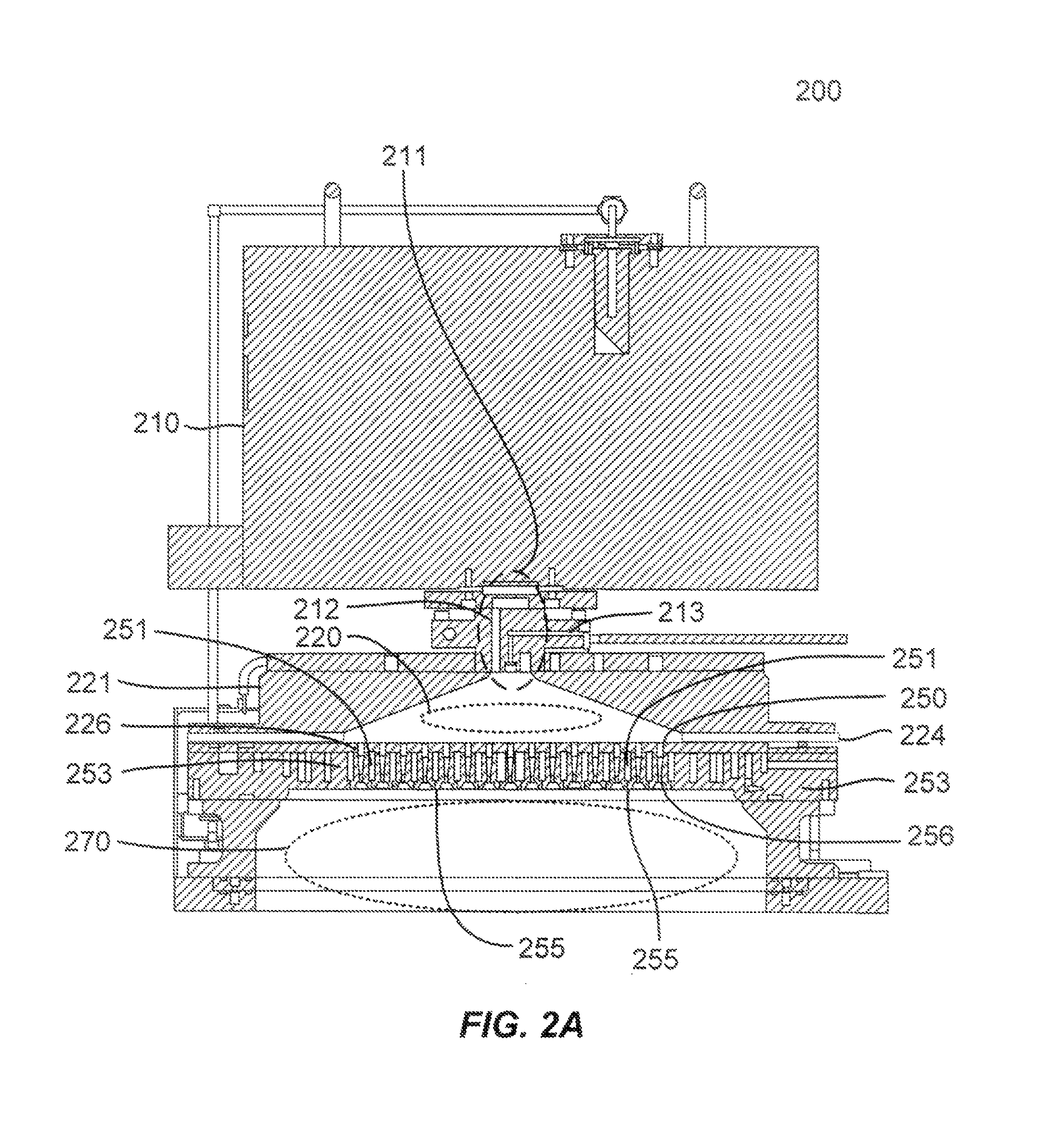

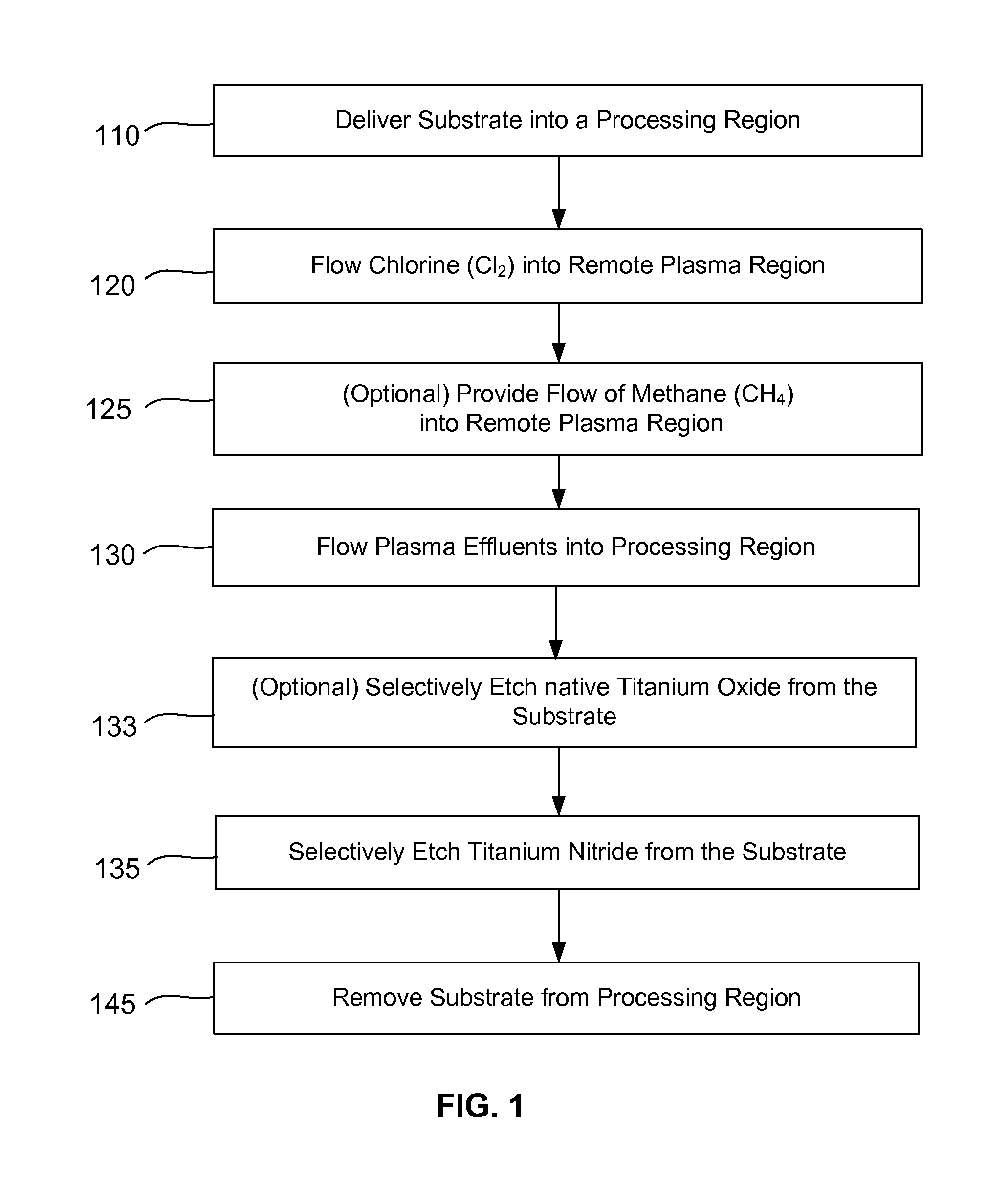

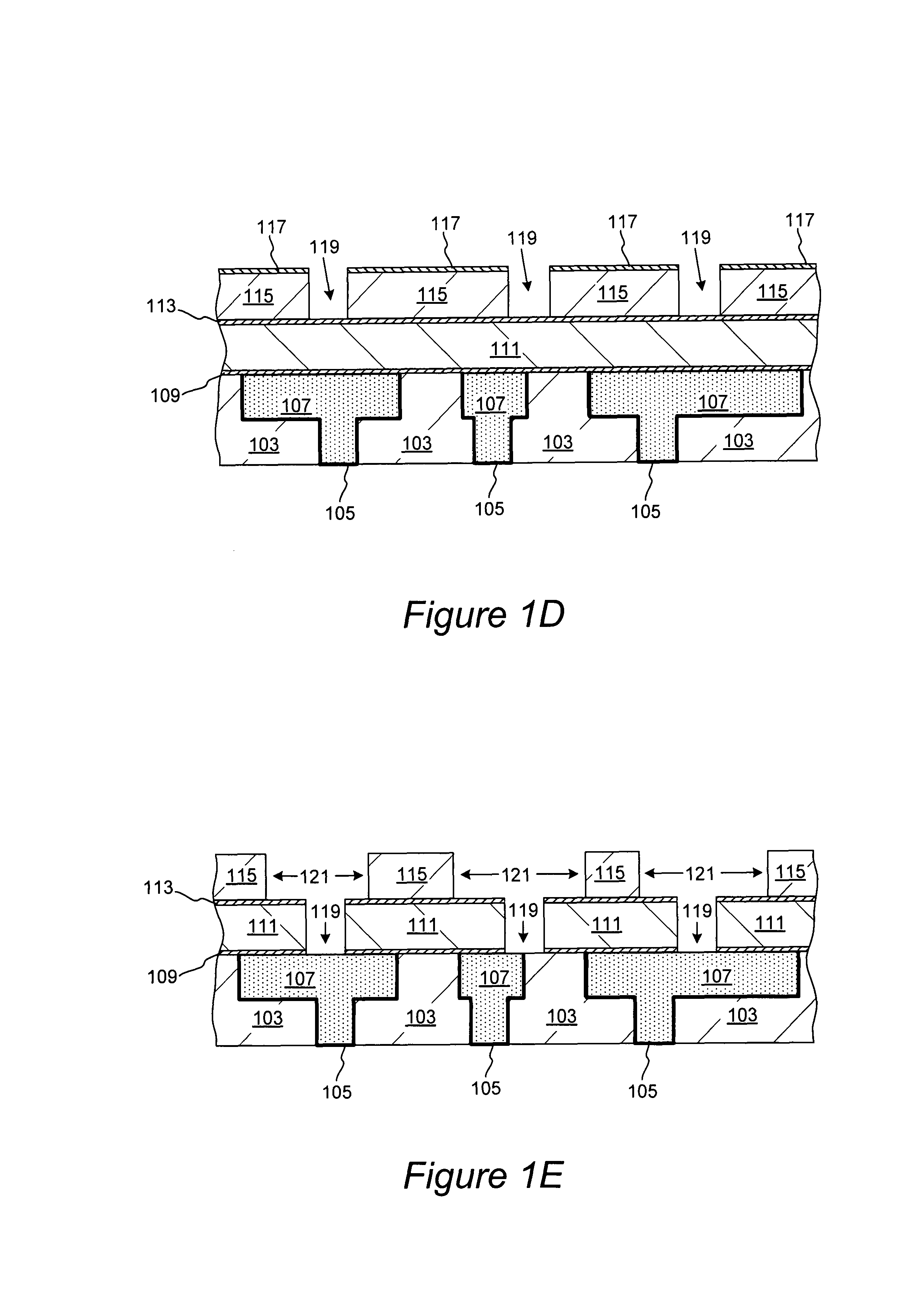

Selective titanium nitride removal

ActiveUS9040422B2Convenient restHigh removal rateElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaTitanium nitride

Methods are described herein for selectively etching titanium nitride relative to dielectric films, which may include, for example, alternative metals and metal oxides lacking in titanium and / or silicon-containing films (e.g. silicon oxide, silicon carbon nitride and low-K dielectric films). The methods include a remote plasma etch formed from a chlorine-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the titanium nitride. The plasma effluents react with exposed surfaces and selectively remove titanium nitride while very slowly removing the other exposed materials. The substrate processing region may also contain a plasma to facilitate breaking through any titanium oxide layer present on the titanium nitride. The plasma in the substrate processing region may be gently biased relative to the substrate to enhance removal rate of the titanium oxide layer.

Owner:APPLIED MATERIALS INC

Selective titanium nitride removal

ActiveUS20140256131A1Convenient restHigh removal rateElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaTitanium nitride

Methods are described herein for selectively etching titanium nitride relative to dielectric films, which may include, for example, alternative metals and metal oxides lacking in titanium and / or silicon-containing films (e.g. silicon oxide, silicon carbon nitride and low-K dielectric films). The methods include a remote plasma etch formed from a chlorine-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the titanium nitride. The plasma effluents react with exposed surfaces and selectively remove titanium nitride while very slowly removing the other exposed materials. The substrate processing region may also contain a plasma to facilitate breaking through any titanium oxide layer present on the titanium nitride. The plasma in the substrate processing region may be gently biased relative to the substrate to enhance removal rate of the titanium oxide layer.

Owner:APPLIED MATERIALS INC

Dry-etch for silicon-and-nitrogen-containing films

ActiveUS20130130507A1Reduces and substantially eliminates numberMaterial removalElectric discharge tubesSemiconductor/solid-state device manufacturingHeterojunctionRemote plasma

A method of etching exposed silicon-and-nitrogen-containing material on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor and an oxygen-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the exposed regions of silicon-and-nitrogen-containing material. The plasmas effluents react with the patterned heterogeneous structures to selectively remove silicon-and-nitrogen-containing material from the exposed silicon-and-nitrogen-containing material regions while very slowly removing other exposed materials. The silicon-and-nitrogen-containing material selectivity results partly from the presence of an ion suppression element positioned between the remote plasma and the substrate processing region. The ion suppression element reduces or substantially eliminates the number of ionically-charged species that reach the substrate. The methods may be used to selectively remove silicon-and-nitrogen-containing material at more than twenty times the rate of silicon oxide.

Owner:APPLIED MATERIALS INC

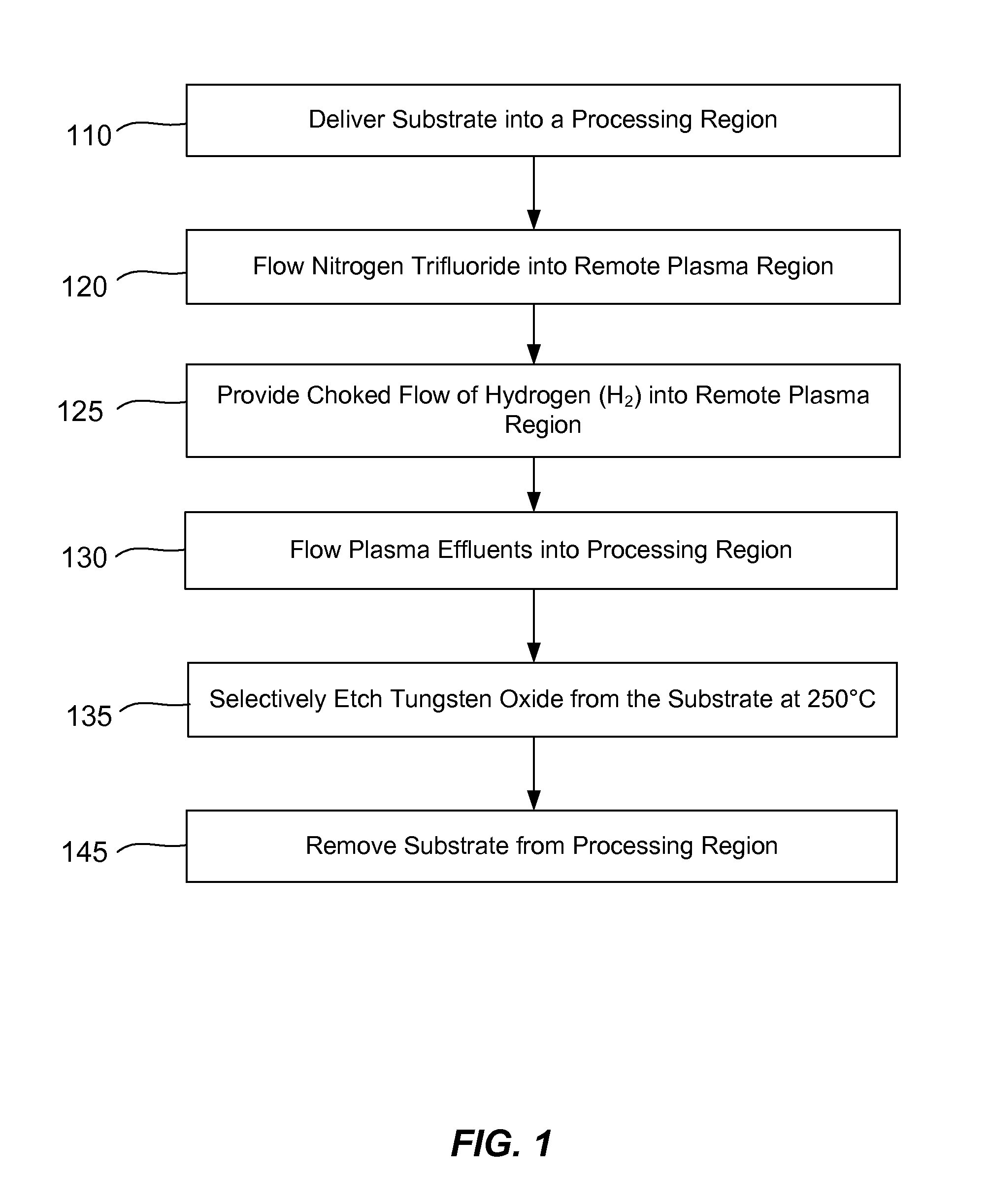

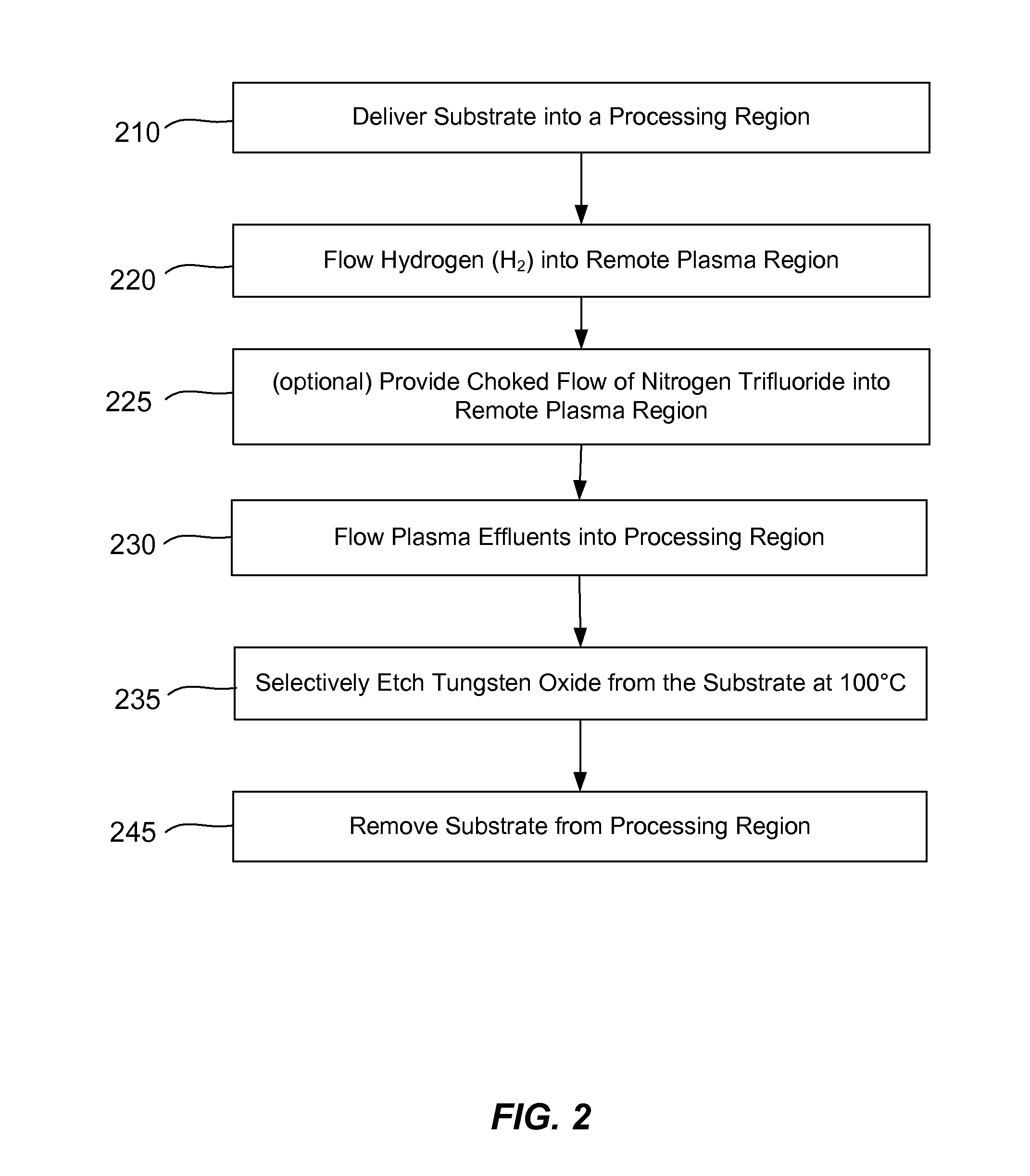

Dry-etch for selective oxidation removal

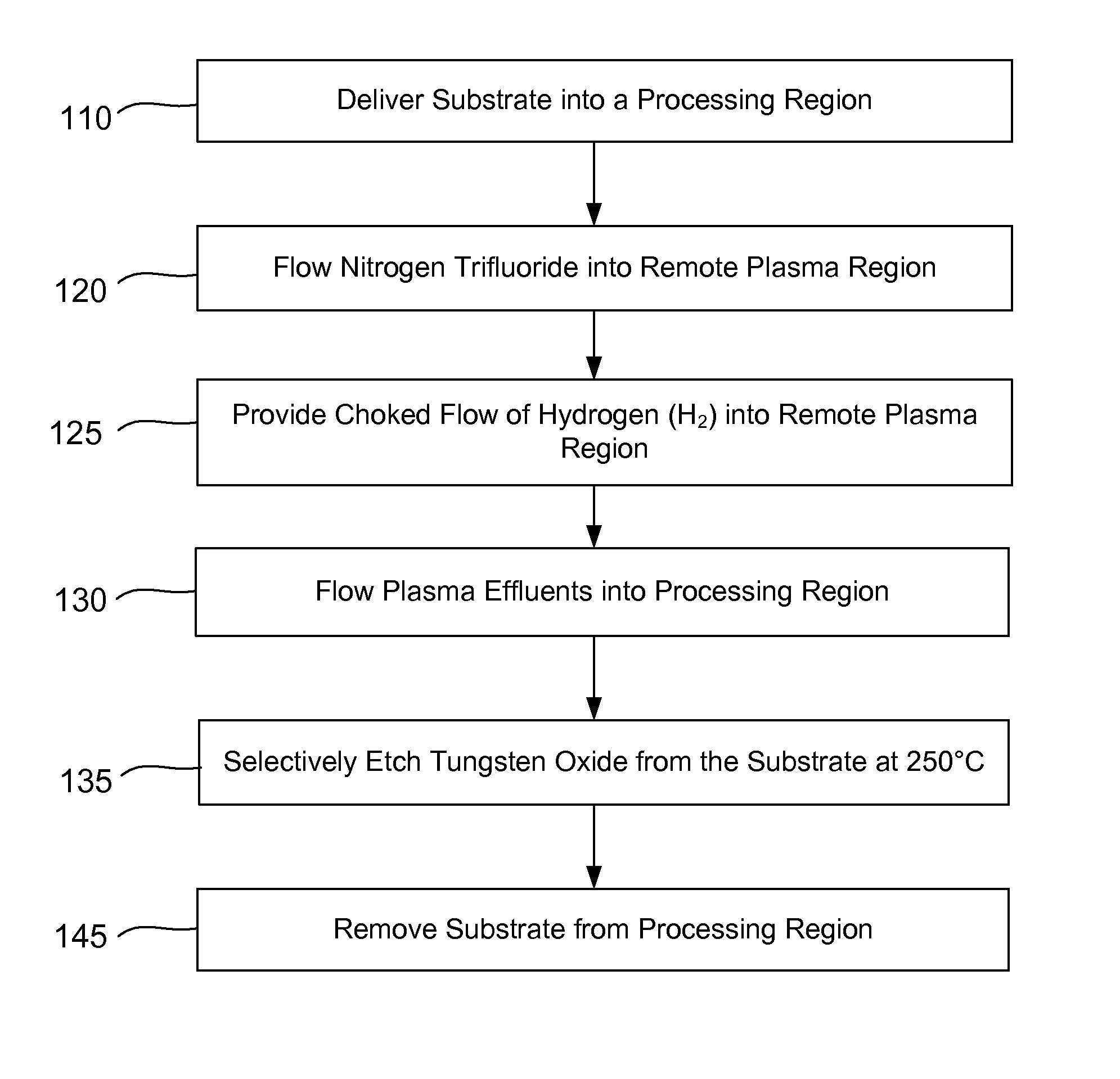

ActiveUS9064816B2Reduces and substantially eliminates numberMaterial removalElectric discharge tubesDecorative surface effectsSurface reactionRemote plasma

Methods of selectively etching tungsten oxide relative to tungsten, silicon oxide, silicon nitride and / or titanium nitride are described. The methods include a remote plasma etch formed from a fluorine-containing precursor and / or hydrogen (H2). Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the tungsten oxide. The plasmas effluents react with exposed surfaces and selectively remove tungsten oxide while very slowly removing other exposed materials. In some embodiments, the tungsten oxide selectivity results partly from the presence of an ion suppression element positioned between the remote plasma and the substrate processing region. The ion suppression element reduces or substantially eliminates the number of ionically-charged species that reach the substrate.

Owner:APPLIED MATERIALS INC

Dry-etch for silicon-and-carbon-containing films

InactiveUS8771536B2Reduces and substantially eliminates numberMaterial removalDecorative surface effectsSemiconductor/solid-state device manufacturingRemote plasmaRegioselectivity

A method of etching exposed silicon-and-carbon-containing material on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor and an oxygen-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the exposed regions of silicon-and-carbon-containing material. The plasmas effluents react with the patterned heterogeneous structures to selectively remove silicon-and-carbon-containing material from the exposed silicon-and-carbon-containing material regions while very slowly removing other exposed materials. The silicon-and-carbon-containing material selectivity results partly from the presence of an ion suppression element positioned between the remote plasma and the substrate processing region. The ion suppression element reduces or substantially eliminates the number of ionically-charged species that reach the substrate. The methods may be used to selectively remove silicon-and-carbon-containing material at more than twenty times the rate of silicon oxide.

Owner:APPLIED MATERIALS INC

Selective titanium nitride removal

ActiveUS20150357205A1Convenient restHigh removal rateElectric discharge tubesSemiconductor/solid-state device manufacturingTitanium nitrideSilicon oxide

Methods are described herein for selectively etching titanium nitride relative to dielectric films, which may include, for example, alternative metals and metal oxides lacking in titanium and / or silicon-containing films (e.g. silicon oxide, silicon carbon nitride and low-K dielectric films). The methods include a remote plasma etch formed from a chlorine-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the titanium nitride. The plasma effluents react with exposed surfaces and selectively remove titanium nitride while very slowly removing the other exposed materials. The substrate processing region may also contain a plasma to facilitate breaking through any titanium oxide layer present on the titanium nitride. The plasma in the substrate processing region may be gently biased relative to the substrate to enhance removal rate of the titanium oxide layer.

