Patents

Literature

30results about How to "Extend sieving time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

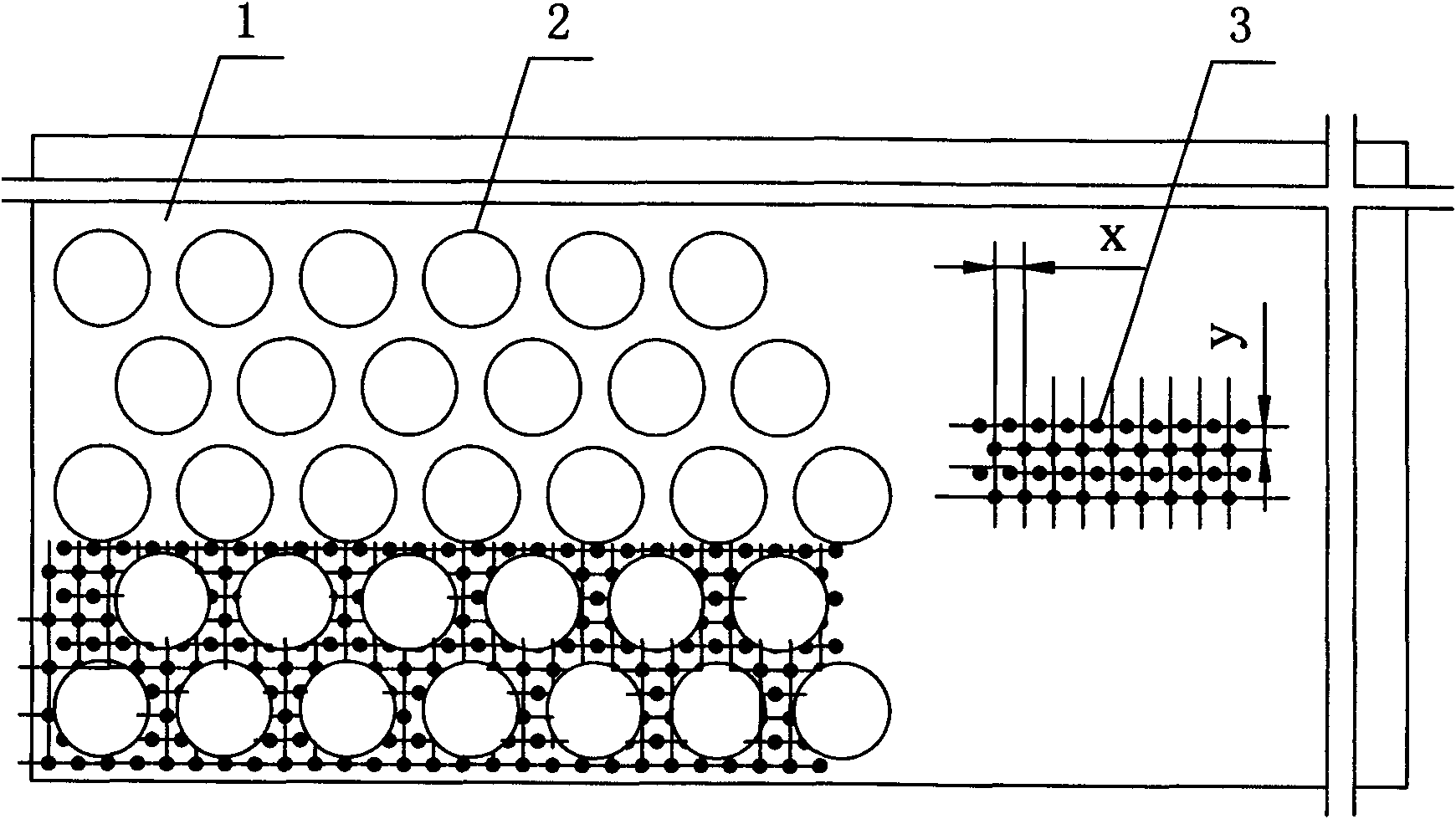

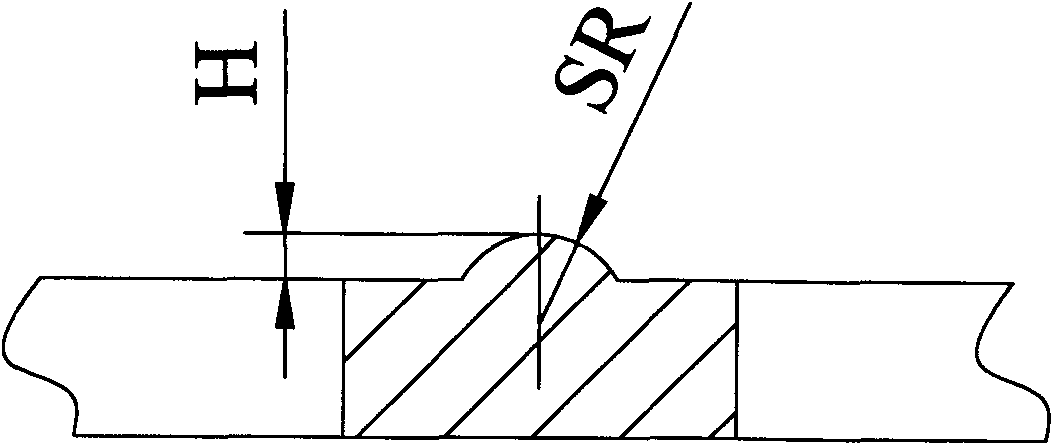

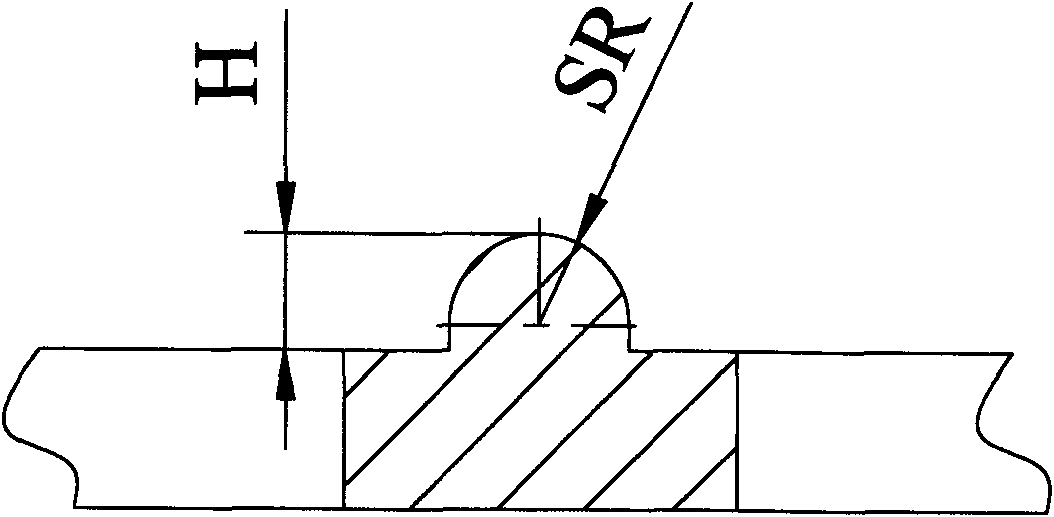

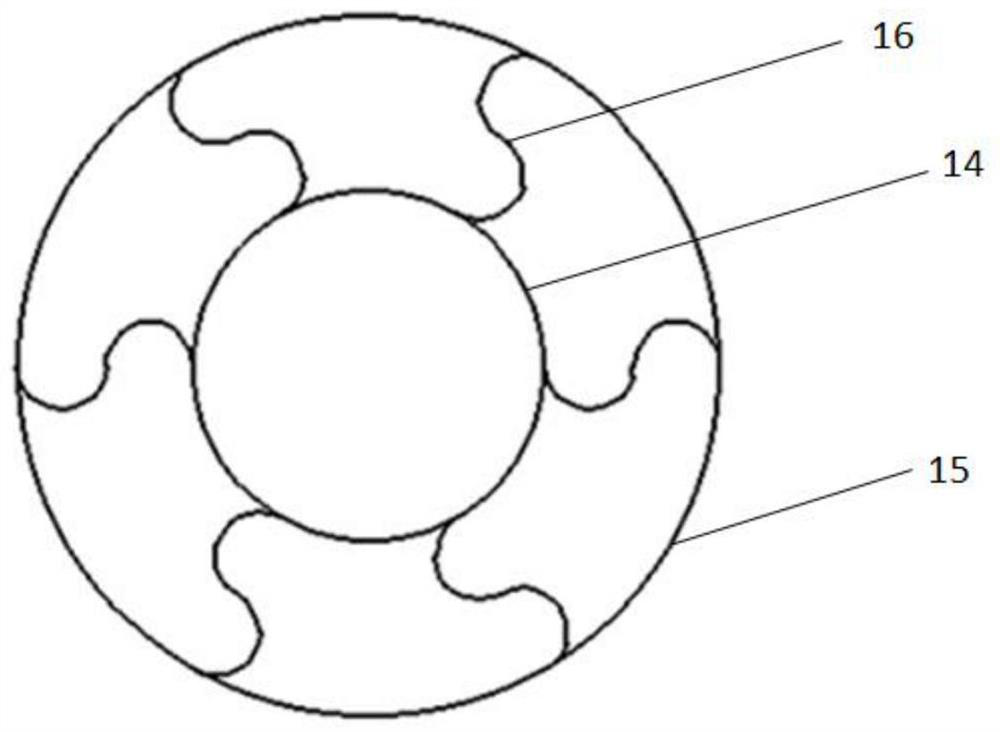

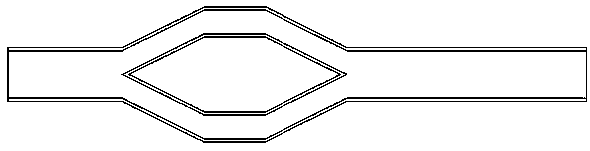

Bionic non-smooth sorting screen surface

The invention belongs to a bionic non-smooth sorting screen surface for agricultural machinery, which solves the problem that wet agricultural materials can stick to a screen and block holes in the screen during sorting and screening. The bionic non-smooth sorting screen surface is characterized in that the surface of a base body of a sorting screen is made into a non-smooth surface with convex bodies or concave elements, wherein the convex bodies or concave elements have the height (H) of 0.5 to 2 mm and correspond to the geometrical dimension of materials to be screened, and the sum of the geometrical projection areas of the convex bodies or the concave elements on the base body of the screen surface and the area of the base body of the screen surface have the ratio of 30 to 70%. Compared with a common smooth sorting screen, the stickiness between the screen surface and the materials to be screened by the bionic non-smooth sorting screen surface is decreased by 40 to 80%, and the effective screening time is prolonged by 6 to 20 times. The invention has the effect on resisting stickiness and preventing blockage and simple structure, and can be obtained through common mechanical process; compared with the cost of a common smooth punched screen, the cost of the invention is increased a little.

Owner:JIANGSU UNIV

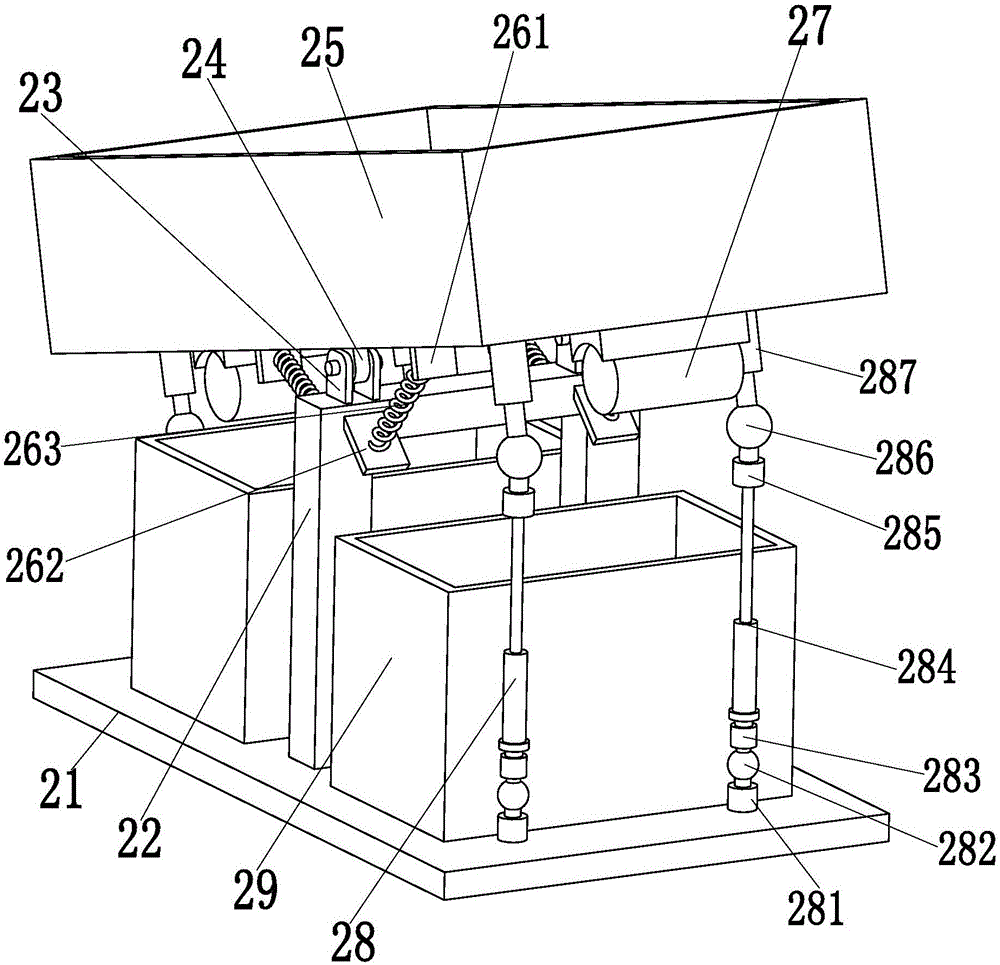

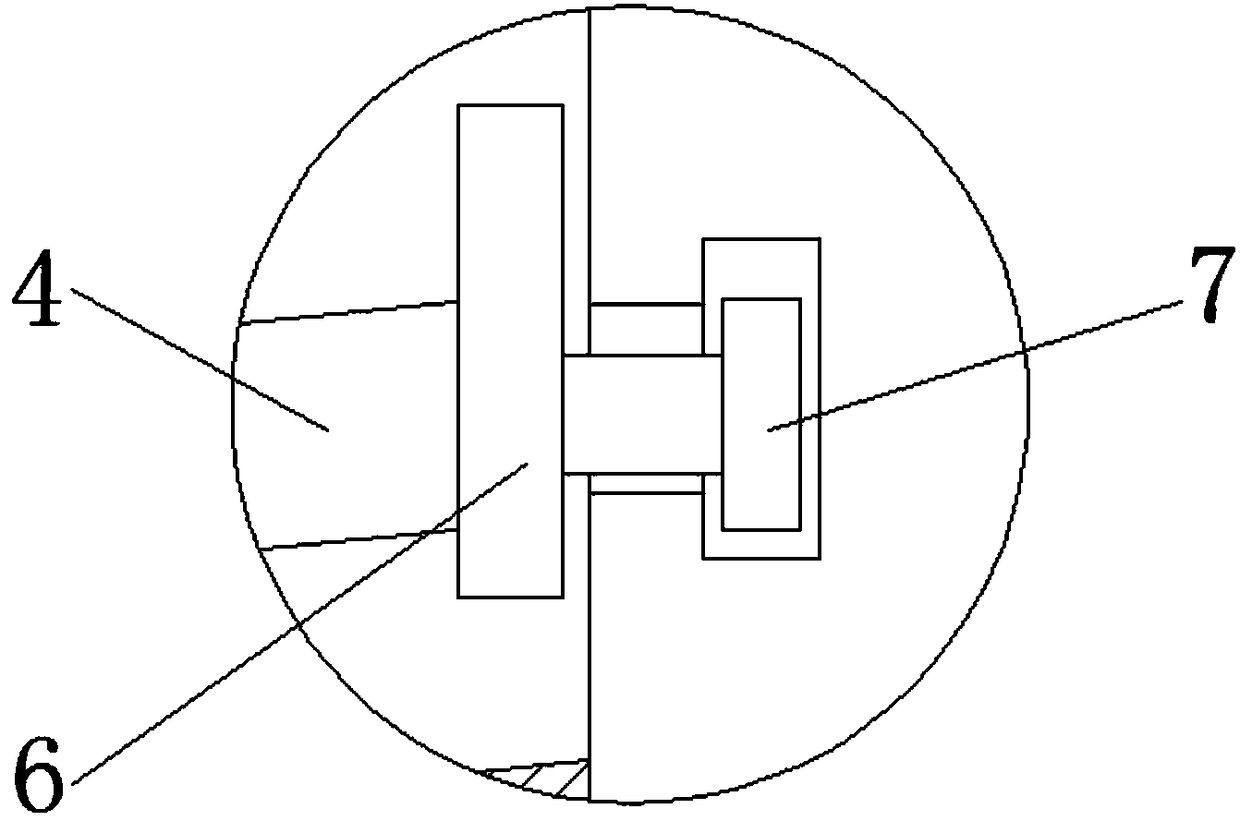

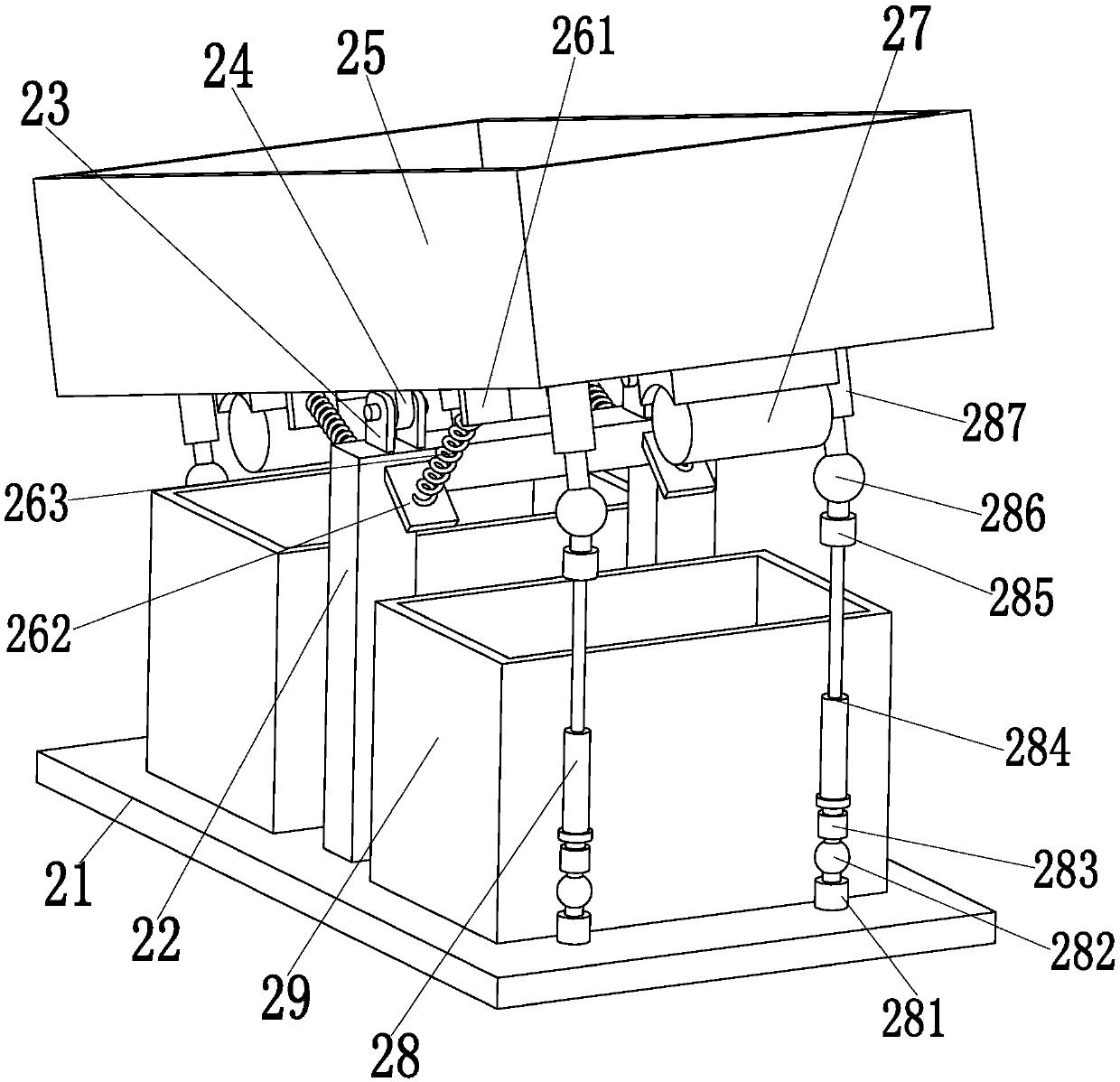

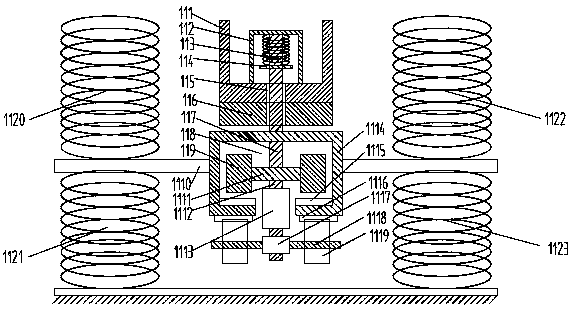

Precise capsule screening device

InactiveCN106111525ARealize automatic screening functionImprove screening effectSievingScreeningEngineering

The invention relates to a precise capsule screening device. The precise capsule screening device comprises a screening support plate; a screening frame is mounted at the middle part of the screening support plate; two pairs of fixed lugs are symmetrically arranged on the upper end surface of the screening frame; rotating lugs are mounted between the two pairs of fixed lugs through pin shafts; two rotating lugs between the two pairs of fixed lugs are symmetrically arranged at the middle part of the lower end surface of a screening box; the screening frame can rotate on two pairs of fixed lugs through the two rotating lugs; four limiting branch chains are respectively mounted between two sides of the screening box and two side walls of the screening frame; and when the screening box continuously rotates up and down, the four limiting branch chains symmetrically distributed on two sides of the screening box achieve an excellent limiting effect, so that the screening box is helped to quickly recover to the middle position, and the up-down rotating amplitude of the screening box is limited. The precise capsule screening device can realize an automatic screening function of unqualified capsules.

