Method of bonding a lenticular lens sheet to plastic objects and objects made from same

a technology of lenticular lens and plastic objects, which is applied in the field of plastic container and object manufacturing, can solve the problems of high temperature, deformation or ruination of ink, and achieve the effect of high quality and efficient and economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

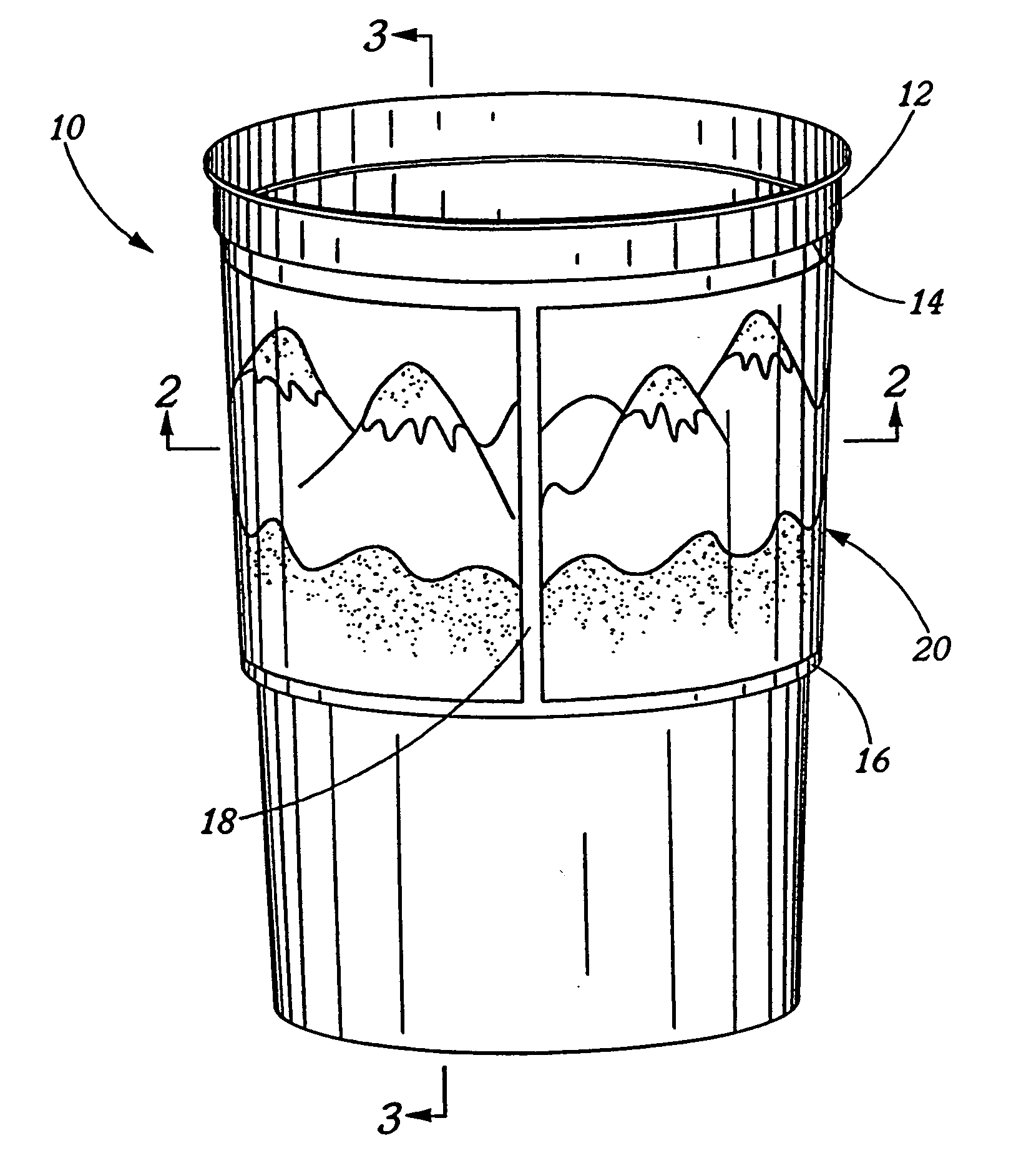

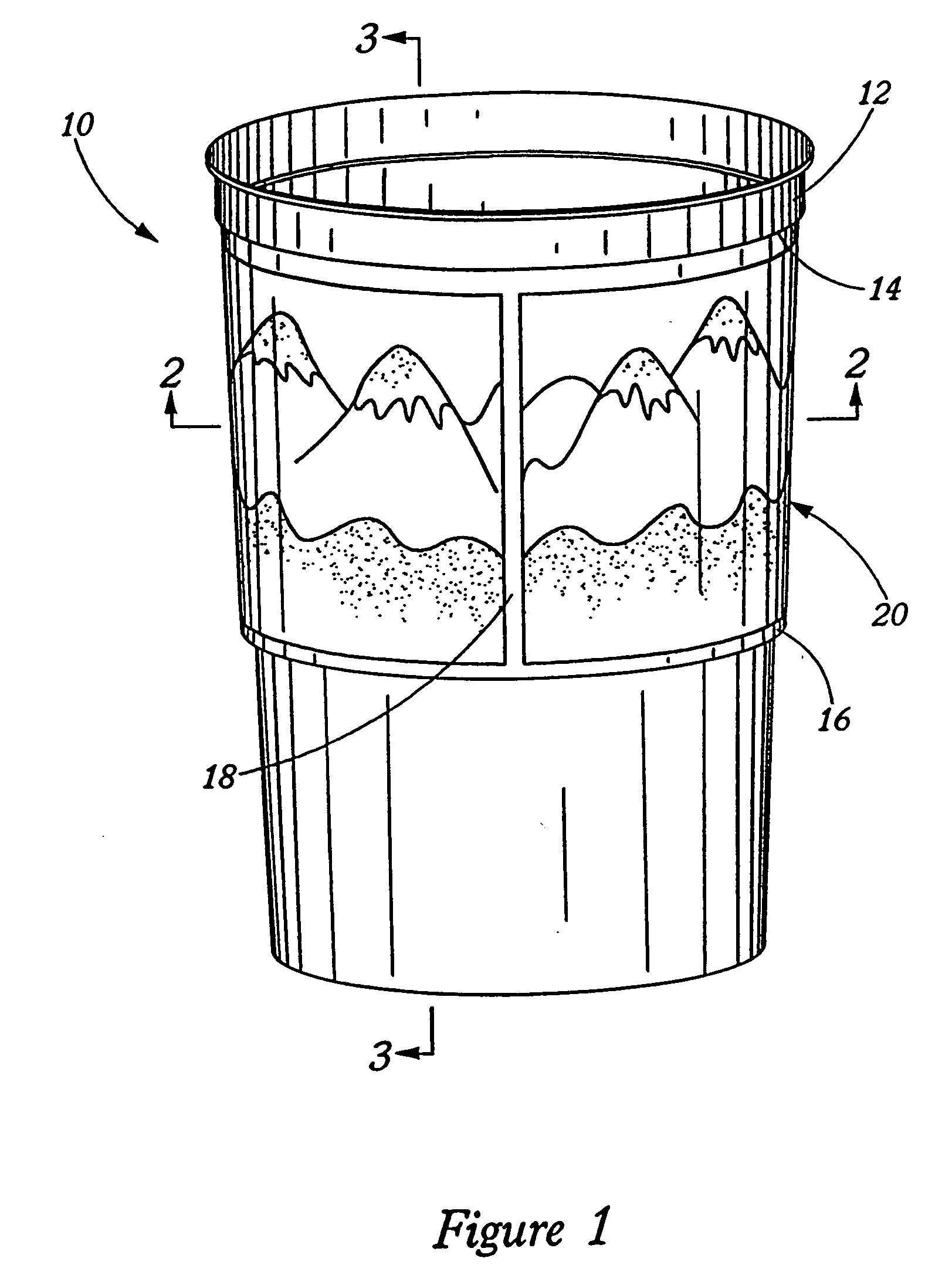

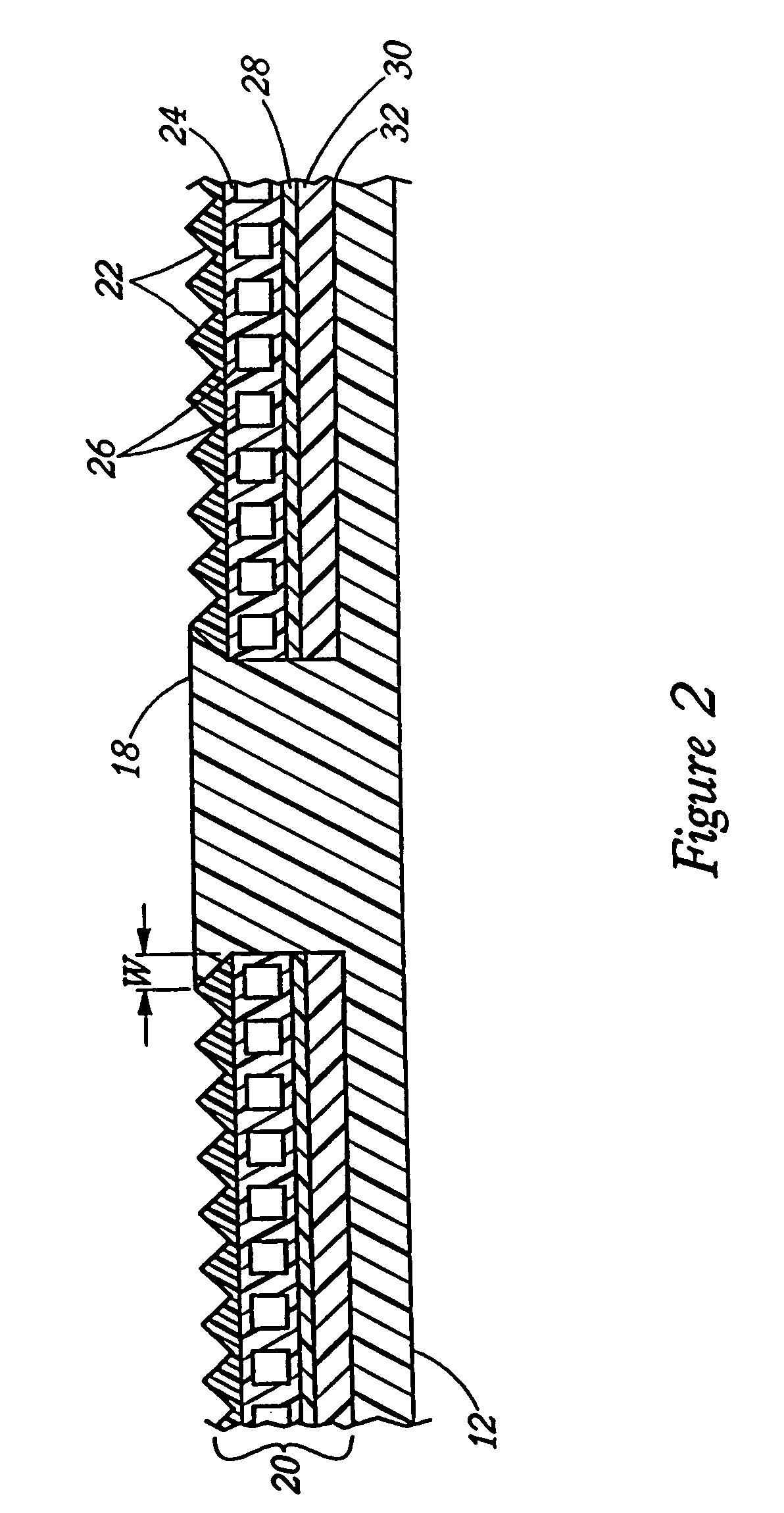

[0024] With the above summery of the invention in mind, the following description discusses the inventive plastic objects according to the invention that have an integral image visible due to a Lenticular insert that is uniquely included as an integral part of the plastic object. The discussion concentrates on the structural and other benefits and features of a container having a Lenticular insert in an outer wall, but, it should be understood that many other objects will similarly benefit from the addition of a Lenticular insert and are considered within the scope of the invention. From the discussion of features of a container fabricated according to the invention, the discussion proceeds to a full discussion of the method of fabricating plastic objects having a Lenticular insert integrally bonded to the plastic that forms the body, walls, or some other portion of the object. Again, the discussion will specifically explain the steps in fabricating a container with a Lenticular ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com