Owner:APPLIED MATERIALS INC

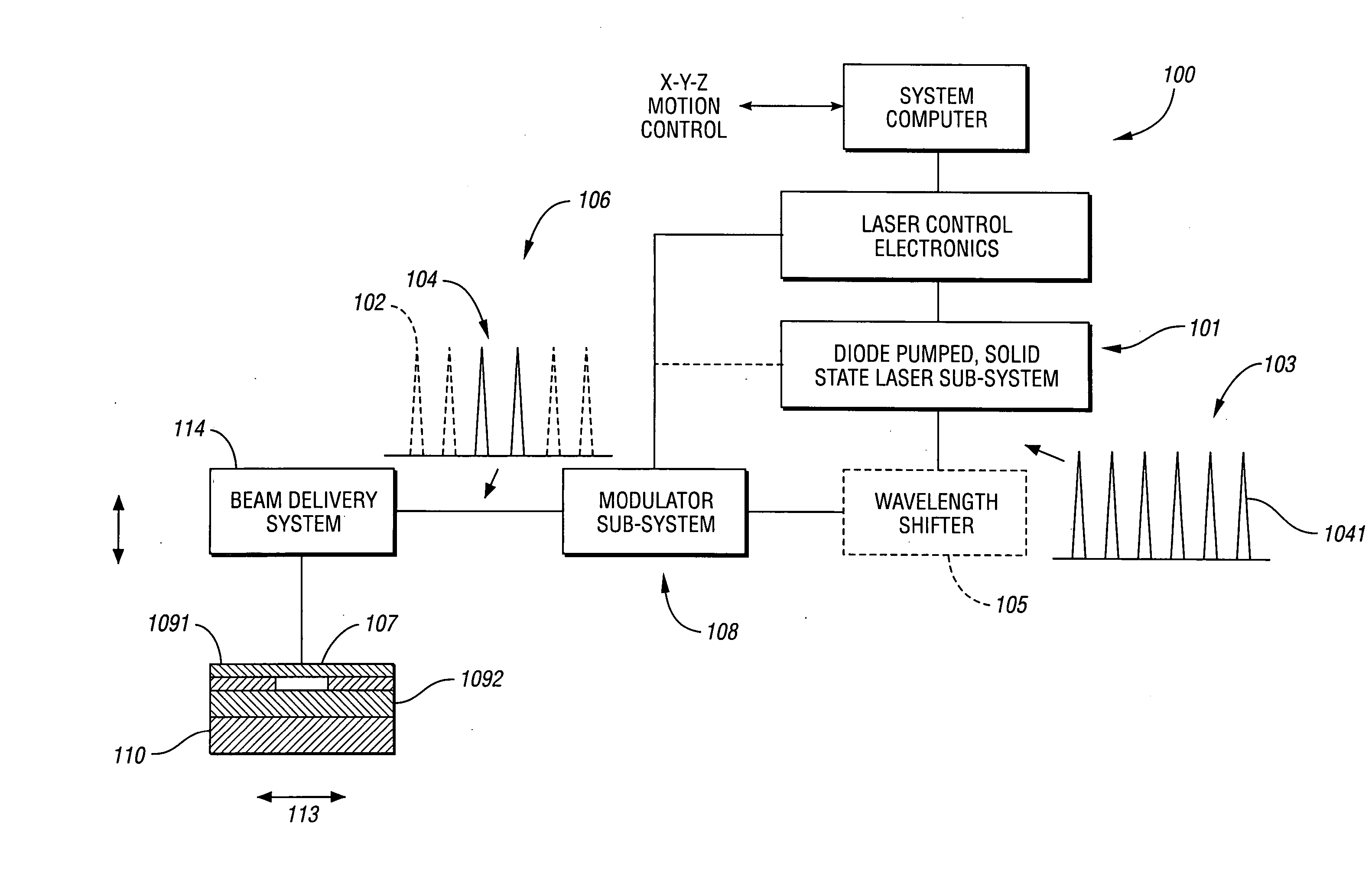

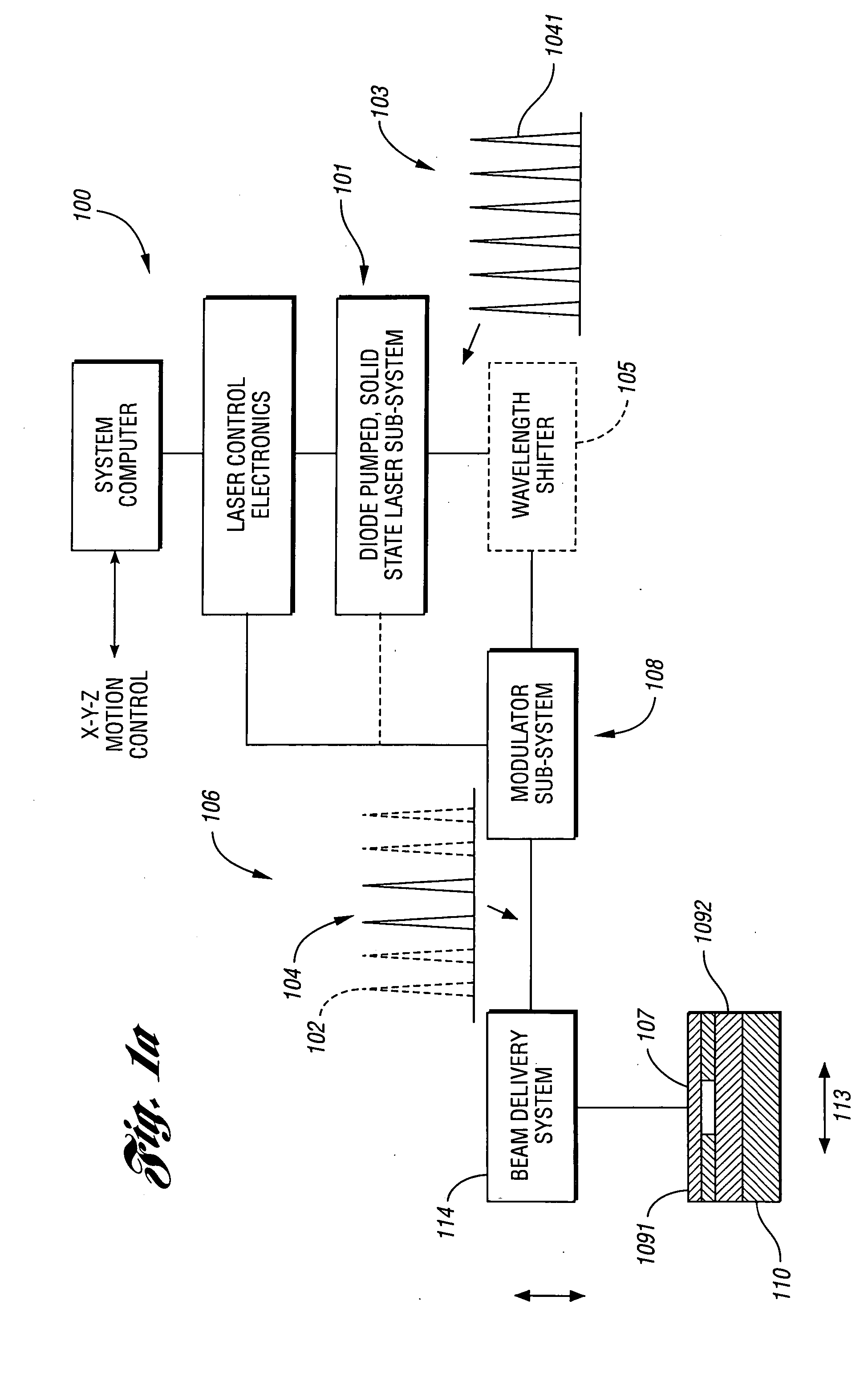

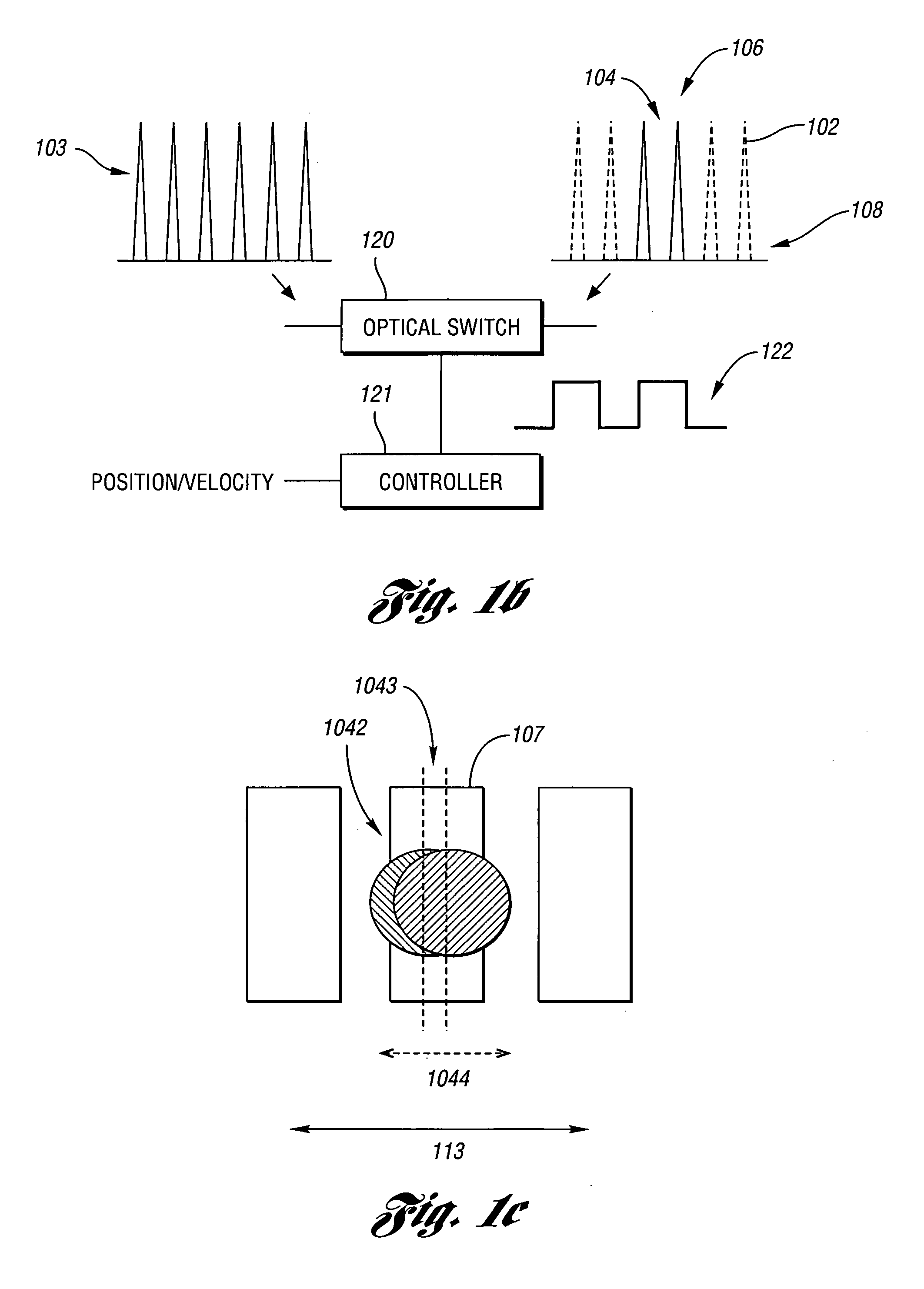

Laser-based system for memory link processing with picosecond lasers

InactiveUS20040134894A1Quality improvementReduce reflectivitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPicosecond laserMicroscopic scale

A laser-based system for processing target material within a microscopic region without causing undesirable changes in electrical or physical characteristics of at least one material surrounding the target material, the system includes a seed laser, an optical amplifier, and a beam delivery system. The seed laser for generating a sequence of laser pulses having a first pre-determined wavelength. The optical amplifier for amplifying at least a portion of the sequence of pulses to obtain an amplified sequence of output pulses. The beam delivery system for delivering and focusing at least one pulse of the amplified sequence of pulses onto the target material. The at least one output pulse having a pulse duration in the range of about 10 picoseconds to less than 1 nanosecond. The pulse duration being within a thermal processing range. The at least one focused output pulse having sufficient power density at a location within the target material to reduce the reflectivity of the target material and efficiently couple the focused output into the target material to remove the target material.

Owner:GSI LUMONICS CORP

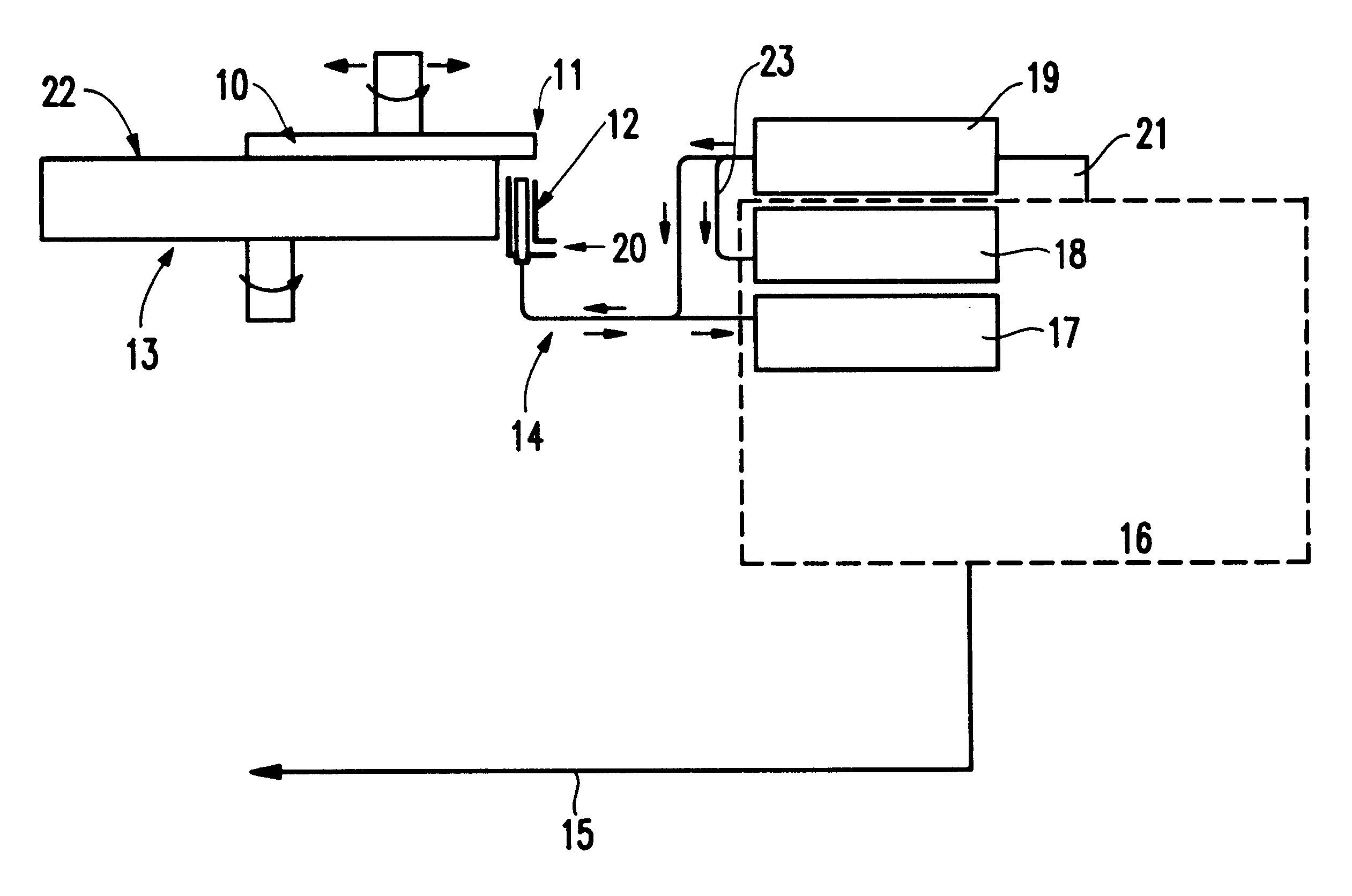

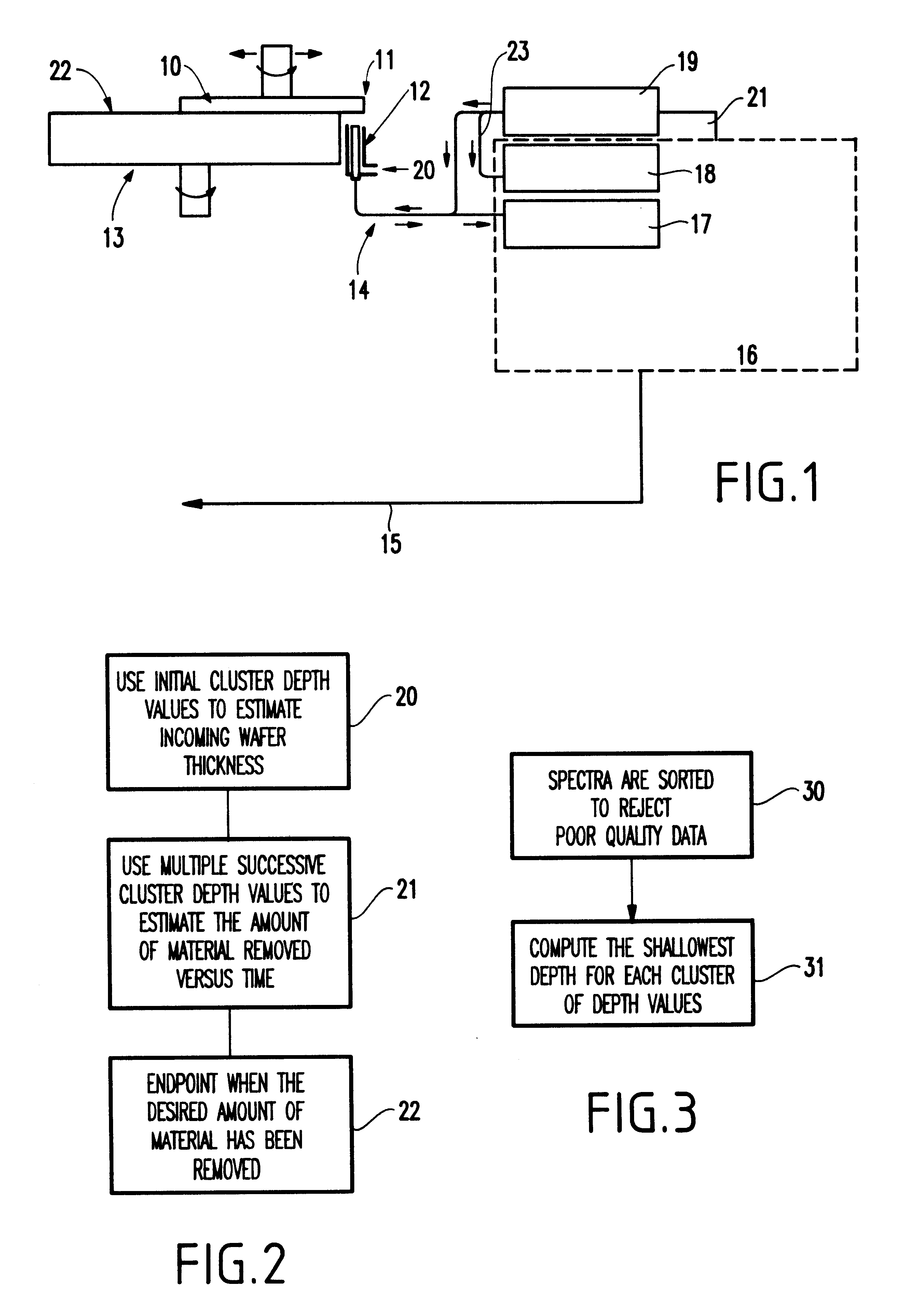

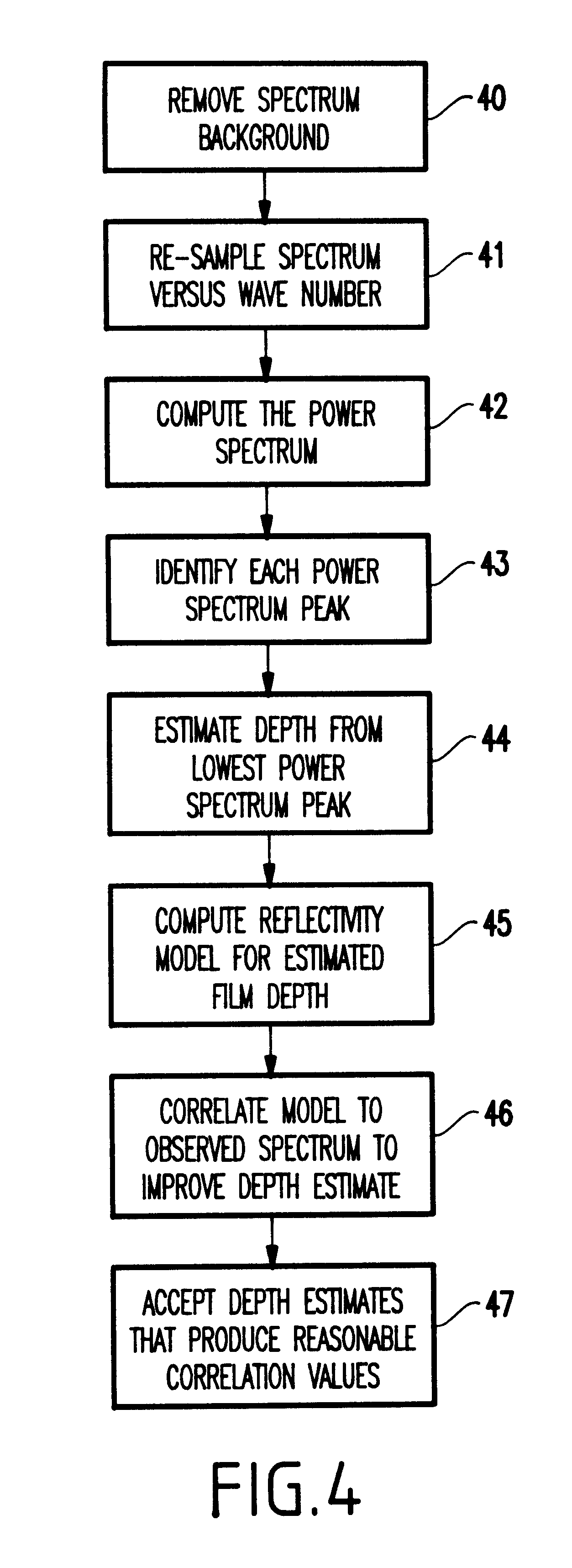

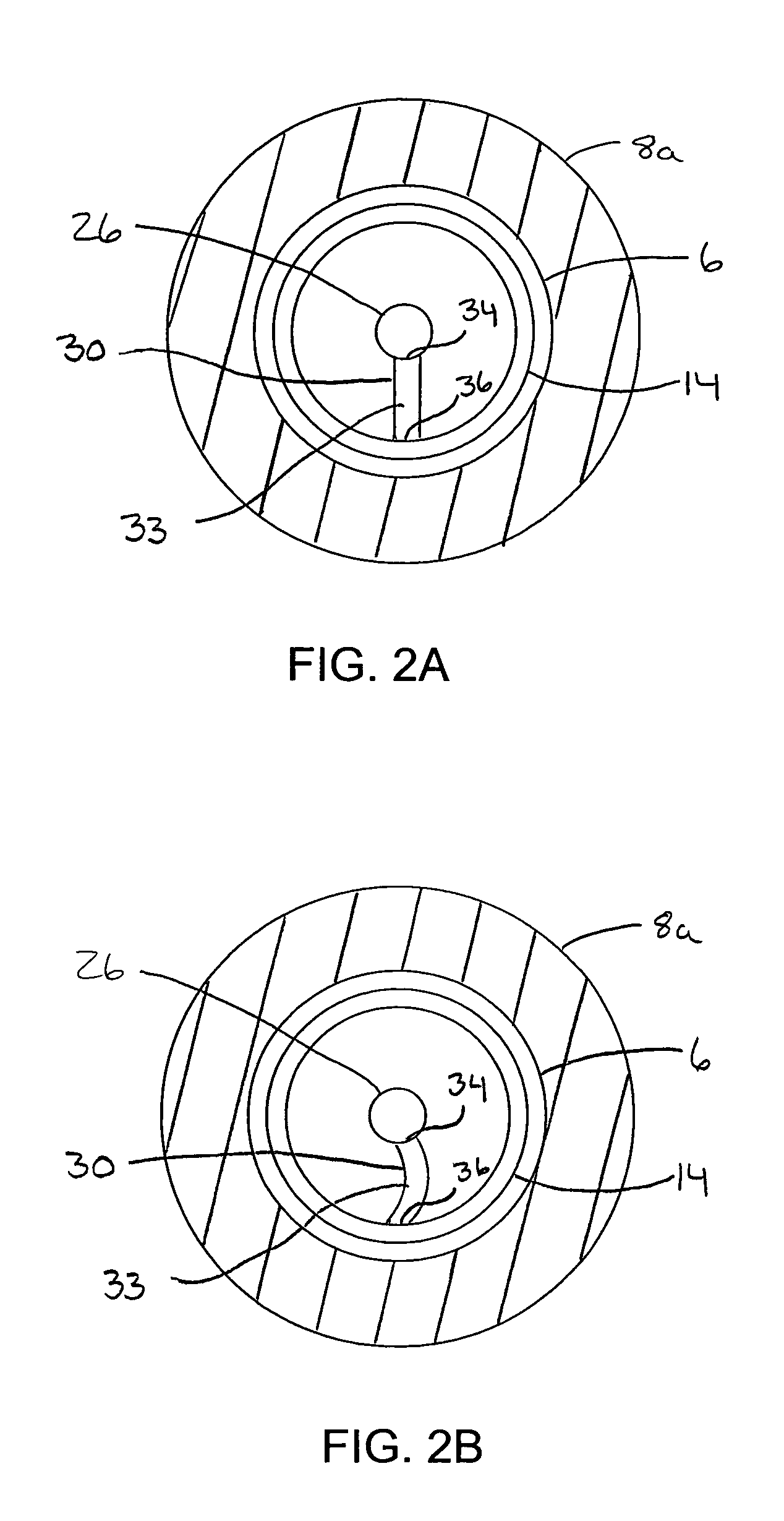

Chemical mechanical polishing in-situ end point system

InactiveUS6334807B1Improve accuracyMaterial removalEdge grinding machinesSemiconductor/solid-state device manufacturingCompound (substance)Point system

A structure and method for polishing a device include oscillating a carrier over an abrasive surface (the carrier bringing a polished surface of the device into contact with the abrasive surface, the oscillating allowing a portion of the polished surface to periodically oscillate off the abrasive surface), optically determining a reflective measure of a plurality of locations of the polished surface as the portion of the device oscillates off the abrasive surface and calculating depths of the locations of the polished surface based of the reflective measure.

Owner:GLOBALFOUNDRIES INC

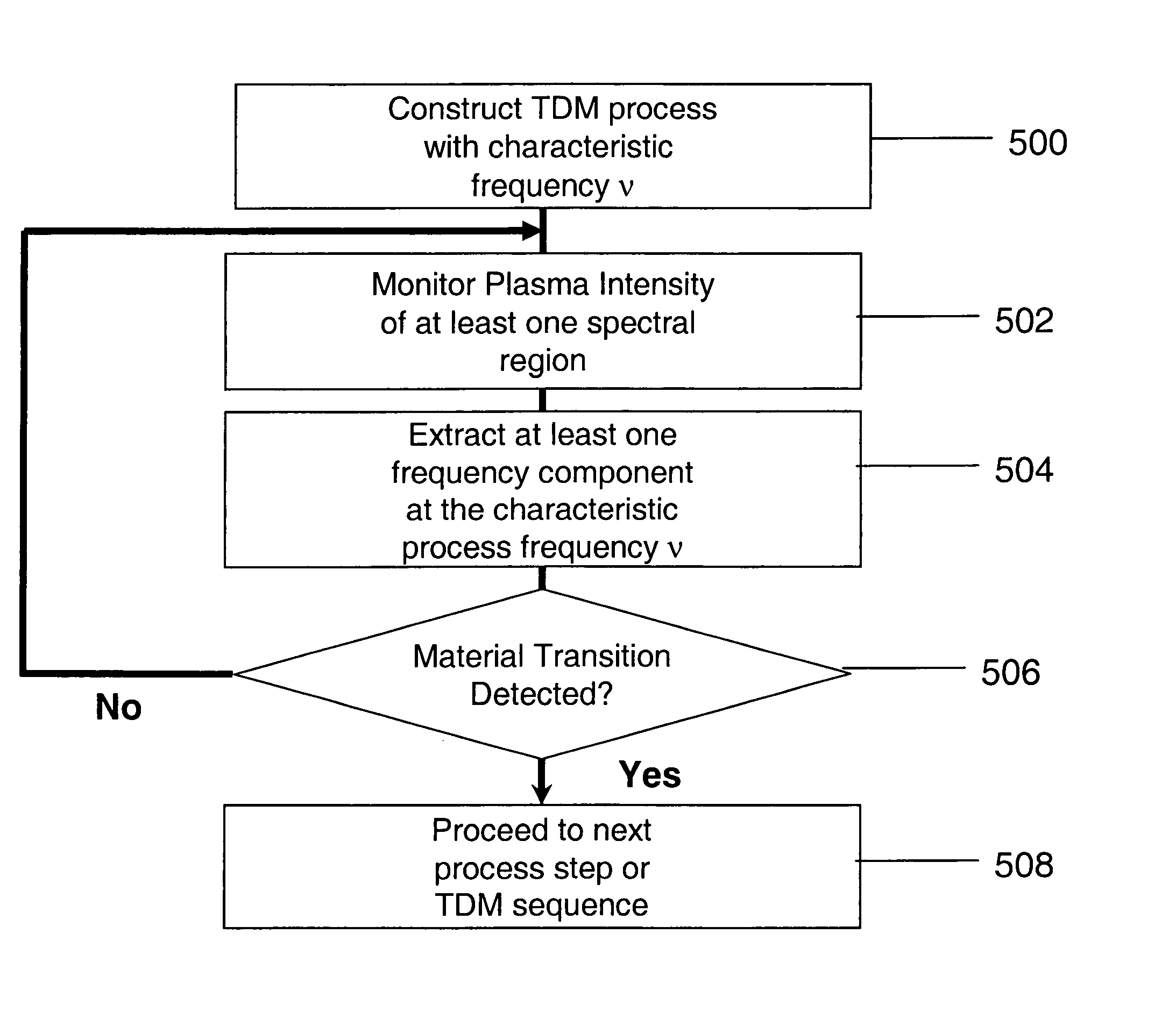

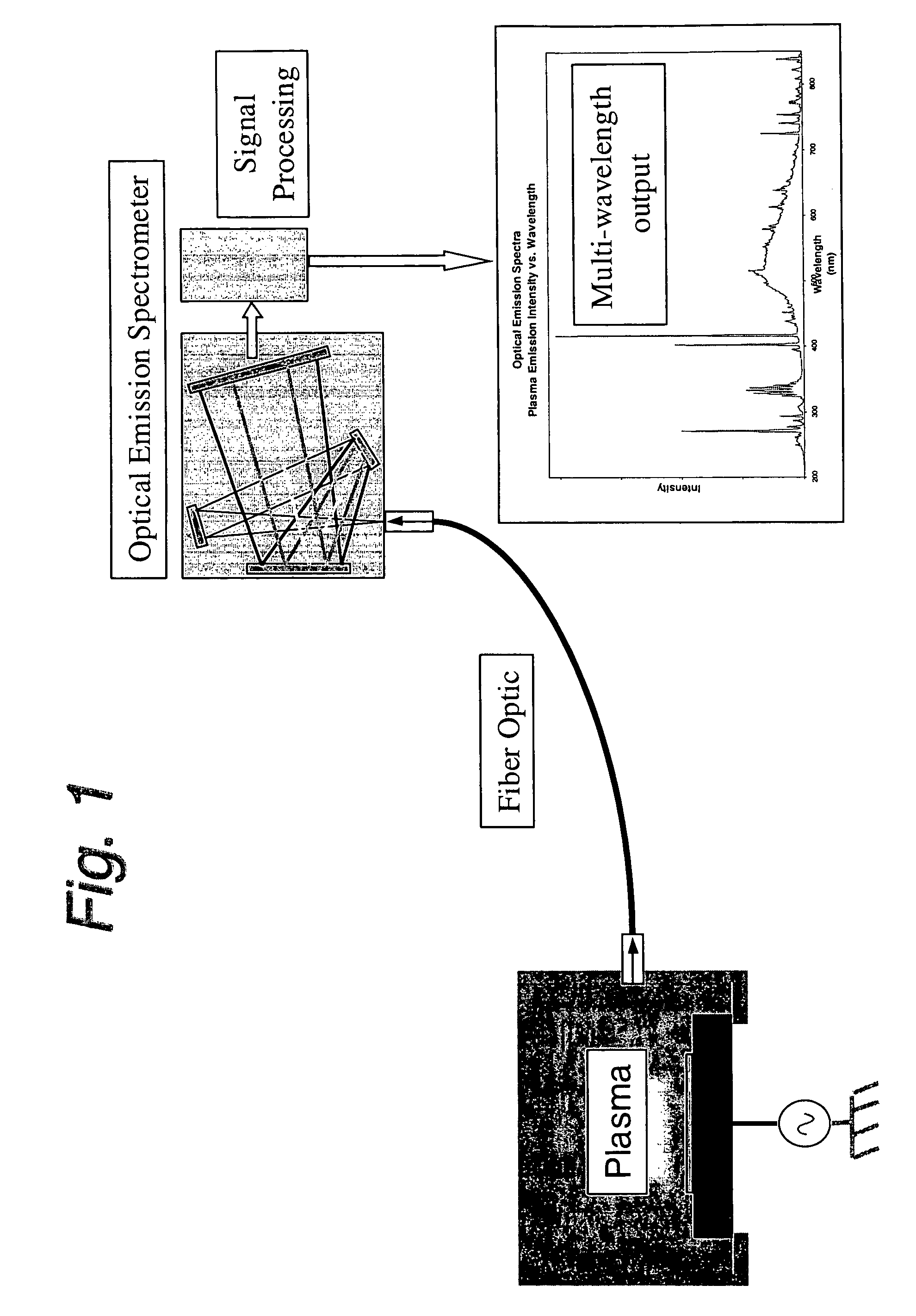

End point detection in time division multiplexed etch processes

ActiveUS6982175B2Material removalSemiconductor/solid-state device testing/measurementElectric discharge tubesSpectral emissionFrequency spectrum

An improved method for determining endpoint of a time division multiplexed process by monitoring an identified region of a spectral emission of the process at a characteristic process frequency. The region is identified based upon the expected emission spectra of materials used during the time division multiplexed process. The characteristic process frequency is determined based upon the duration of the steps in the time division multiplexed process. Changes in the magnitude of the monitored spectra indicate the endpoint of processes in the time division multiplexed process and transitions between layers of materials.