Owner:XUCHANG UNIV

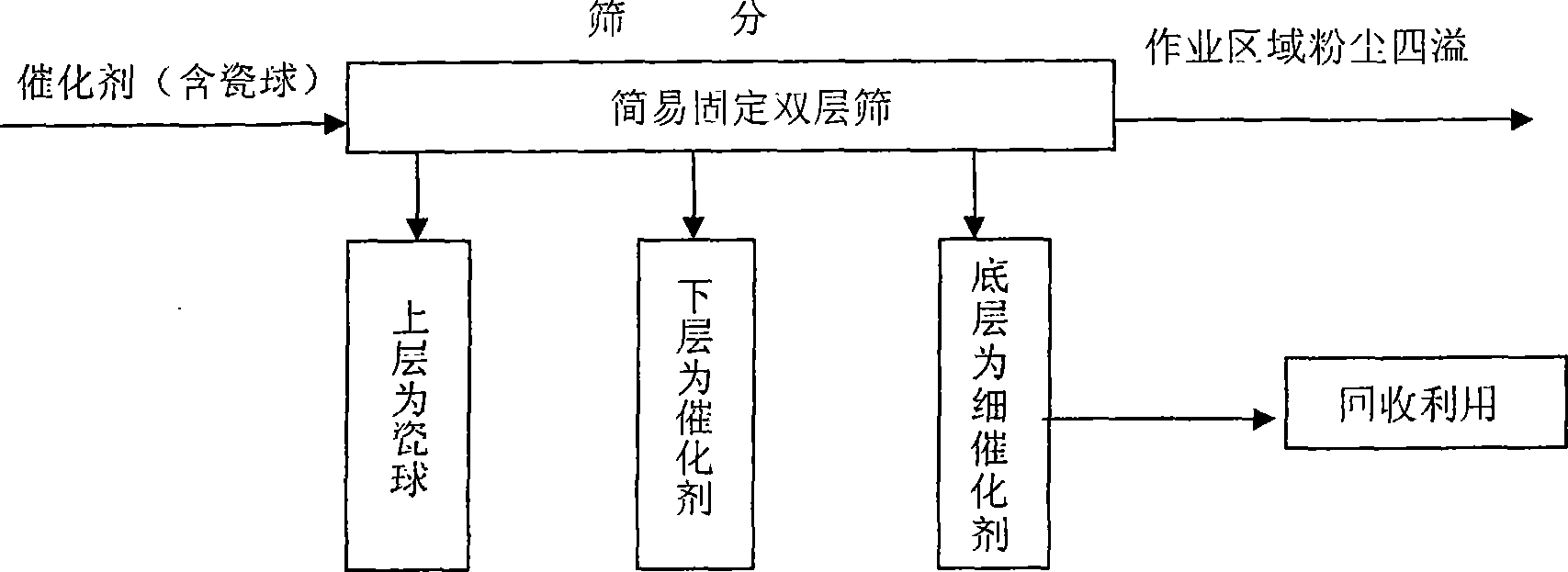

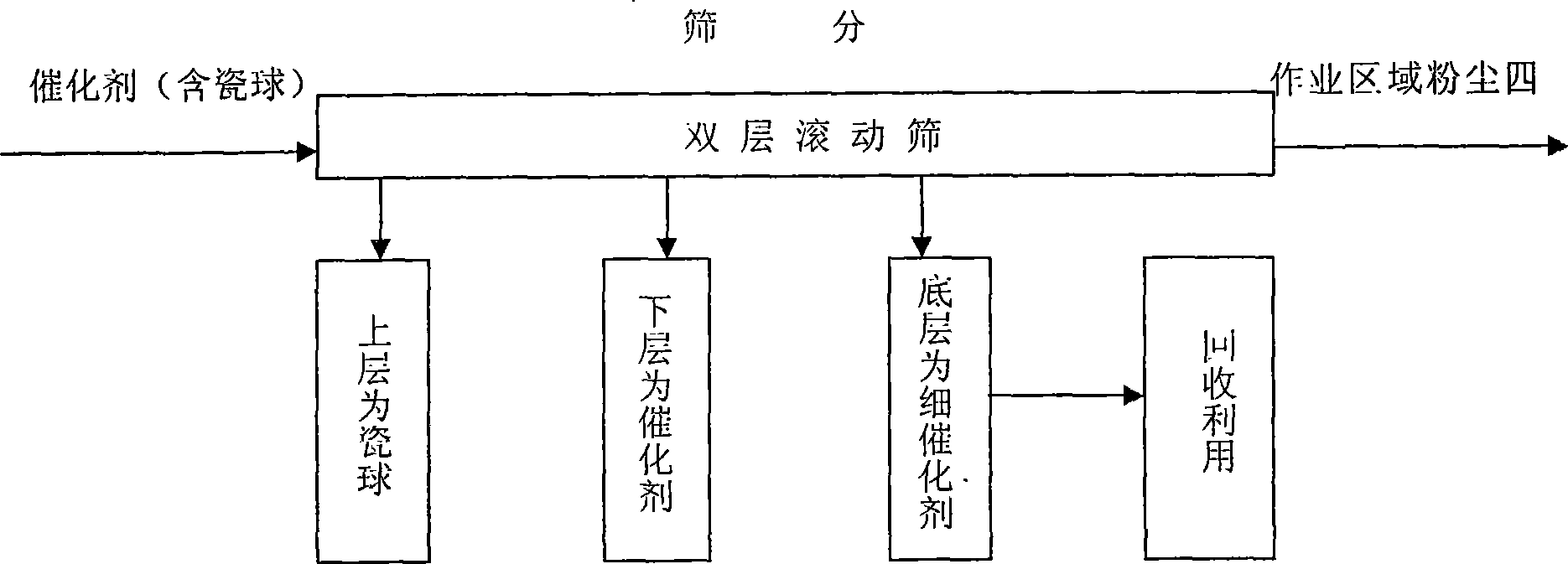

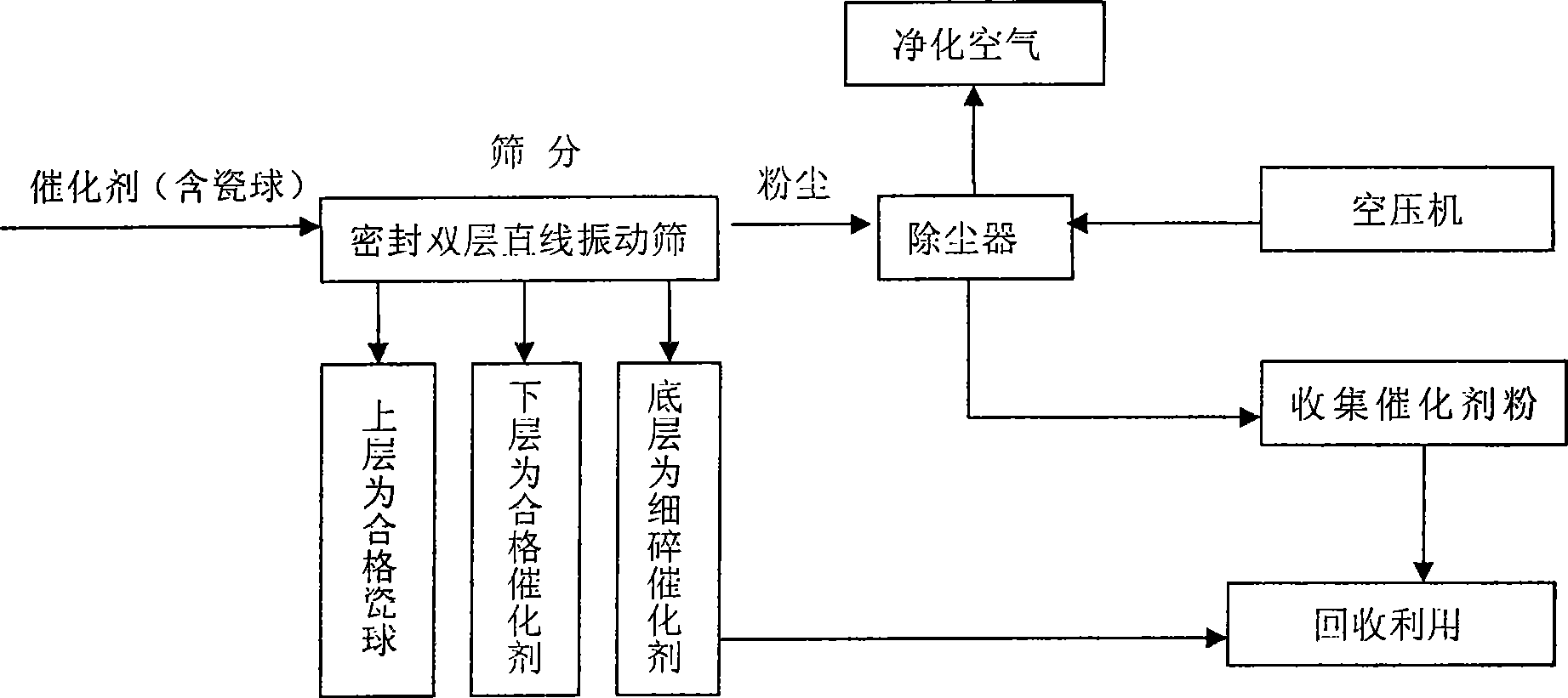

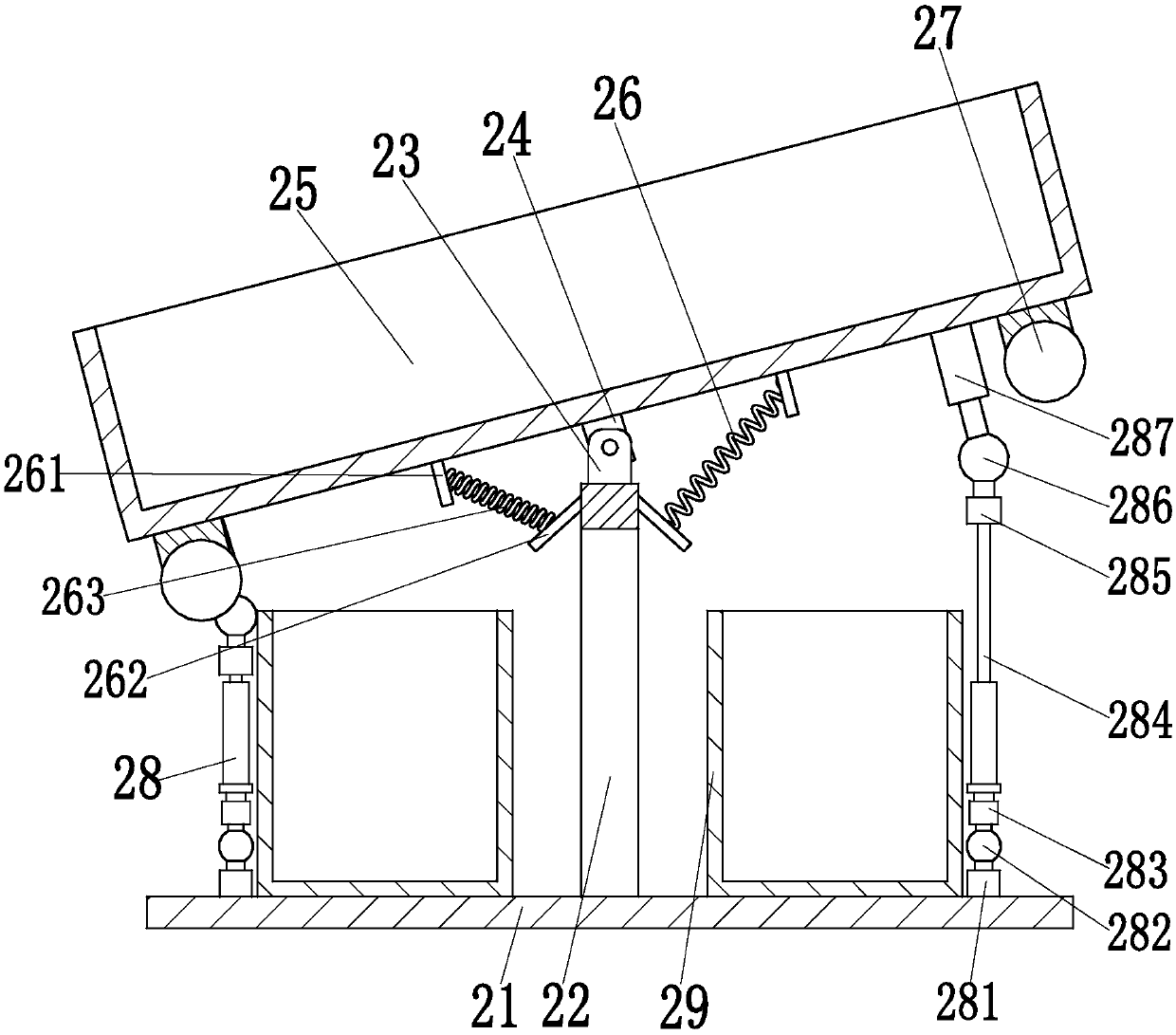

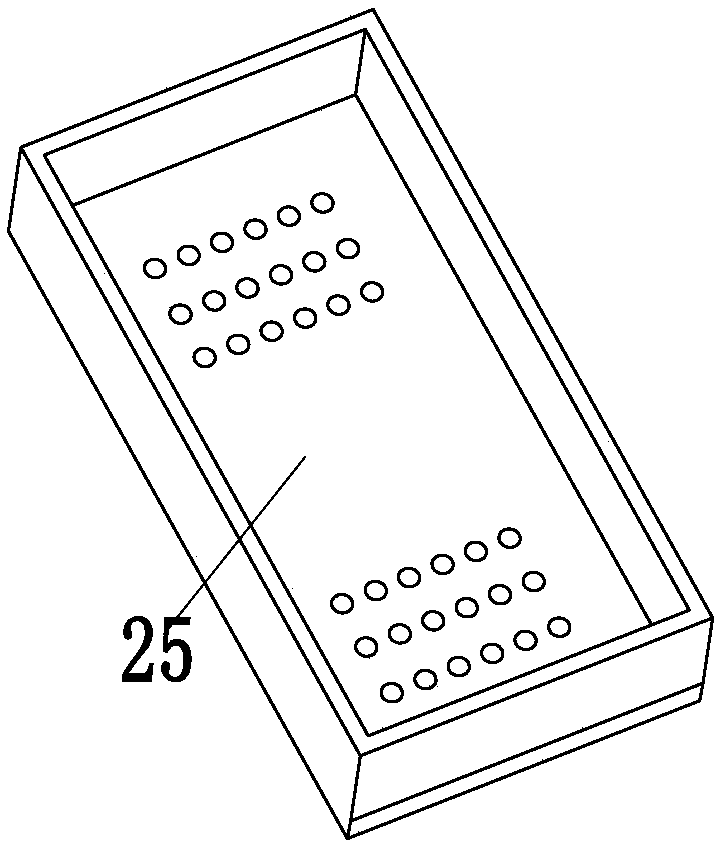

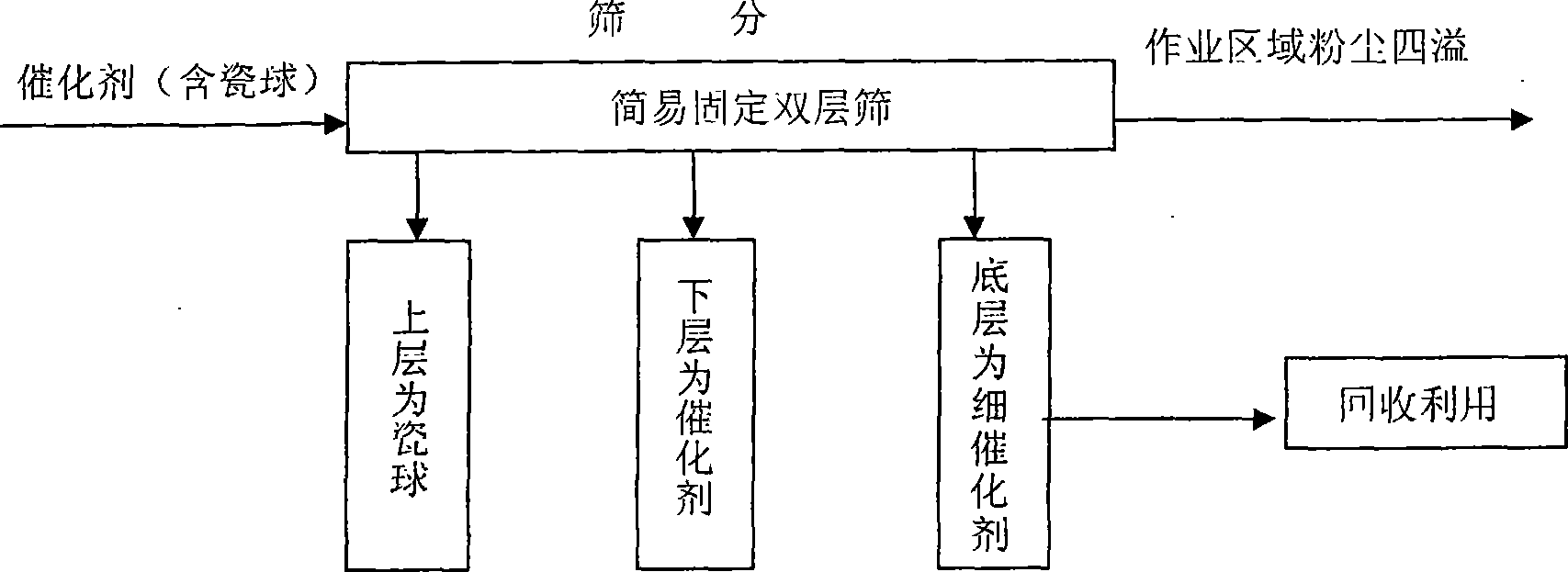

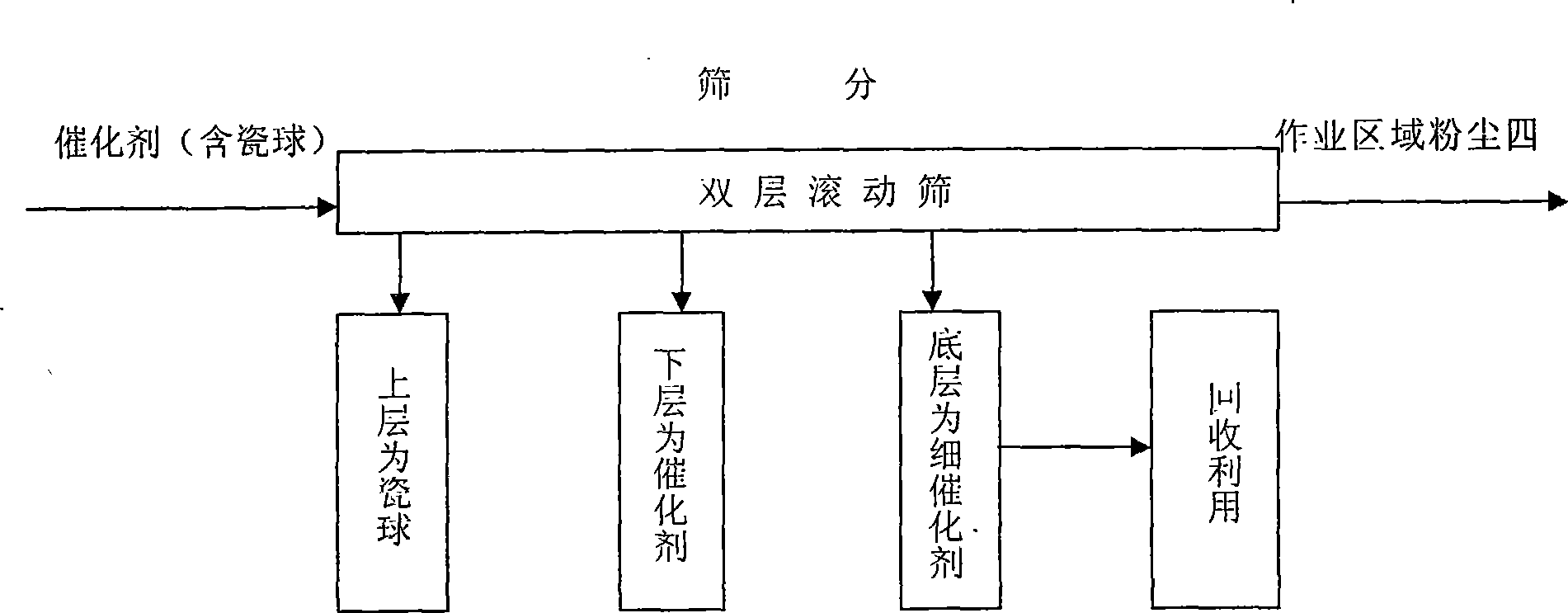

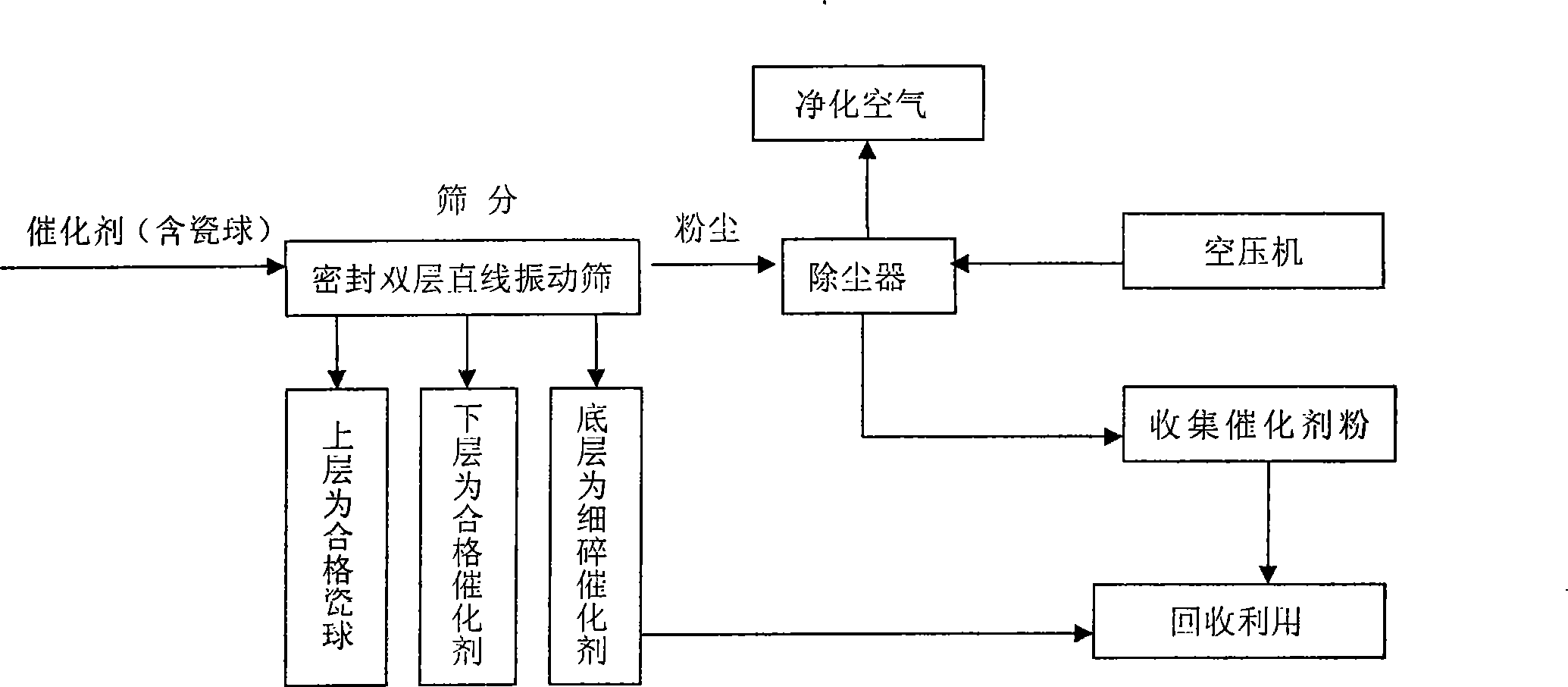

Catalyst screening method during preparation of sulphuric acid

InactiveCN101391755AReduce energy consumptionImprove efficiencySulfur-trioxide/sulfuric-acidWorking environmentEconomic benefits

The invention discloses a sulfuric acid catalyst screening method, which comprises: the catalyst is placed in a sealed double-layer linear mechanical vibrating screen to be screened level by level and the dusts generated during screening are filtered by a dust catcher; the screened thin catalyst grains and the catalyst dusts collected by the dust catcher are bagged respectively for later recycling. The application of the method can dramatically enhance the work environment and the dust density of the screening work zone is less than 3mg / m<3>, thus effectively protecting the health of workers. The improvement of environment can reduce the investment cost and the total screening cost can be saved by 5 to 10 percent, thus enhancing the economic benefit. The screening time can be dramatically shortened so as to obtain more time for the starting of sulfuric acid apparatus and guarantee smooth completion of the manufacturing task, thus having positive practical meaning and high popularization and application value.

