Frame bottom cocoon harvesting machine

A technology of cocoon picking and conveying mechanism, applied in animal husbandry and other directions, can solve the problems that the simple cocoon picker is not easy to control, affects the quality of silkworm cocoons, and reduces the quality of silkworm cocoons, and achieves the effect of saving consumption, improving the effect of scraping and sweeping, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

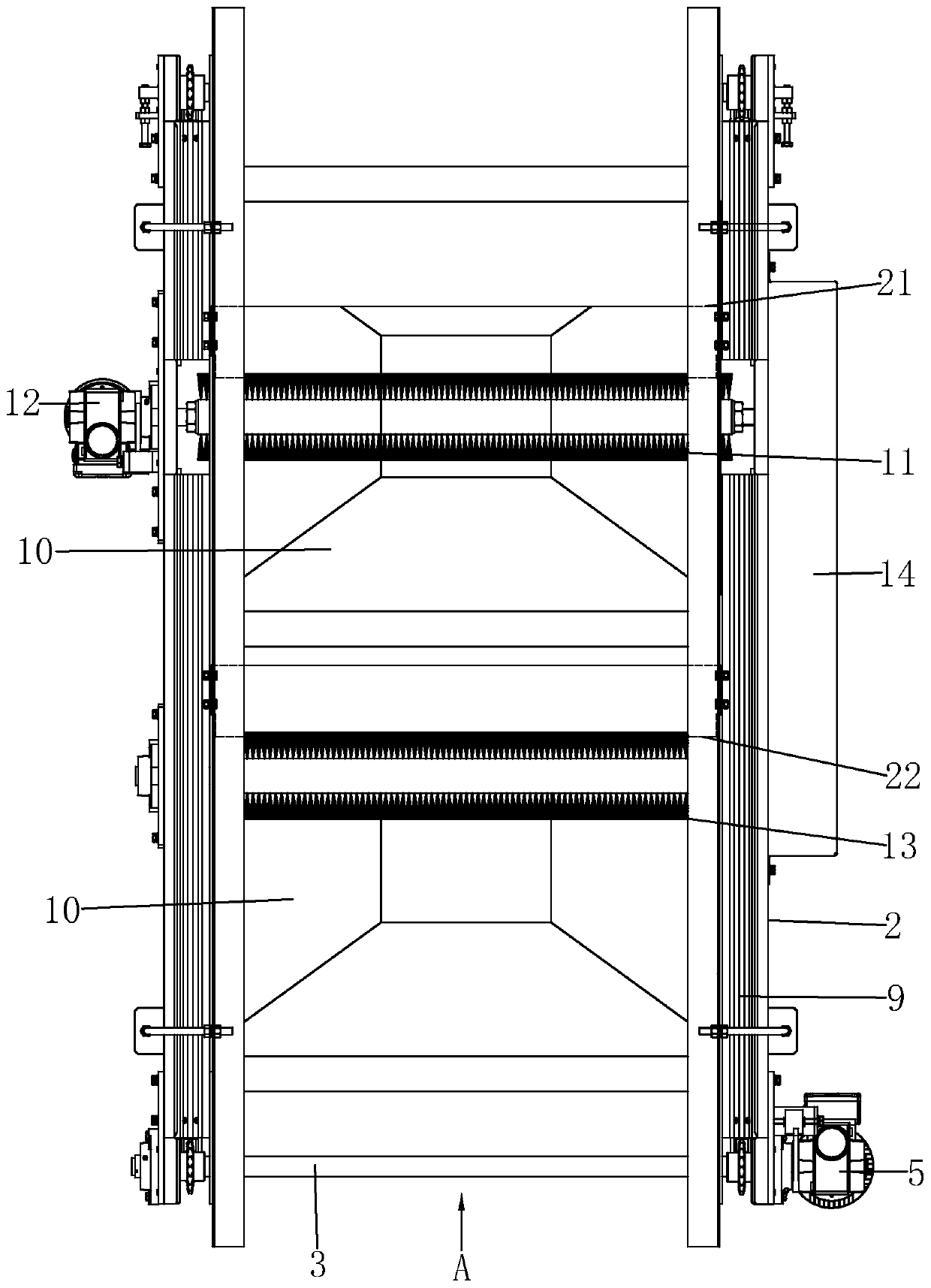

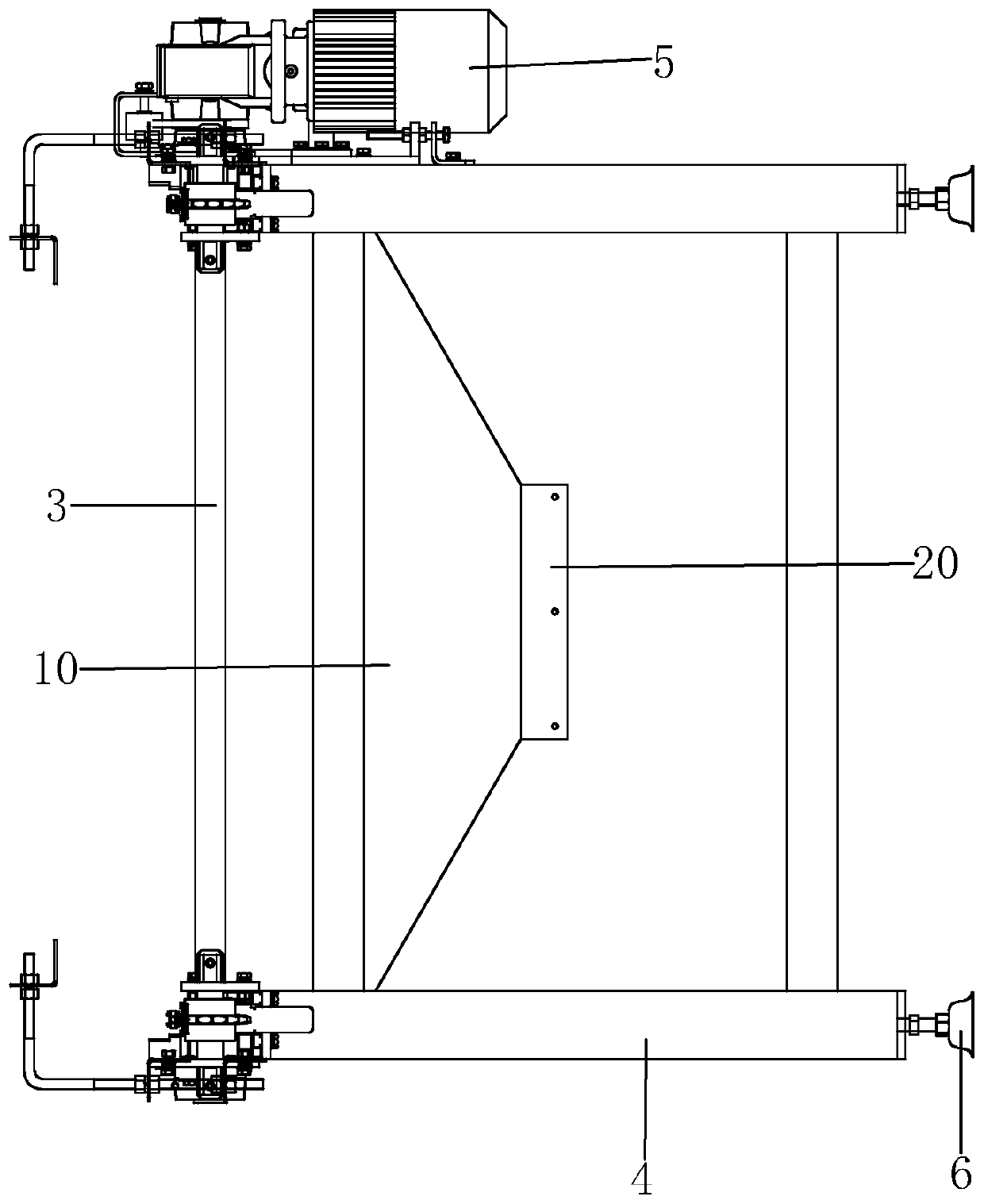