Owner:PLASMA THERM

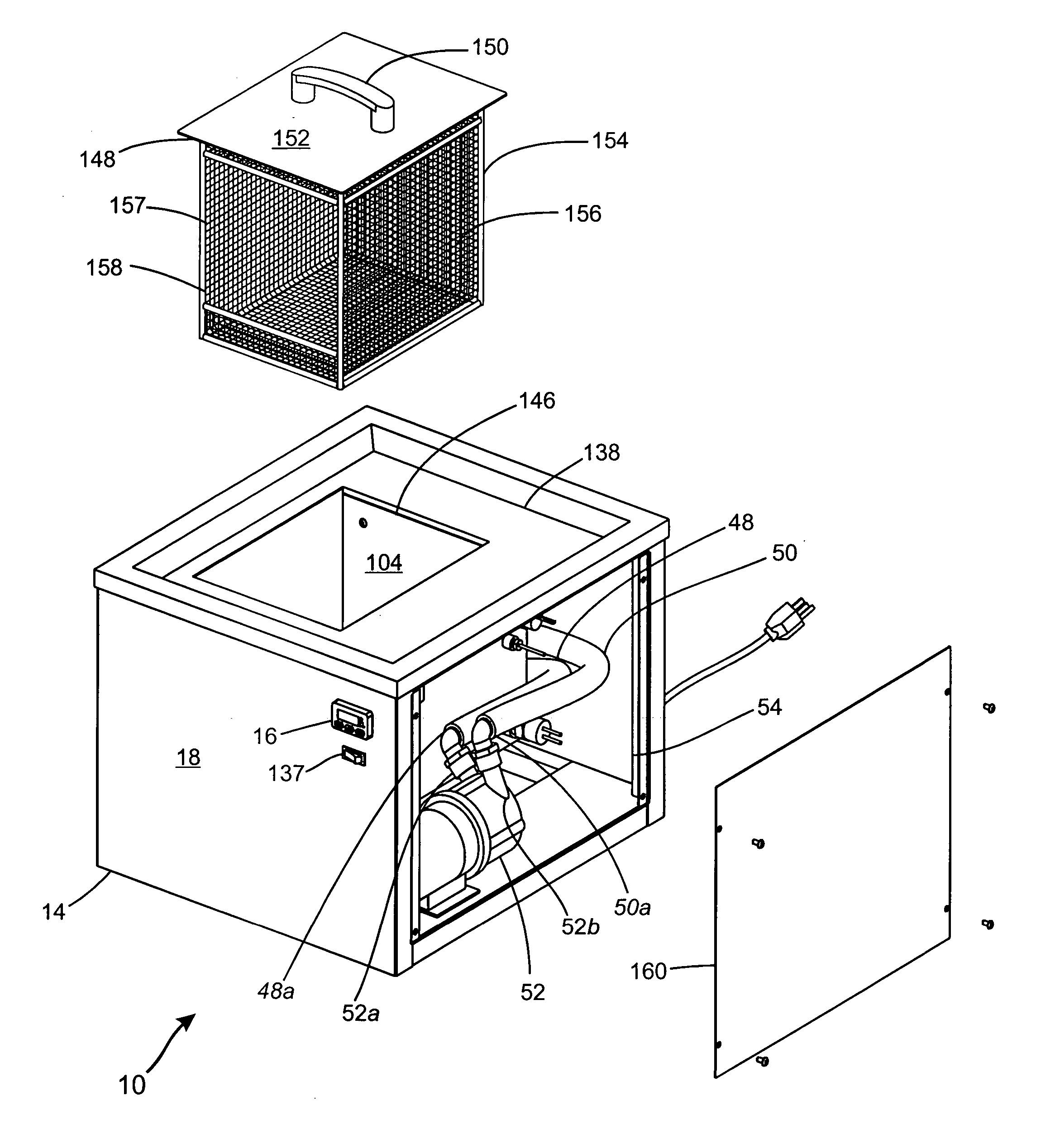

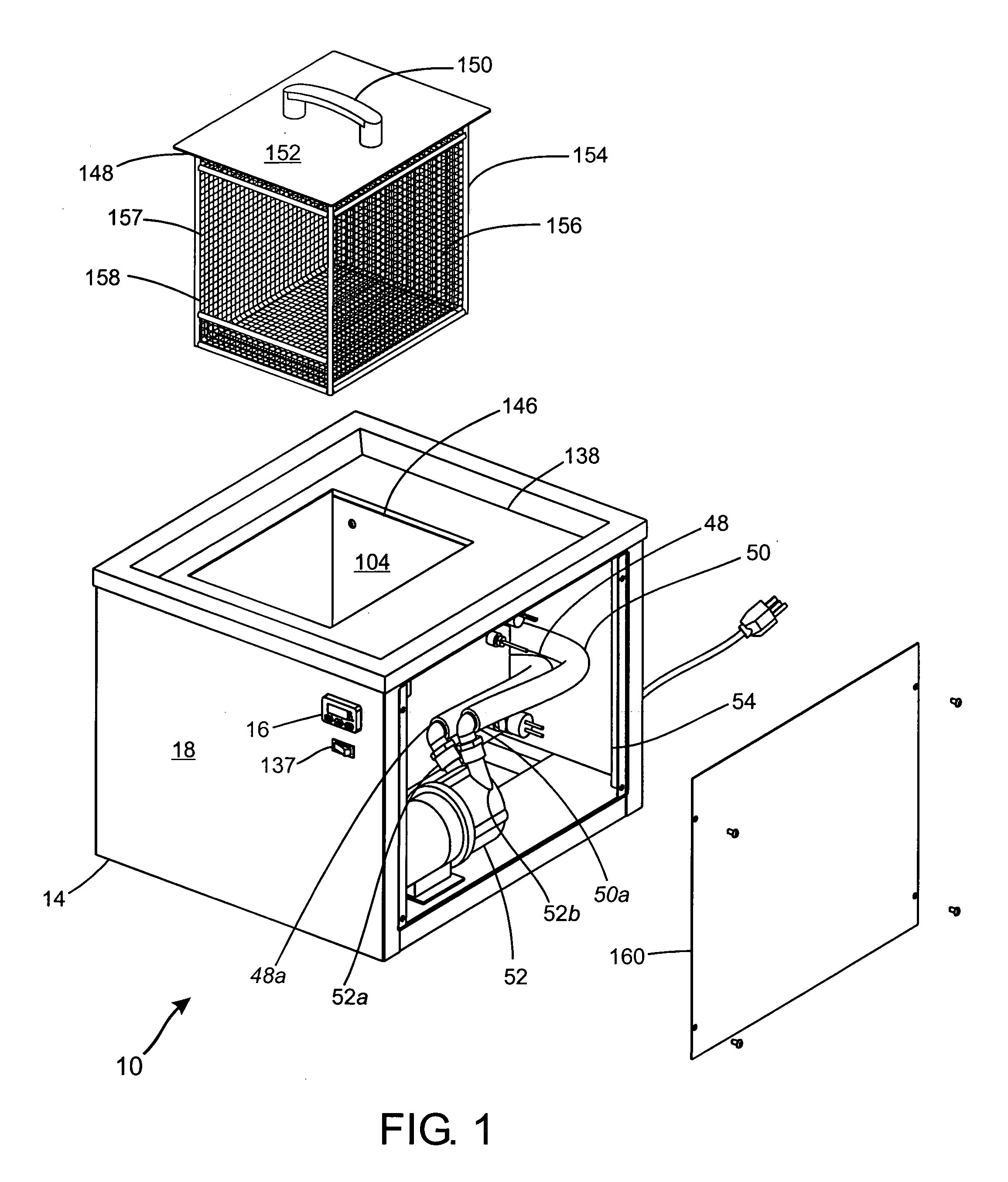

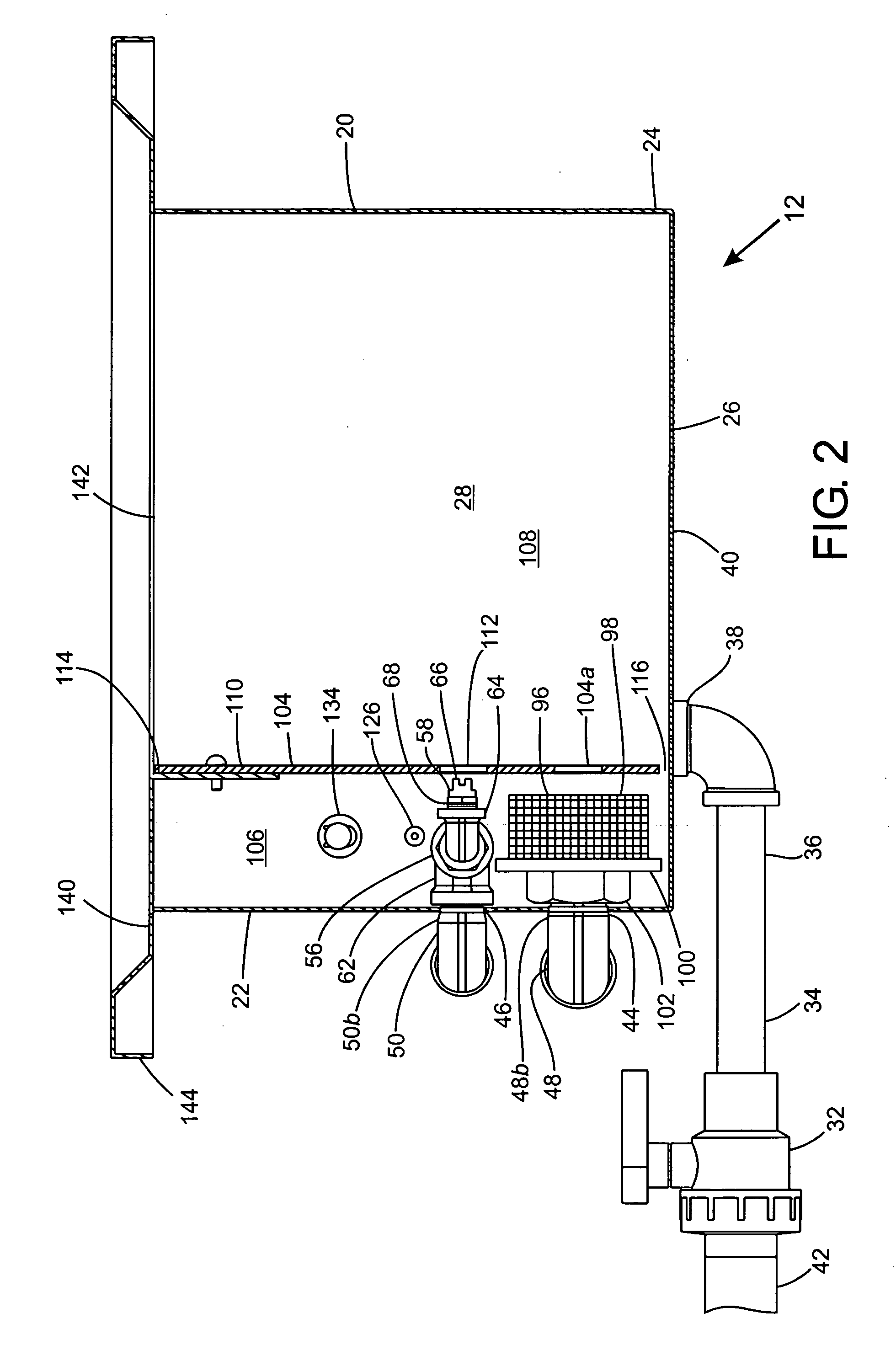

Apparatus and method of removing water soluble support material from a rapid prototype part

ActiveUS20050103360A1Low costEasy to useAdditive manufacturing apparatusHollow article cleaningSupport removalPotassium hydroxide

The support removal apparatus comprising in combination a retention tank having a manifold assembly comprising a plurality of nozzle heads in hydraulic communication with the discharge side of a pump, collectively configured for agitating an aqueous cleaning solution comprised of sodium or potassium hydroxide, sodium or potassium carbonate, and water; a heating element mounted within the retention tank for heating the aqueous cleaning solution to a predetermined temperature set point; a basket strainer mounted within the retention tank in hydraulic communication with the intake side of the pump to mitigate passage of small rapid prototype parts and residual support material therethrough and into the pump and manifold assembly; a work surface mounted atop the retention tank and having a movable lid fitted with a basket for containing small rapid prototype parts; a thermocouple for maintaining the temperature within a tolerable range for optimum removal of support material; a level indicator to ensure adequate solution level in the retention tank for operability of the pump and heating element; a cabinet having interface controller mounted on an exterior panel thereof for setting timer and heat functions; and a microprocessor having capabilities for making minute adjustments to the heating element via feedback from the thermocouple and controlling operation of the pump and heating element for a pre-set time interval.

Owner:TAFOYA DAVID JONATHAN

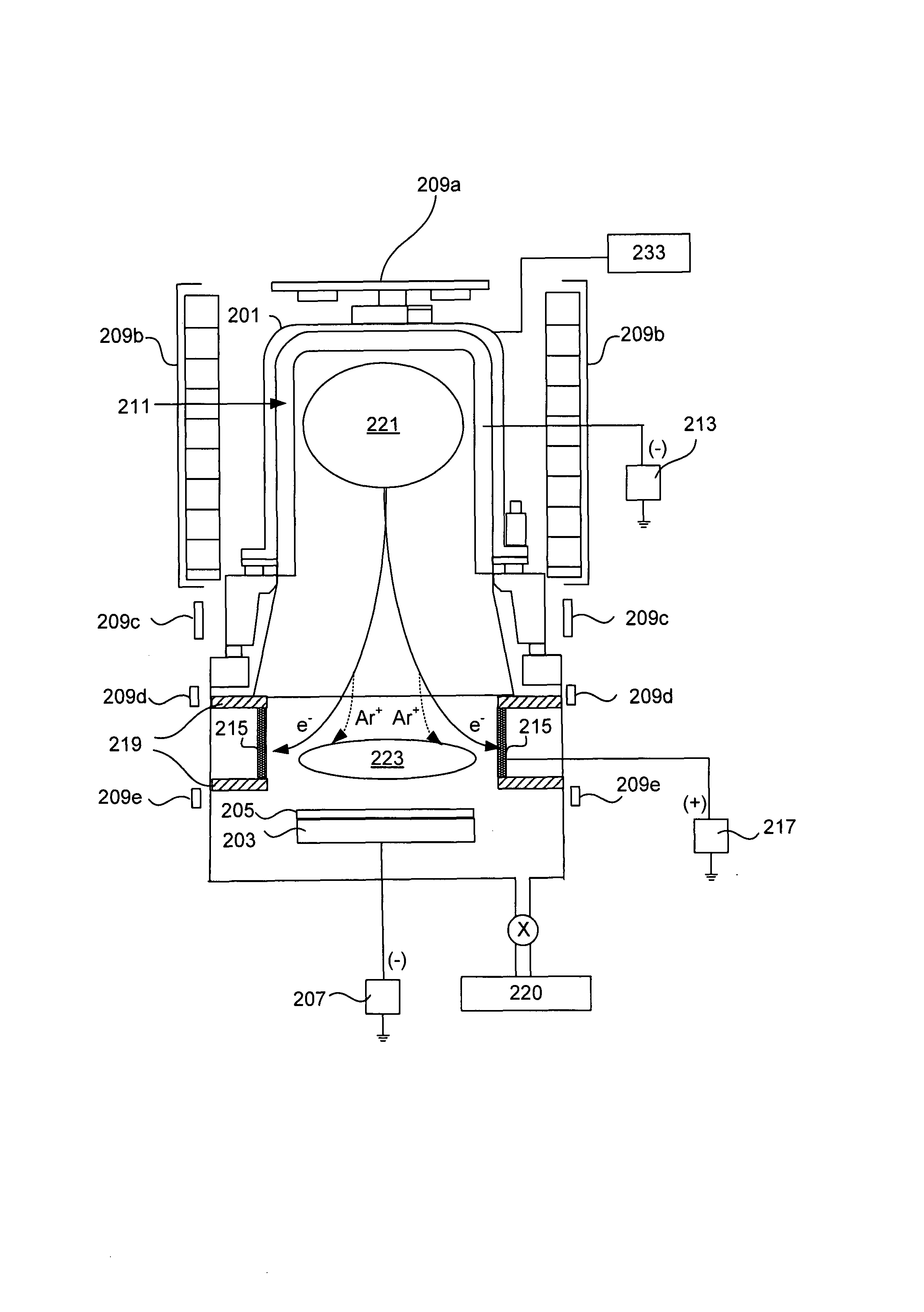

Method and apparatus for increasing local plasma density in magnetically confined plasma

ActiveUS7922880B1Easily damagedLow reliabilityCellsElectric discharge tubesPlasma densityHigh density

Local plasma density, e.g., the plasma density in the vicinity of the substrate, is increased by providing an ion extractor configured to transfer ions and electrons from a first region of magnetically confined plasma (typically a region of higher density plasma) to a second region of plasma (typically a region of lower density plasma). The second region of plasma is preferably also magnetically shaped or confined and resides between the first region of plasma and the substrate. A positively biased conductive member positioned proximate the second region of plasma serves as an ion extractor. A positive bias of about 50-300 V is applied to the ion extractor causing electrons and subsequently ions to be transferred from the first region of plasma to the vicinity of the substrate, thereby forming higher density plasma. Provided methods and apparatus are used for deposition and resputtering.

Owner:NOVELLUS SYSTEMS

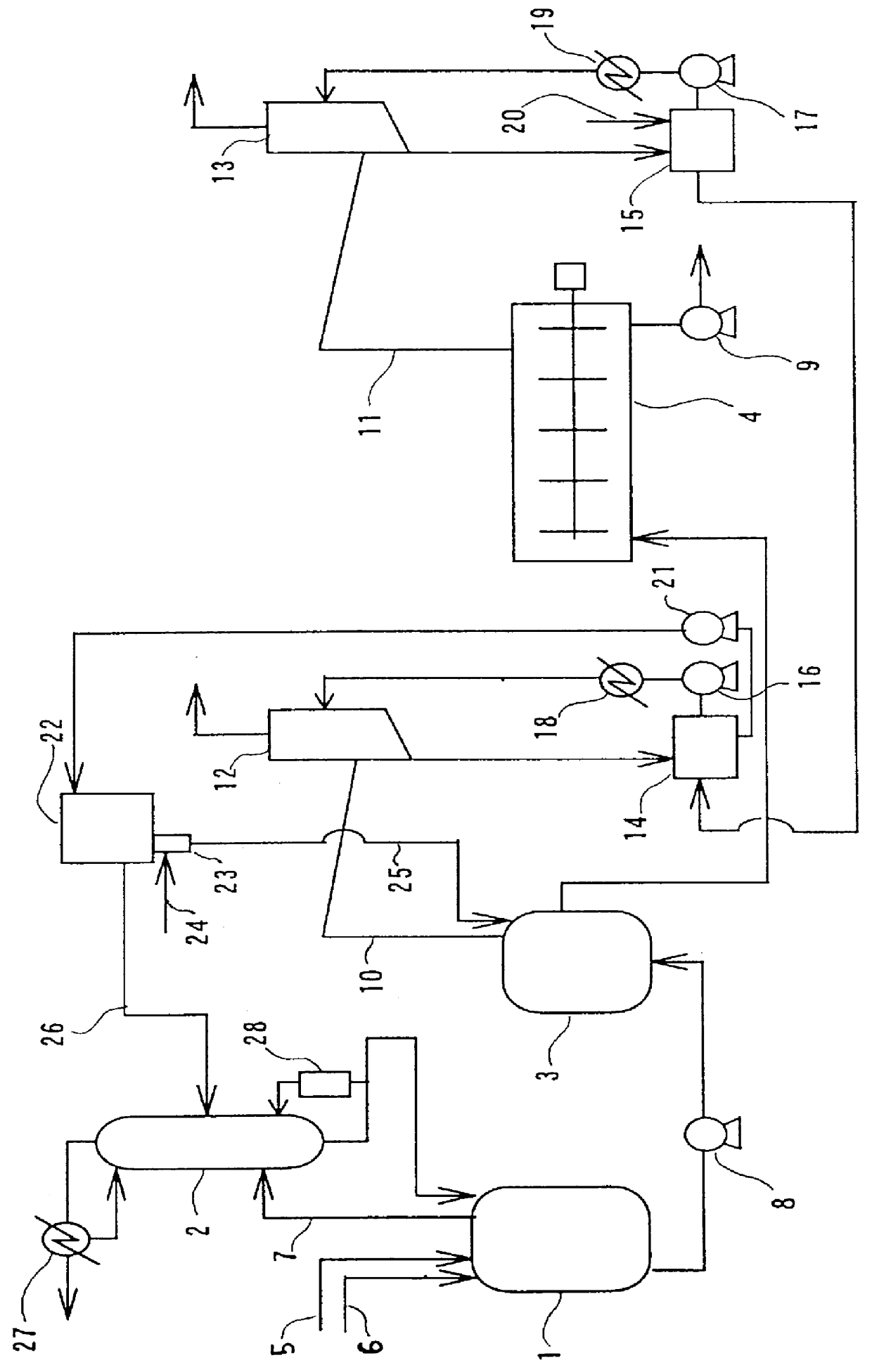

Process for continuously producing polyesters

PCT No. PCT / JP98 / 01977 Sec. 371 Date Dec. 21, 1998 Sec. 102(e) Date Dec. 21, 1998 PCT Filed Apr. 30, 1998 PCT Pub. No. WO98 / 50448 PCT Pub. Date Nov. 12, 1998A method for continuously producing a polyester by continuously melt-polymerizing a raw material consisting of a dicarboxylic acid component composed of mainly an aromatic dicarboxylic acid and containing an alicyclic dicarboxylic acid or an aliphatic dicarboxylic acid, or their ester-forming derivatives with a diol component, characterized in that said diol component as a distillate in the polycondensation reaction, including an adhering material, is condensed, said adhering material is separated centrifugally, and then the residual diol component, after distillation, is supplied to an esterification reaction or an ester interchange reaction.