Owner:云南云天化股份有限公司三环分公司 +1

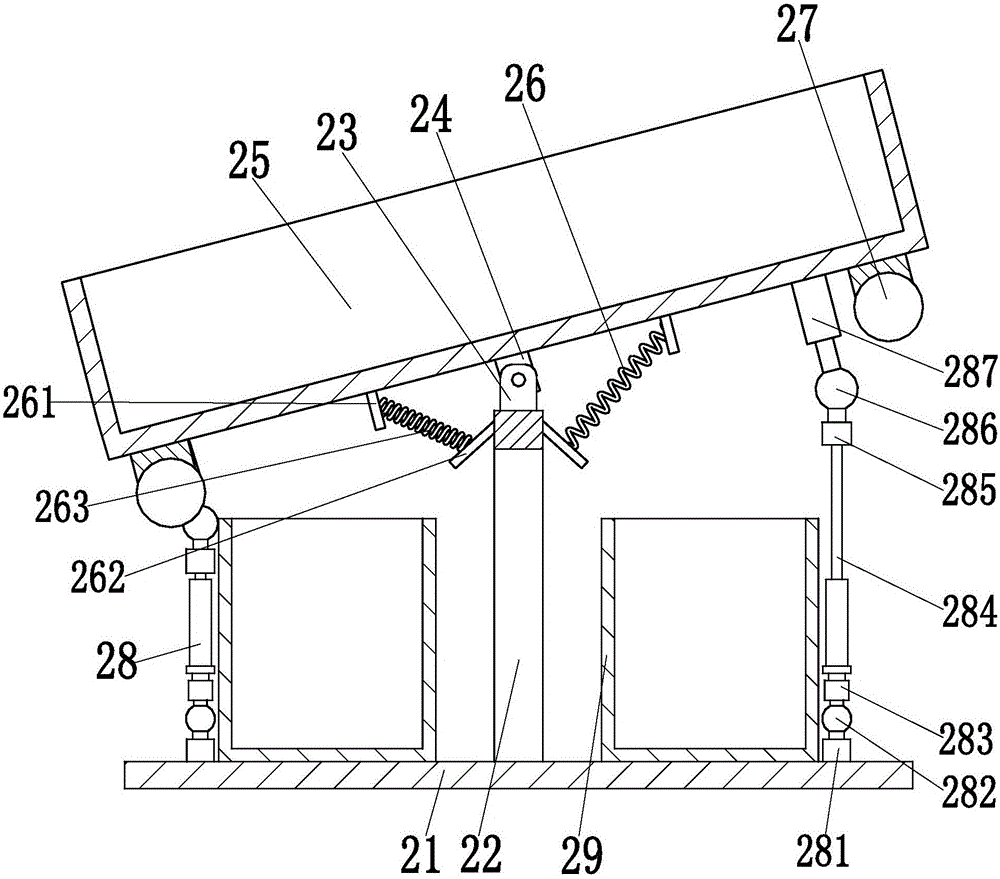

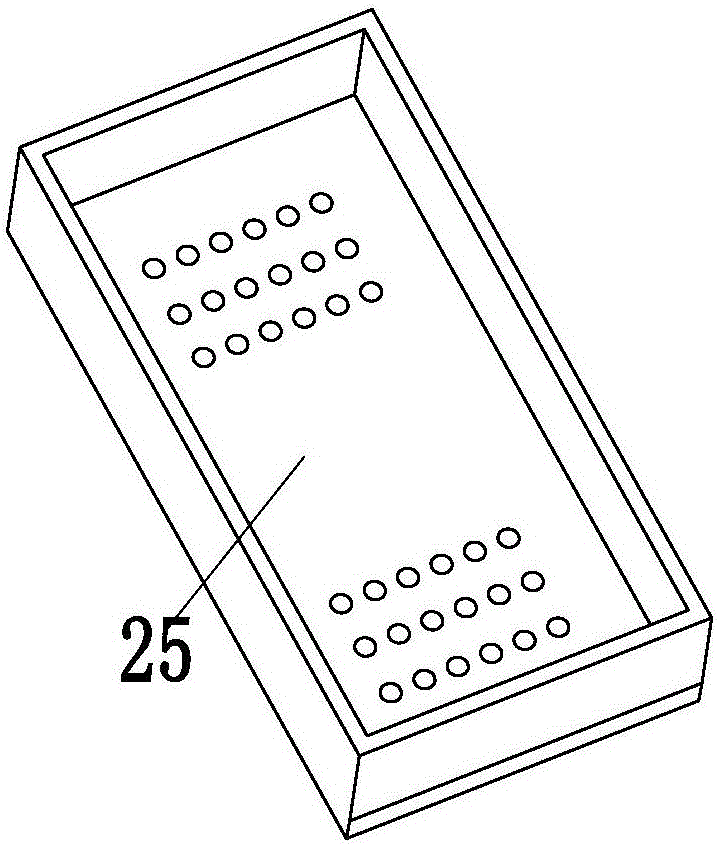

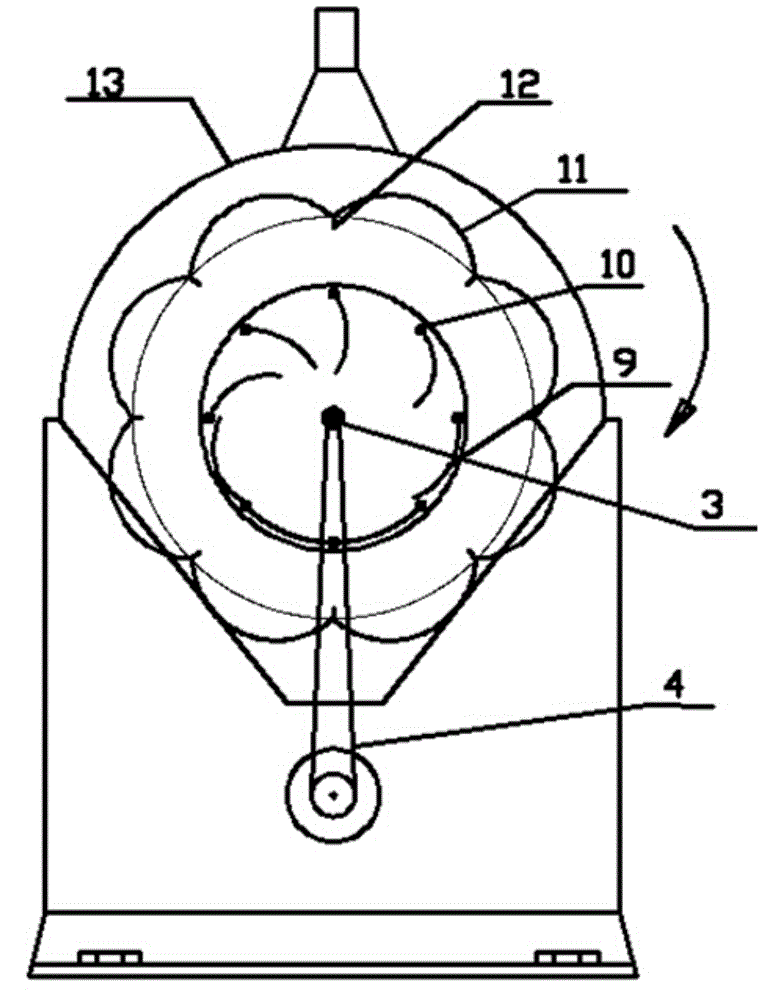

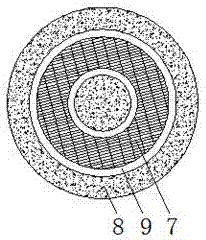

Double-layer rotary sieve

The invention discloses a double-layer rotary sieve. The double-layer rotary sieve is fixed on a supporting seat and comprises a shell, an outer sieve and an inner sieve, wherein the inner sieve is arranged at the inner layer of the outer sieve; the shell is arranged at the outer part of the outer sieve; sieving holes are arranged on sieve plates of the outer sieve and the inner sieve; a plurality of arc-shaped lining plates are arranged in the inner sieve and are close to the inner sieve; the heads and the tails of the two adjacent lining plates are attached to enclose into a cylindrical shape same as the inner sieve; one end of each arc-shaped lining plate is connected with a rib frame of the inner wall of the inner sieve by a hinge and the other end of each arc-shaped lining plate is movable; in the cylinder rotating process of the inner sieve, the arc-shaped lining plates rotate in a following manner, the tail ends of the arc-shaped lining plates fall gradually and fall vertically when reaching the high point, and then sieved materials fall again by means of the gravity action, so that secondary sieving is realized, the locking of the sieving holes is avoided and the sieving effect is better.