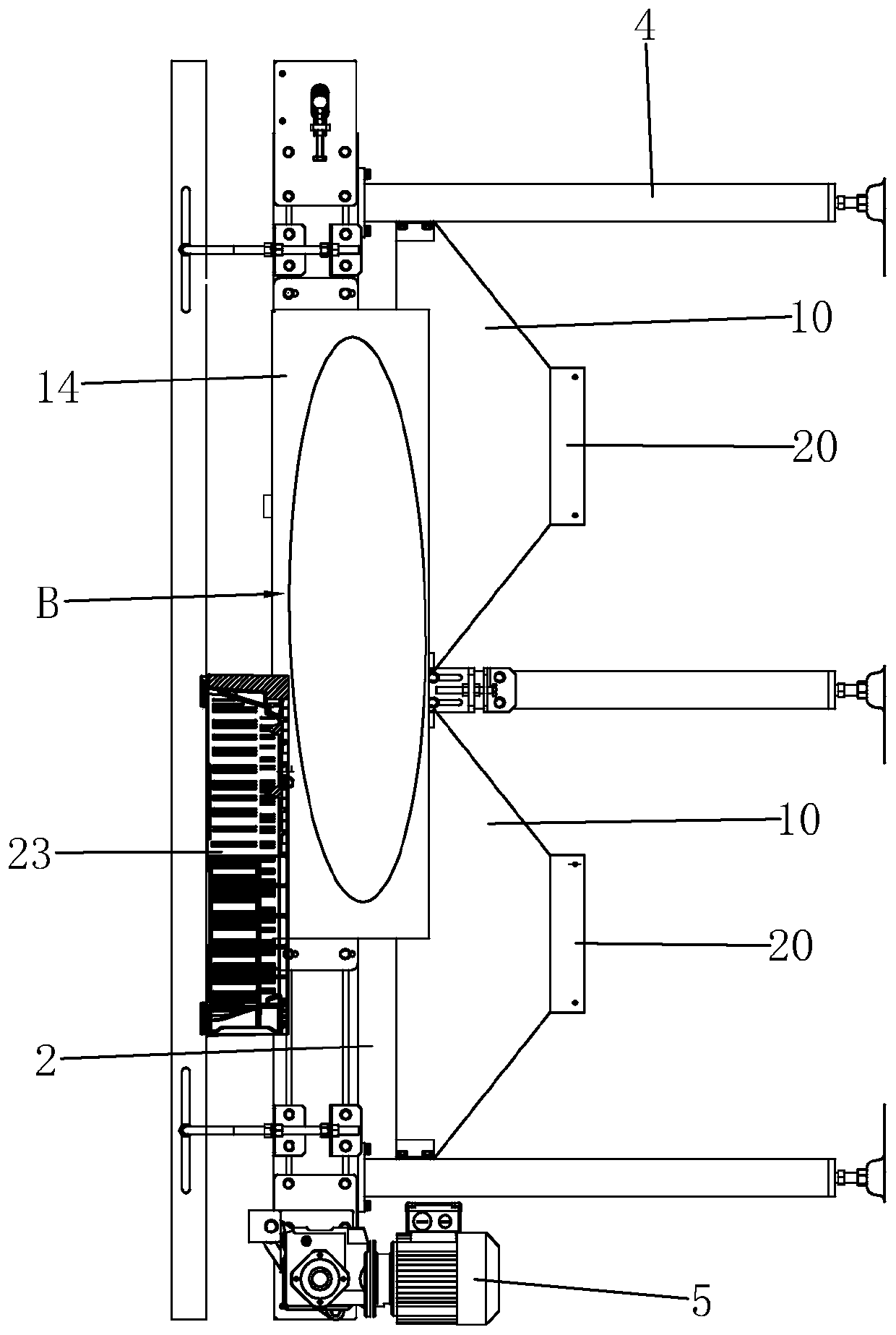

[0033] Such as Figure 1 to Figure 5 Shown, is embodiment one of the present invention

[0034]A cocoon harvesting machine at the bottom of a frame includes a conveying mechanism 1, which includes a beam 2, a drive shaft 3, legs 4 and a drive motor 5, and the legs 4 are symmetrically distributed on the bottom surface of the beam 2, and are stably supported, reliable and stable. The bottom of the support leg 4 is provided with an anchor foot 6, which plays a load-bearing role and has a large load-bearing capacity, and avoids the bottom of the support leg 4 from directly contacting the ground and wear and tear. The drive motor 5 is connected to one end of the drive shaft 3, the drive shaft 3 is arranged between the beams 2, the drive shaft 3 is provided with a driving gear 7, the beam 2 is connected with a driven gear 8, and between the driven gear 8 and the drive gear 7 Connected with a transmission chain 9, during the cocoon picking process, the cultivation frame 23 is sent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com