Owner:TEIJIN LTD

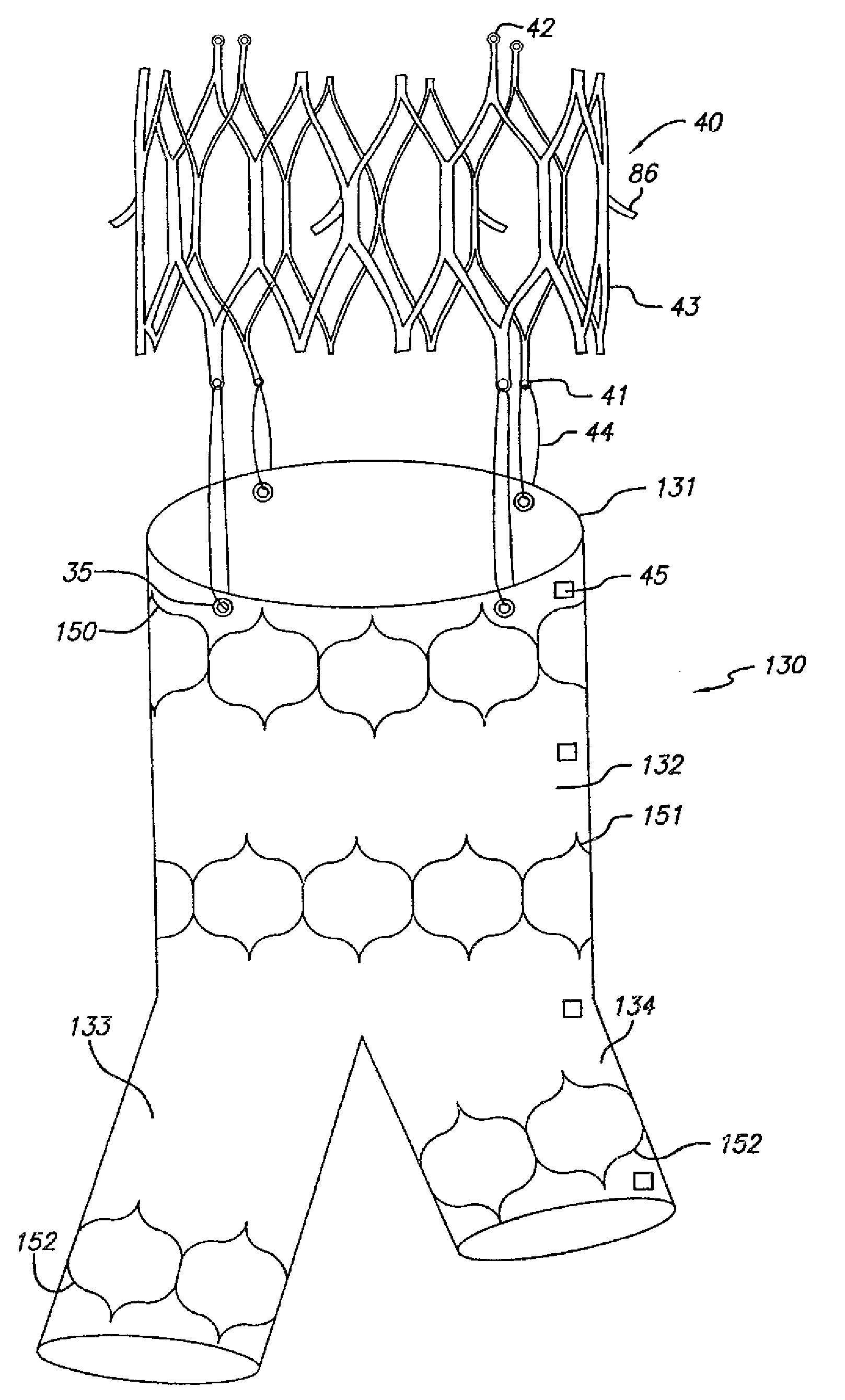

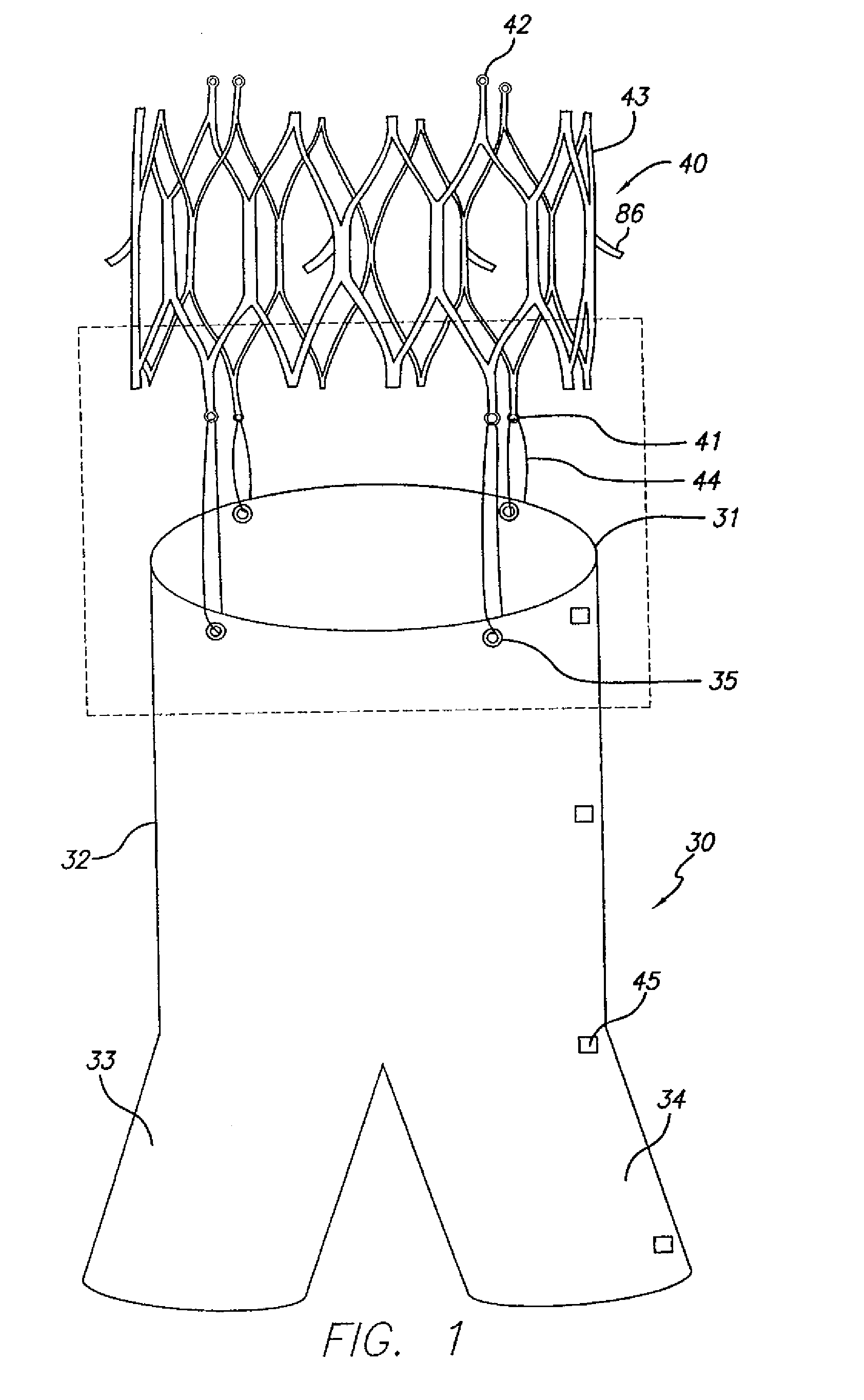

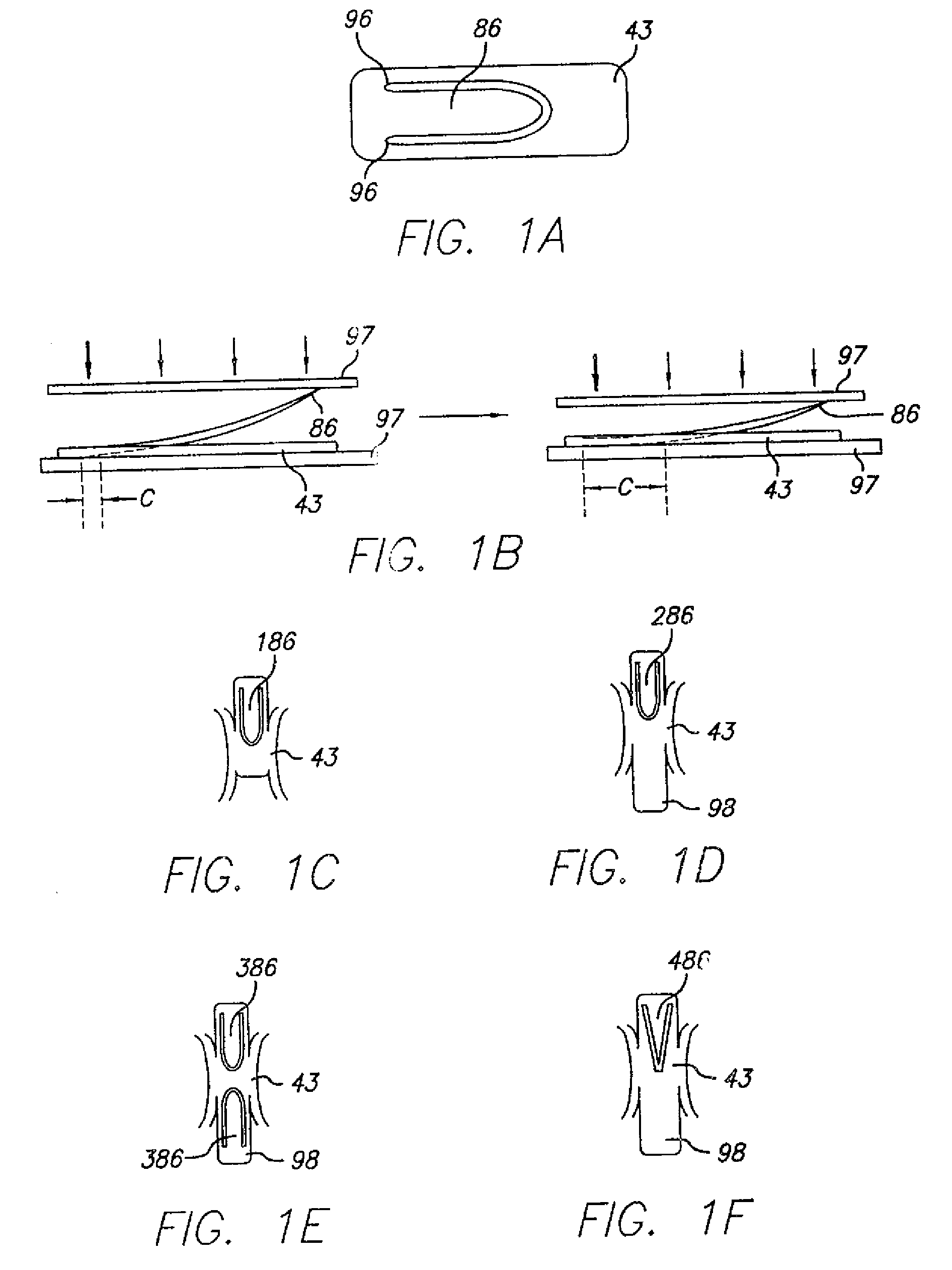

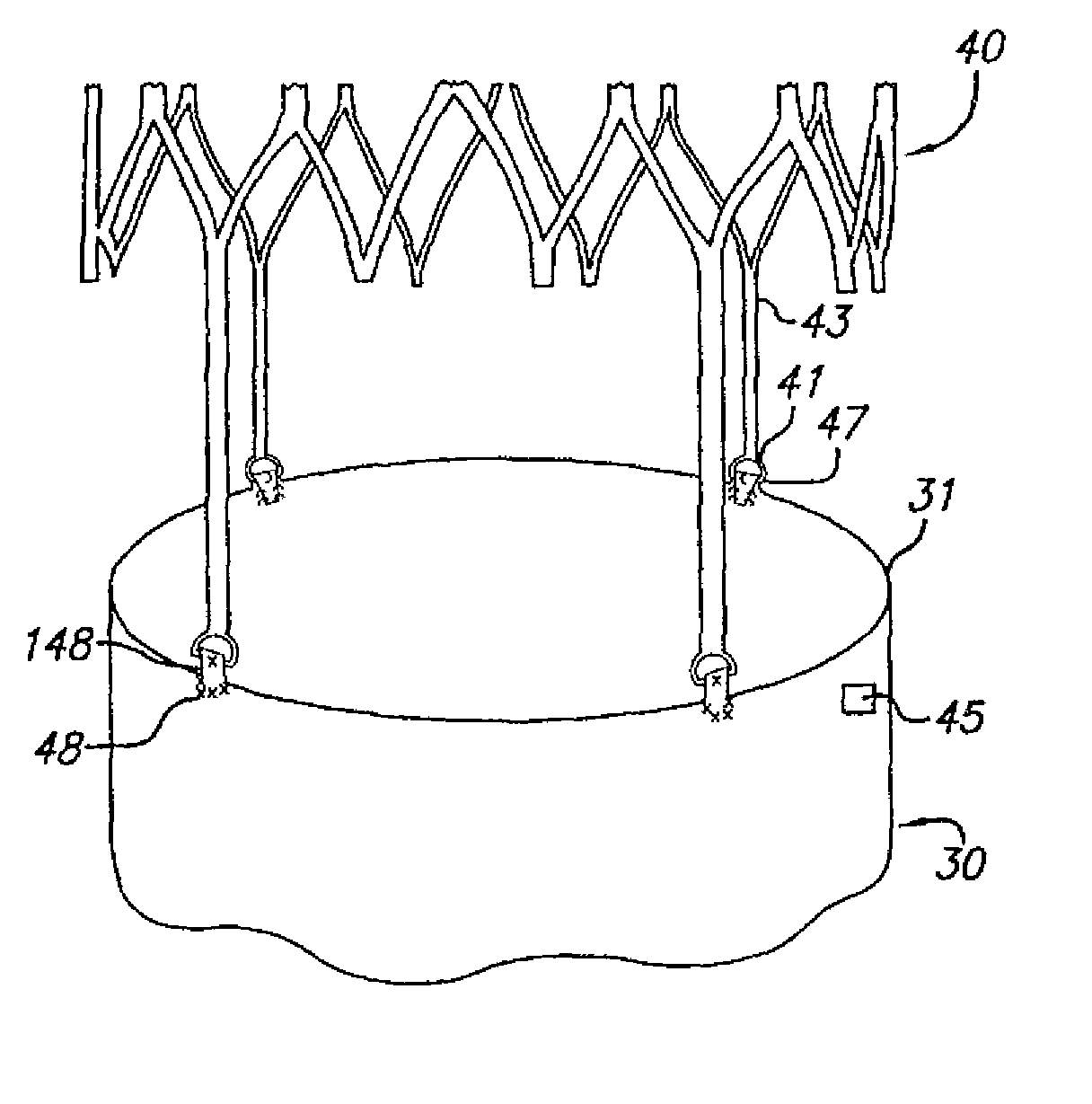

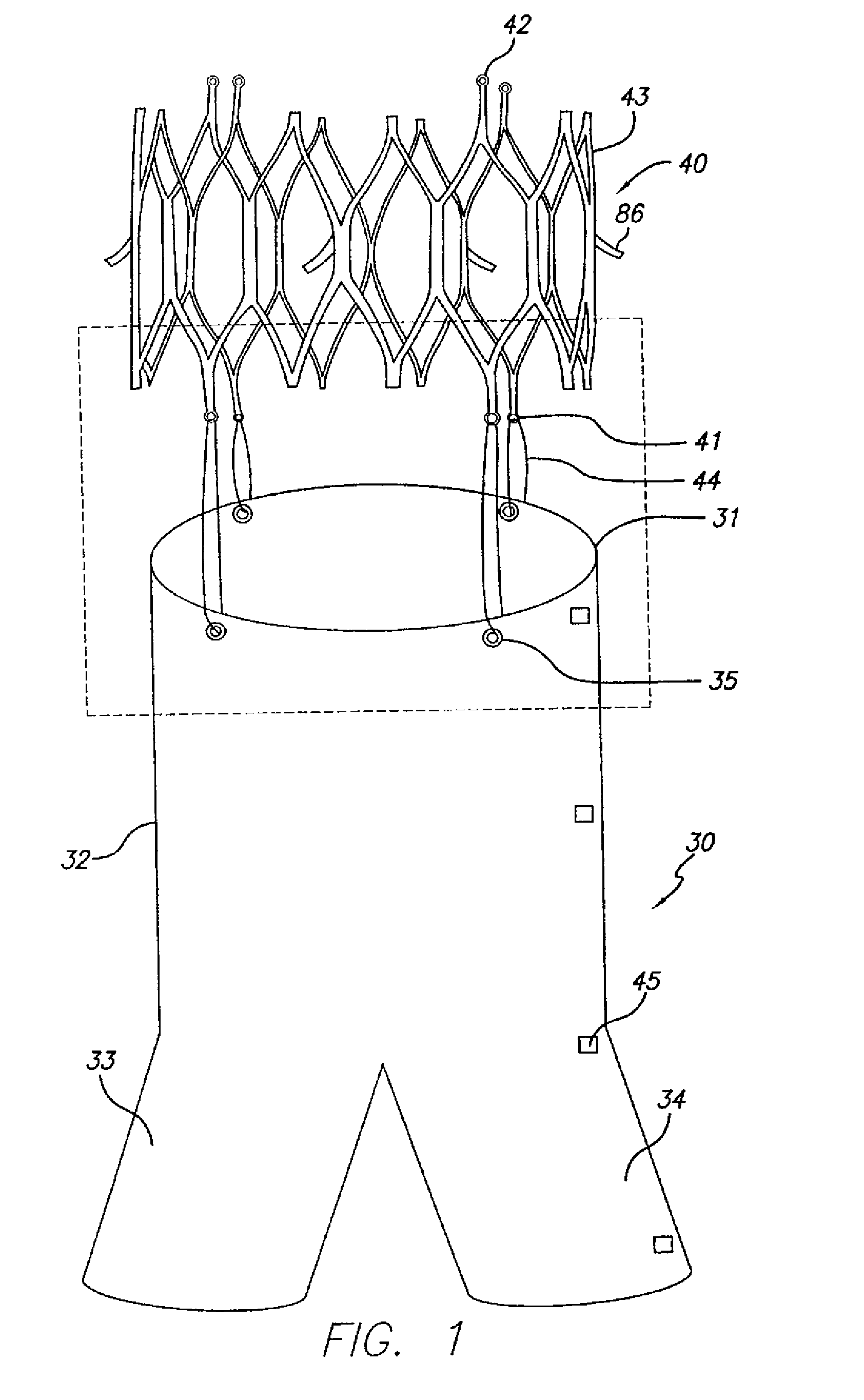

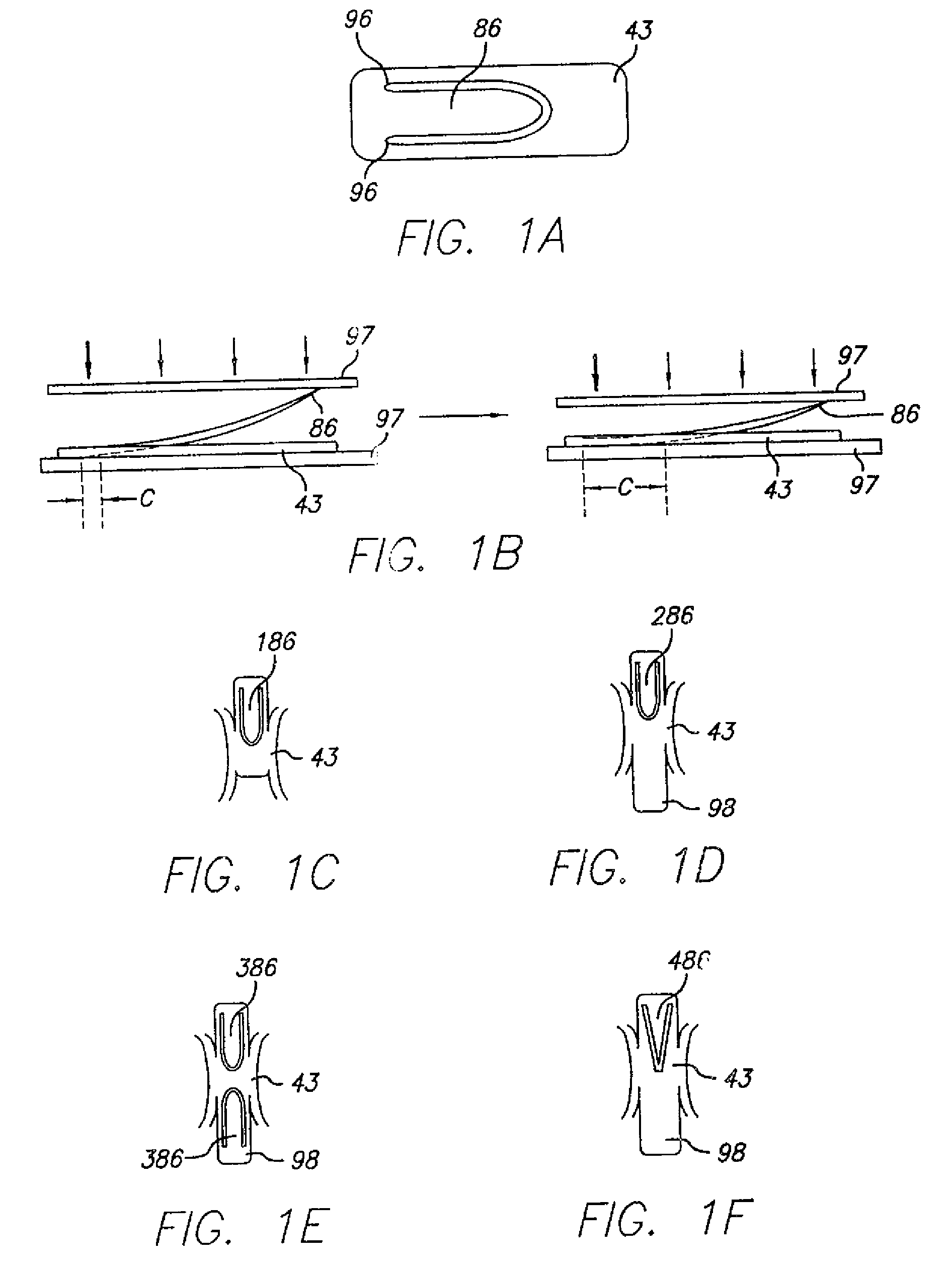

Endovascular graft device and methods for attaching components thereof

InactiveUS20100161028A1Facilitate accurate catheterization and deploymentReduce the possibilityStentsBlood vesselsBiomedical engineeringBlood vessel

Owner:LIFEPORT SCI

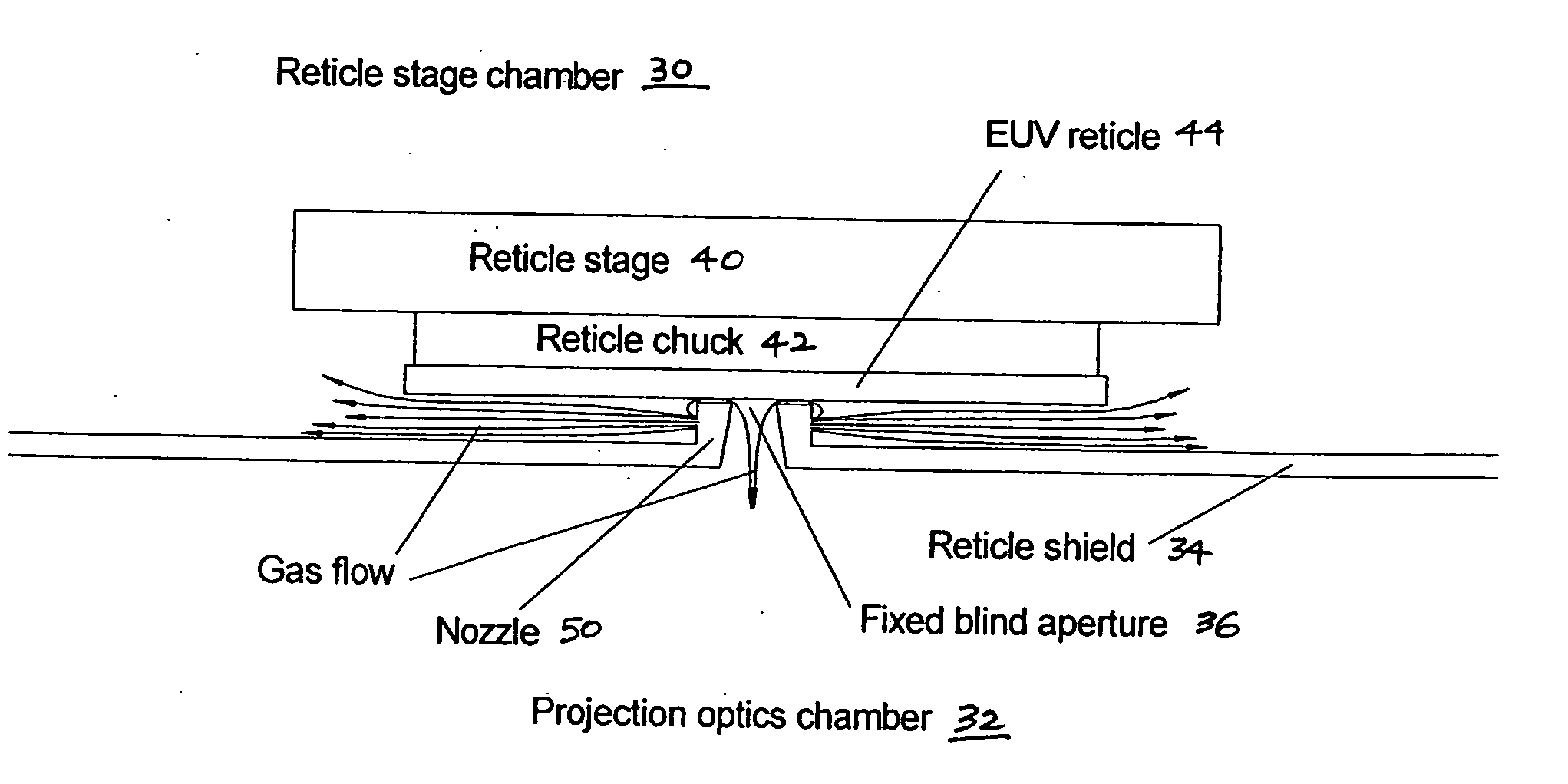

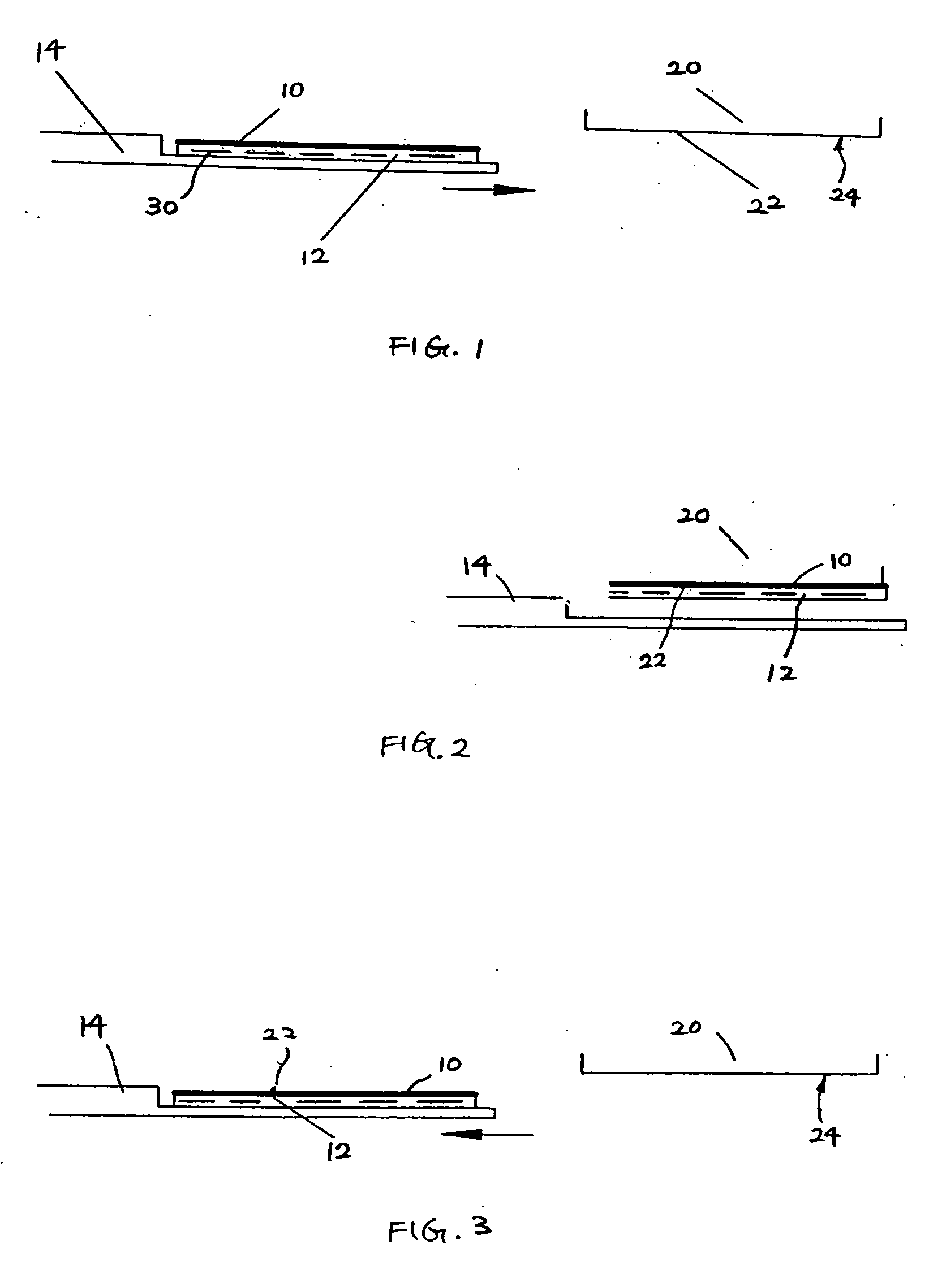

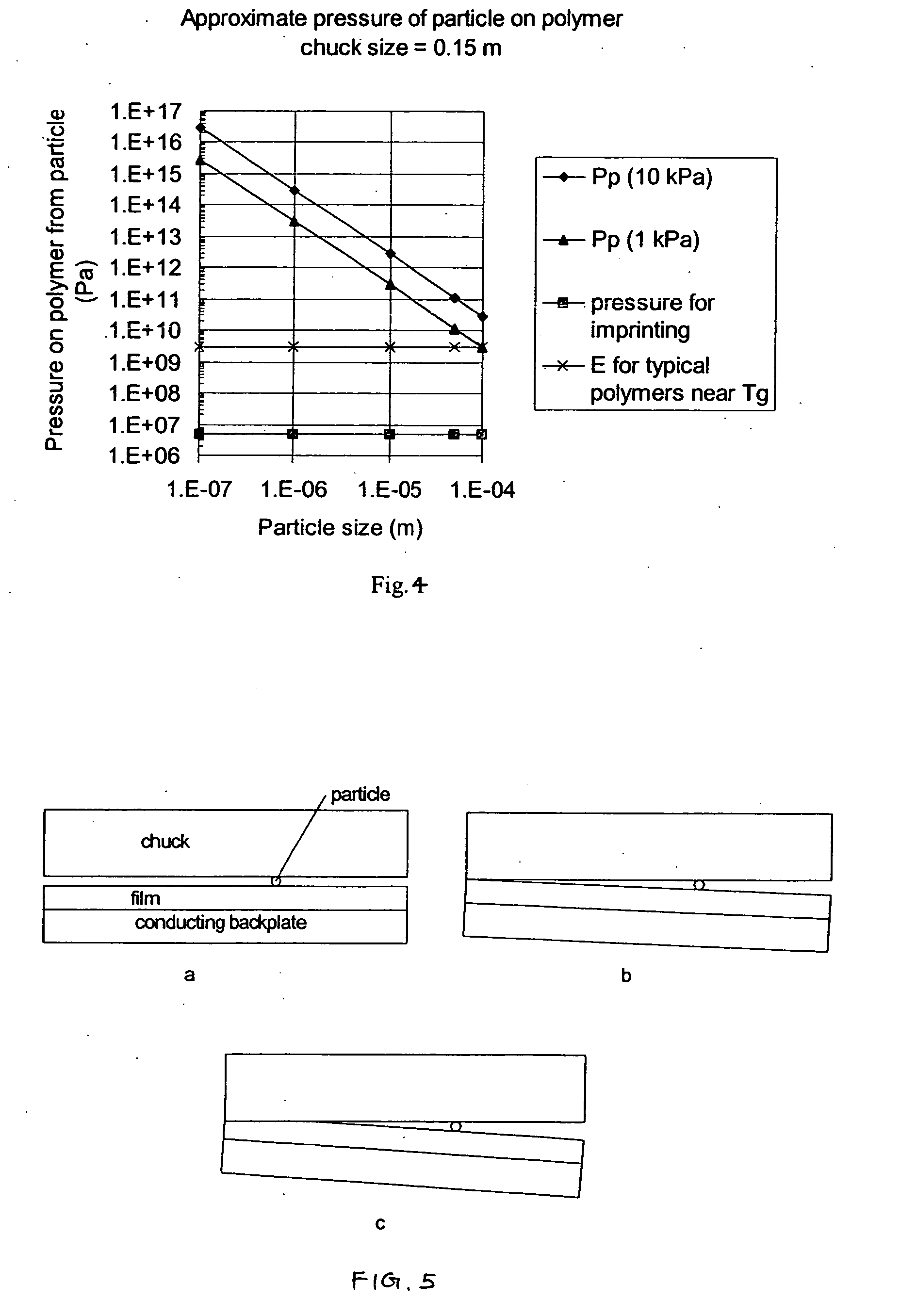

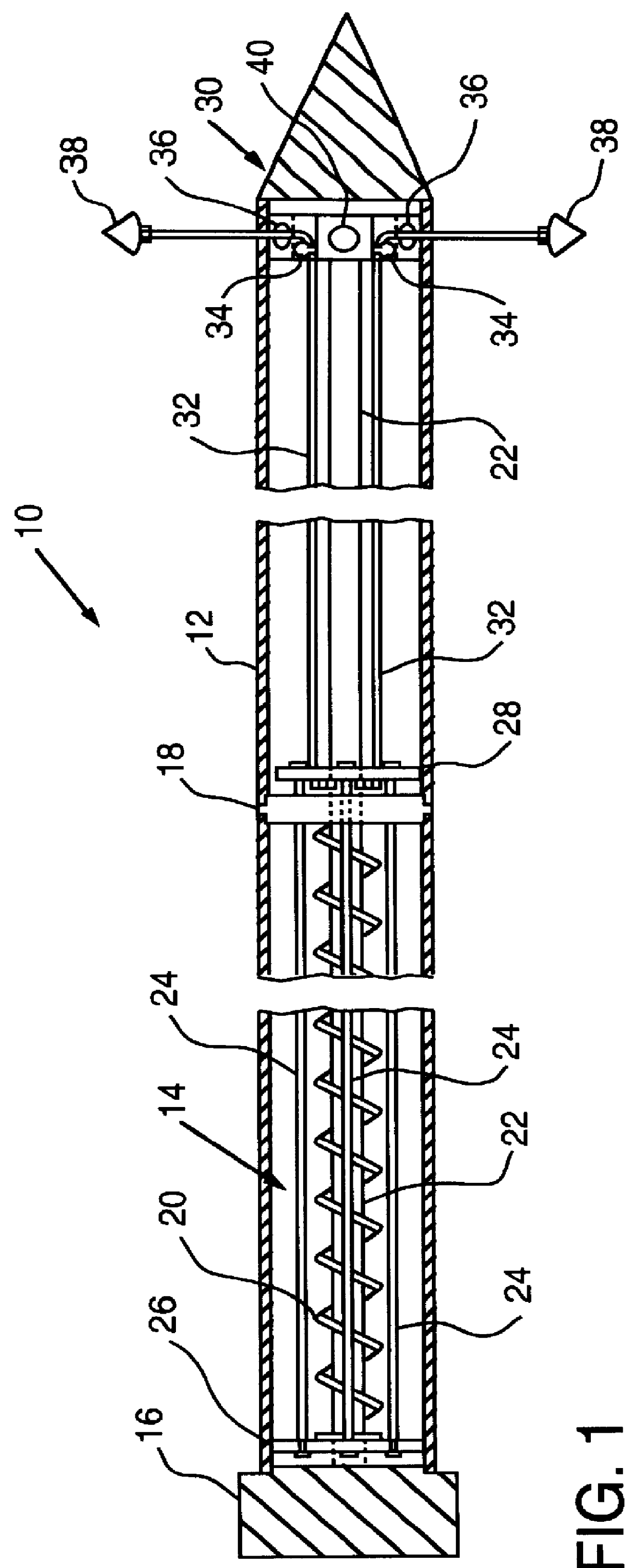

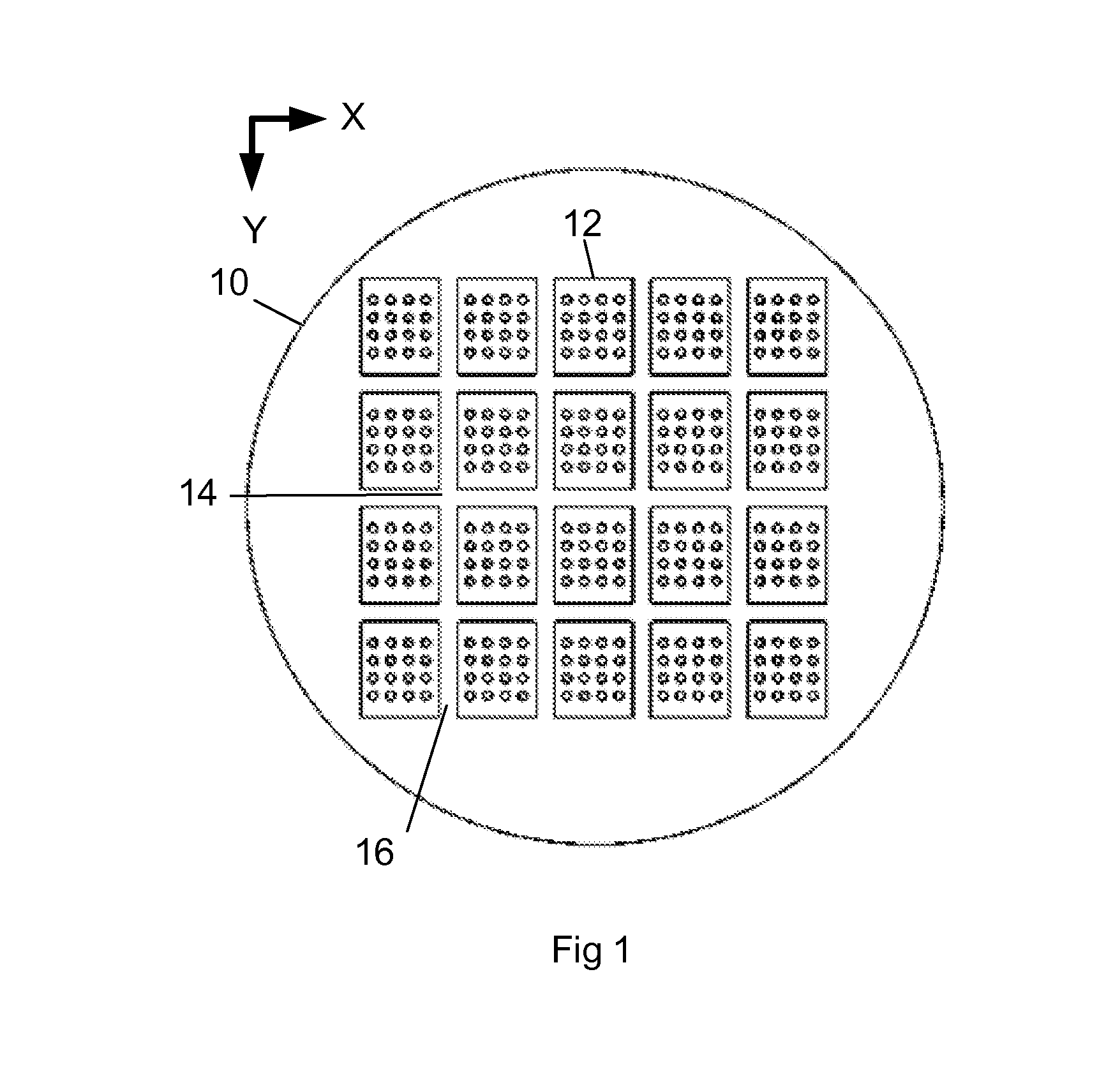

Cleaning chuck in situ

InactiveUS20060162739A1Easy to separateImprove abilitiesLighting and heating apparatusPhotomechanical apparatusEngineeringElectrical and Electronics engineering

Embodiments of the invention provide a method and an apparatus for in situ chuck cleaning, which advantageously reduces downtime to restore flatness. In one embodiment, a method of cleaning a chuck in situ comprises providing a cleaning layer on a substrate, the cleaning layer comprising a deformable material; positioning the substrate to place the cleaning layer in contact with a chuck surface of the chuck in situ, the chuck surface having thereon a material to be removed from the chuck surface; pressing the cleaning layer against the chuck surface with a sufficient pressure to allow the material on the chuck surface to be attached to the cleaning layer; and removing the substrate with the cleaning layer and the material attached thereto from the chuck.