Owner:LUOYANG INST OF SCI & TECH

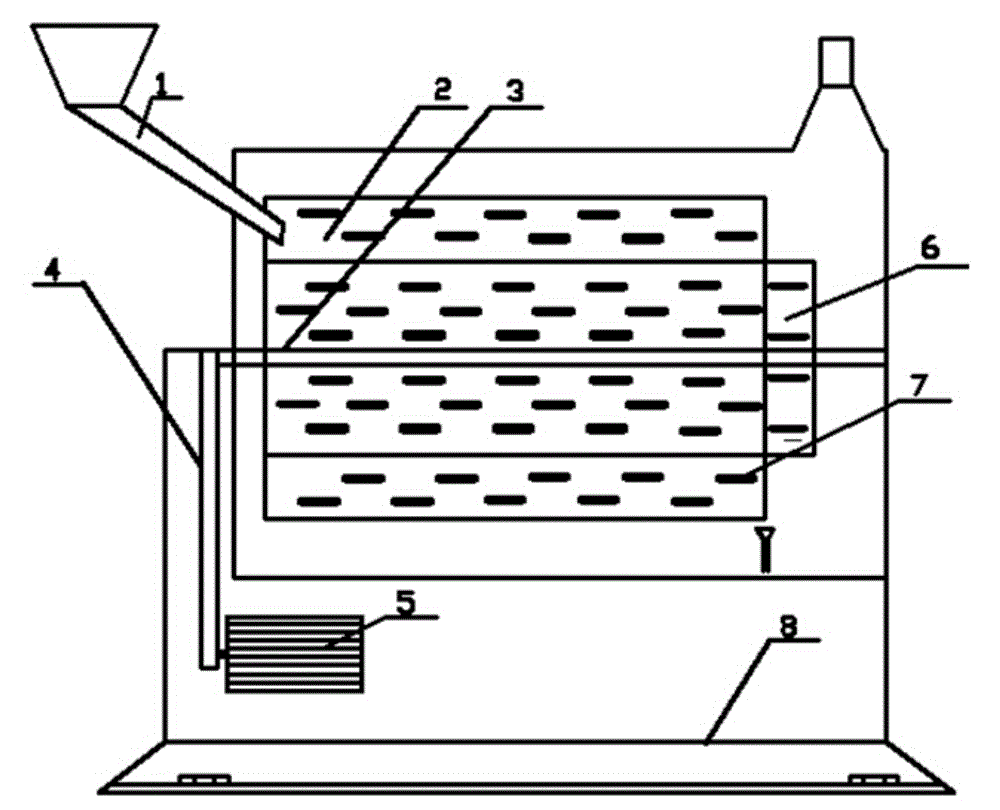

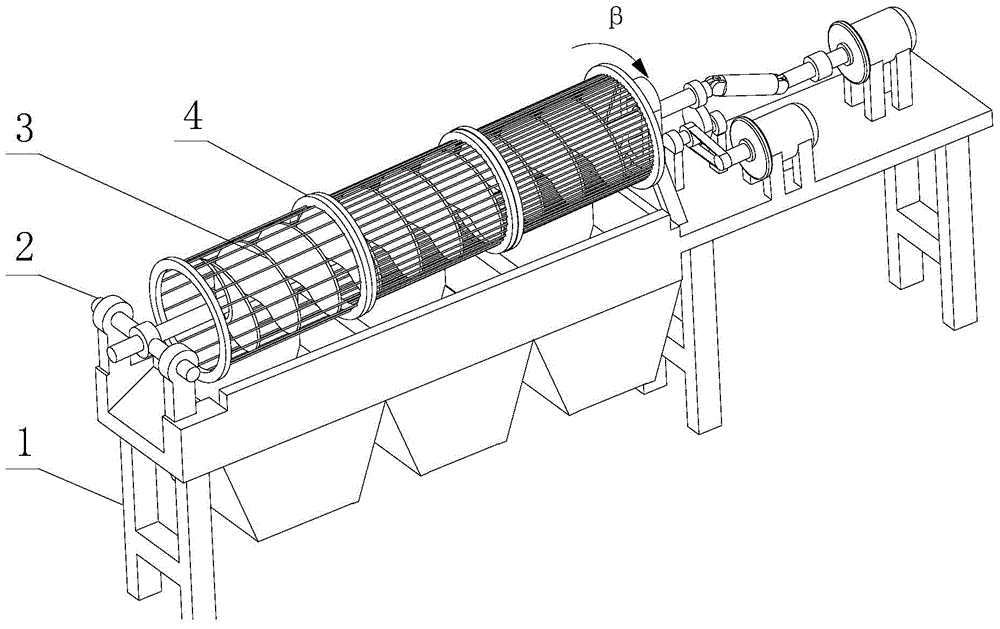

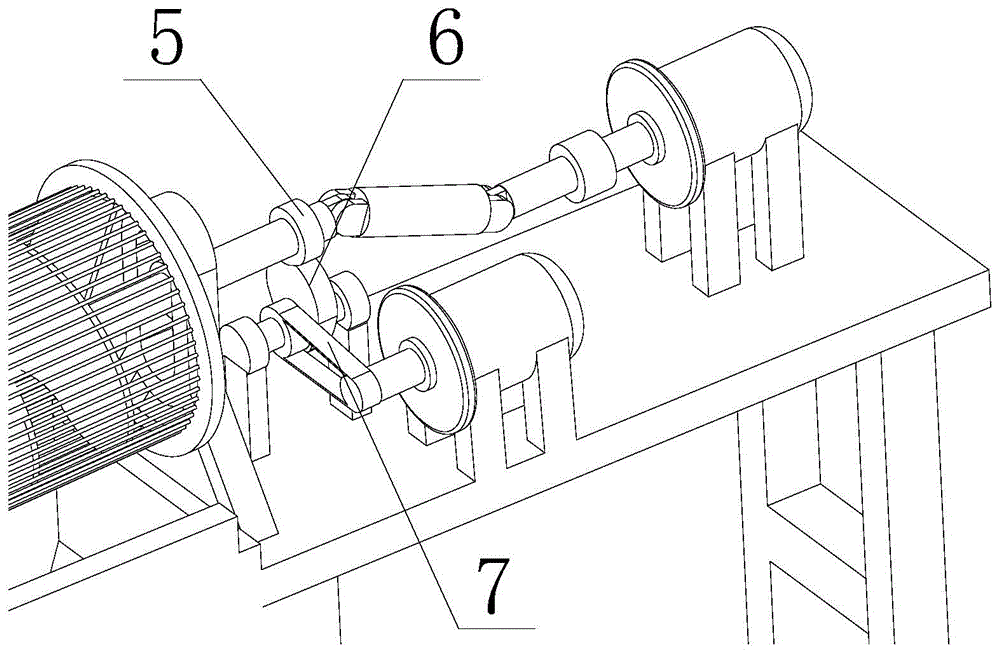

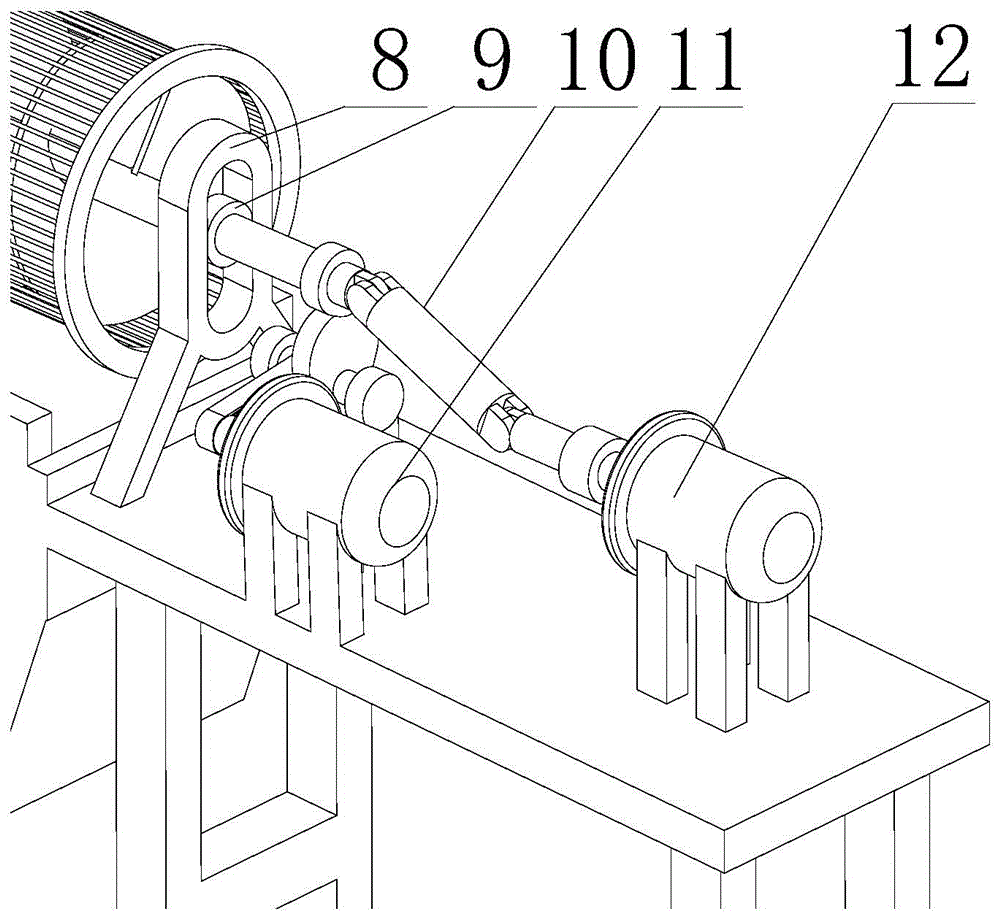

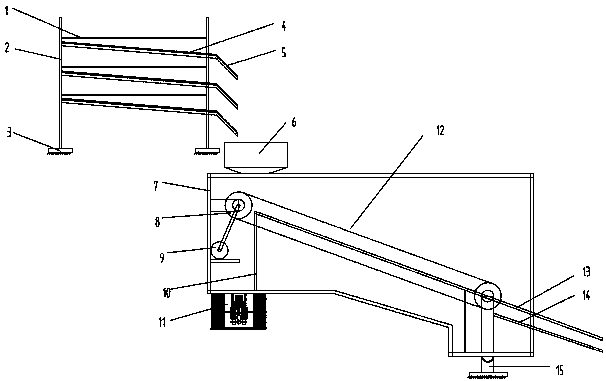

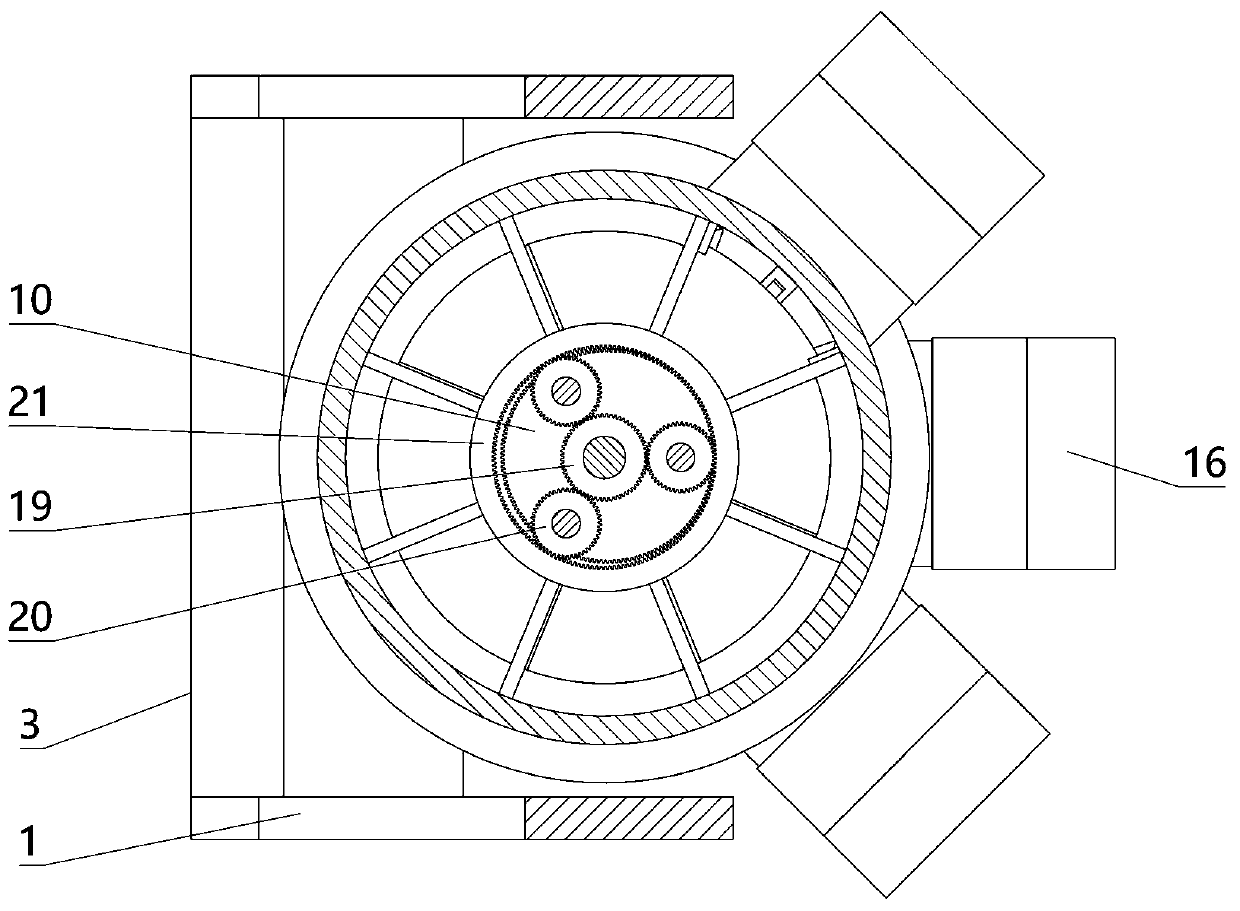

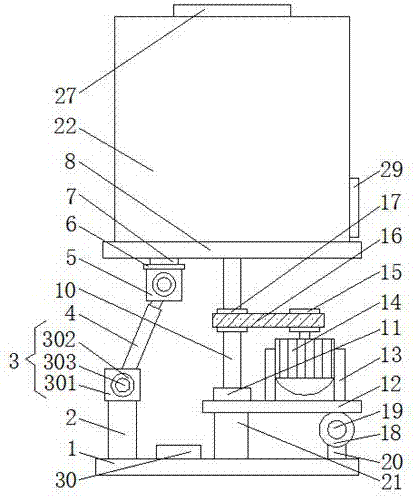

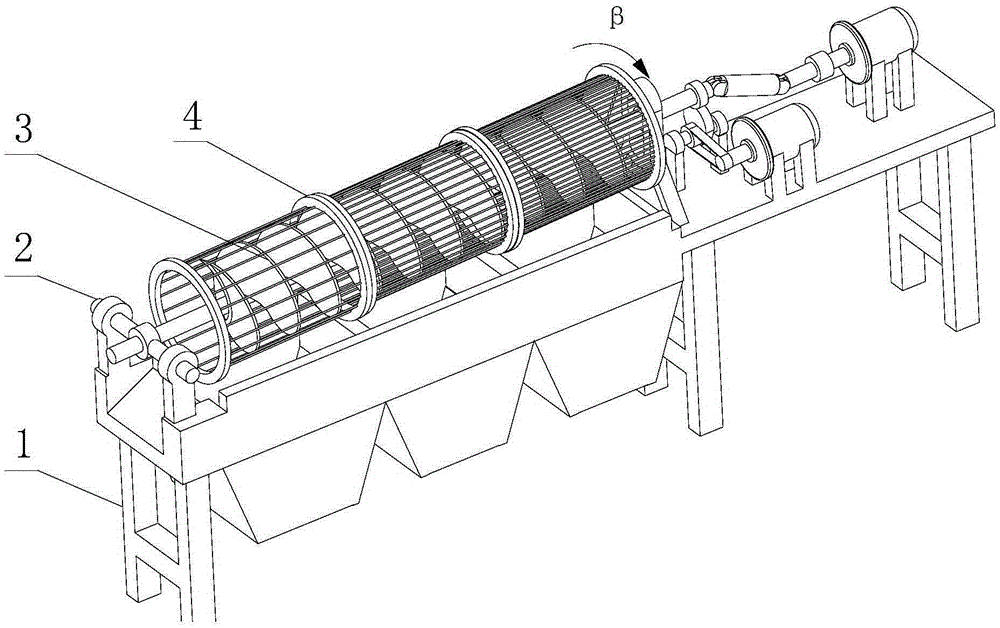

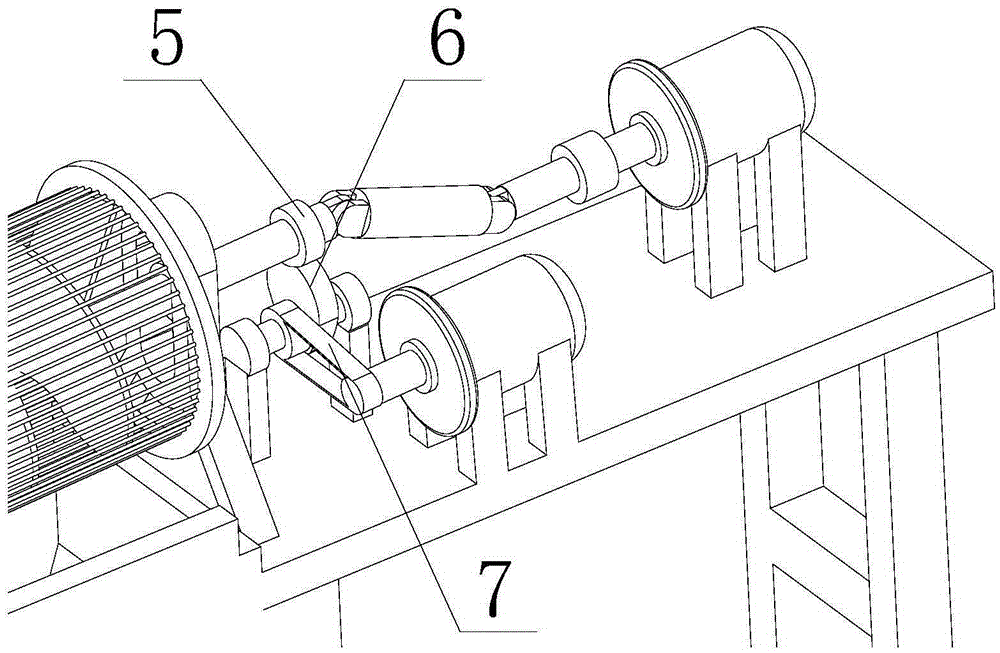

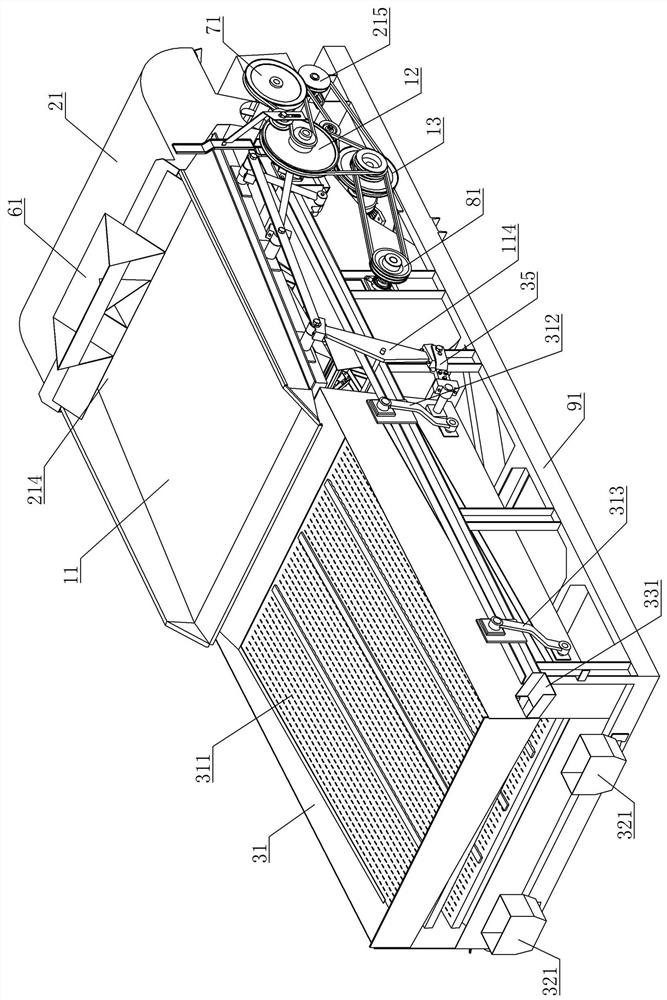

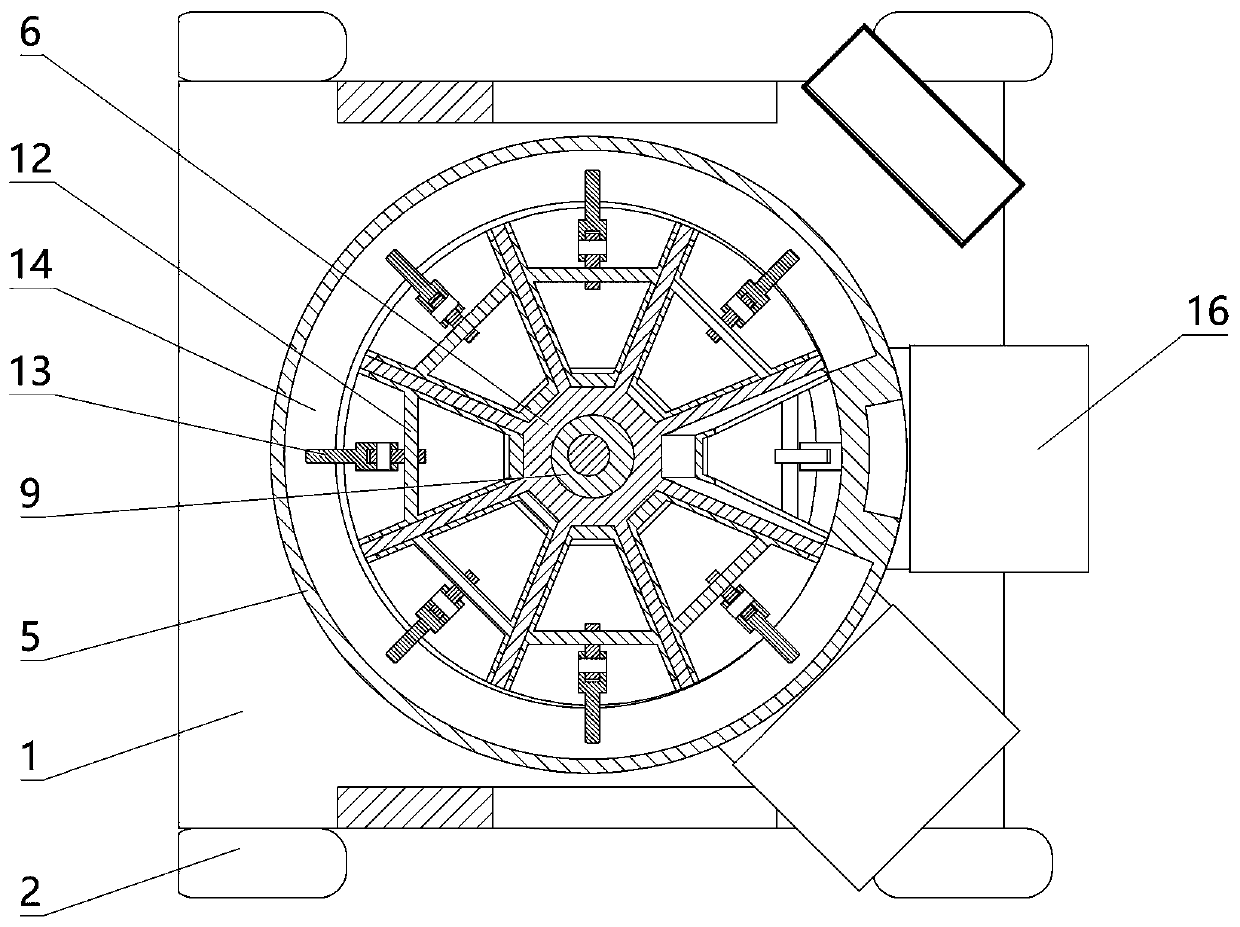

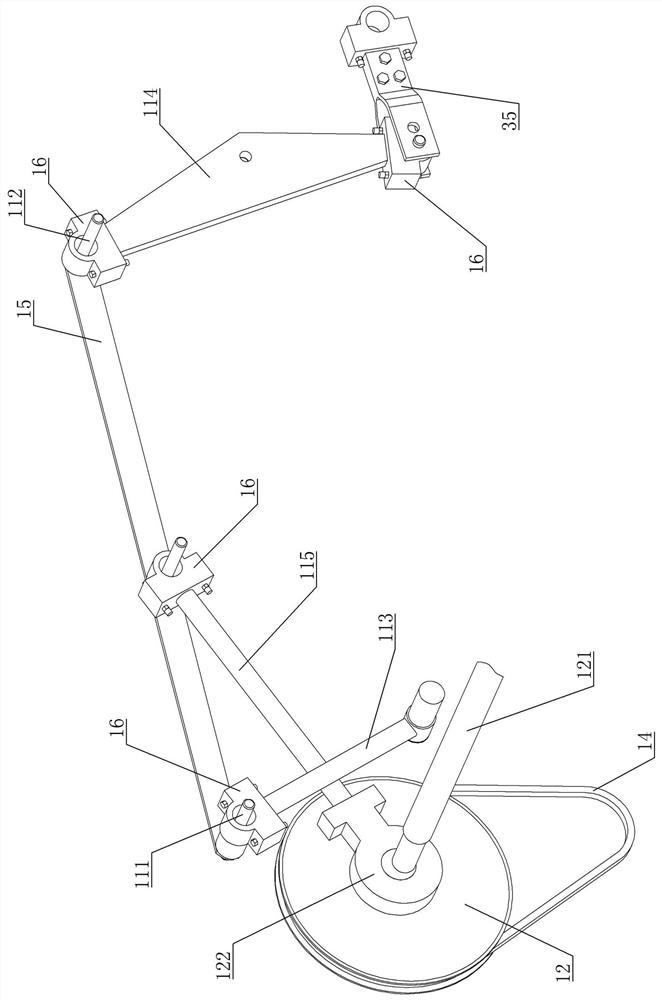

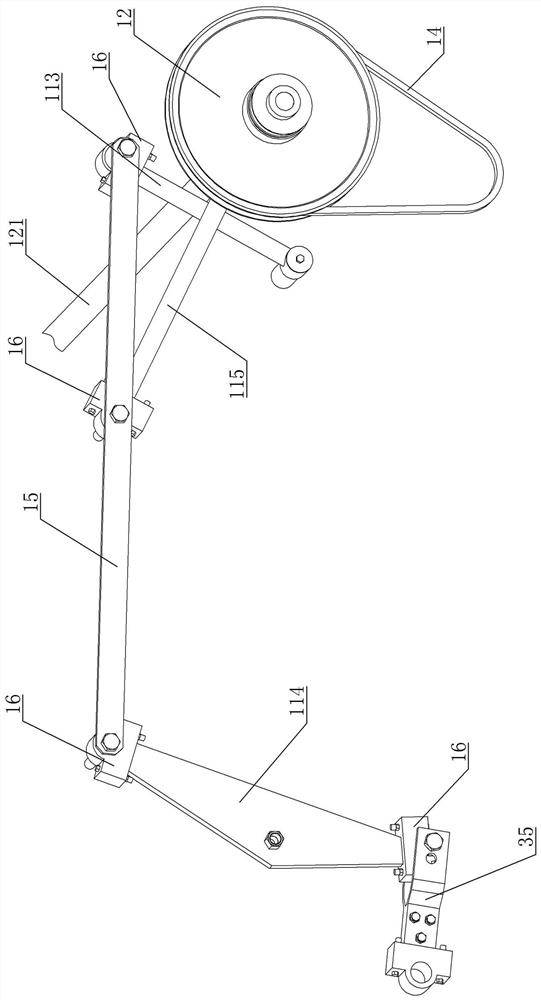

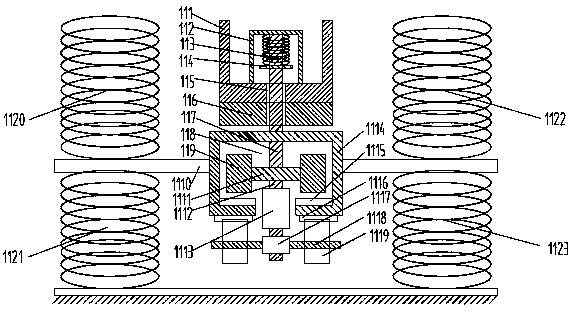

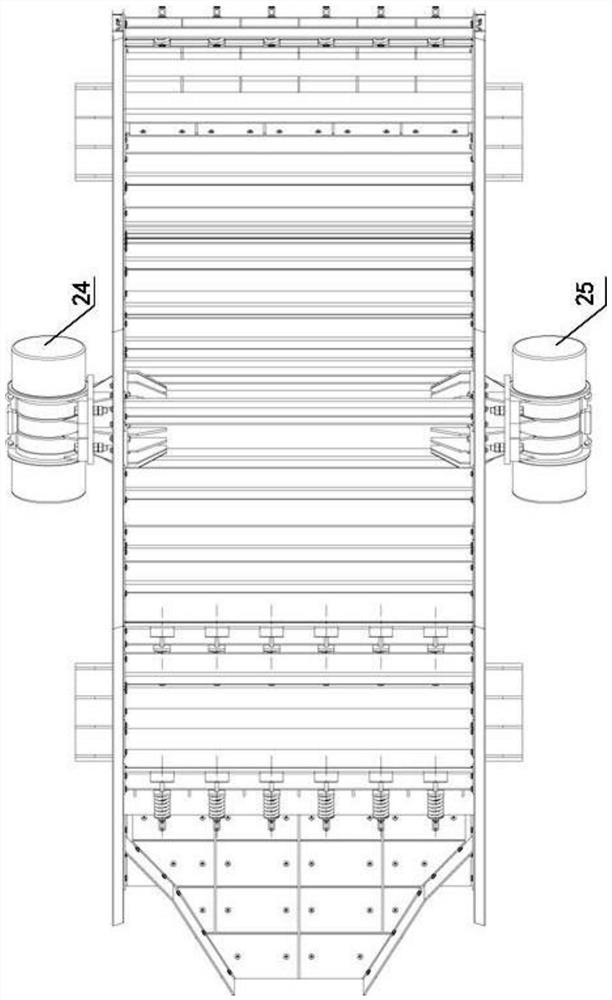

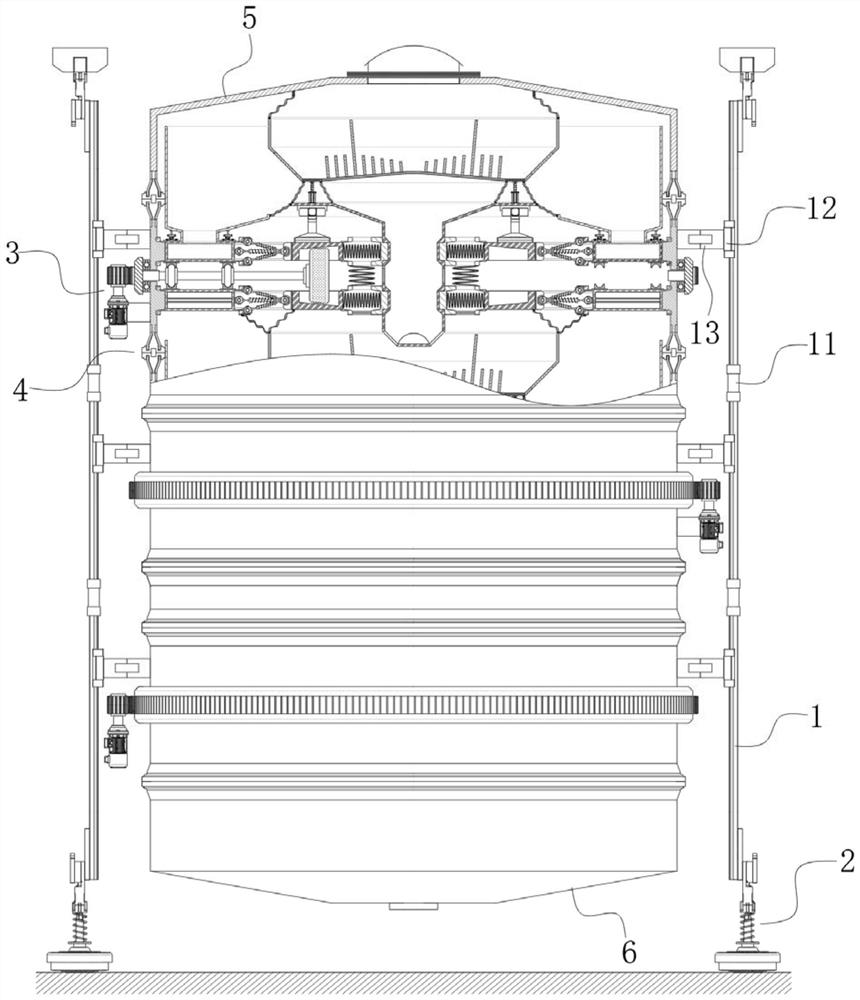

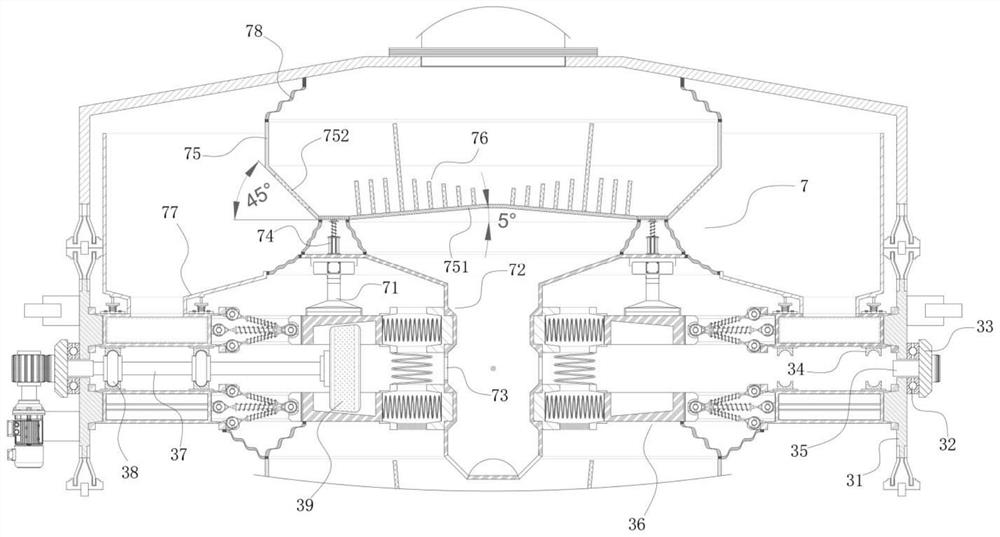

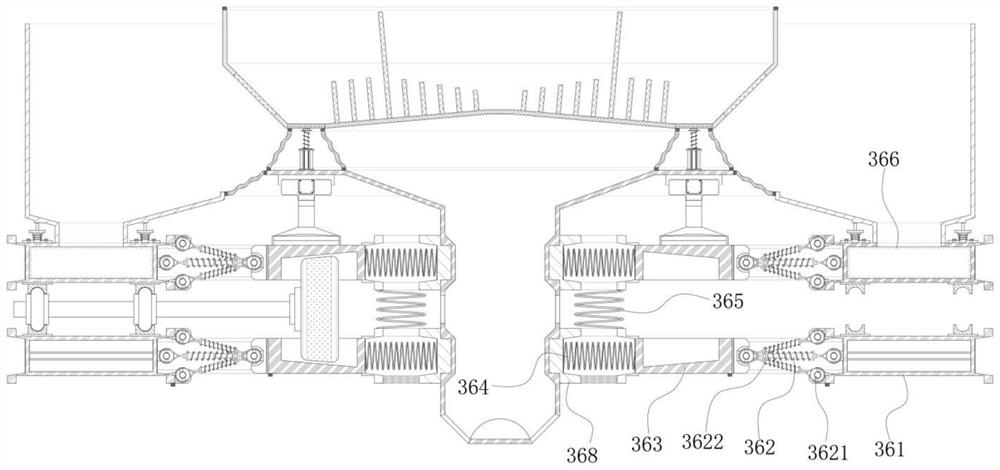

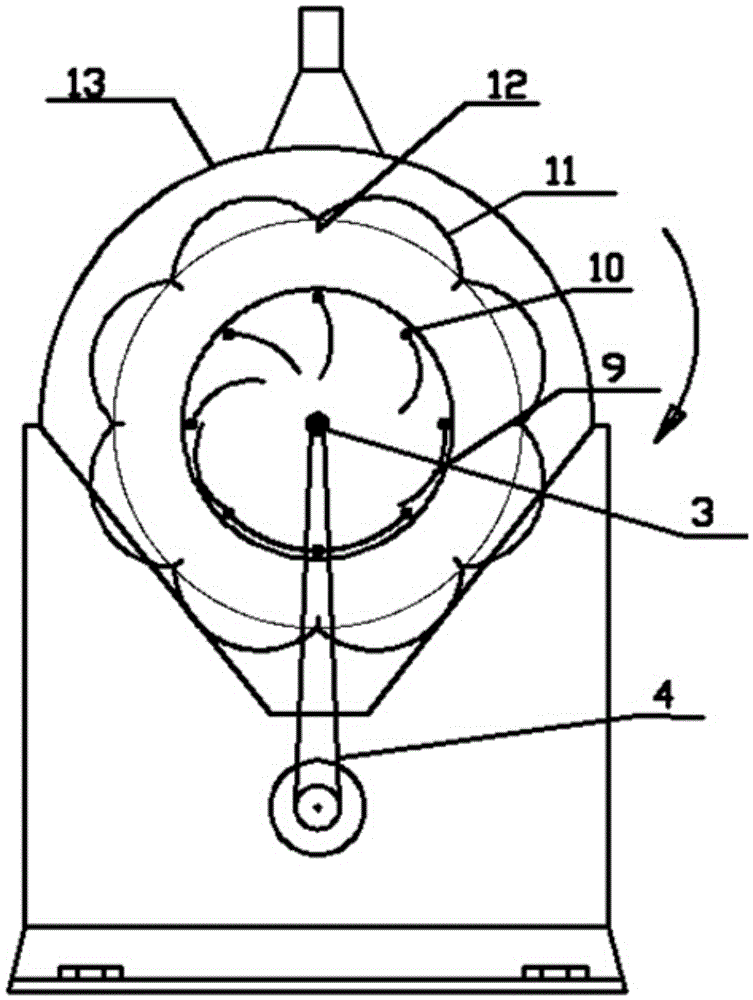

Vibrating drum screening machine capable of sorting for multiple times

ActiveCN104353603AExtend sieving timeImprove screening effectSievingScreeningRotational axisEngineering

The invention discloses a vibrating drum screening machine capable of sorting for multiple times. A frame is provided with a vibrating rotating shaft; a helical blade is fixed to the vibrating rotating shaft; the outer side of the helical blade is fixedly connected with a rotary screen; one end of the vibrating rotating shaft is arranged on the frame and can rotate around the frame; the other end of the vibrating rotating shaft is provided with a vibrating translation bearing and a vibrating transmission bearing; the vibrating translation bearing is arranged in a vibrating restraining support and is used for limiting the vibrating rotating shaft to vertically move only; the frame is provided with a vibrating motor and a rotating motor; the output shaft of the vibrating motor is provided with a shaft of a cam through belt connection; the vibrating transmission bearing is arranged on the top of the cam; the vibrating rotating shaft is connected with the output shaft of the rotating motor through a universal coupling. When the vibrating drum screening machine is used for screening goods, the vibrating frequency and the rotation speed of a drum can be freely adjusted, the screening efficiency is improved, and the vibrating drum screening machine is safe, reliable and convenient to operate.

Owner:GUANGXI UNIV

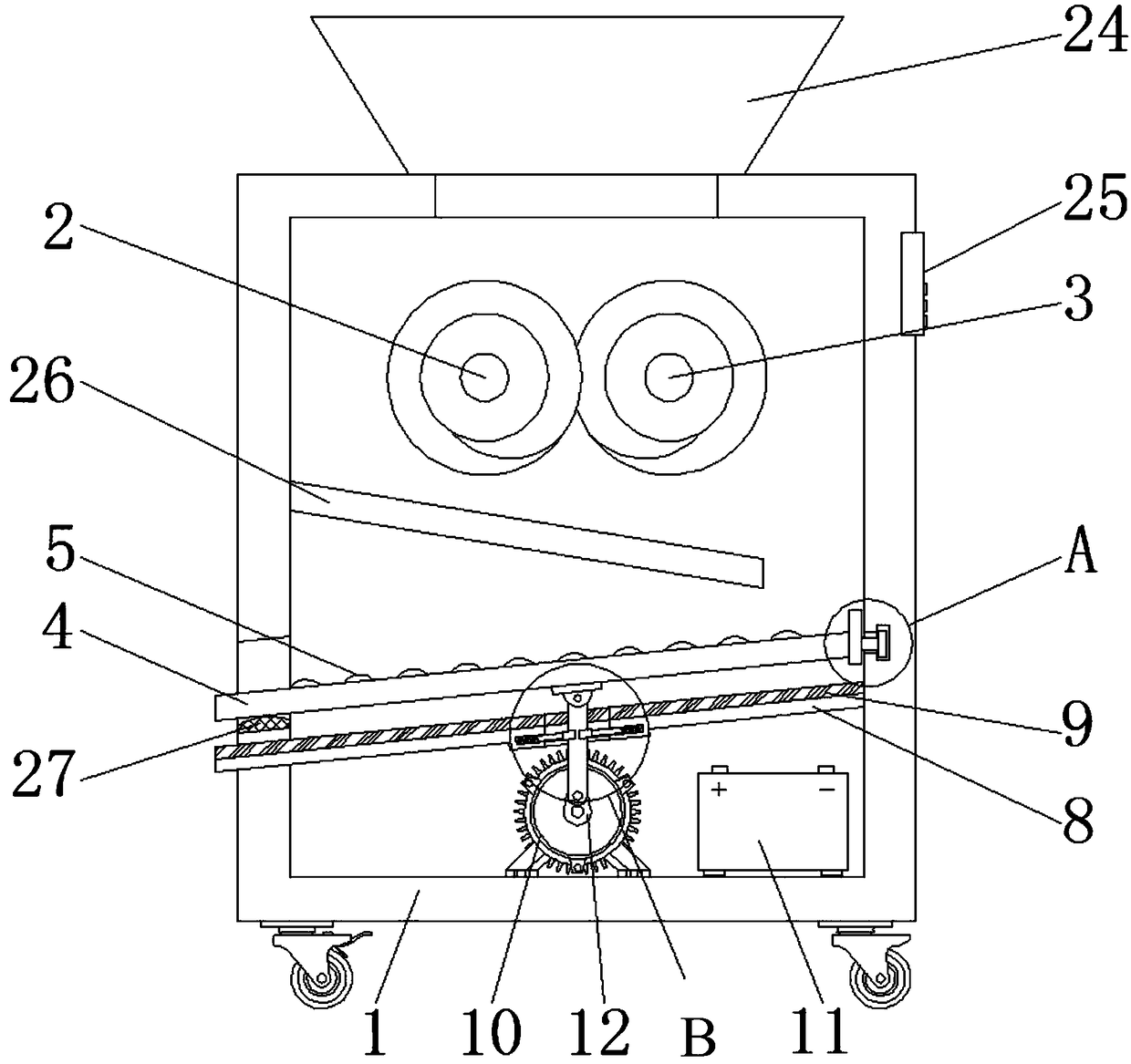

Computer waste plastic part recycling processing device

InactiveCN108116818AAvoid affecting product qualityExtend sieving timeRefuse receptaclesEngineeringMechanical engineering