Owner:NIKON CORP

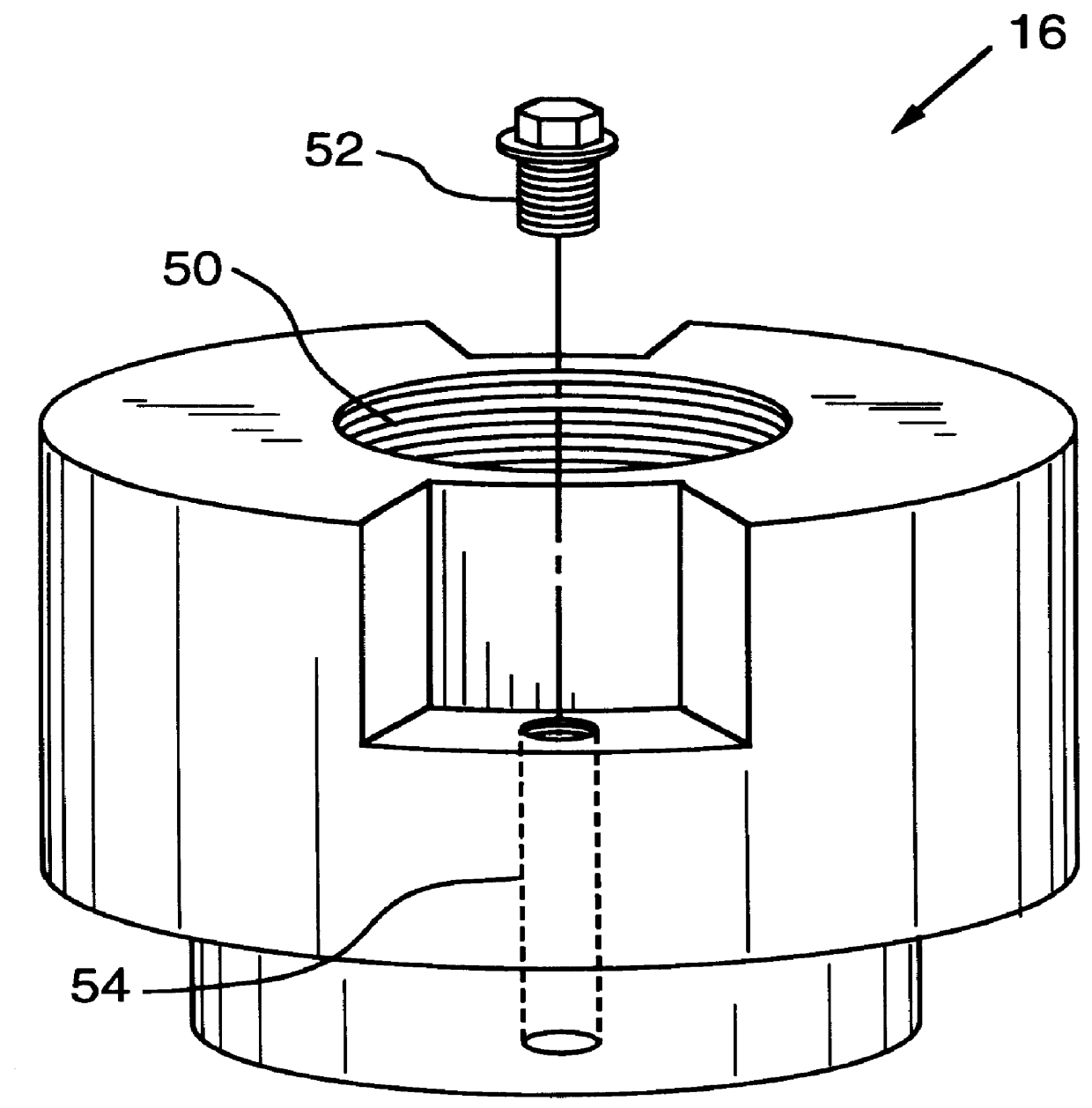

Method and apparatus for rotary mining

InactiveUS6065551AMaterial removalCost-effectiveEarth drilling toolsDrill bitsCompression deviceMechanical engineering

The present invention is directed to a rotary mining apparatus. The apparatus includes an elongated housing with a leading end and an opposite trailing end. The apparatus also includes a compression device coupled to the housing. The apparatus further includes a plurality of cables extending along the housing. Each of the cables has an end connected to the compression device. The apparatus also includes a plurality of cutting devices attached to the cables at ends of the cables opposite the ends connected to the compression device. The present invention is also directed to a method of removing subterranean material. The method includes the step of inserting a rotary mining device having radially extendable cutting devices into a subterranean shaft. The method also includes the steps of rotating the mining device such that the cutting devices contact the sides of the shaft and extending the cutting devices into the sides of the shaft.

Owner:FAMILY TRUST OF ALLEN J GOURLEY & FAITH KIMKO GOURLEY THE +1

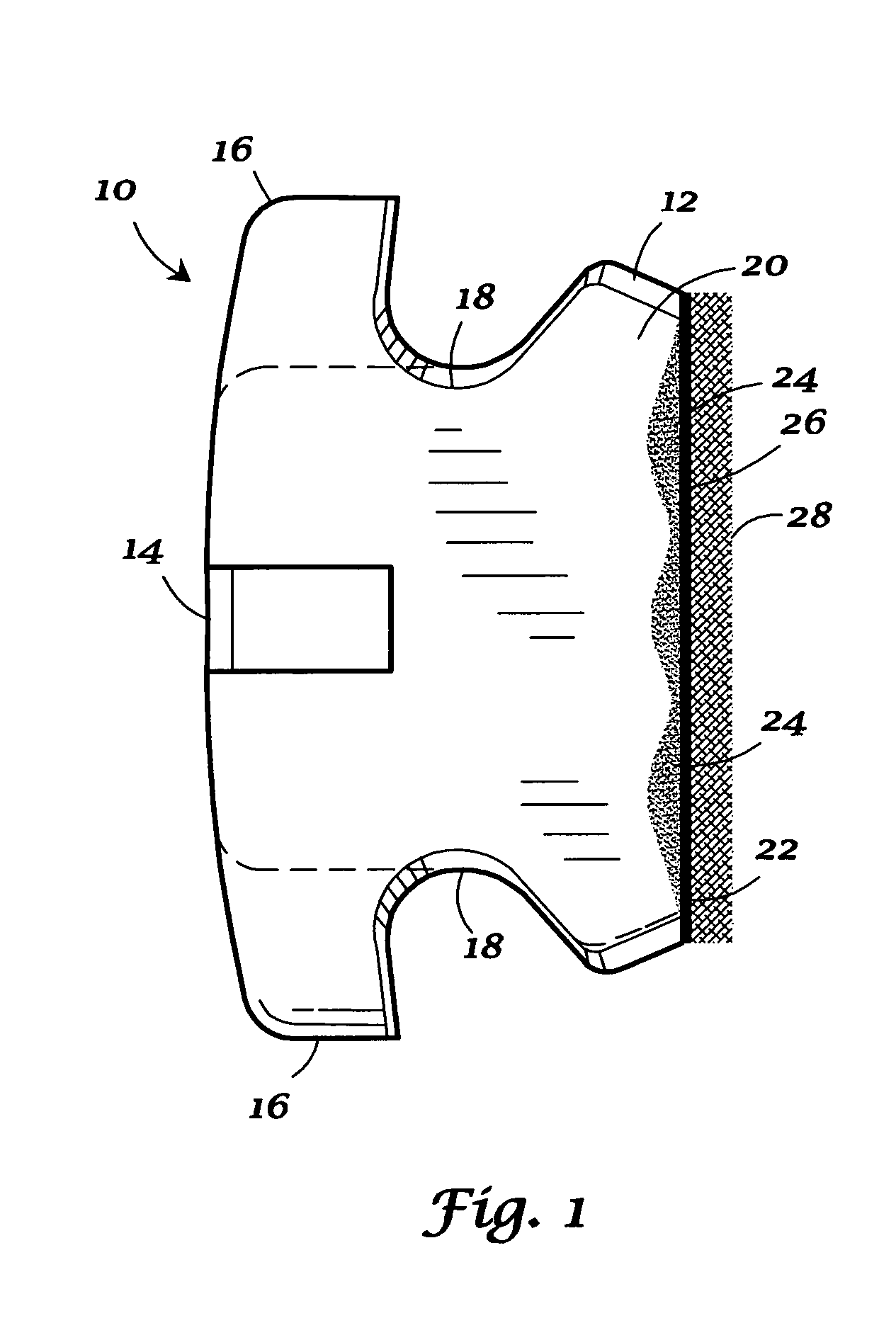

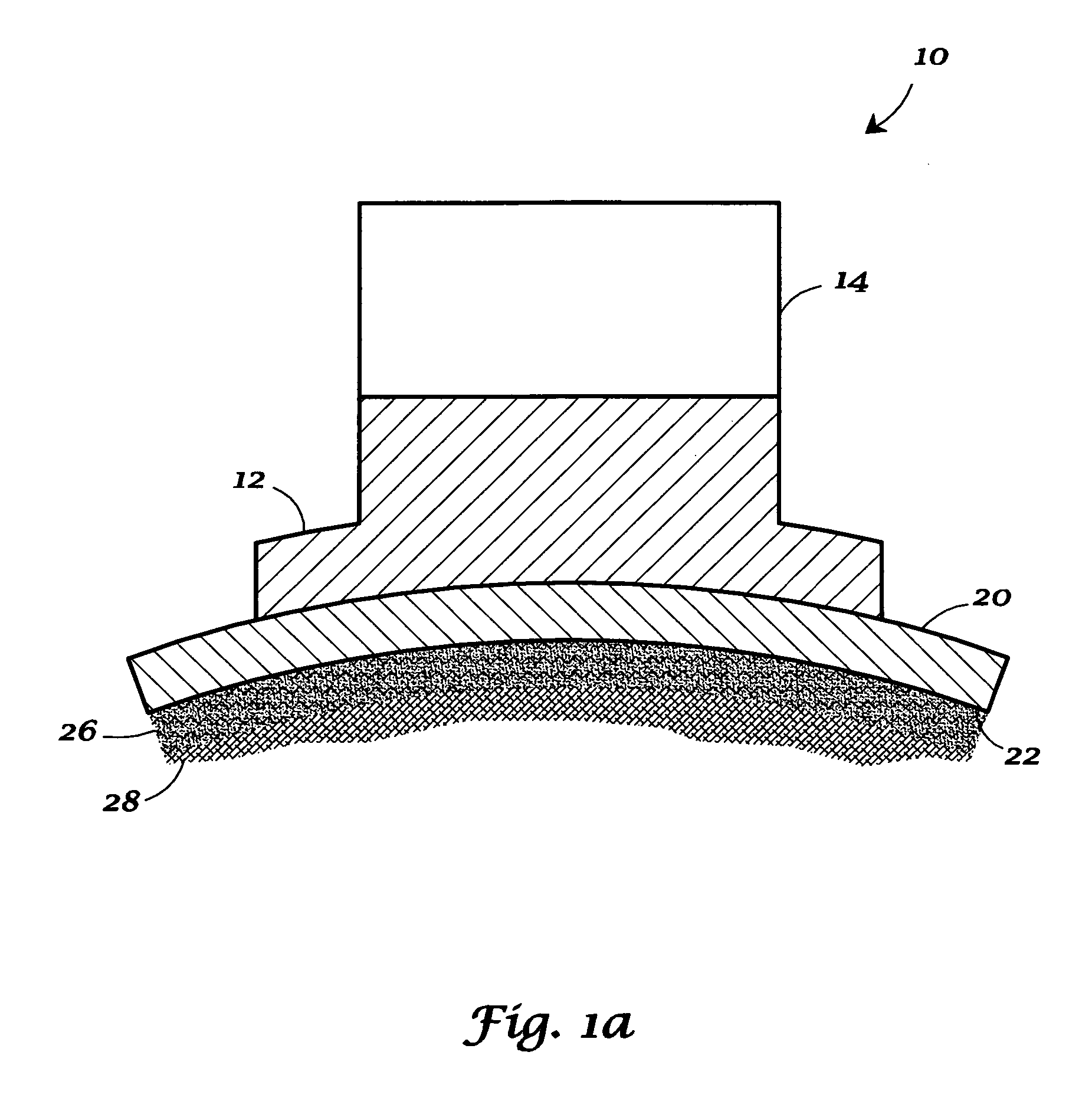

Methods for indirect bonding of orthodontic appliances

ActiveUS8308478B2High strengthIncrease elasticityBracketsTeeth fillingDental patientsDental restorative materials

Improved methods for indirect bonding of orthodontic appliances, such as brackets, to the tooth surfaces of dental patients are provided. The methods use a transfer tray to accurately position the brackets on the tooth surfaces. Preferably, the tray is made of an ethylene vinyl acetate copolymer (EVA) / siloxane material. The brackets are coated with a protective coating to prevent them from becoming embedded in the tray. Preferably, a translucent, blue-tinted coating is used to cover the brackets. Dental restorative materials are used to bond the brackets to the teeth. The transfer tray is then removed from the mouth, while the appliances remain firmly bonded to the tooth surfaces.

Owner:DENTSPLY SIRONA INC

Tantalum barrier removal solution

InactiveUS20030181345A1Reduce erosionMaterial removalPigmenting treatmentSoap detergents with inorganic compounding agentsGuanidine derivativesTantalum nitride

A chemical mechanical planarization solution is useful for removing tantalum barrier materials. The solution includes by weight percent 0 to 25 oxidizer, 0 to 15 inhibitor for a nonferrous metal and 0 to 20 complexing agent for the nonferrous metal, 0.01 to 12 tantalum removal agent selected from the group consisting of formamidine, formamidine salts, formamidine derivatives, guanidine derivatives, guanidine salts and mixtures thereof, 0 to 5 abrasive, 0 to 15 total particles selected from the group consisting of polymeric particles and polymer-coated coated particles and balance water. The solution has a tantalum nitride to TEOS selectivity of at least 3 to 1 as measured with a microporous polyurethane polishing pad pressure measure normal to a wafer less than 20.7 kPa.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

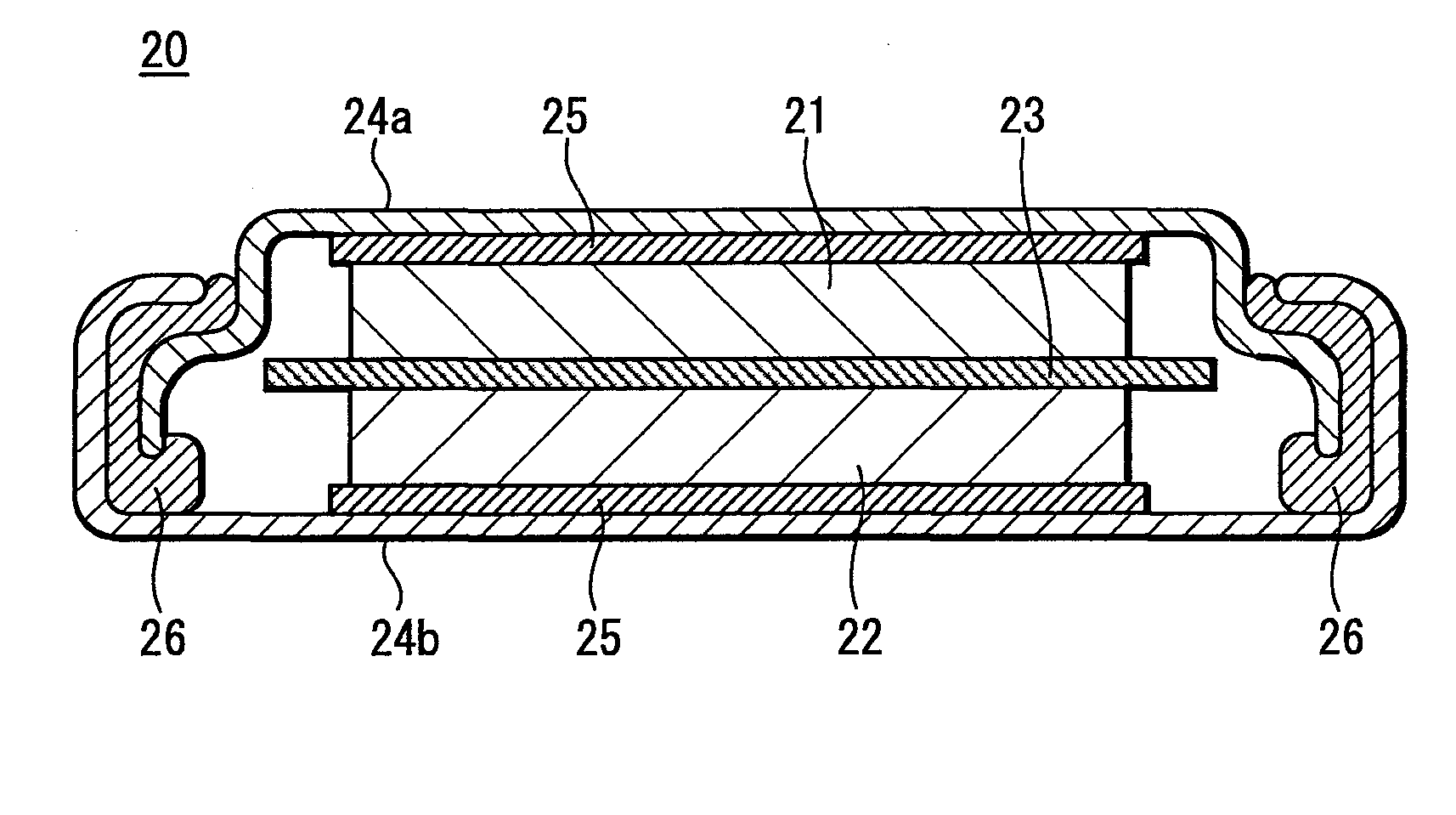

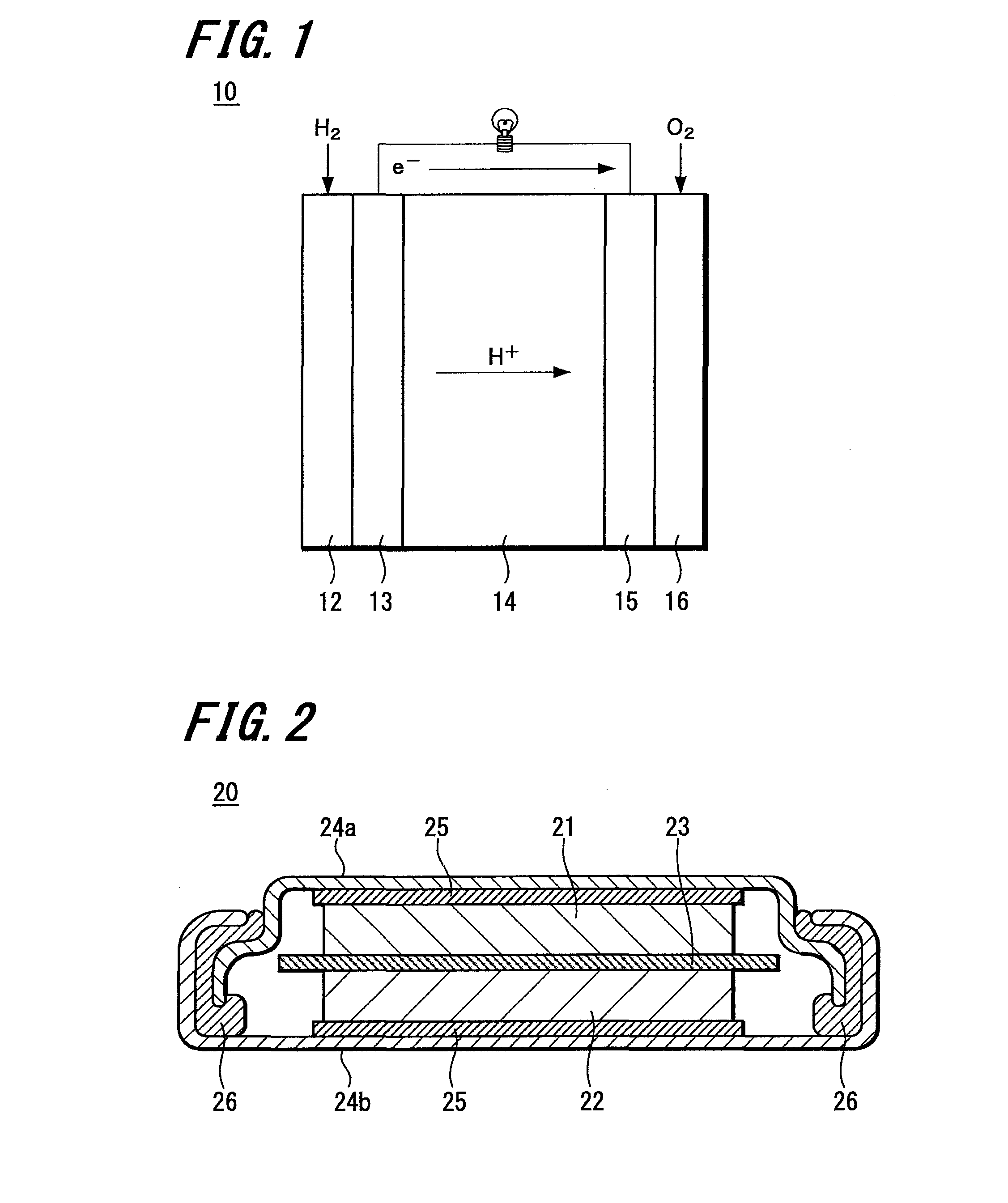

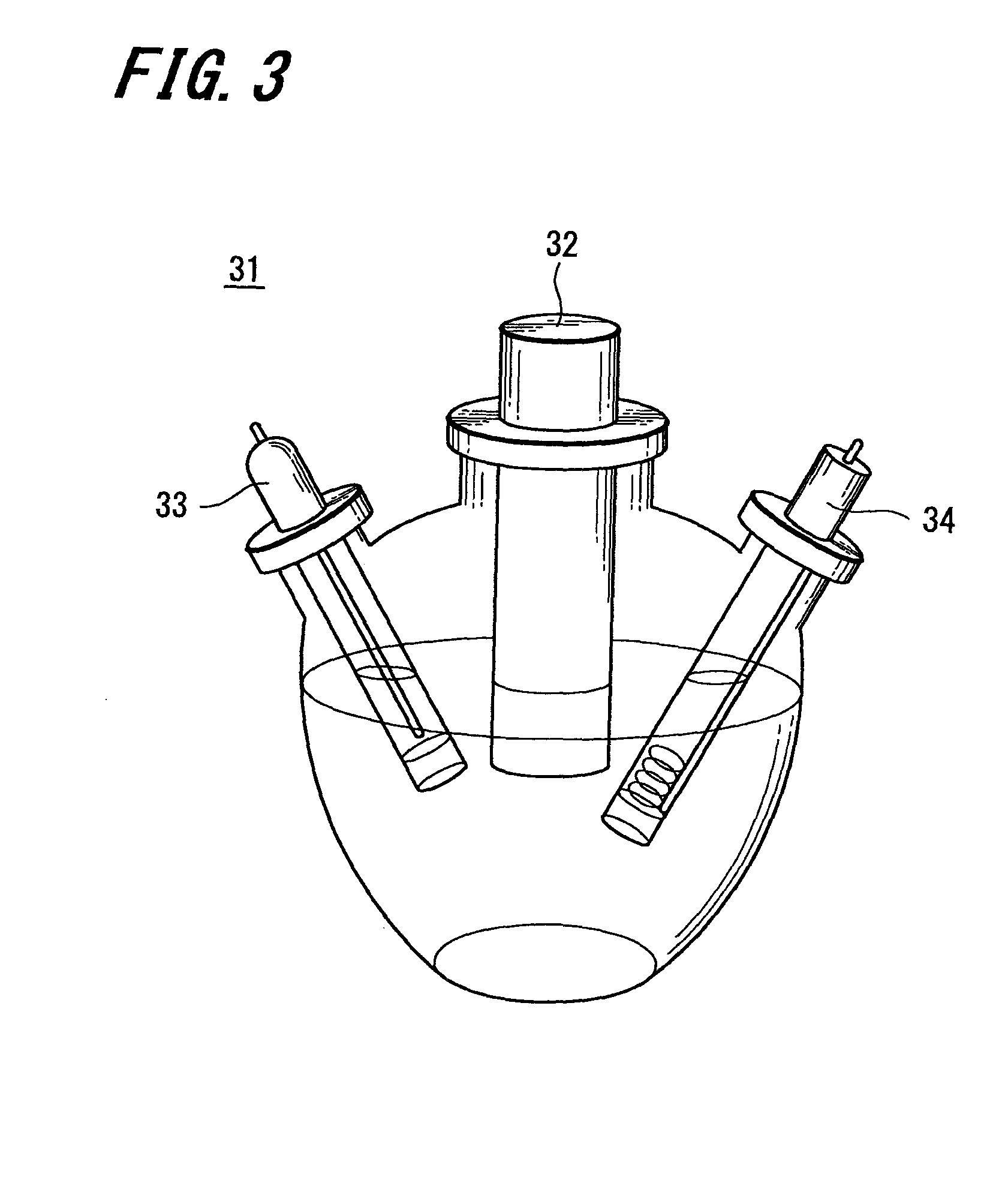

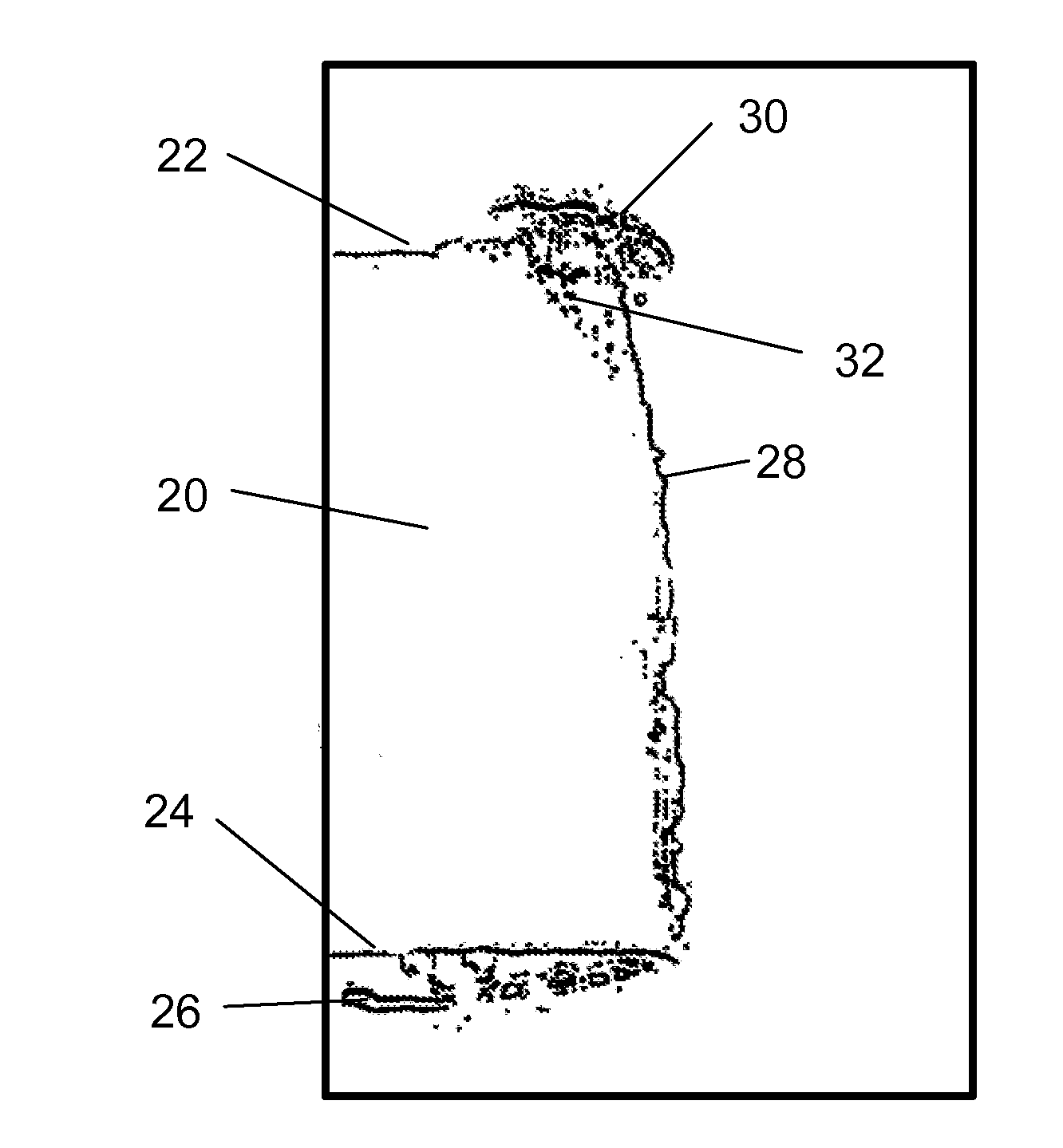

Carbon catalyst, slurry containing the carbon catalyst, process for producing carbon catalyst, and fuel cell, storage device, and environmental catalyst each employing carbon catalyst

InactiveUS20100323272A1Reduced responseImprove responseMaterial nanotechnologyCyanogen compoundsFiberFuel cells

The present invention is made to provide a carbon catalyst capable of preventing the coarsening of particles of nanoshell structure of carbon which causes reduction in activity for oxygen reduction reaction. The carbon catalyst is produced by the steps of: preparing a carbon precursor polymer; mixing a transition metal or a compound of the transition metal into the carbon precursor polymer; spinning the mixture of the carbon precursor polymer and the transition metal or the compound of the transition metal into fibers; and carbonizing the fibers.