The invention discloses a computer waste plastic part recycling processing device which comprises a box body, and relates to the technical field of computer parts. A first roller shaft and a second roller shaft are sequentially rotatably connected inside the box body from left to right, an inclined plate is fixedly mounted inside the box body and located below the first roller shaft and the secondroller shaft, a sieve plate passes through the left wall of the box body and located below the inclined plate, a blocking strip is fixedly mounted at the top of the sieve plate, a baffle is fixedly mounted on the right side of the sieve plate, the right side of the baffle is slidably connected with the right side of the inner wall of the box body through a sliding block, and a supporting block isfixedly connected inside the left wall of the box body and located below the sieve plate. According to the computer waste plastic part recycling processing device, the inclined plate is utilized to concentrate crushed plastic fragments to the highest position of the sieve plate to slide down, the screening time of the crushed plastic fragments on the sieve plate can be prolonged by being matchedwith a blocking strip, and the screening quality is improved. An electromagnet can be used to adsorb fine metals such as screws in the crushed plastic fragments to prevent the later melting from affecting the product quality.

Owner:曹诗晴

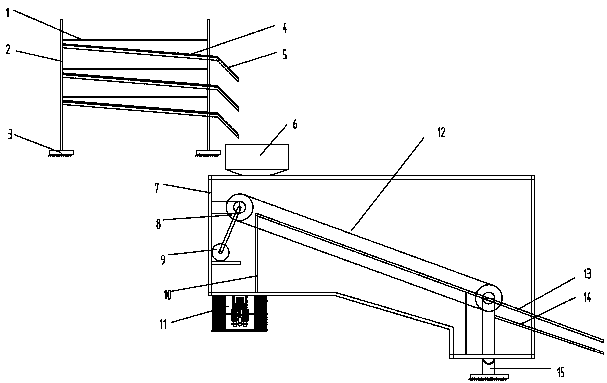

Raw coal conveying method

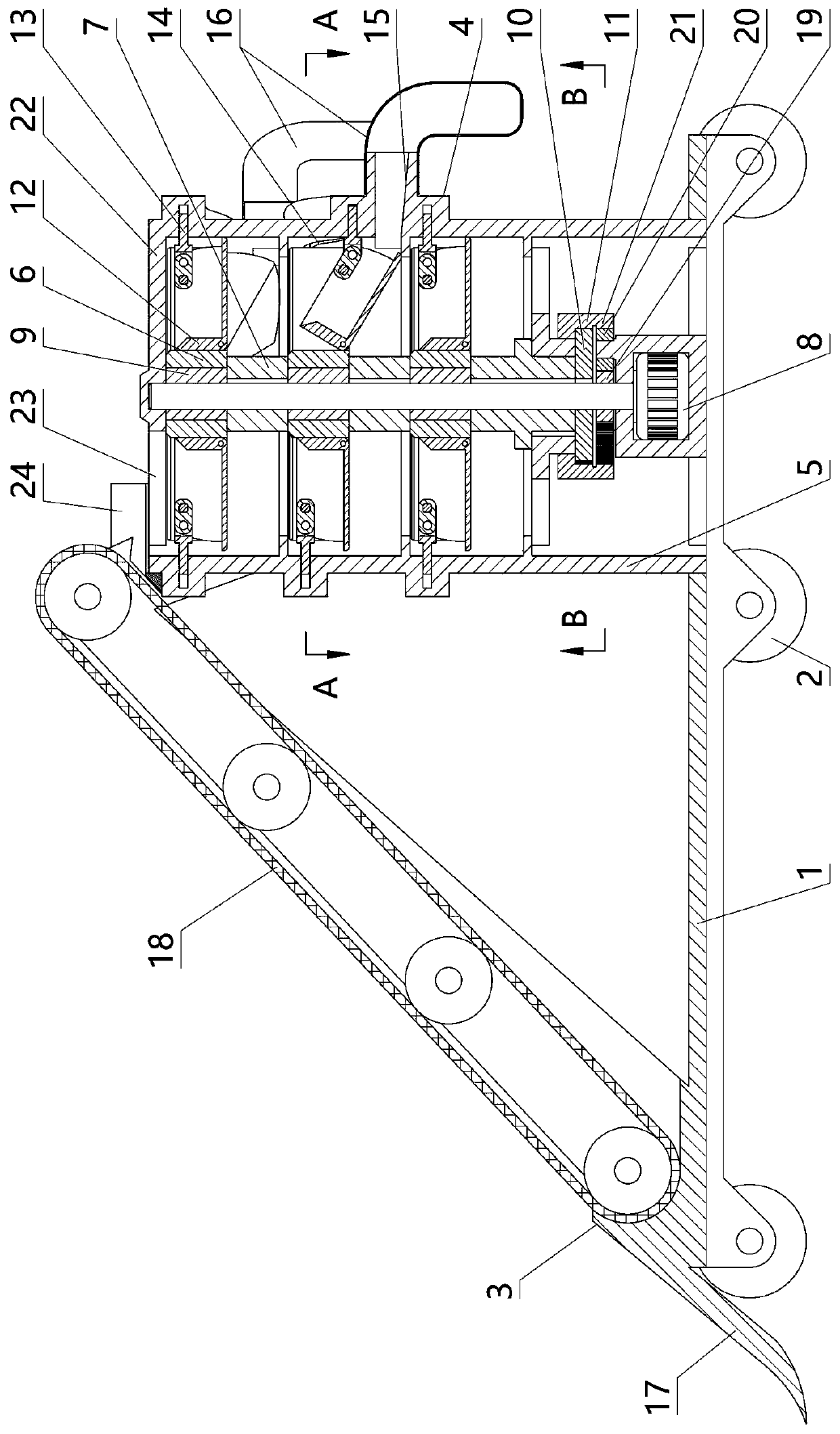

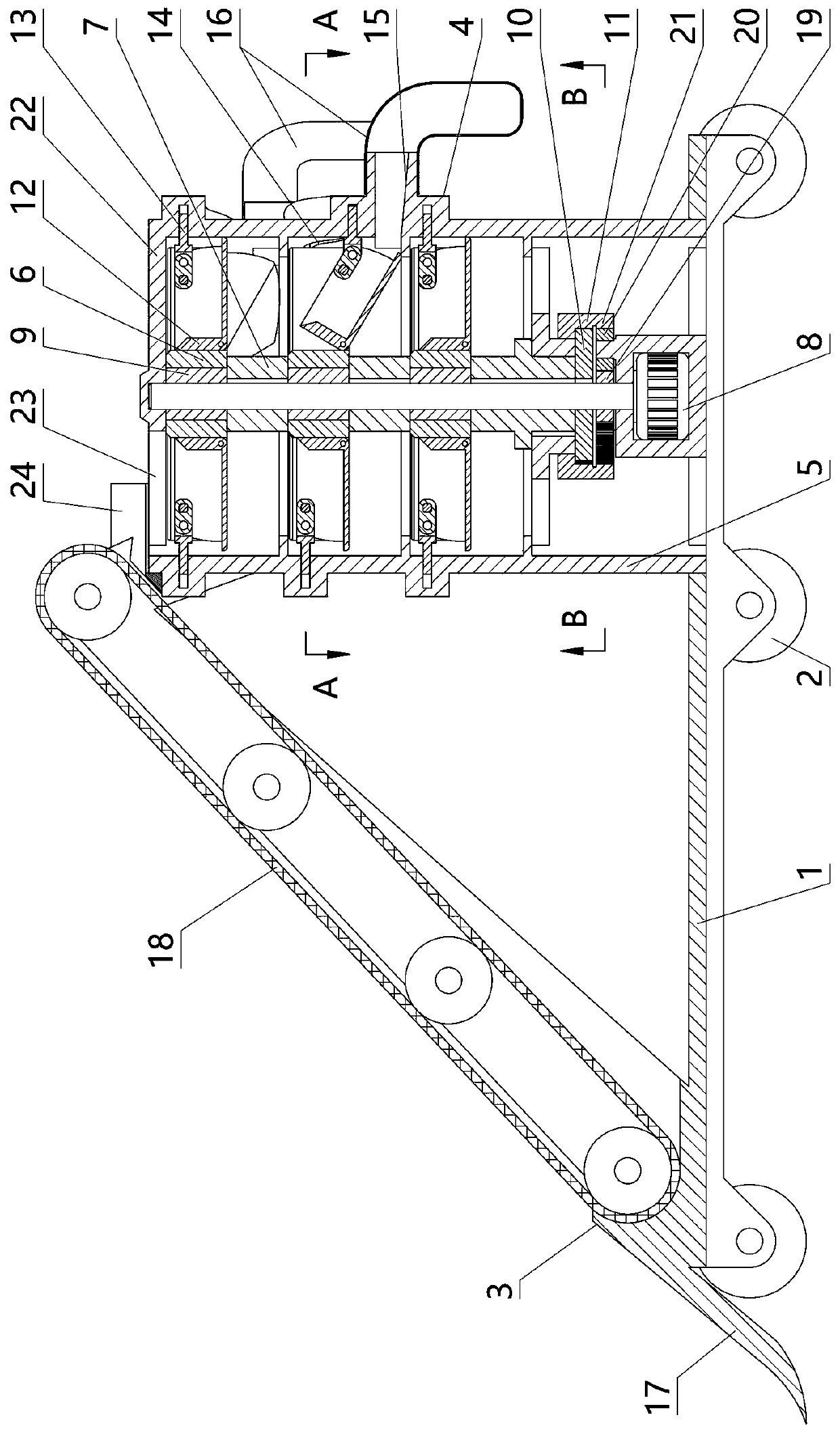

ActiveCN107555195AEasy to installExtend sieving timeLoading/unloadingJigging conveyorsUltimate tensile strengthConveyor belt

Sundry screens are arranged through supports, holes are formed in the sundry screens, slide way grooves are formed under the holes, raw coal is conveniently collected, the raw coal which is separatedout can be further subjected to washing processing to be used as fuel, the pollution degree of the environment is decreased, the effect of the fuel is better brought into play, and waste utilization for shaft backfilling and the like can also be achieved for sundries. By means of the arrangement, the structure is simple and efficient. By means of the invention, reverse operation is achieved whilescreening is conducted through a conveyor belt so that the screening time can be prolonged; separation processing can be effectively conducted for the raw coal, the raw coal which is separated out canbe collected after being conveyed, and therefore the separation and utilization efficiency of the raw coal is effectively improved, pollution and waste caused by the raw coal are reduced, the whole device is convenient to use and high in utilization rate, and the labor intensity is lowered.