Owner:GUNMA UNIVERSITY +1

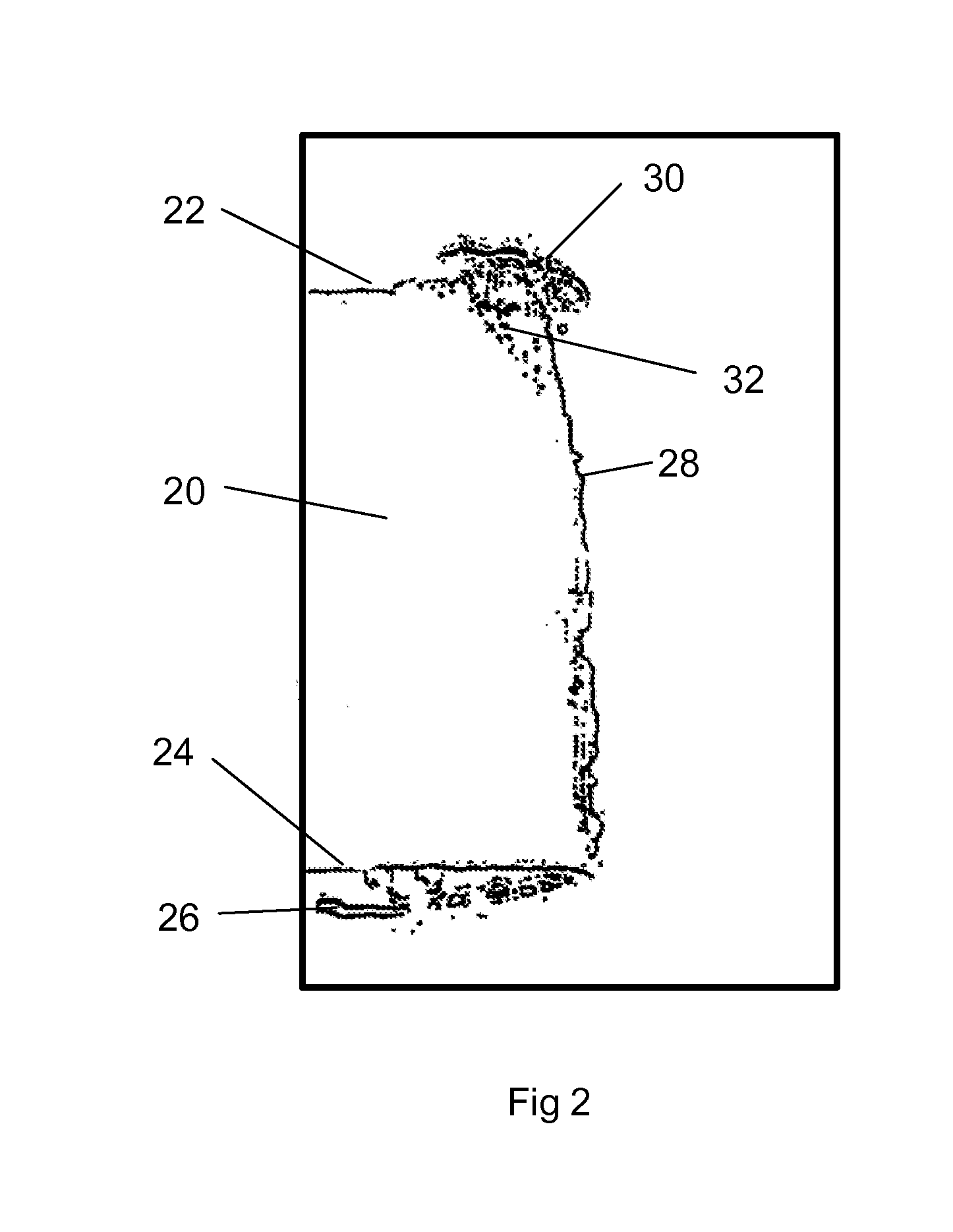

Method and apparatus for laser singulation of brittle materials

ActiveUS20110240616A1Improve throughputSmall sizeSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesBreaking strengthLaser cutting

An improved method for singulation of electronic substrates into dice uses a laser to first form cuts in the substrate and then chamfers the edges of the cuts by altering the laser parameters. The chamfers increase die break strength by reducing the residual damage and removes debris caused by the initial laser cut without requiring additional process steps, additional equipment or consumable supplies.

Owner:ELECTRO SCI IND INC

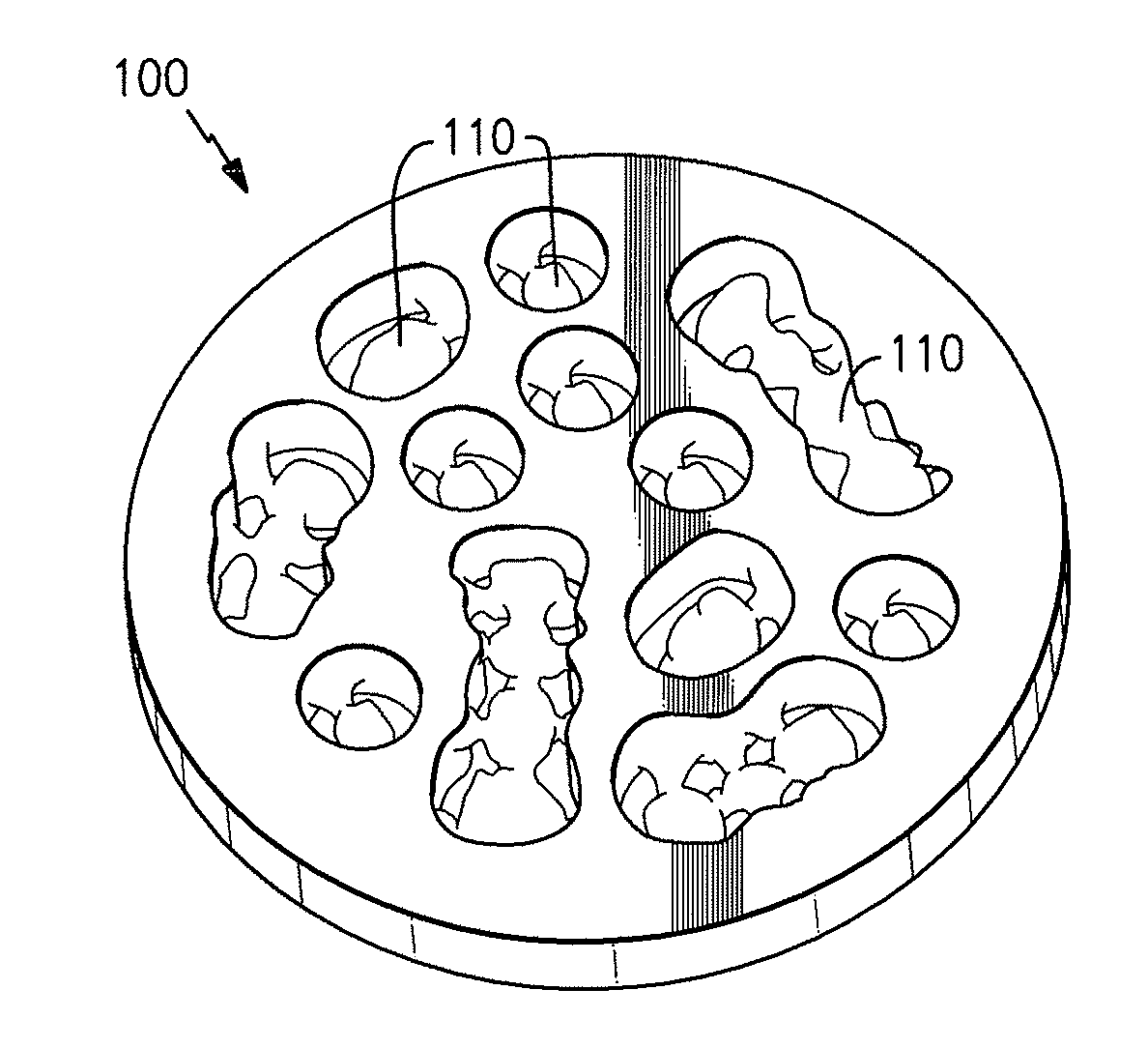

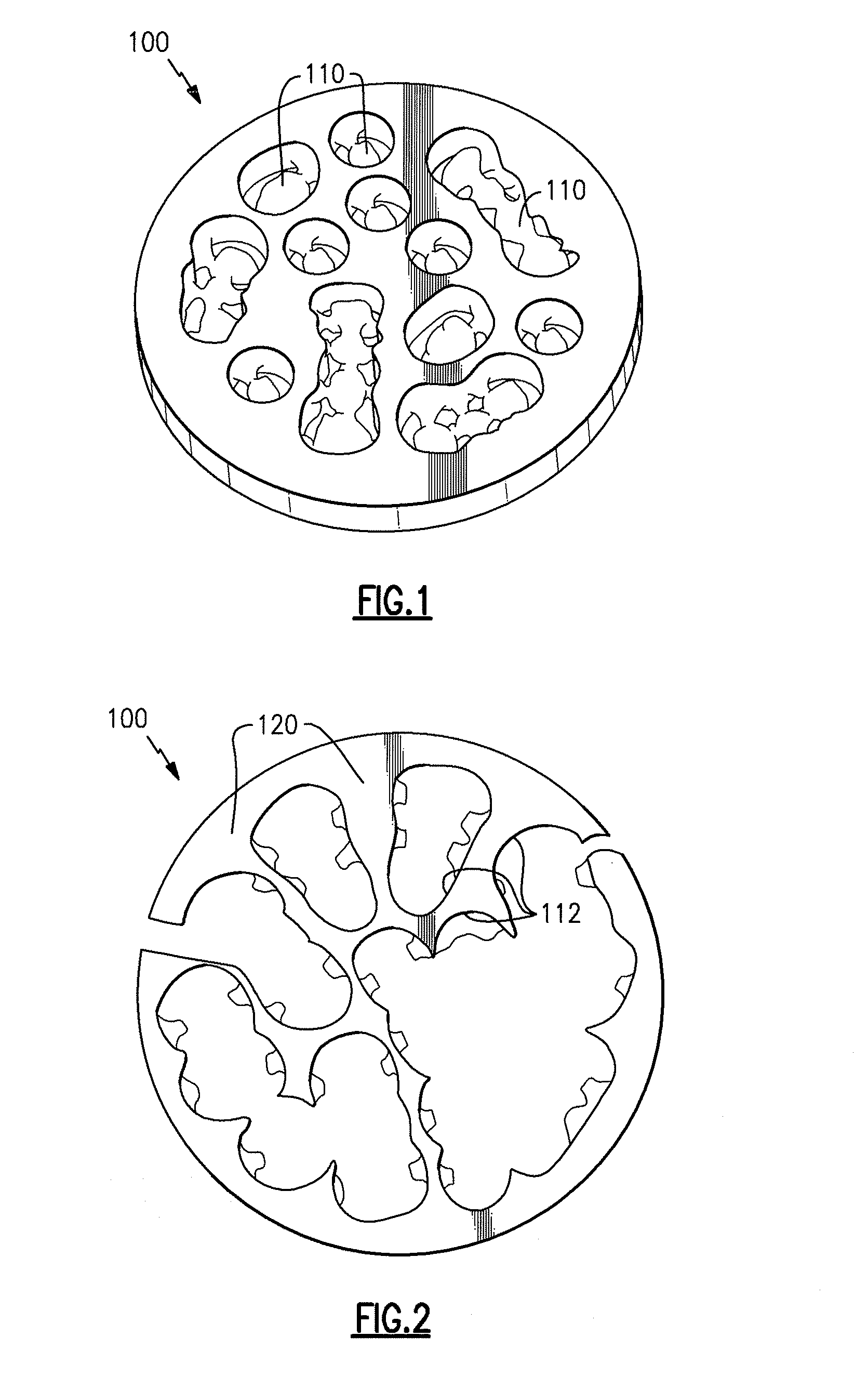

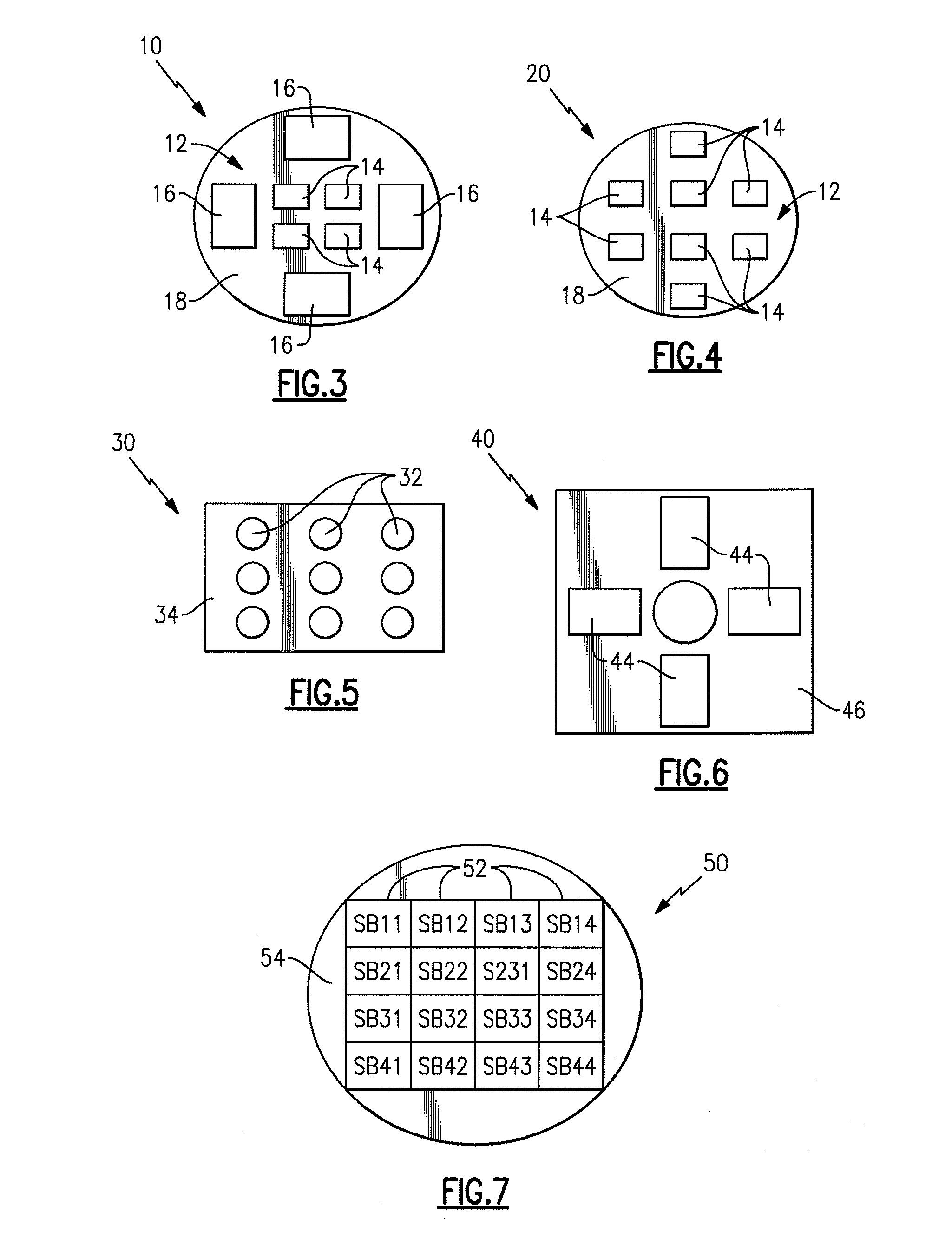

Addressable Matrices/Cluster Blanks for Dental CAD/CAM Systems and Optimization Thereof

ActiveUS20090023112A1Maximum interchangabilityMaximum flexibilityDwelling equipmentDental toolsEngineeringCam

A cluster mill blank includes a framework constructed to cooperate with a blank holder of an existing CAD / CAM system, and a plurality of sub-blanks attached to the framework forming an addressable matrix or cluster blank. CAD / CAM systems including such a framework, as well as associated methods are described.

Owner:IVOCLAR VIVADENT AG

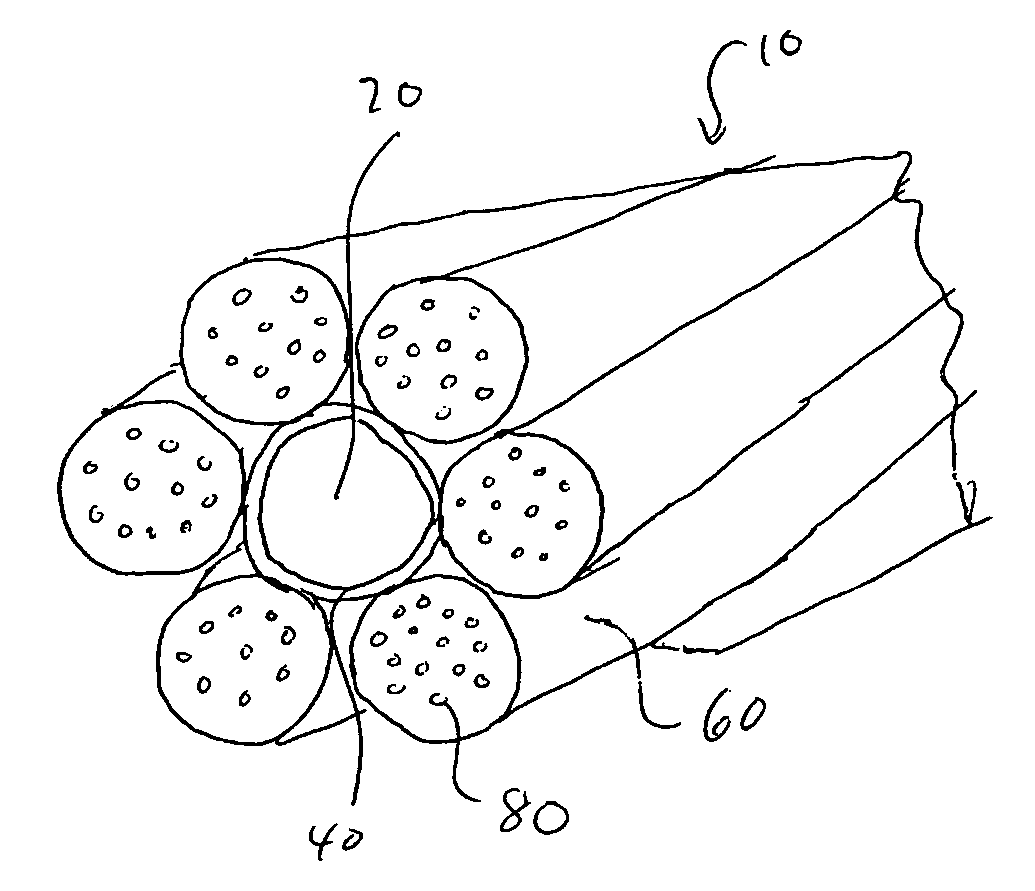

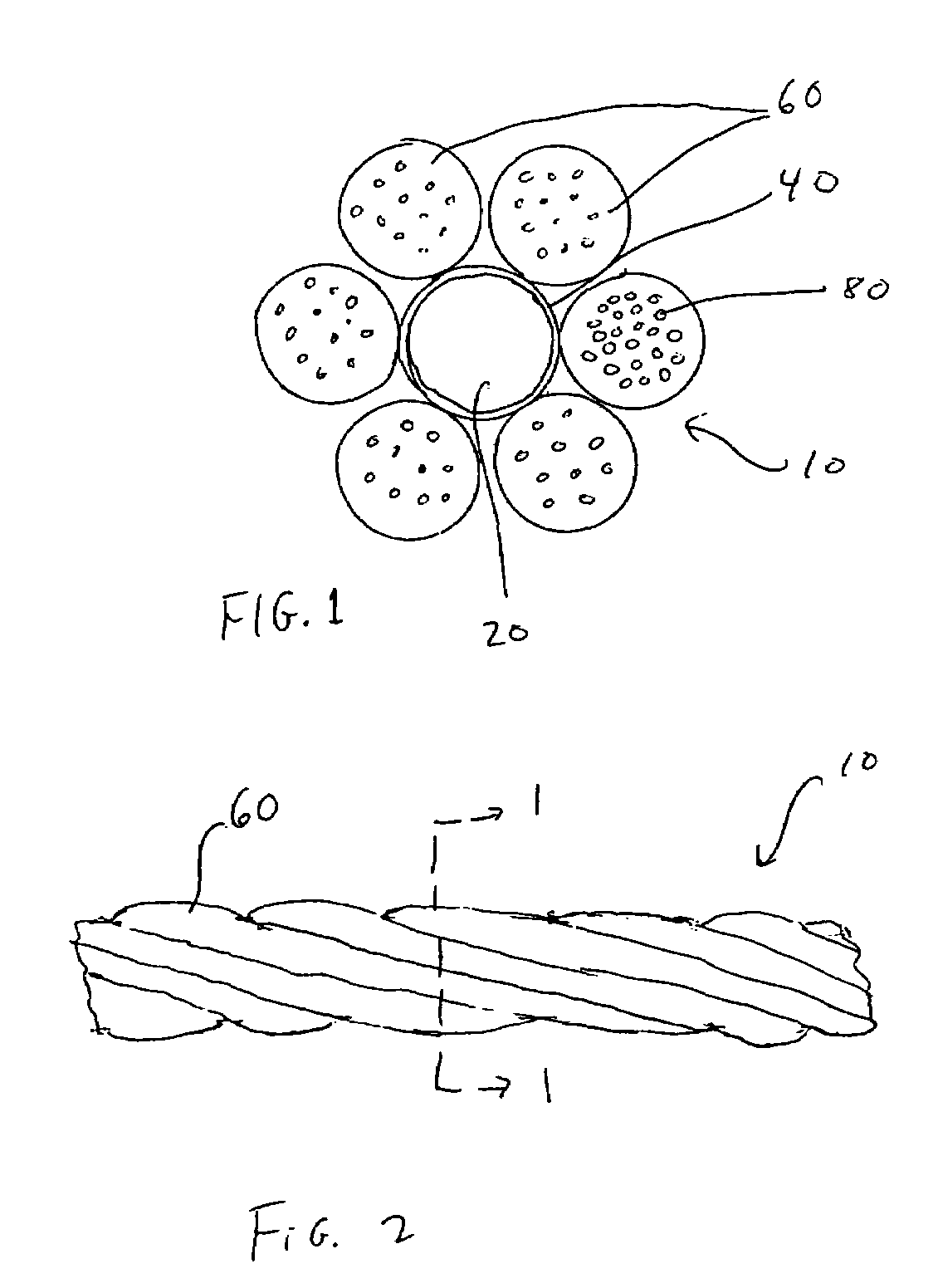

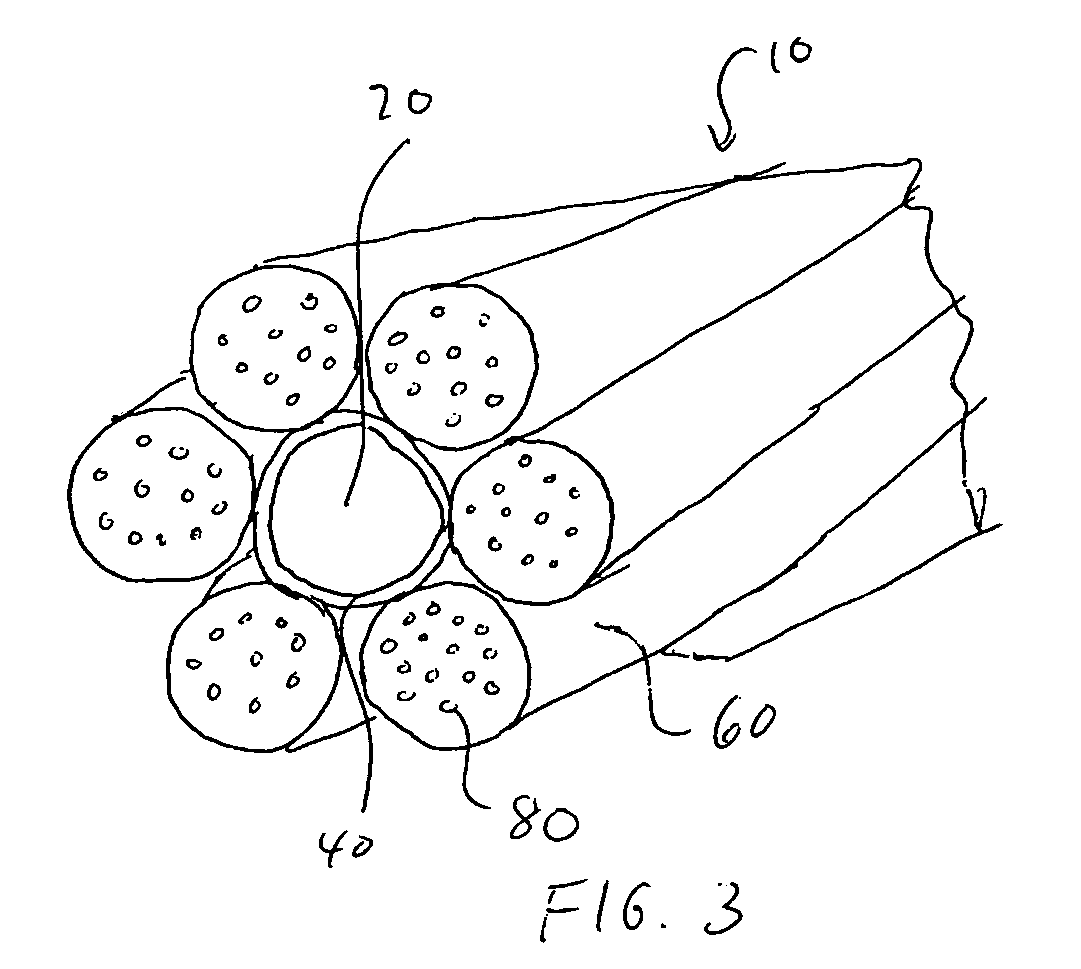

Cable element having repositionable pressure sensitive adhesive to couple buffer tubes to a central strength member

ActiveUS7212715B2Reduce the amount requiredEliminates stranding material and stranding stepFibre mechanical structuresUltimate tensile strengthMechanical engineering