Owner:准格尔旗昶旭煤炭有限责任公司

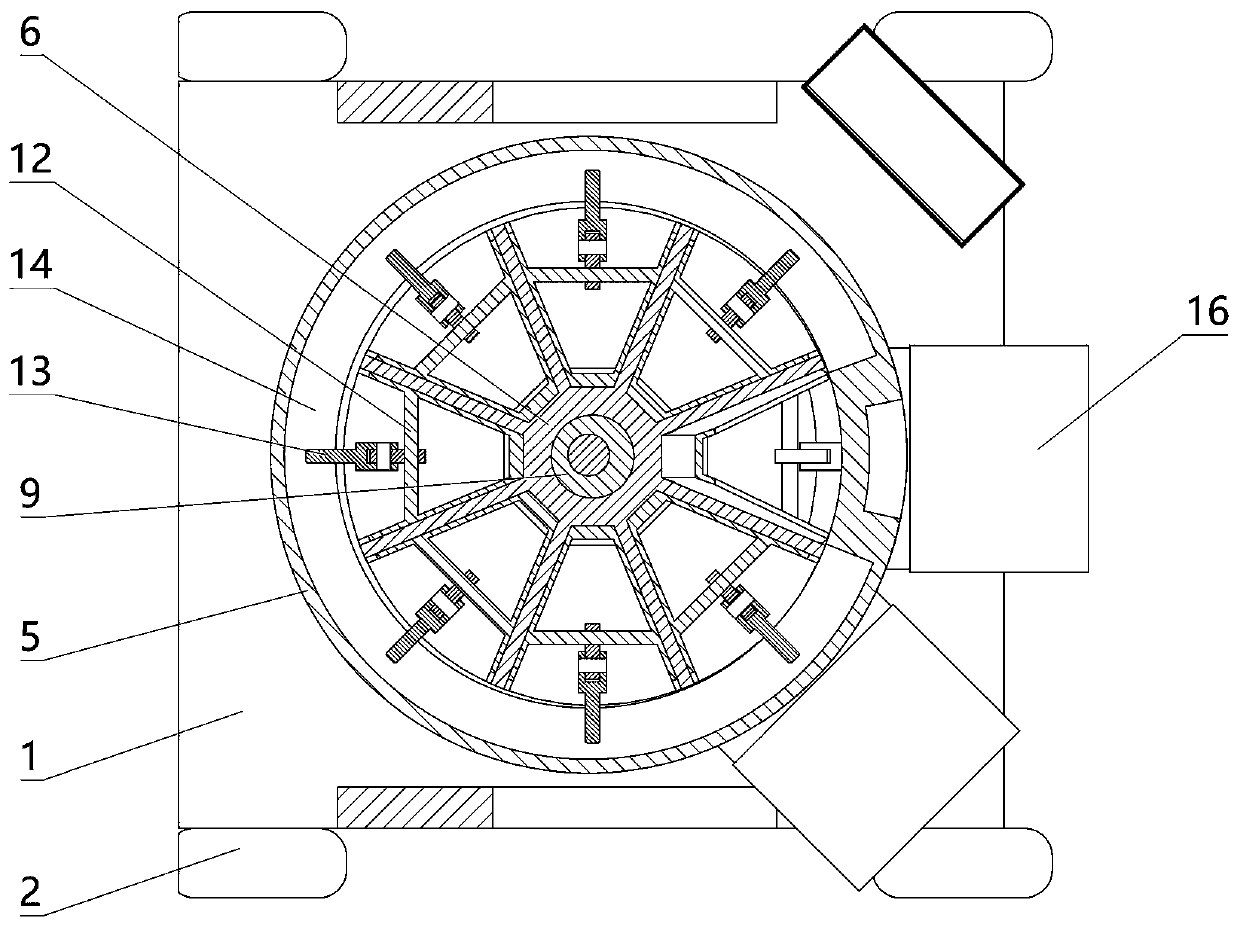

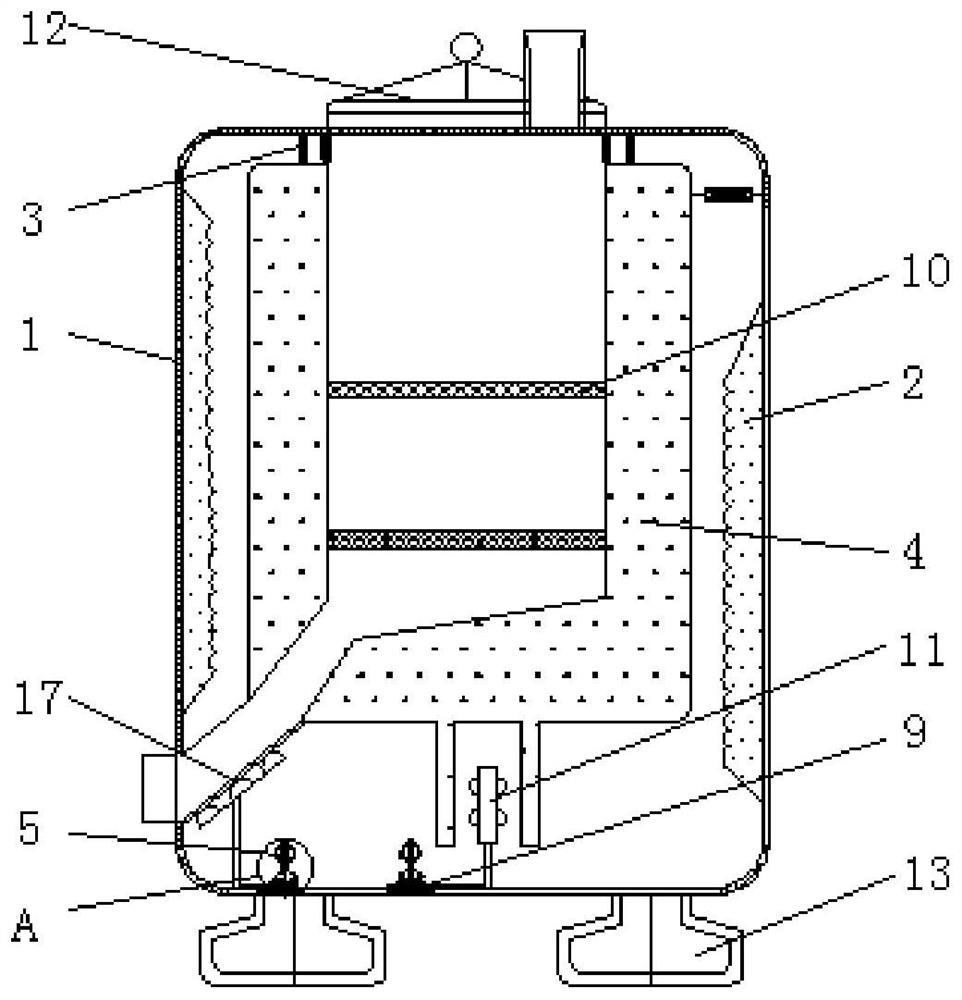

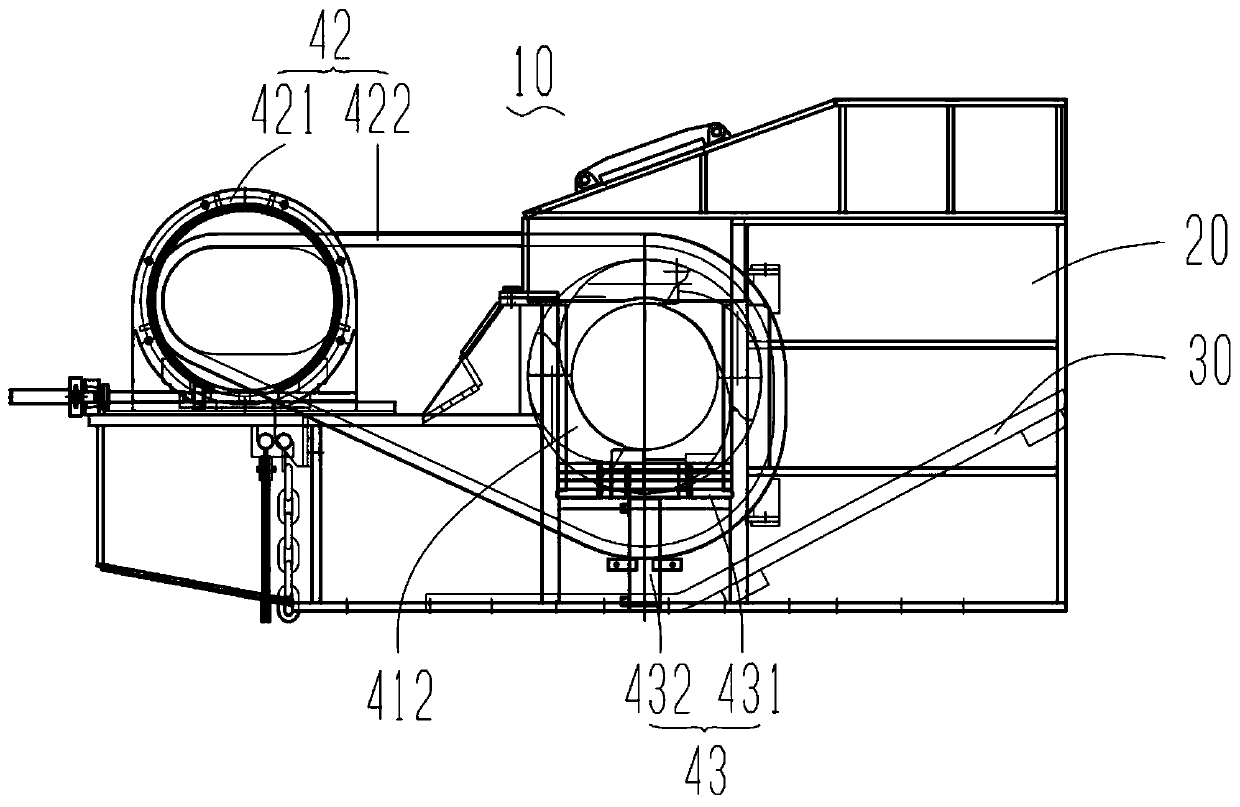

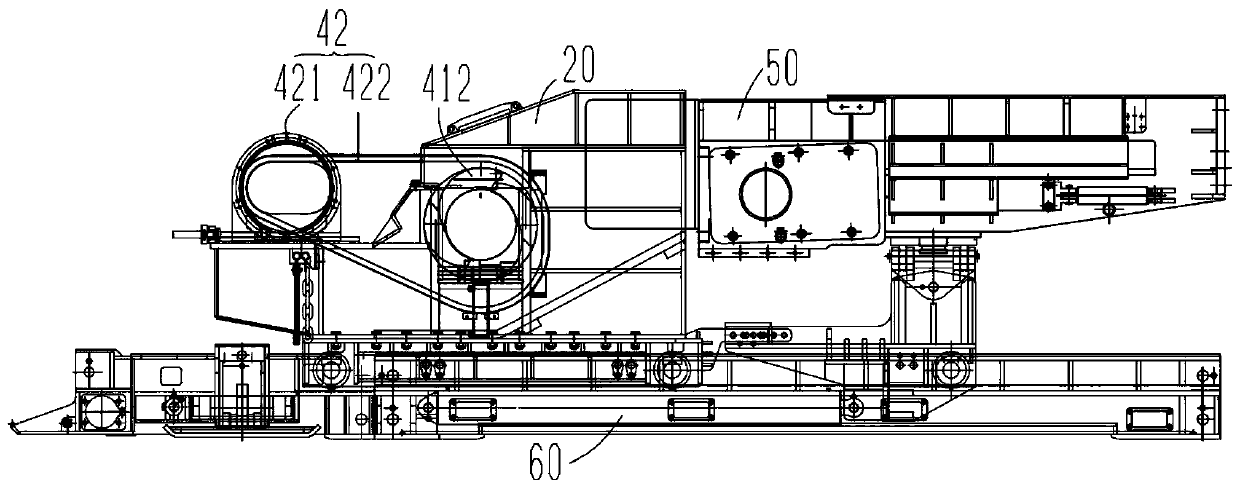

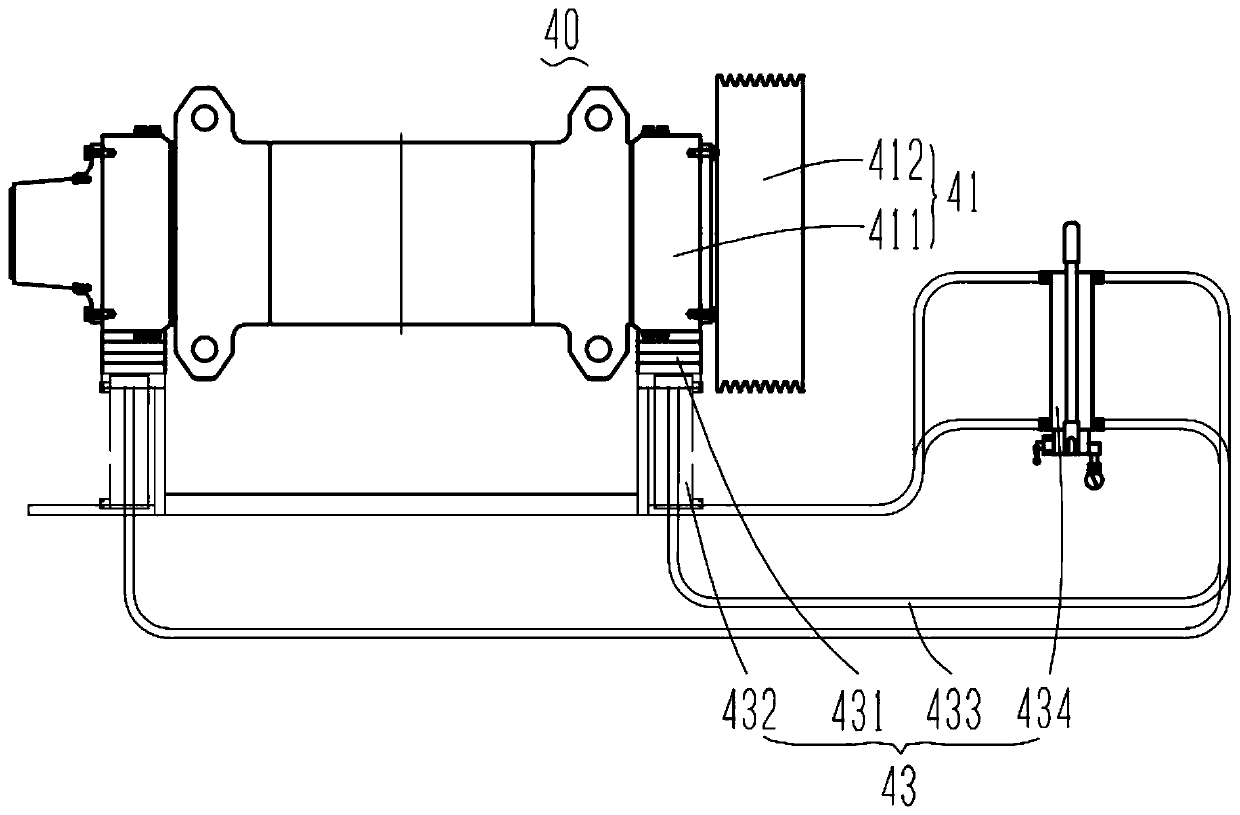

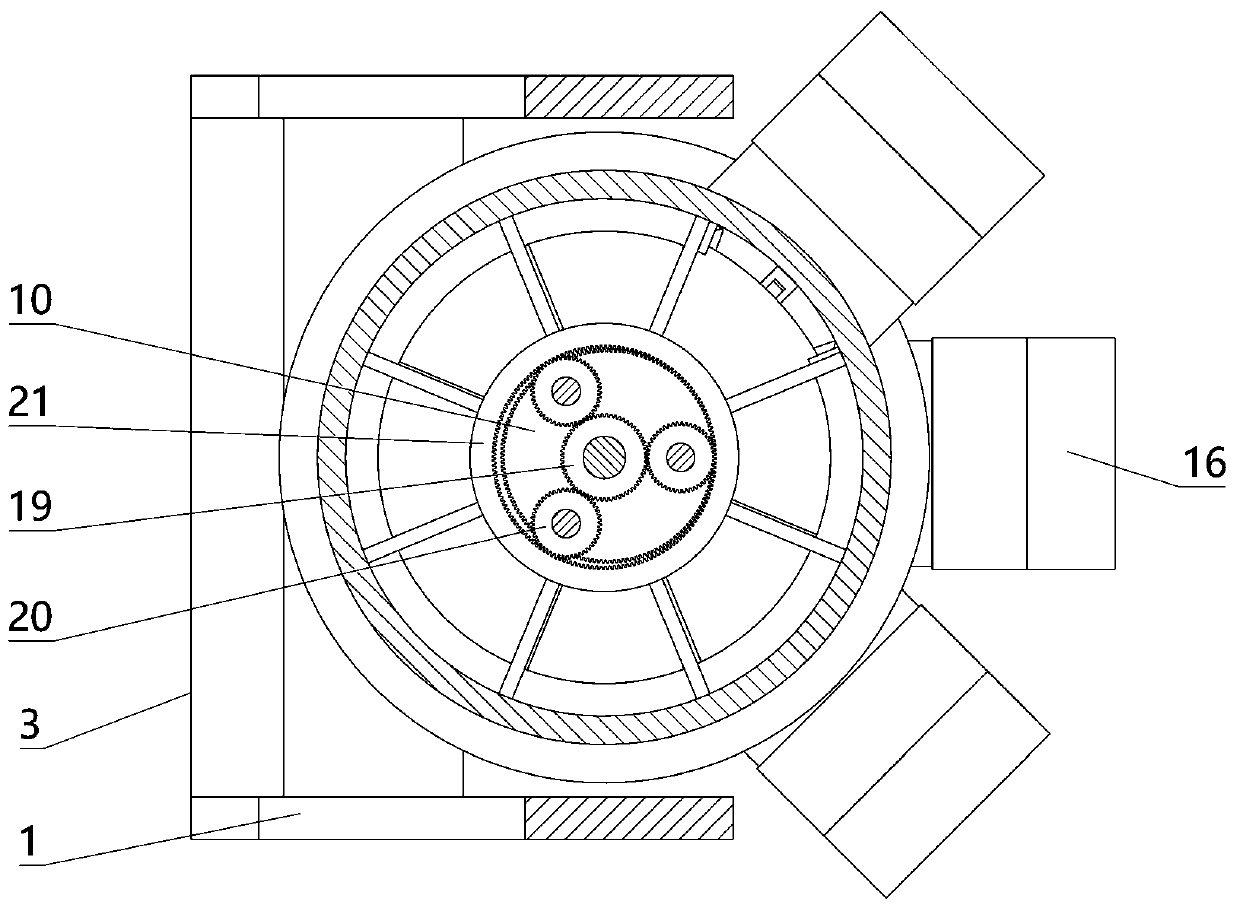

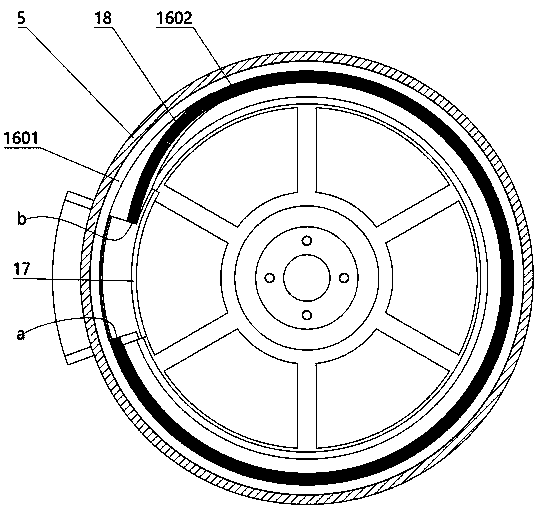

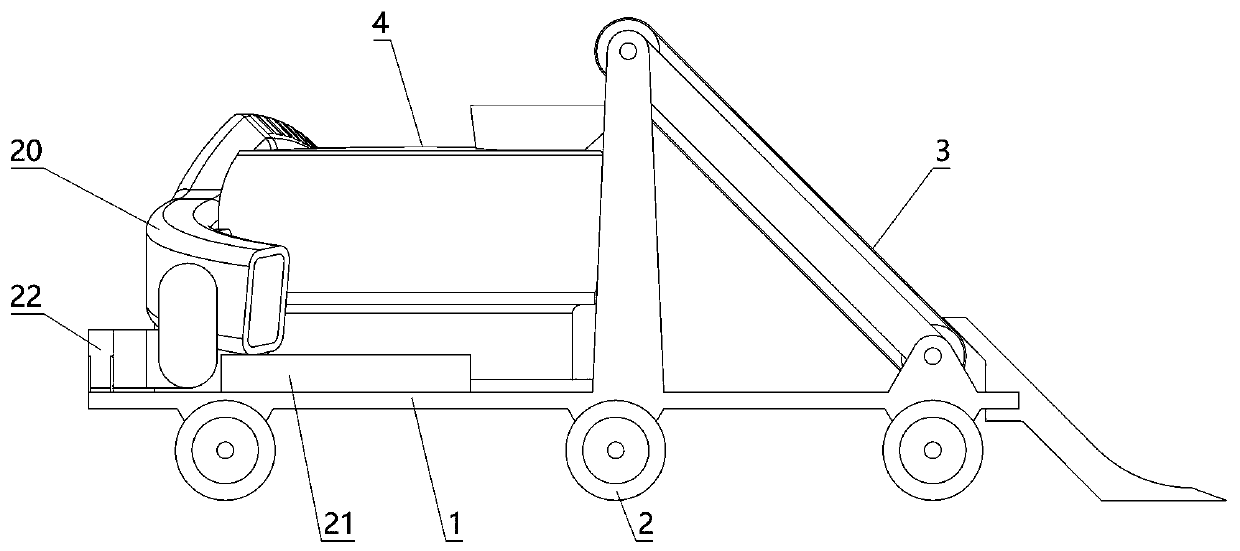

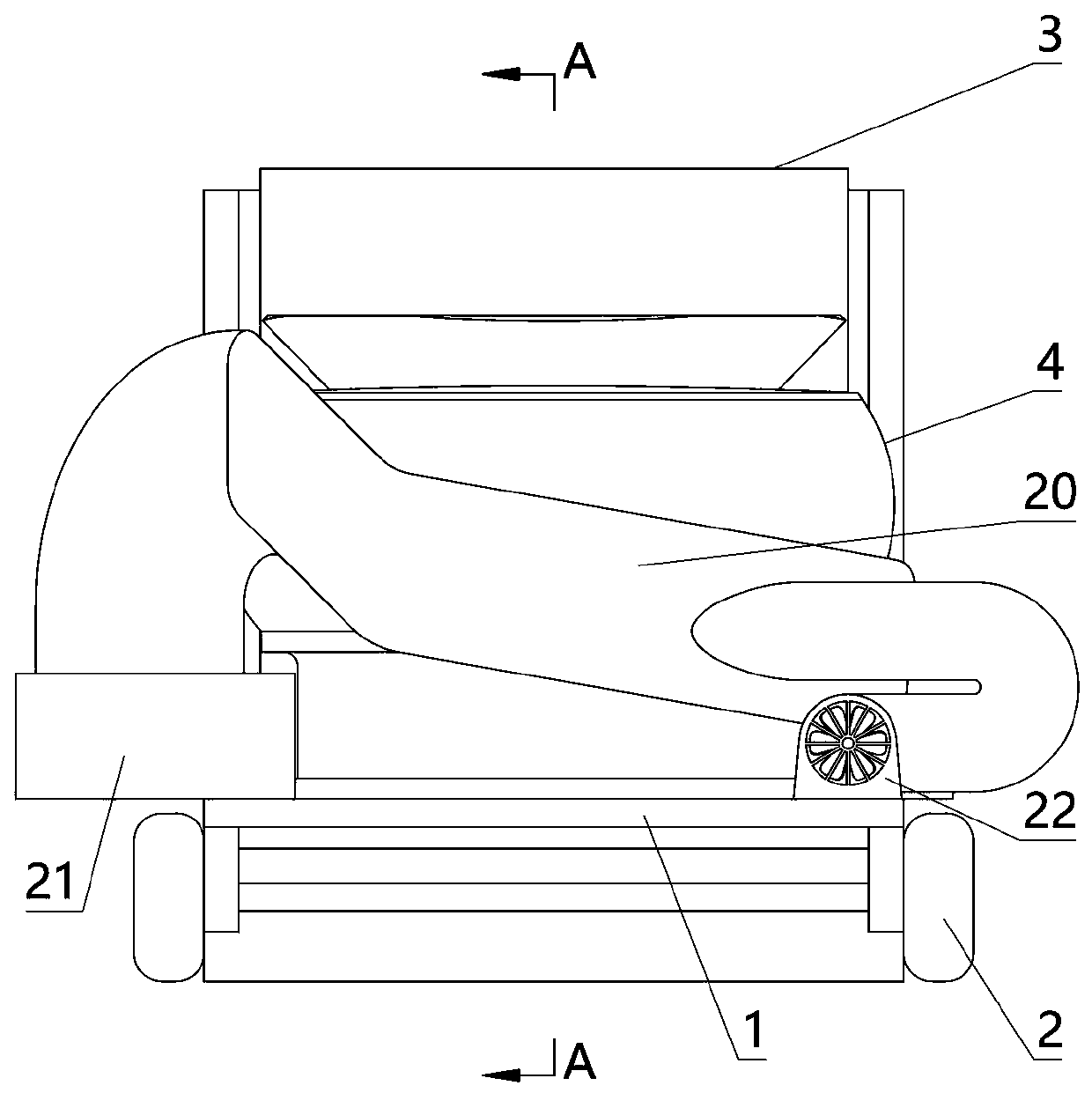

Hydraulic mechanical linkage environment-friendly vehicle for beach cleaning

ActiveCN110201879AFully filteredGood for shake offSievingConstructionsVehicle frameHydraulic machinery

The invention relates to a hydraulic mechanical linkage environment-friendly vehicle for beach cleaning. The hydraulic mechanical linkage environment-friendly vehicle comprises a frame, wheels, a feeding device and a screening device, wherein the screening device comprises a vertical cylinder body; a plurality of vertically distributed screen frames are arranged on the inner side of the cylinder body; the adjacent screen frames are connected through isolation columns; a motor is arranged on the cylinder body; the plurality of screen frames are sequentially connected with the motor through eccentric shaft sleeves; gears are coaxially arranged on the screen frames; gear rings which are coaxial with the motor are arranged on the cylinder body, and the gears are engaged with the gear rings; aplurality of horizontal screen hoppers are distributed on the screen frames in the circumference direction; guide rods which are arranged in the radial direction are hinged to the screen hoppers; thescreen hoppers are hinged to the screen frames, and hinge axes are perpendicular to axes of the screen frames and the guide rods; hinge axes of the guide rods and the screen hoppers are parallel to the hinge axes of the screen hoppers and the screen frames; guide grooves corresponding to the screen frames one by one are formed in the cylinder body; the outer end portions of the guide rods are arranged in the corresponding guide grooves in a sliding mode; a part of each guide groove is in an arc sinking shape; a discharging port is formed in the cylinder body; and a collecting bag is arranged at the discharging port. According to the hydraulic mechanical linkage environment-friendly vehicle, multi-stage deep filtering and classified screening are achieved.

Owner:王鸳

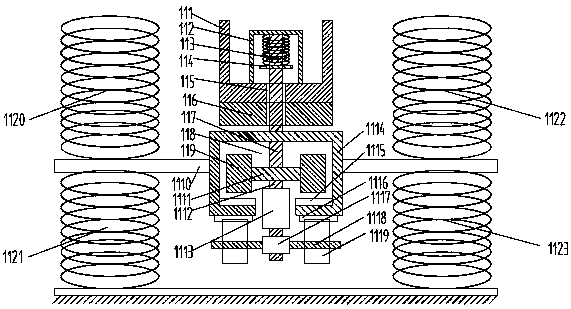

Metal powder granularity screening device for selective laser melting forming

PendingCN114054336AImprove screening efficiencyInhibit the phenomenon of sticking and cloggingSievingAdditive manufacturing apparatusSelective laser meltingVibration amplitude

The invention discloses a metal powder granularity screening device for selective laser melting forming, and belongs to the technical field of preparation of special equipment for screening metal powder for additive manufacturing. The problems that an arch bridge effect exists in the screening process of an existing metal powder screening device, fine powder easily blocks a screen, the powder screening efficiency is low, and the powder size grading effect is not obvious are solved. The device comprises a multi-layer screen, an ultrasonic conversion device, a rubber elastic vibration ball and the like. Target powder is screened out by adjusting the combined action of ultrasonic vibration and the vibrator, coarse and fine particles in metal powder are separated through ultrasonic vibration, the probability that fine powder is adhered and taken away by the coarse powder is reduced, meanwhile, the situation that the fine powder is blocked can be reduced through high-amplitude vibration of the vibrator, and the powder screening rate can be overall improved through vibration bounce of the elastic vibration ball; and fine screening work of the metal powder for additive manufacturing is achieved.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

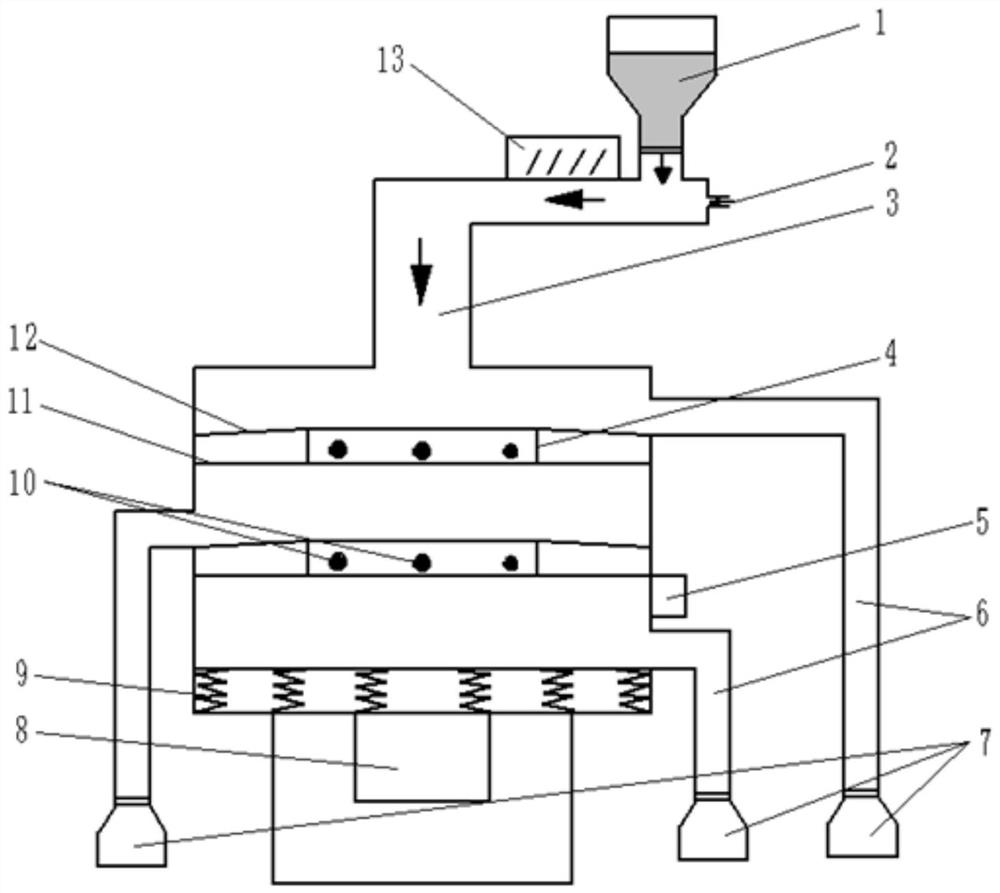

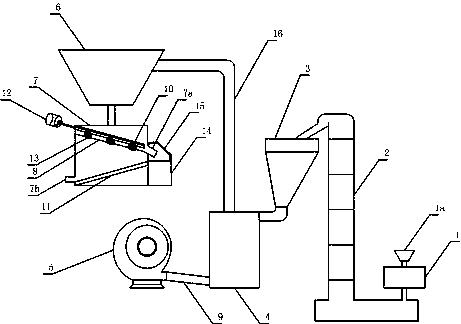

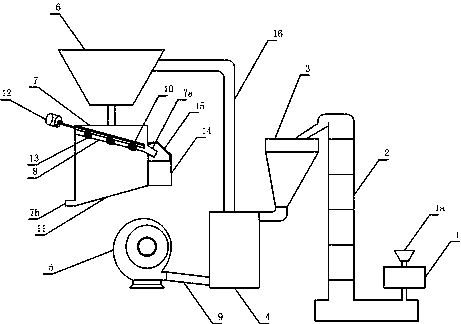

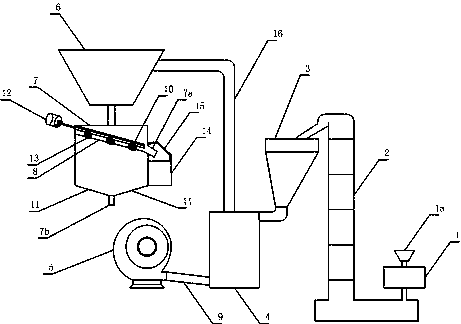

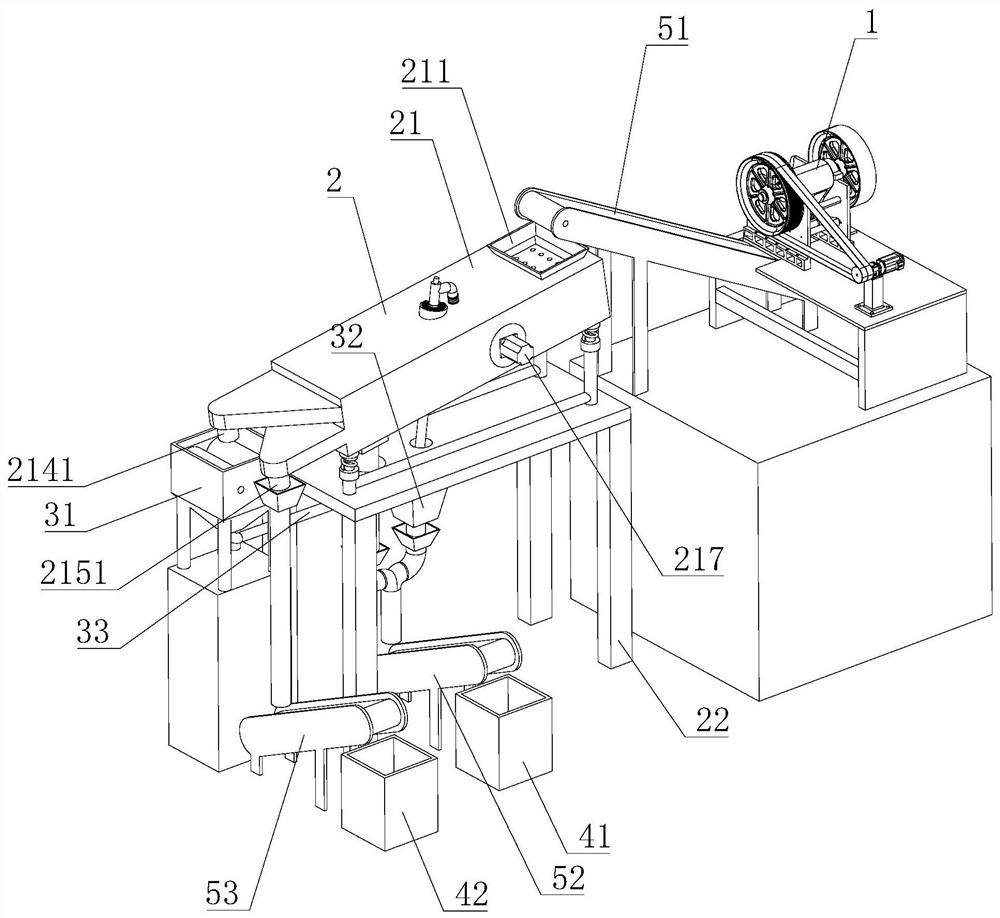

Pulverizing and screening and processing system for powder materials

The invention discloses a pulverizing and screening and processing system for powder materials. The pulverizing and screening and processing system comprises a crusher, a hoister, a pulverizer, a material box, an air blower, a hopper and a filling box, wherein the hoister is arranged between a discharge hole of the crusher and a feeding hole of the pulverizer; the pulverizer, the material box, thehopper and the filling box are connected in sequence; an air supply pipe is arranged between the material box and the air blower; the filling box is provided with a coarse material discharge hole anda fine material discharge hole; a vibrating screen is slantwise arranged in the filling box, inclines towards the coarse material discharge hole and extends to the coarse material discharge hole; thevibrating screen is connected to a driving device for driving the vibrating screen to vibrate; at least one material guide plate is arranged below the vibrating screen; and the material guide plate inclines towards the fine material discharge hole and extends to the fine material discharge hole. According to the technical scheme provided by the invention, the inclined arrangement of the vibratingscreen and the material guide plate enables the powder materials to be fully screened, and facilitates the smooth discharge of the fine materials.