Owner:DRAKA COMTEQ BV

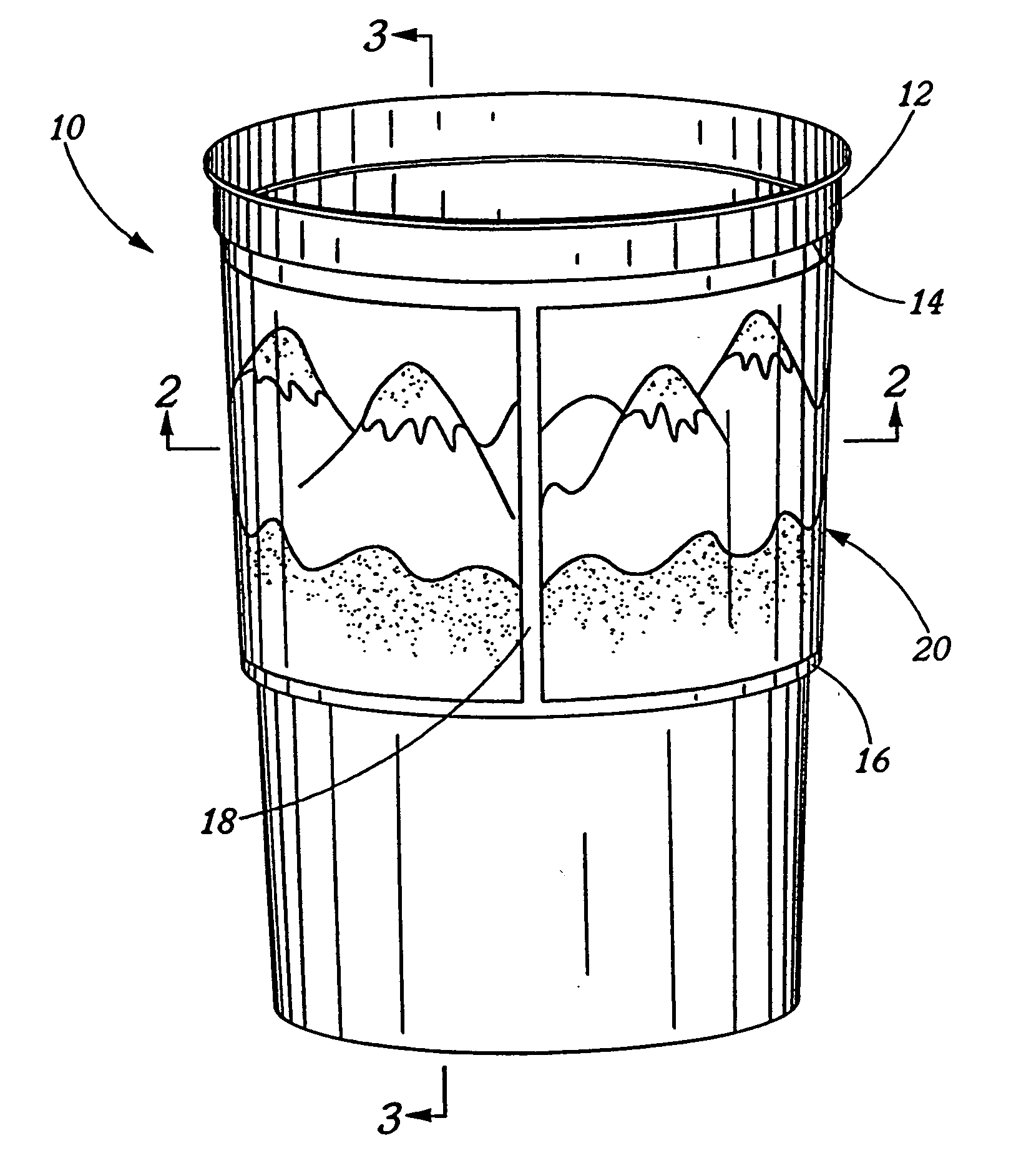

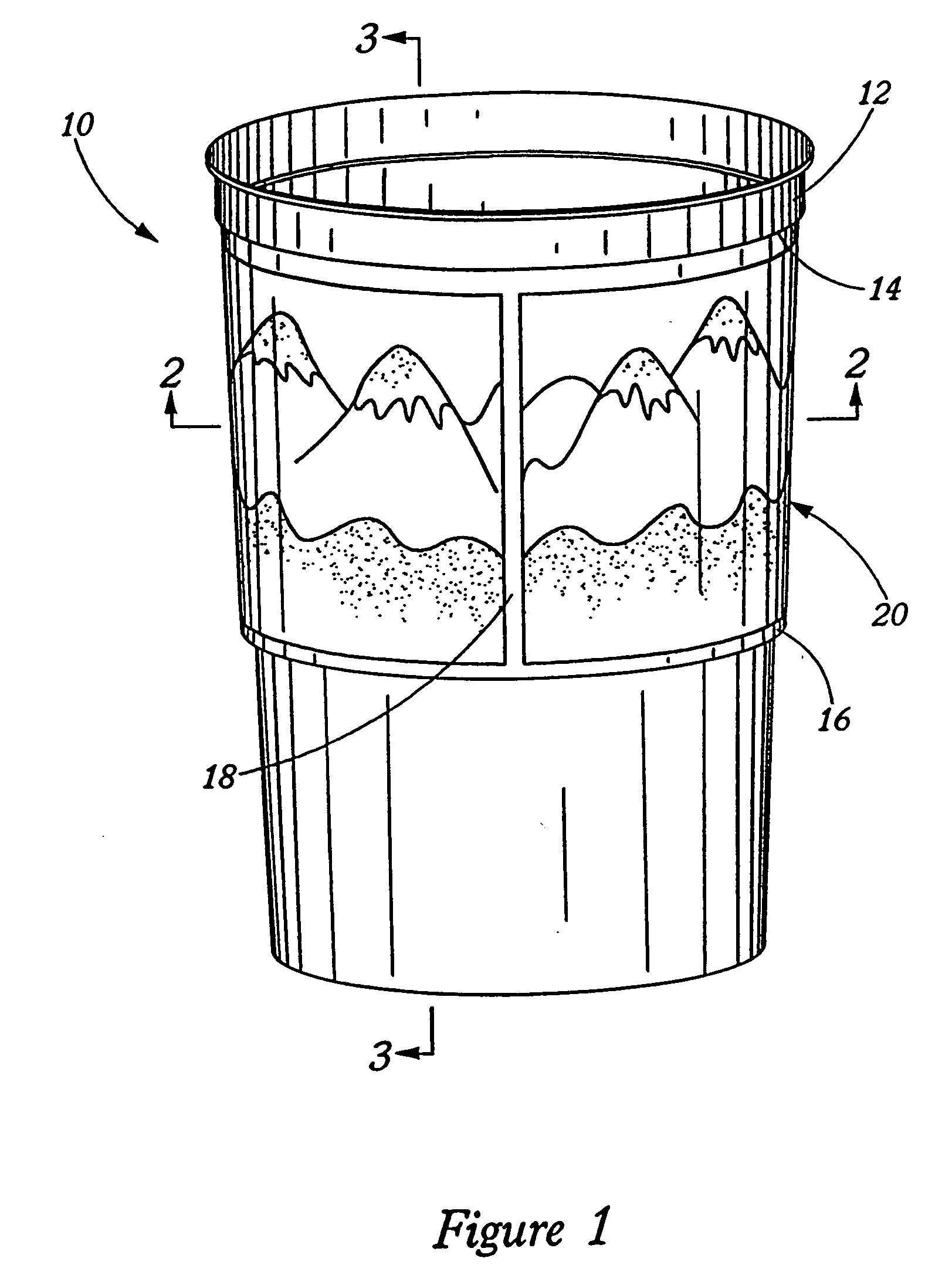

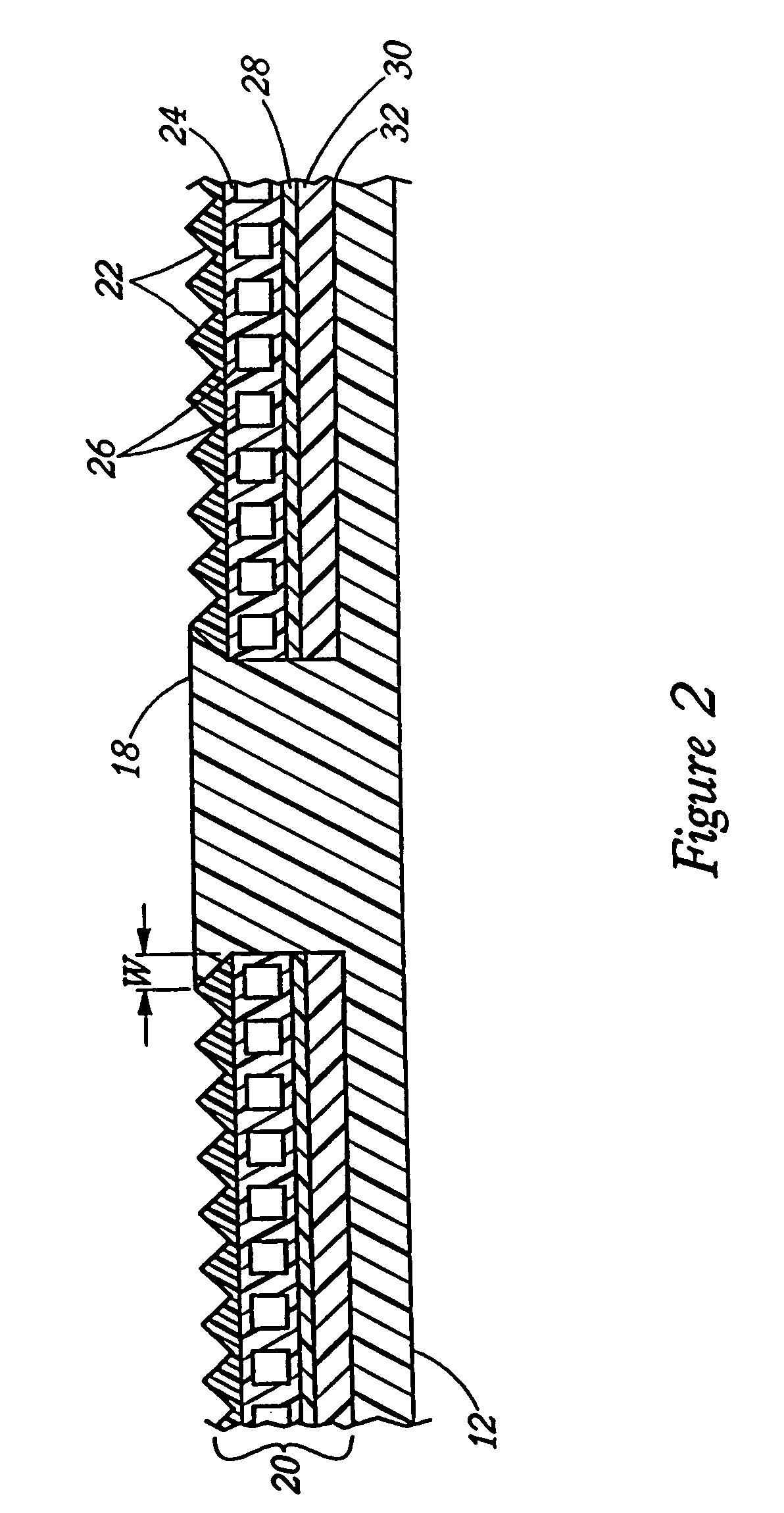

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20050053737A1Efficient and economicalQuality improvementEnvelopes/bags making machineryContainer decorationsPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

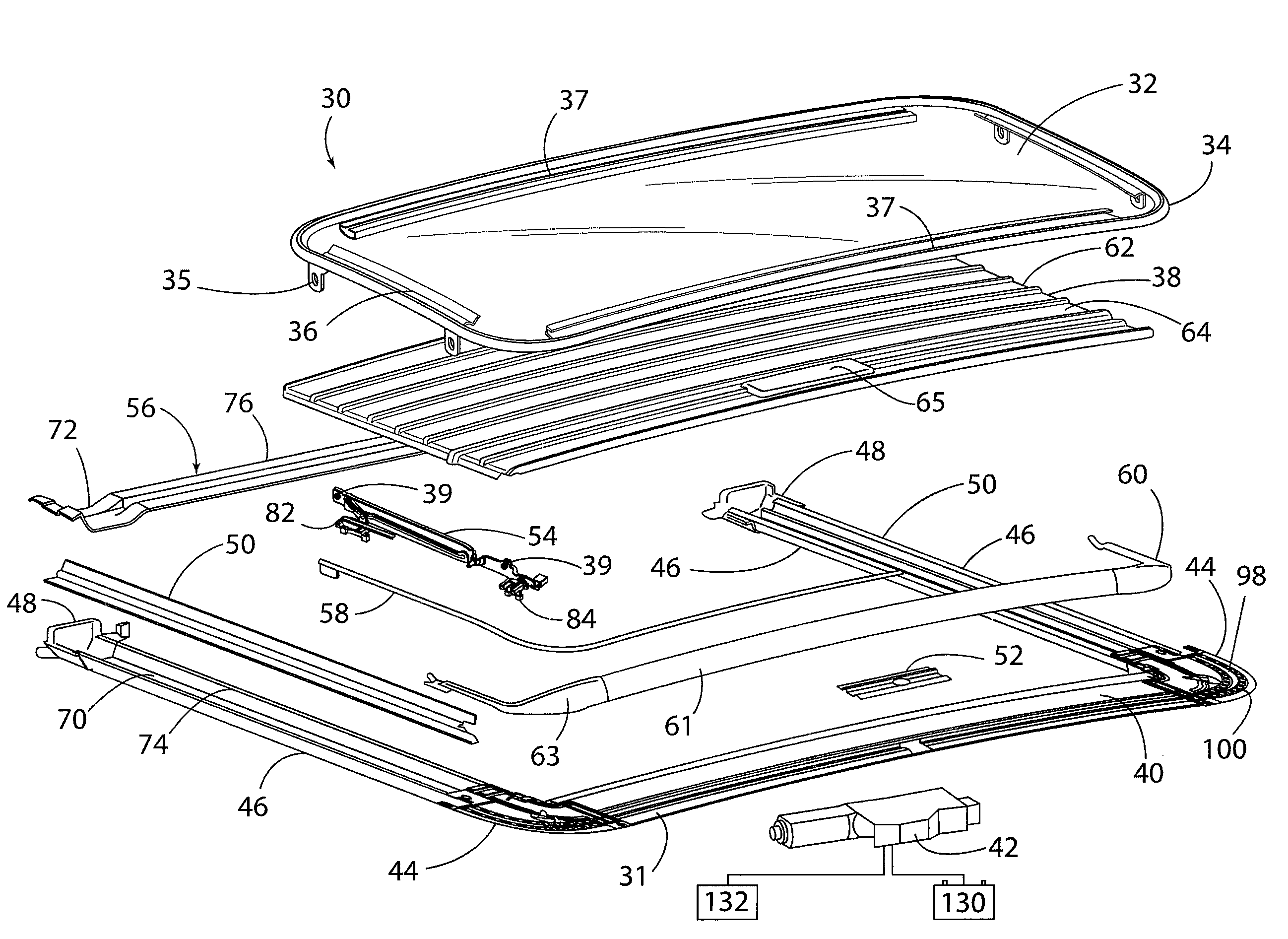

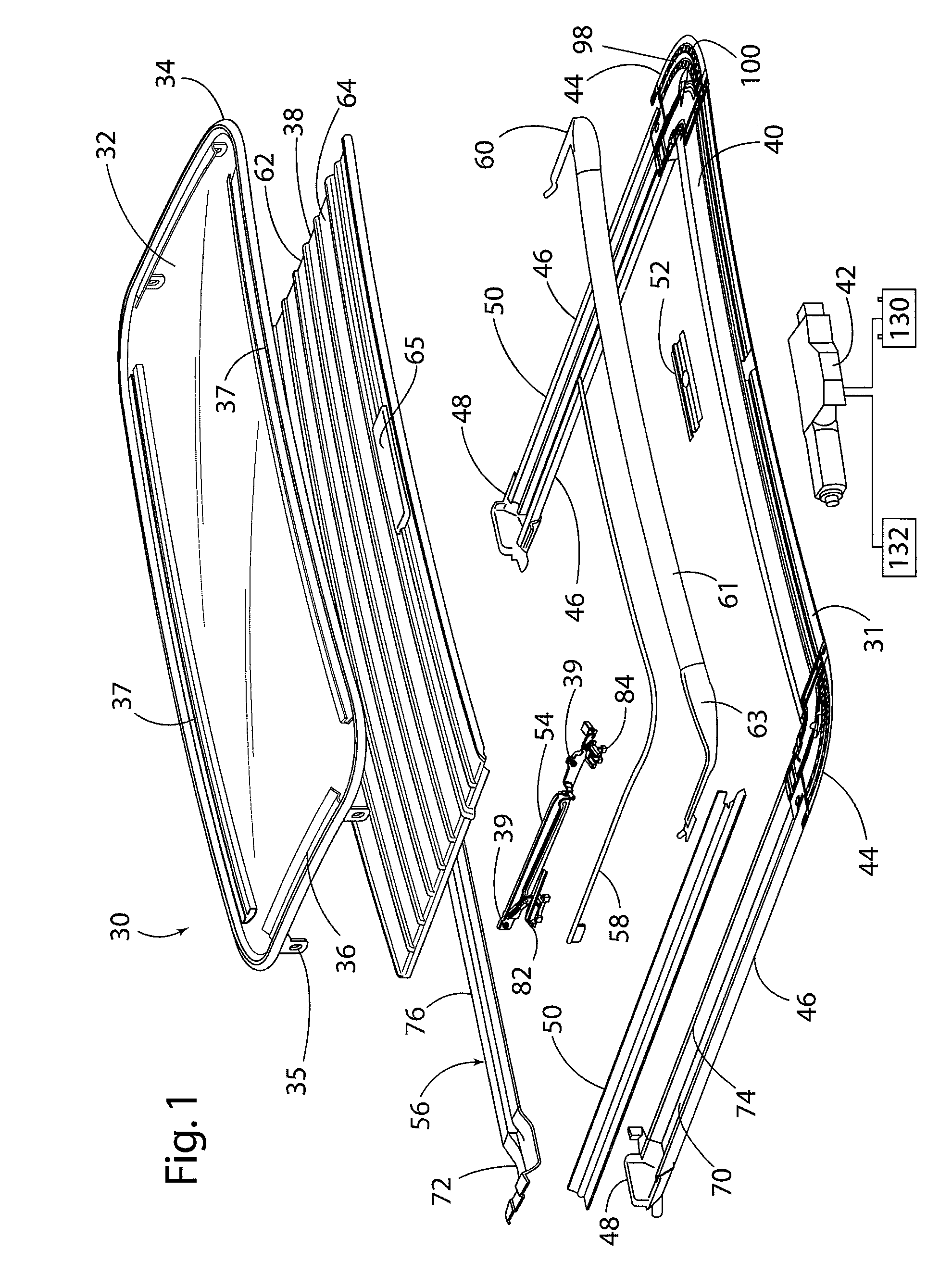

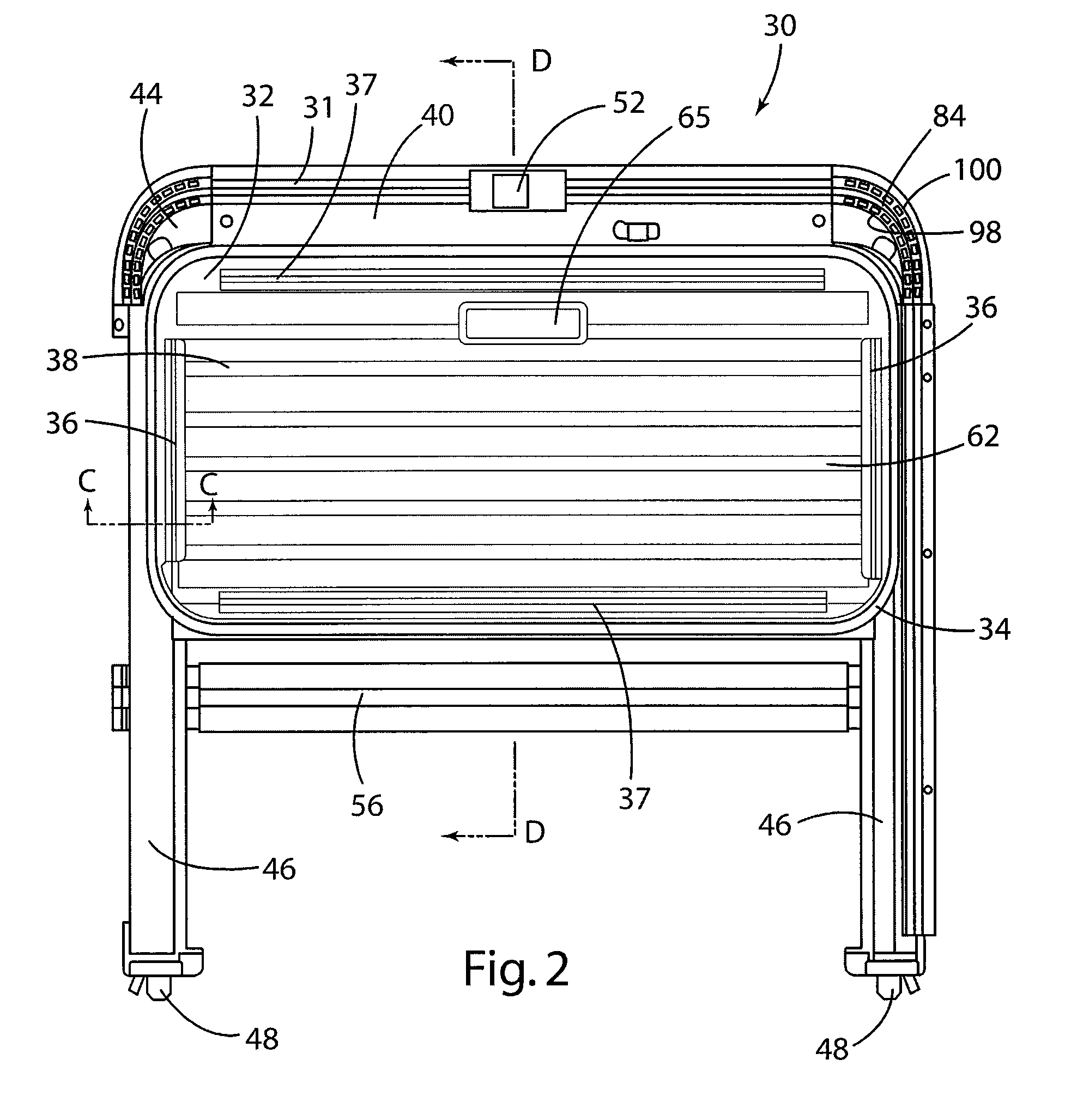

Modular tilt slide sunroof assembly and method of manufacture

InactiveUS20100320808A1Cost efficientDecreased time to assemblyEngine sealsSuperstructure subunitsModularityEngineering

A sunroof assembly with a composite water management assembly having side rails with a water trough connected at one end to end caps and to a pair of corners at the other, which connect to a front rail at substantially right angles to the side rails. This composite assembly can be connected by vibration welding. A reinforcement bar can be connected at substantially right angles to the rearward end of vertically oriented slide tracks snap fitted into substantially the length of the side rails. A pair of mirror slide mechanisms with vertically oriented mounts are retained, but free to slide, within a channel of the slide track and outboard of the water trough. A movable panel such as a glass sunroof are attached to the slide mechanism. A sunshade can be added that also combines water shedding ribs to channel water to the water trough.

Owner:WEBASTO AG

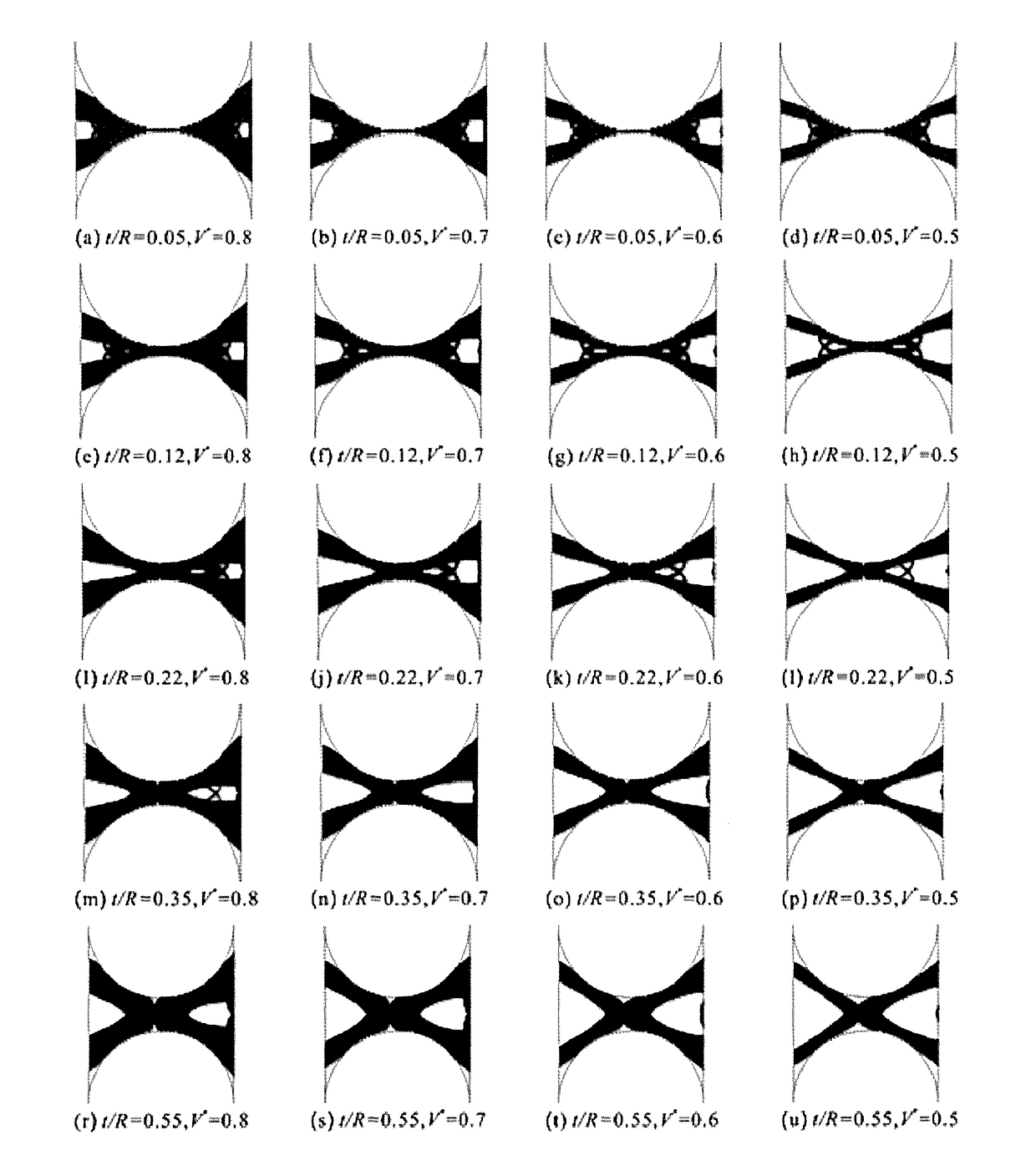

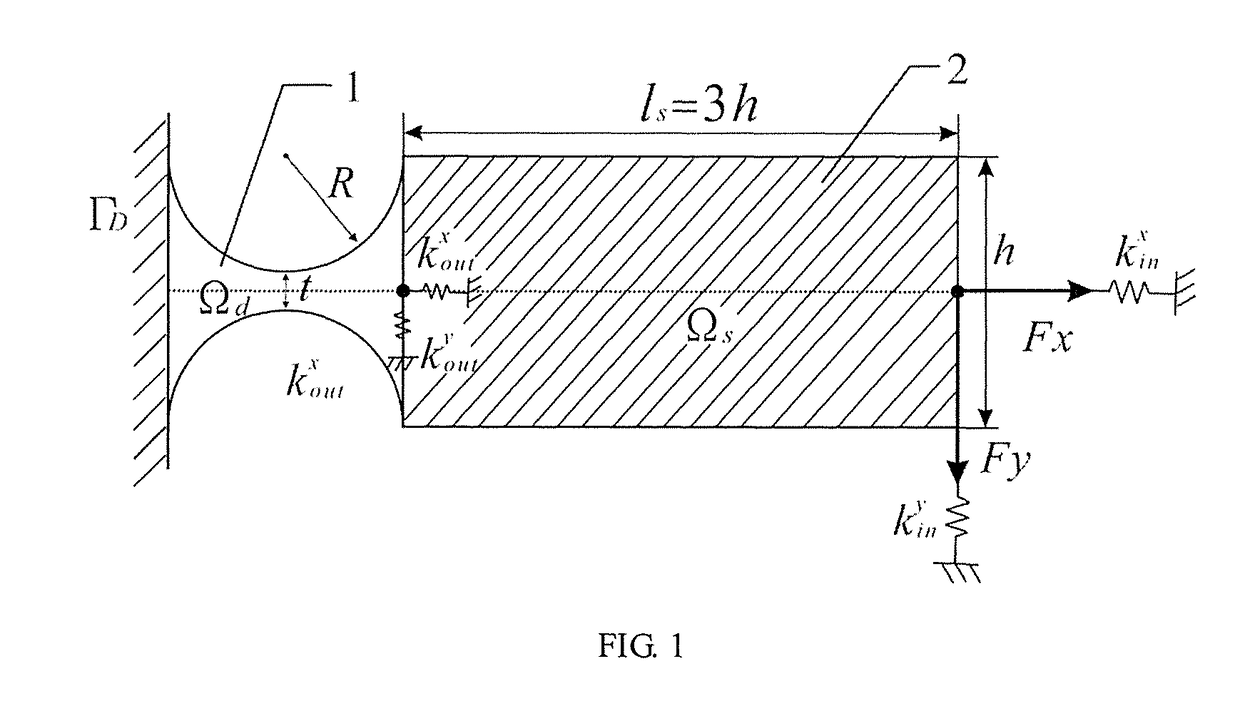

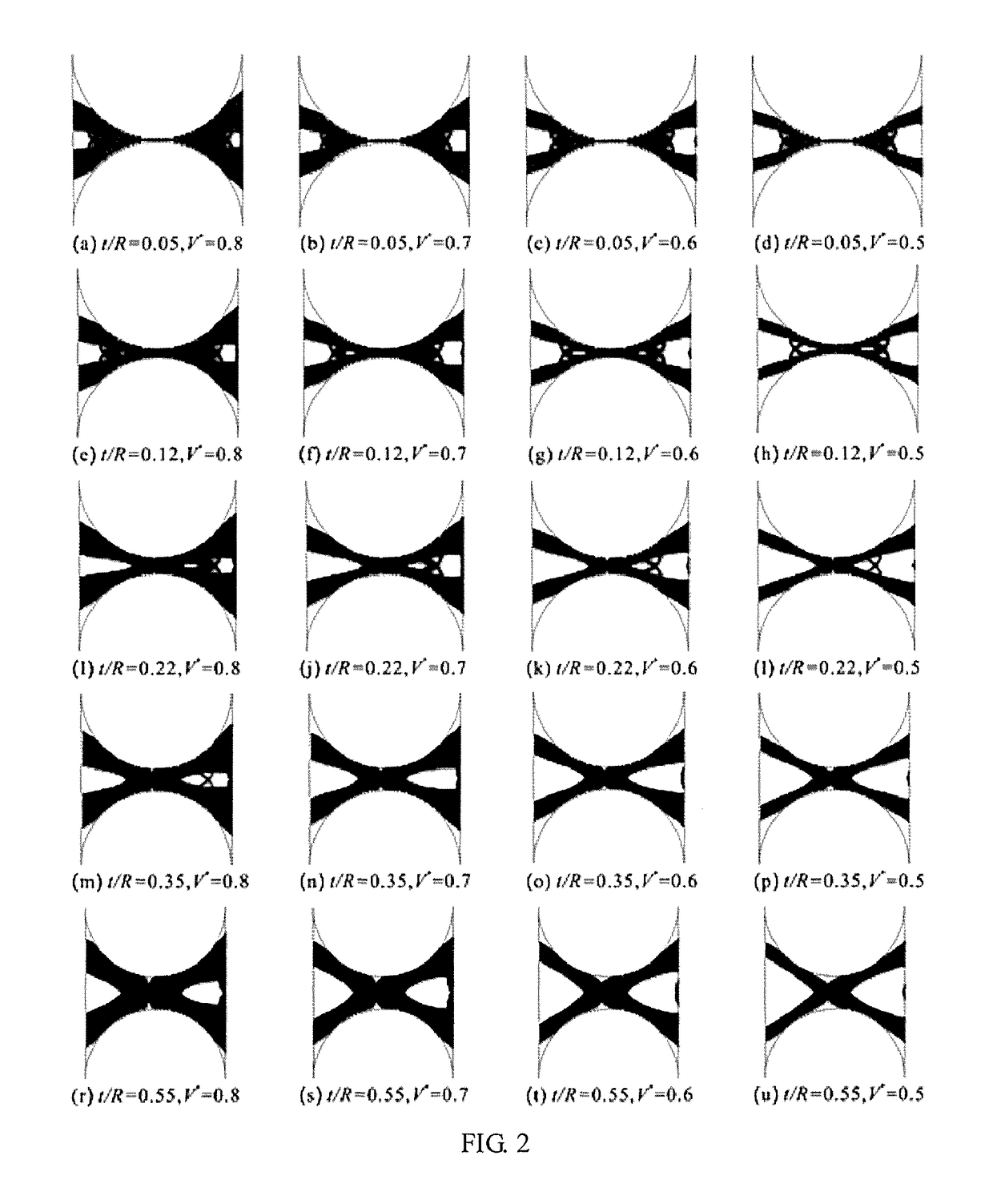

Design method of topology optimization for flexible hinge

ActiveUS20180210983A1Improve performanceMaterial removalGeometric CADDigital data processing detailsElement modelTruss topology optimization

A design method of topology optimization for flexible hinge is disclosed in the invention, comprising following steps: step 1: establishing a design model of topology optimization for flexible hinge, setting an outline of flexible hinge with a typical notch as a shape of design domain and defining a rigid region (non-design domain); step 2: establishing a finite element model of topology optimization for flexible hinge; step 3: establishing a mathematical model of topology optimization problem for flexible hinge based on the finite element model; step 4: calculating a sensitivity of topology optimization problem for flexible hinge; step 5: employing an optimization algorithm to solve the topology optimization problem for flexible hinge, updating a design variable and obtaining a final topology result graph; step 6: according to the final topology result graph obtained by the topology optimization, extracting its outline and obtaining a novel flexible hinge by appropriate modification. Using the method of topology optimization, the invention designs the flexible hinge on a concept level. The novel flexible hinge can be designed with a more complex structure and more excellent performances, having a larger flexibility, a higher precision and a smaller maximum stress.

Owner:SOUTH CHINA UNIV OF TECH

Endovascular graft device and methods for attaching components thereof

InactiveUS8172892B2Facilitate accurate catheterization and deploymentReduce the possibilityStentsBlood vesselsBiomedical engineeringBlood vessel

Owner:LIFEPORT SCI

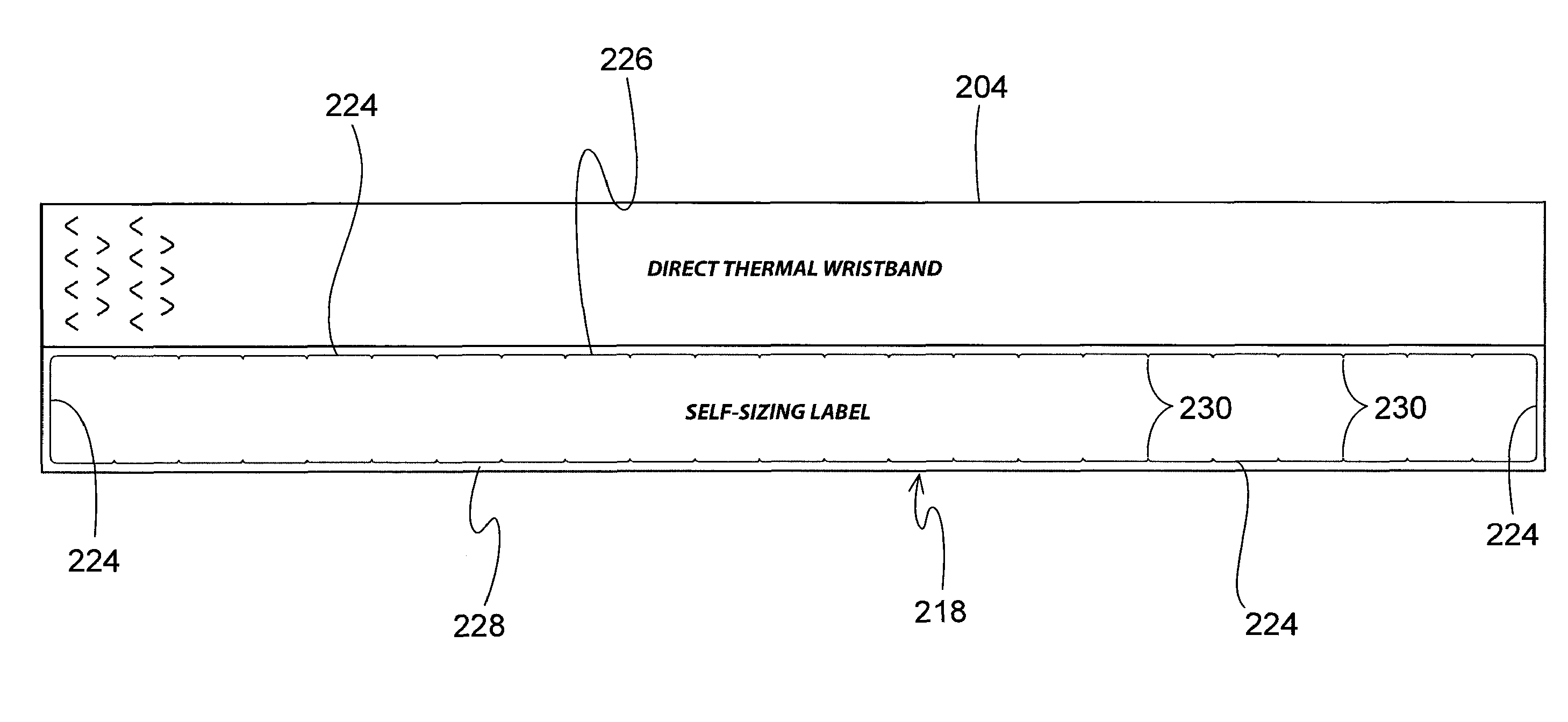

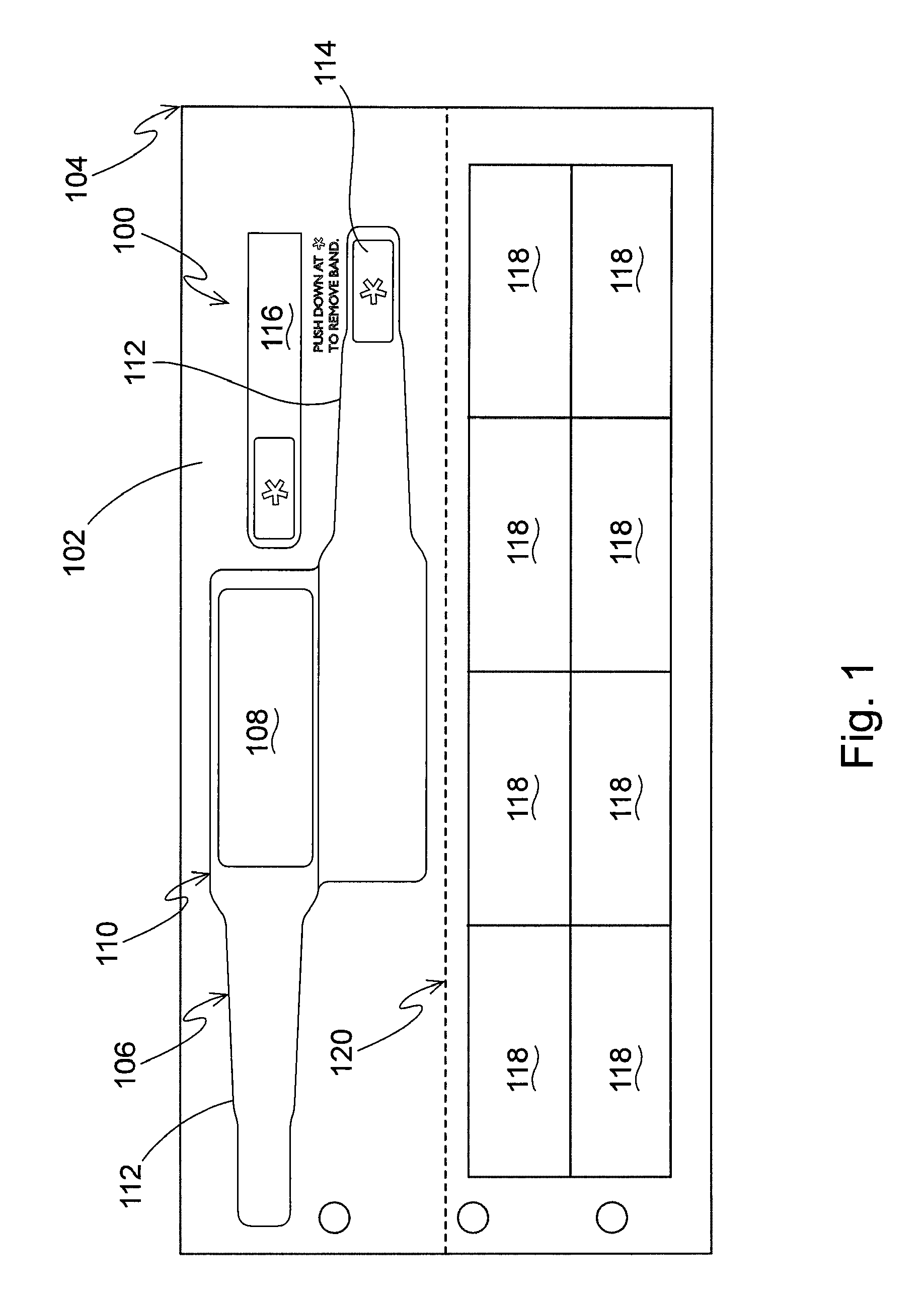

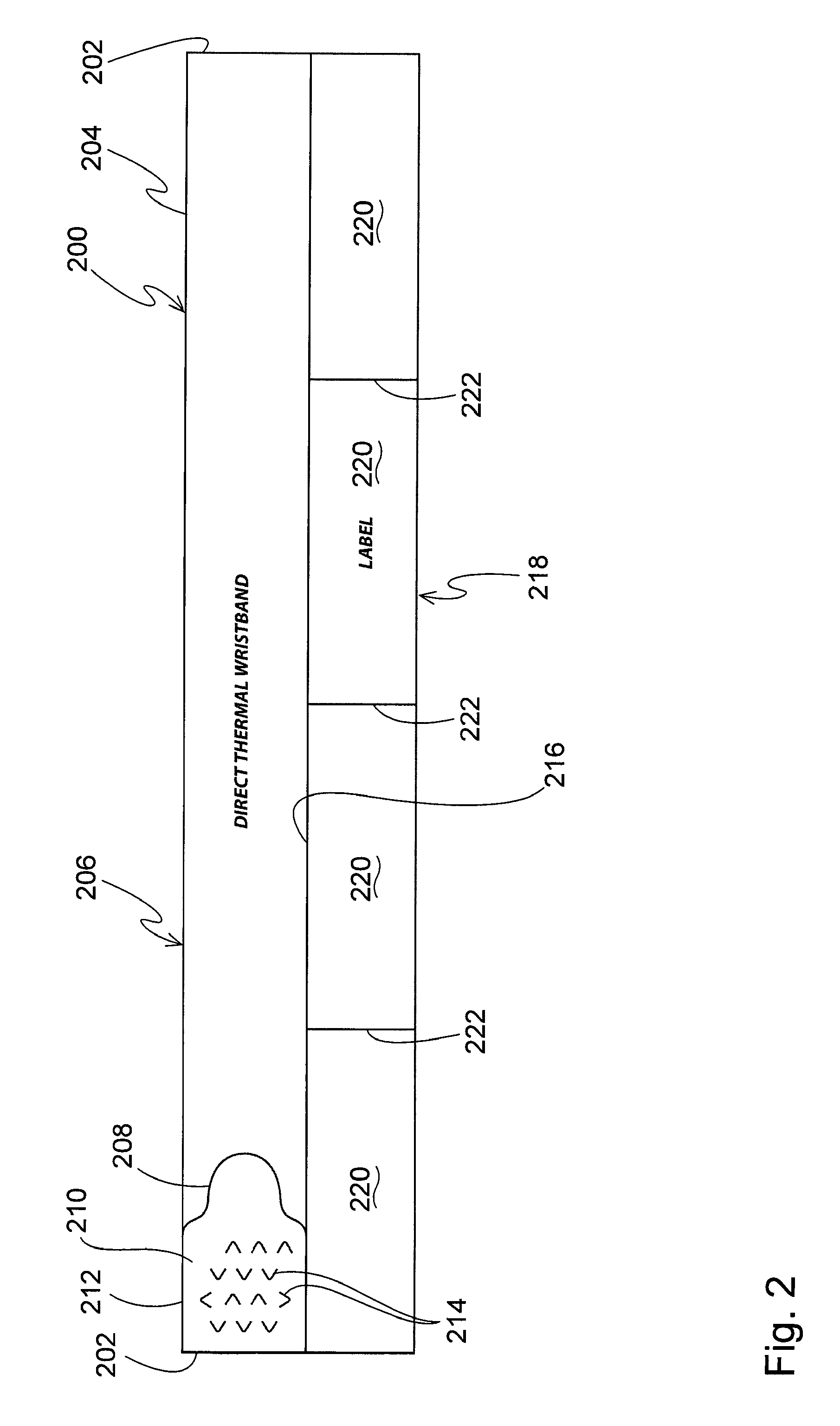

Continuous strip of thermal wristband/label forms

A thermal printer processible combination wristband / label form has a top portion comprising a wristband which occupies substantially the entirety of thereof and a bottom portion comprising one of several alternative embodiments of labels. The label embodiments include a plurality of individually formed labels, a plurality of labels occupying substantially the entirety of the bottom portion, and a die cut defining a label portion with pairs of nicks spaced along an upper and lower border of the die cut and between which a user may tear off labels of a desired length including different lengths. The form is produced in quantity and joined together into a fan fold strip having an overall width of a nominal two inches so as to be capable of being printed by relatively older thermal printers having a nominal two inch throat.

Owner:ZEBRA TECH CORP

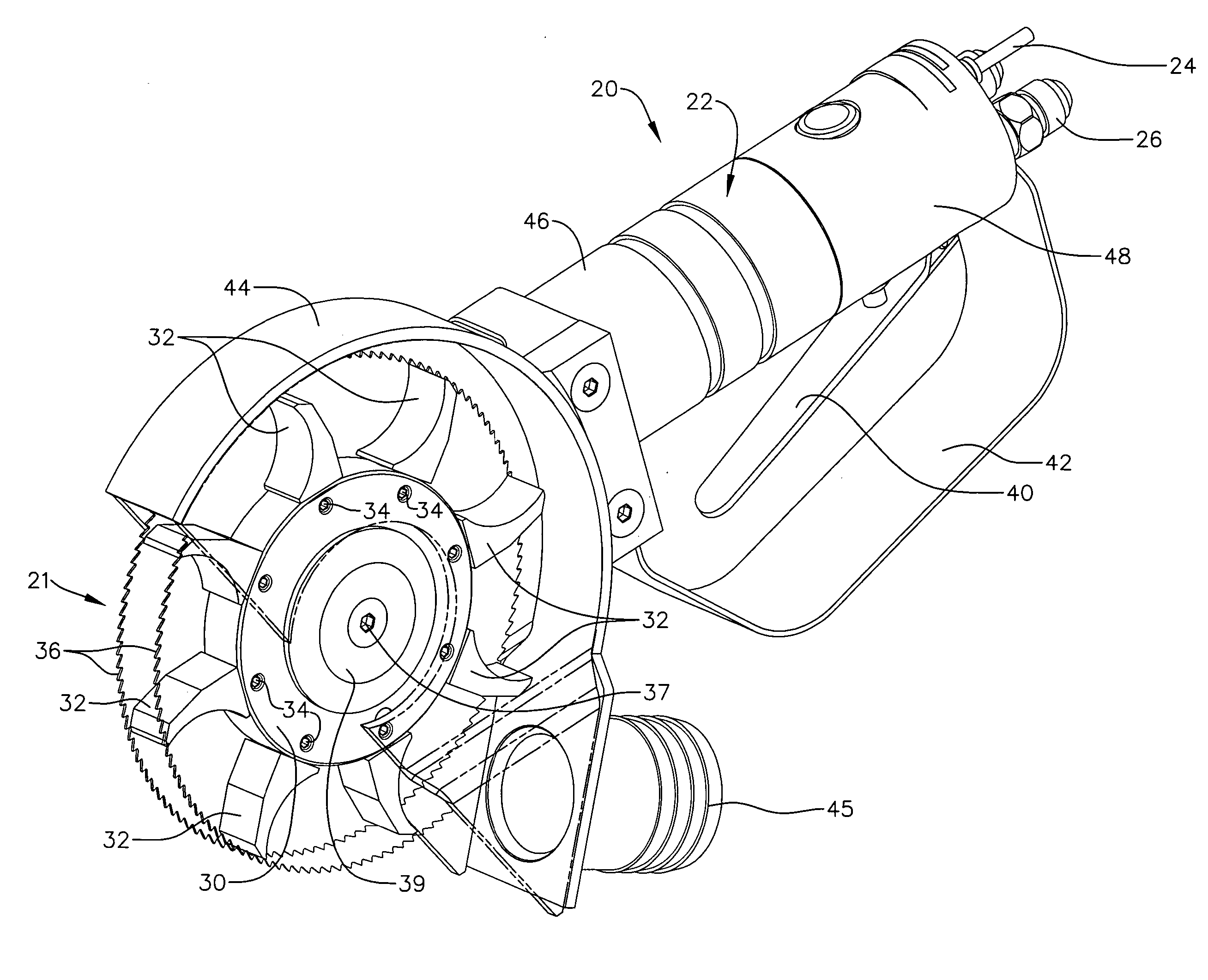

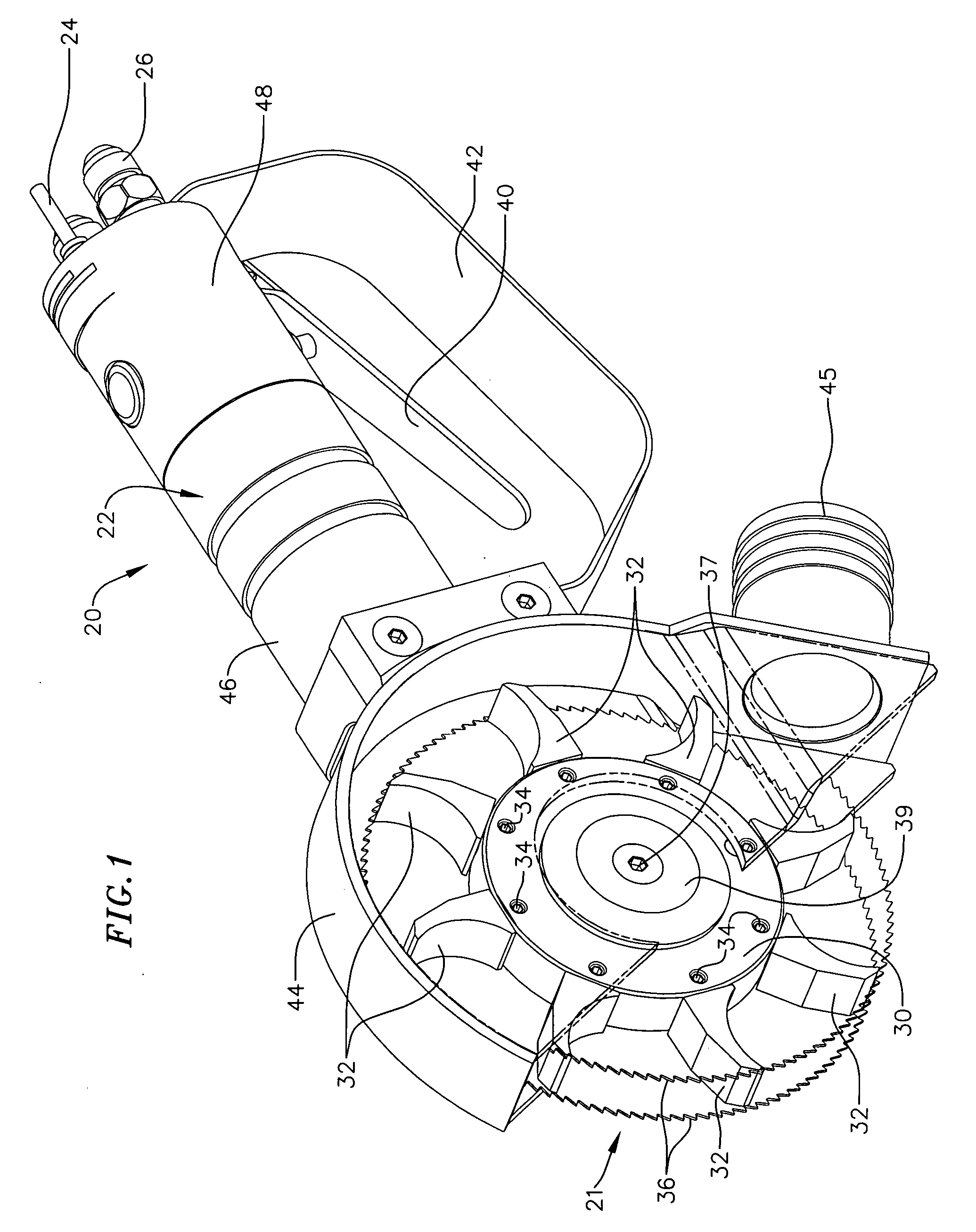

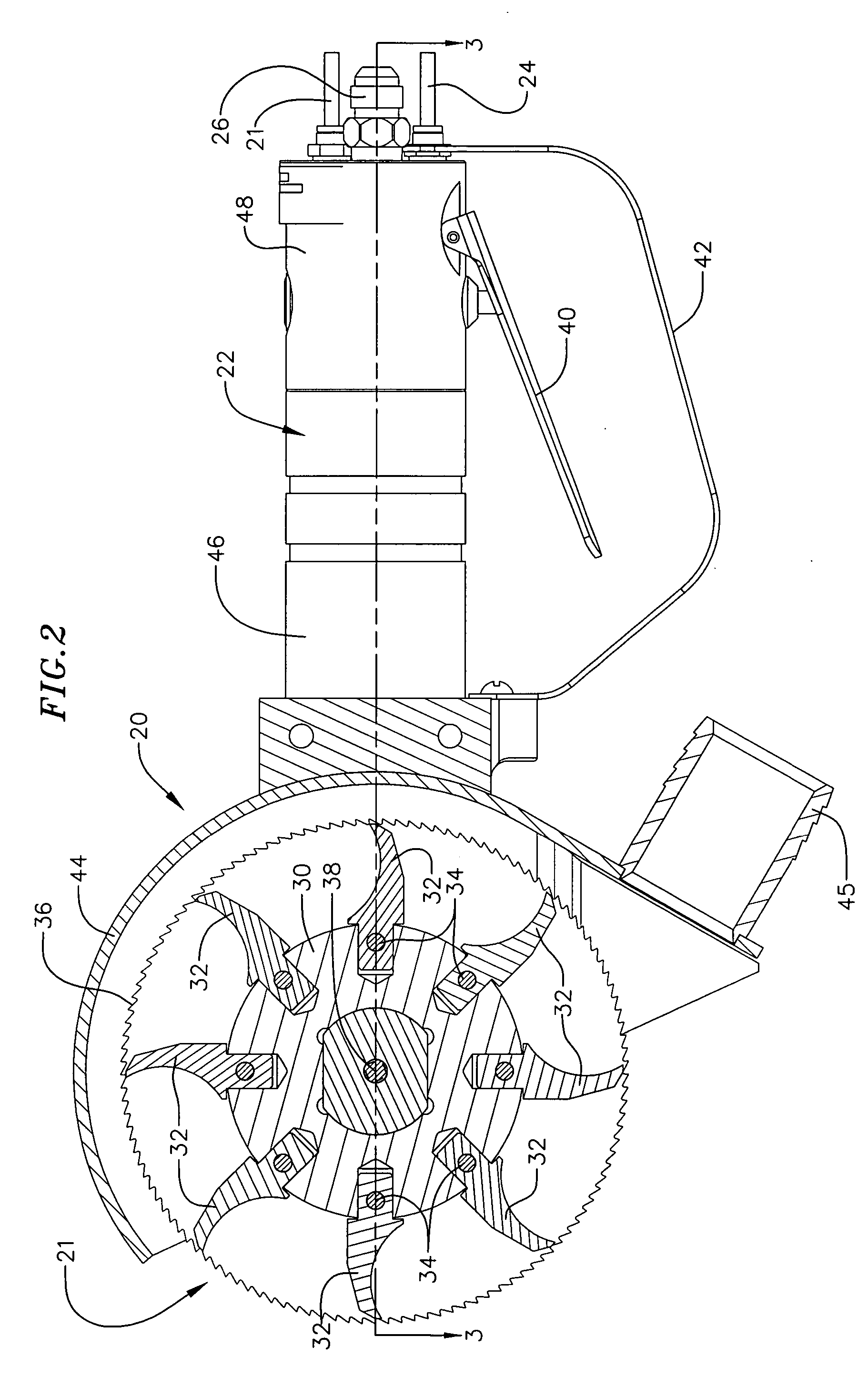

Multi-purpose cutting tool

InactiveUS20060200152A1Efficient removalMaterial removalMetal sawing devicesEviscerating scissorsSpinal cordCircular saw

A multi-purpose cutting device for removing the spinal cord and spinal meninx lining of the spinal cord of a slaughtered animal which has been longitudinally cut in two along the length of the spinal cord. The cutting device comprises a rotary cutting tool having a hub with radially outwardly projecting cutting fingers equidistantly spaced apart around the hub. The cutting fingers have blunt ends and are of substantially uniform length. A pair of circular saw blades are rigidly secured to opposite faces of the cutting tool. The saw blades have a circumference that approximately matches the effective circumference of the working ends of the cutting fingers. In use, when the cutting device is powered by a drive motor, the cutting fingers and saw blades rotate in unison. The cutting fingers rotate to remove the spinal cord and spinal meninx from the carcass while the saw blades cut into bone along opposite sides of the meninx. The saw blades assist the cutting fingers in dislodging regions of bone material in which the spinal cord or meninx materials may be lodged.

Owner:KENTMASTER MFG

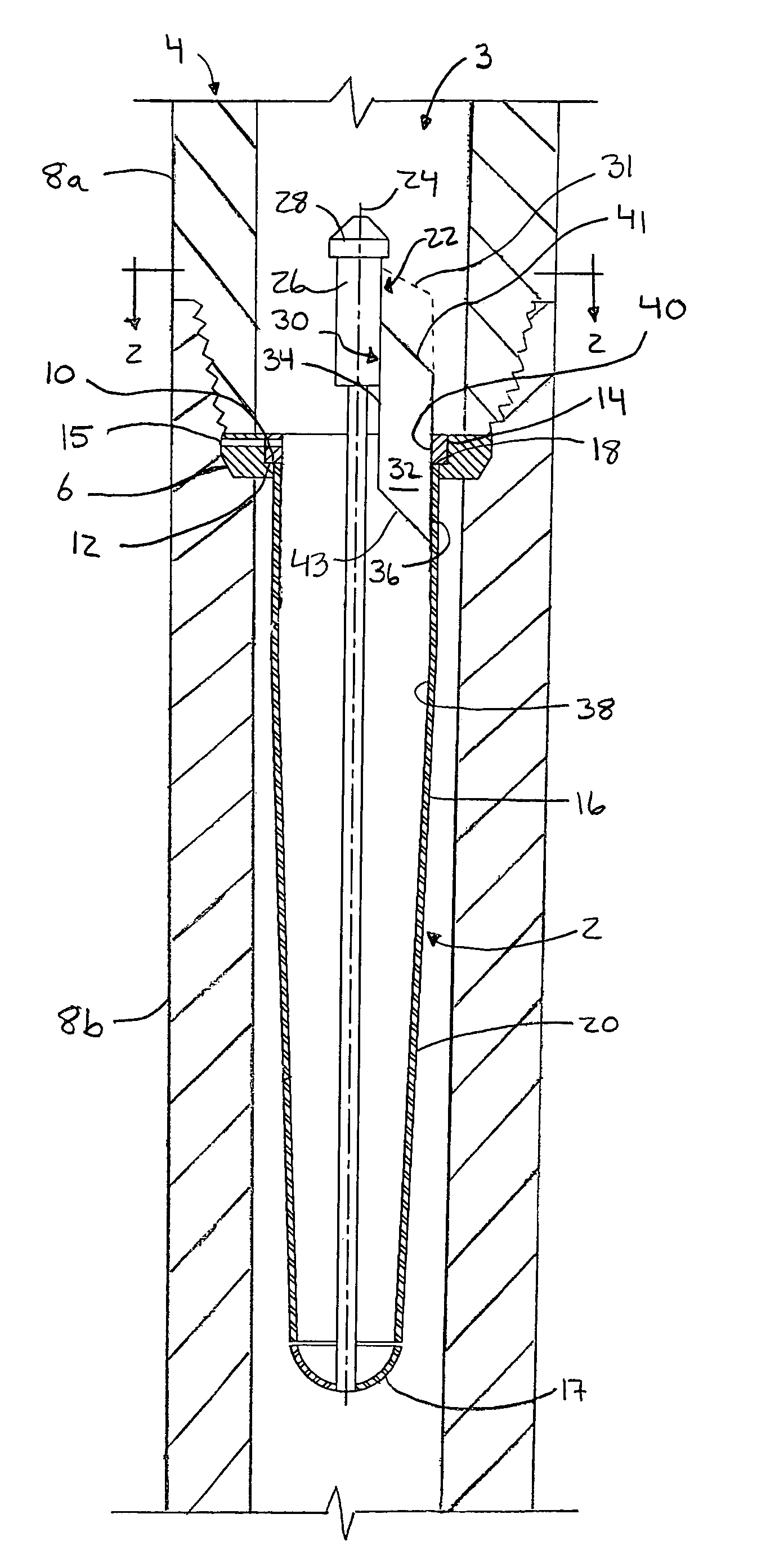

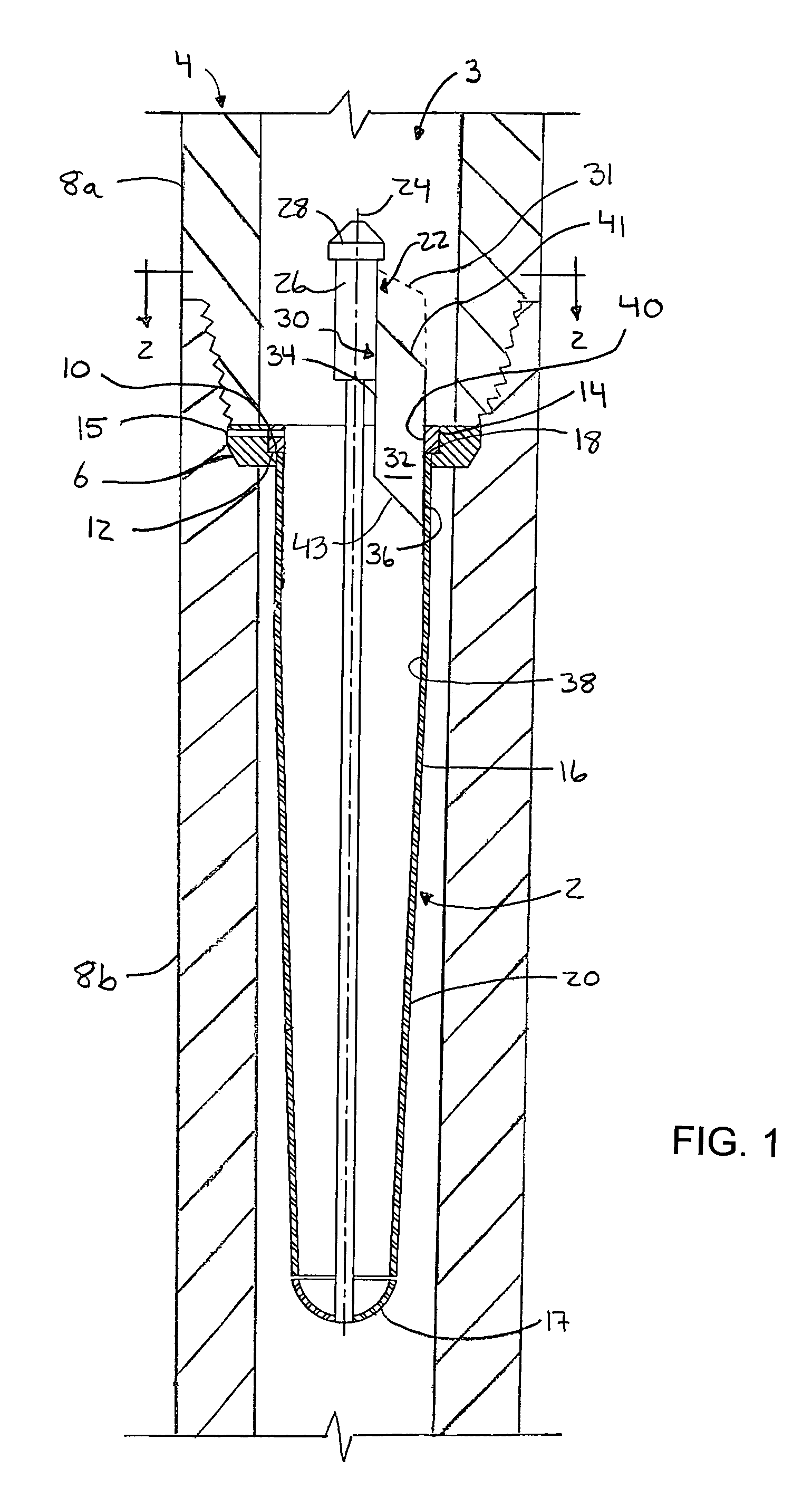

Drill pipe screen

InactiveUS7243742B2Minimize flow disturbanceNot easy to wearFluid removalMembrane filtersEngineeringDistributor

A retrievable drill pipe screen is adapted for releasable connection within a drill pipe string. The screen has a planar support plate for connecting a perforated tubular screen body to a fish neck wherein the plane of the planar support plate is generally parallel to the axis of the screen body. The orientation of the planar support plate provides minimal resistance to fluid flowing into the screen body while also reducing vortex effects that cause wear of screen components. Preferably, a wear distributor sleeve is fit within the screen body for protecting against wear of the screen caused by fluid flow and a retaining rod can secure the bottom of the screen body to the fish neck in the event that a lower portion of the screen body becomes detached.

Owner:KUTRYK ED A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com