Owner:HUANGSHI JINZHAOYANG POWDER MATERIALS

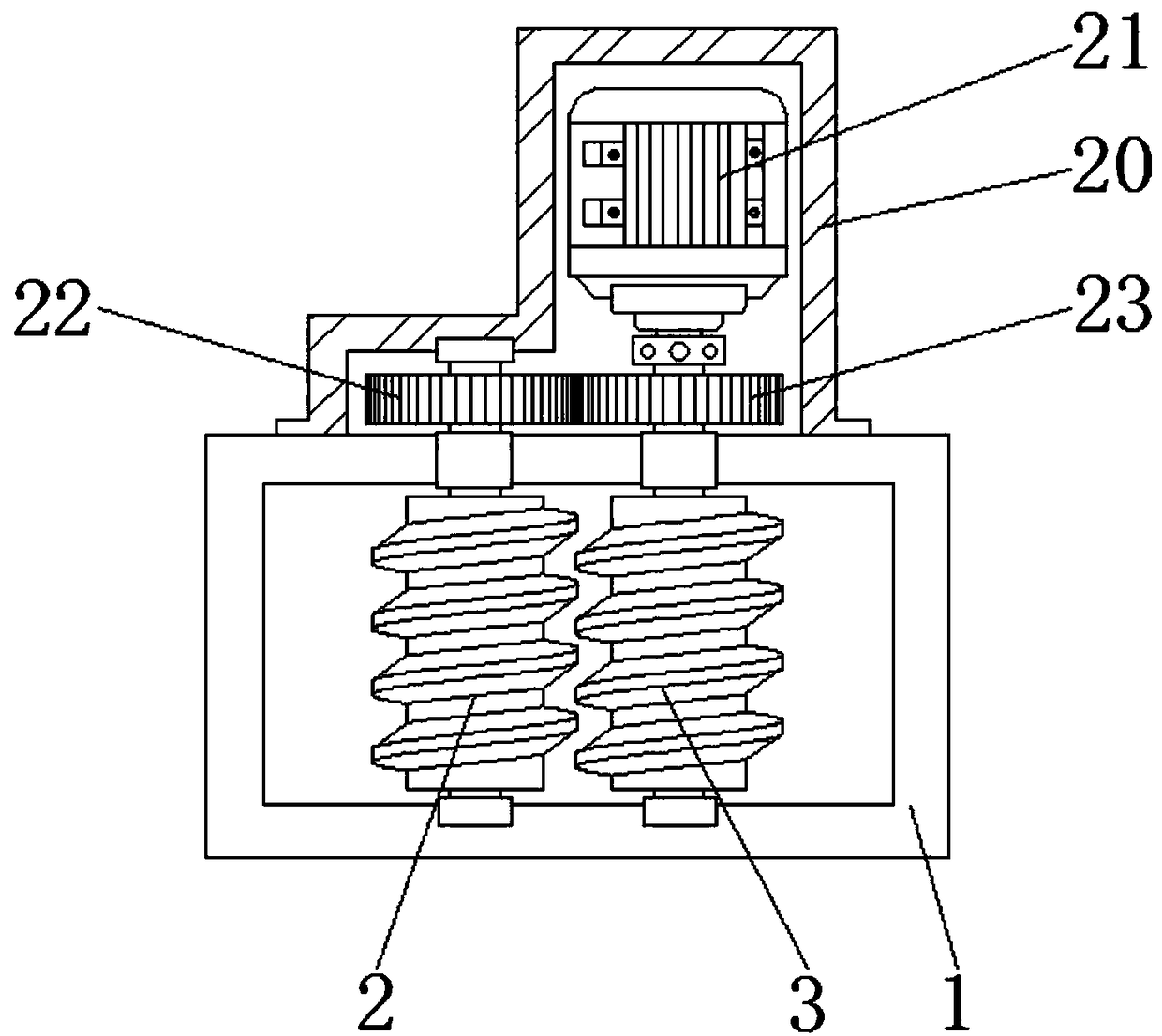

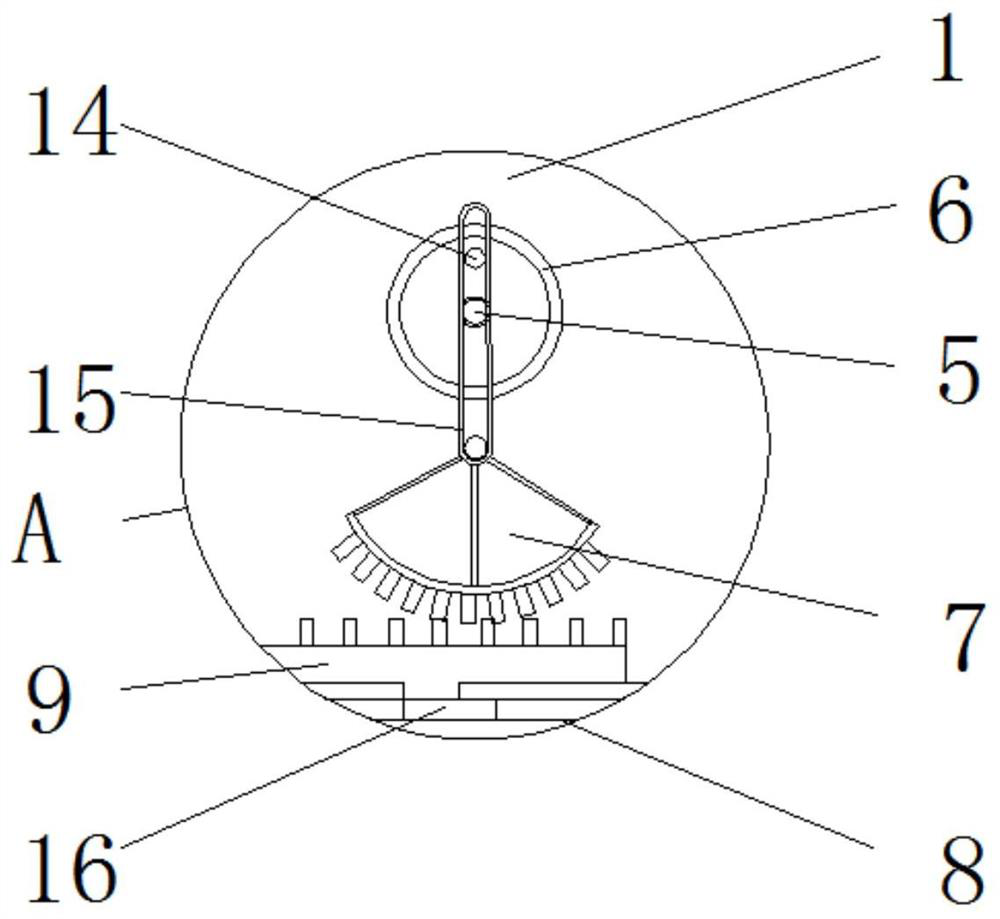

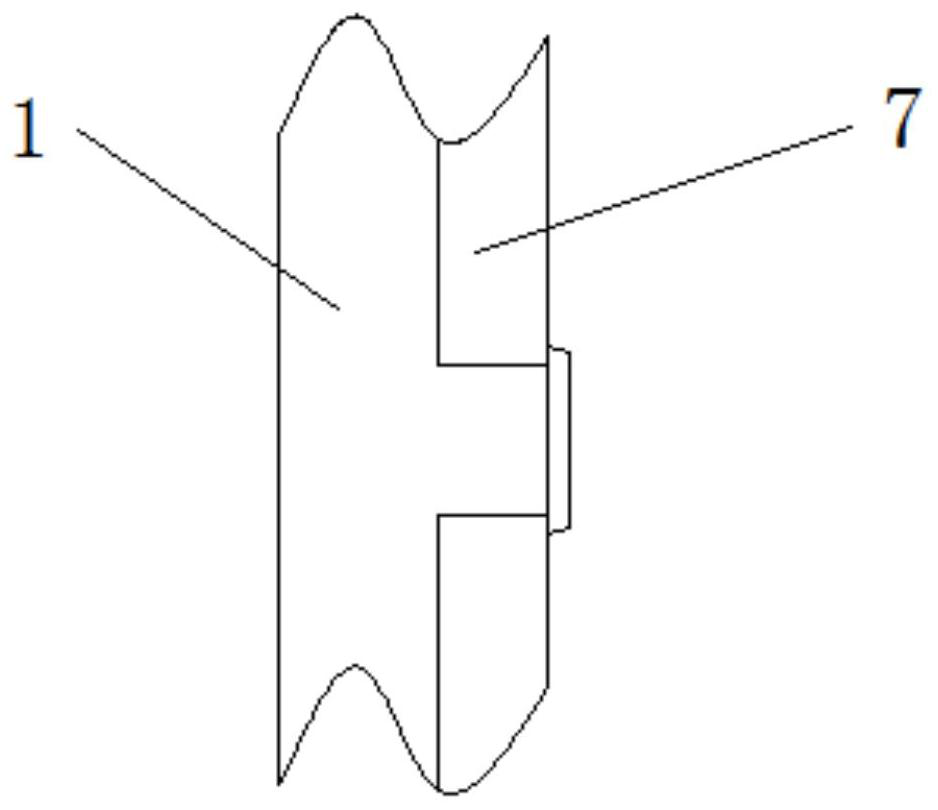

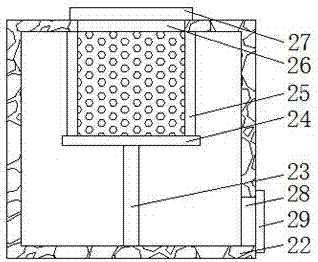

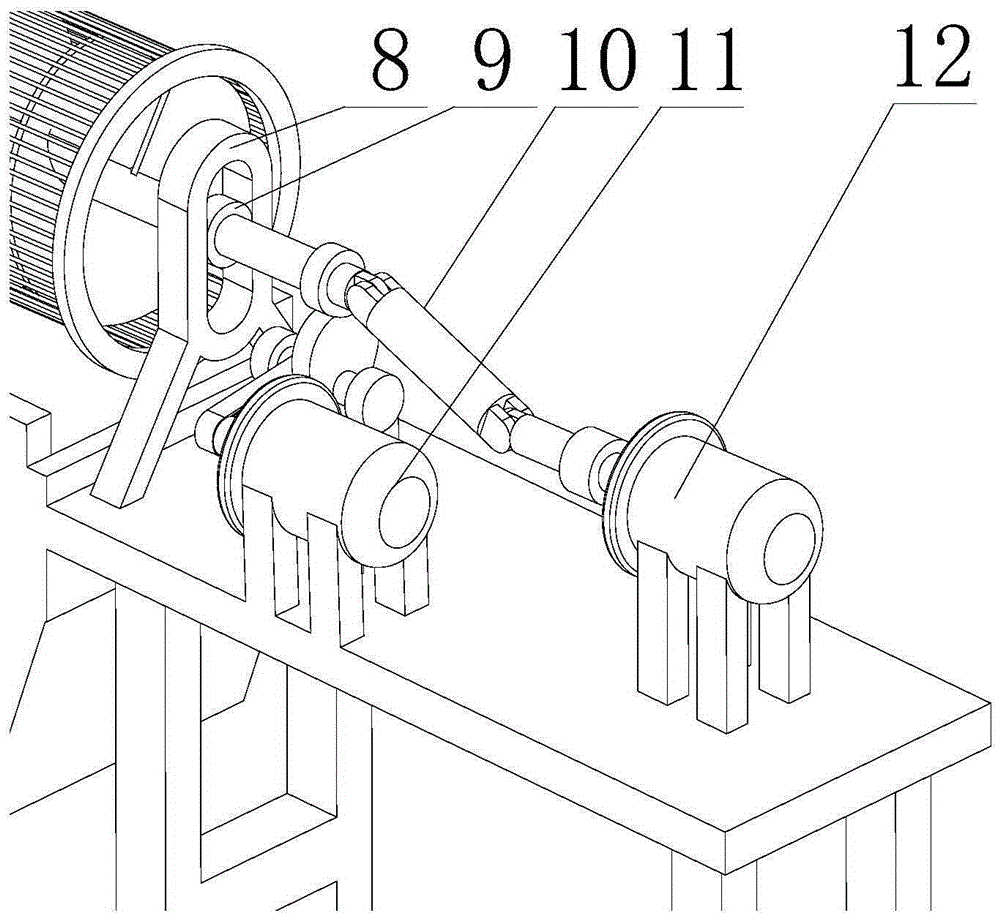

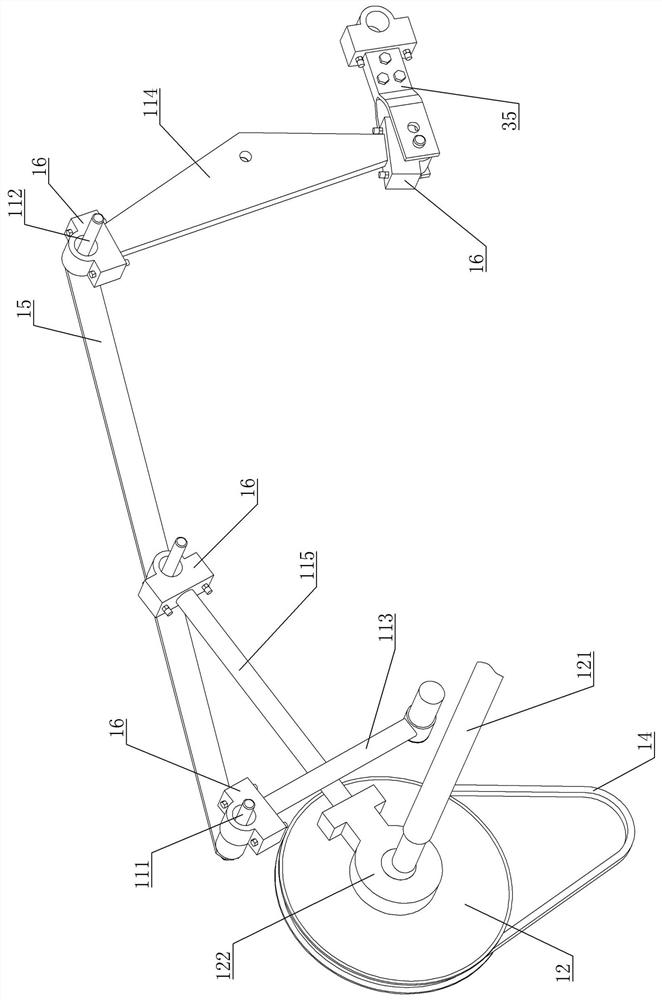

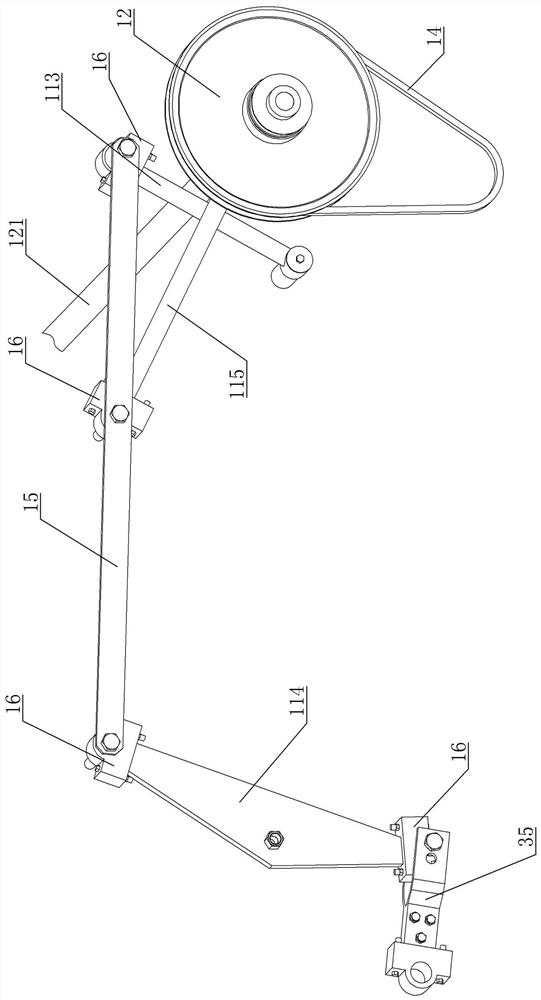

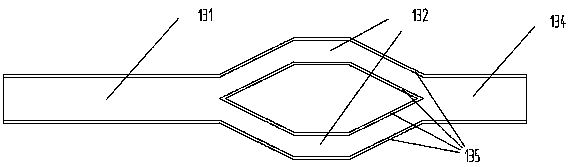

Pendulum type impurity removing and screening mechanism for fused quartz processing

InactiveCN112807814AExtend sieving timeImprove work efficiencyMoving filtering element filtersGear wheelElectric machinery

The invention discloses a pendulum type impurity removing and screening mechanism for fused quartz processing. The mechanism comprises a base body, a motor, a sector gear, a gear strip and a conveying belt; an anti-collision strip is fixedly installed in the base body; a movable tank is hung in the base body through a chain; the motor is fixedly installed at the bottom of the base body; a rubber ball is fixedly connected to the upper portion of the gear strip; the sector gear is fixedly installed at the bottom end of a movable frame; the lower portion of the sector gear is meshed with the gear strip; and a sliding block is fixedly connected to the lower portion of the gear strip. With the pendulum type impurity removing and screening mechanism for fused quartz processing, the discharging speed and quantity are increased, and the work efficiency can be improved; two layers of filter screens with different densities are arranged in the movable tank, and the whole movable tank can undergo pendulum motion due to collision of the rubber ball at the bottom of the base body, thus, through combination of the two layers of filter screens and the rubber ball,the screening speed is increased, and the screening precision is improved.

Owner:熊健

Choiceness device used for soybean processing

InactiveCN107952653AIncrease collection speedReduce sieving timeSievingScreeningEngineeringUltimate tensile strength

The invention discloses a sorting device for soybean processing, comprising a base plate, two support blocks are arranged on the left side of the upper surface of the base plate, and the upper surfaces of the two support blocks are fixedly connected with the lower surface of a first rotating device , and the upper surfaces of the two first rotating devices are fixedly connected with the lower surface of the second rotating device through electric push rods, and the upper surface of the second rotating device is fixedly connected with the lower surface of the slider through a fixed plate, and the sliding The block is arranged in the chute provided on the lower surface of the first support plate. The bean processing device is equipped with an electric push rod, a slider, a chute, a first support plate, a motor, a belt, a second bearing and a net cylinder, so that workers can collect the soybeans required in the net cylinder. Thereby reducing the work intensity of the workers, saving the physical strength of the workers, improving the workers' collection speed of soybeans, saving the workers' screening time of soybeans, and improving the work efficiency of the workers.

Owner:WUXI SUYA FOOD CO LTD

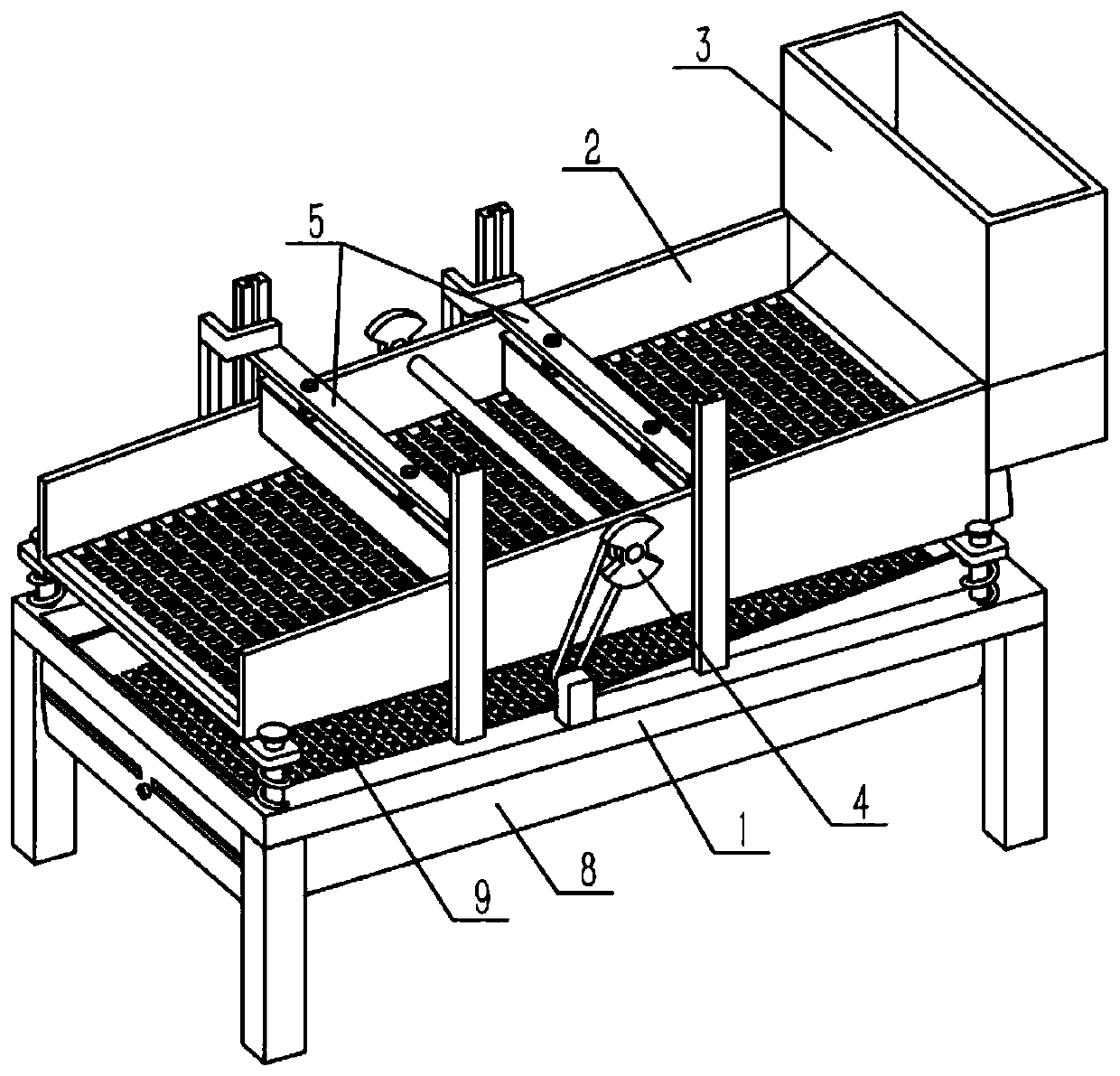

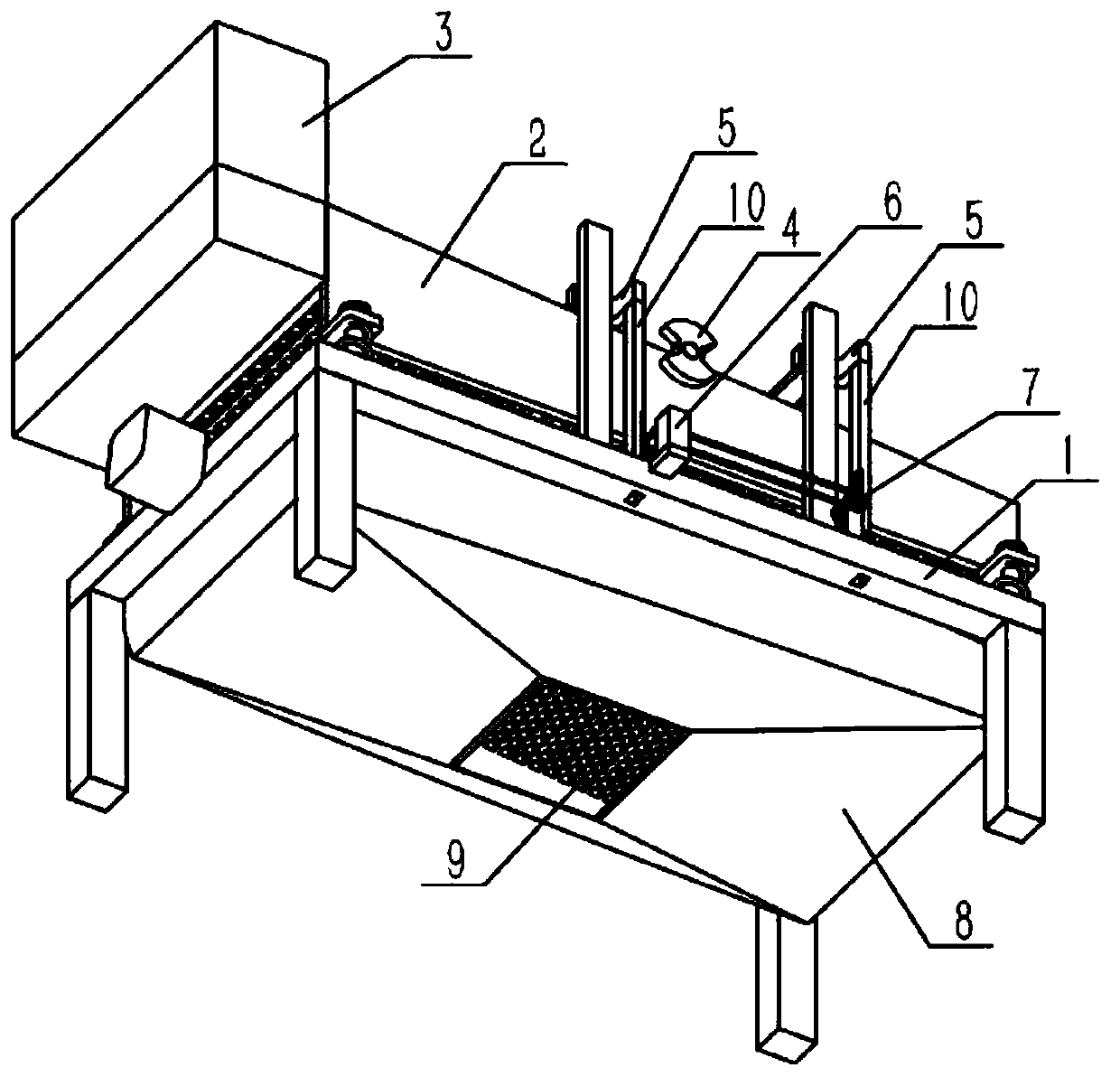

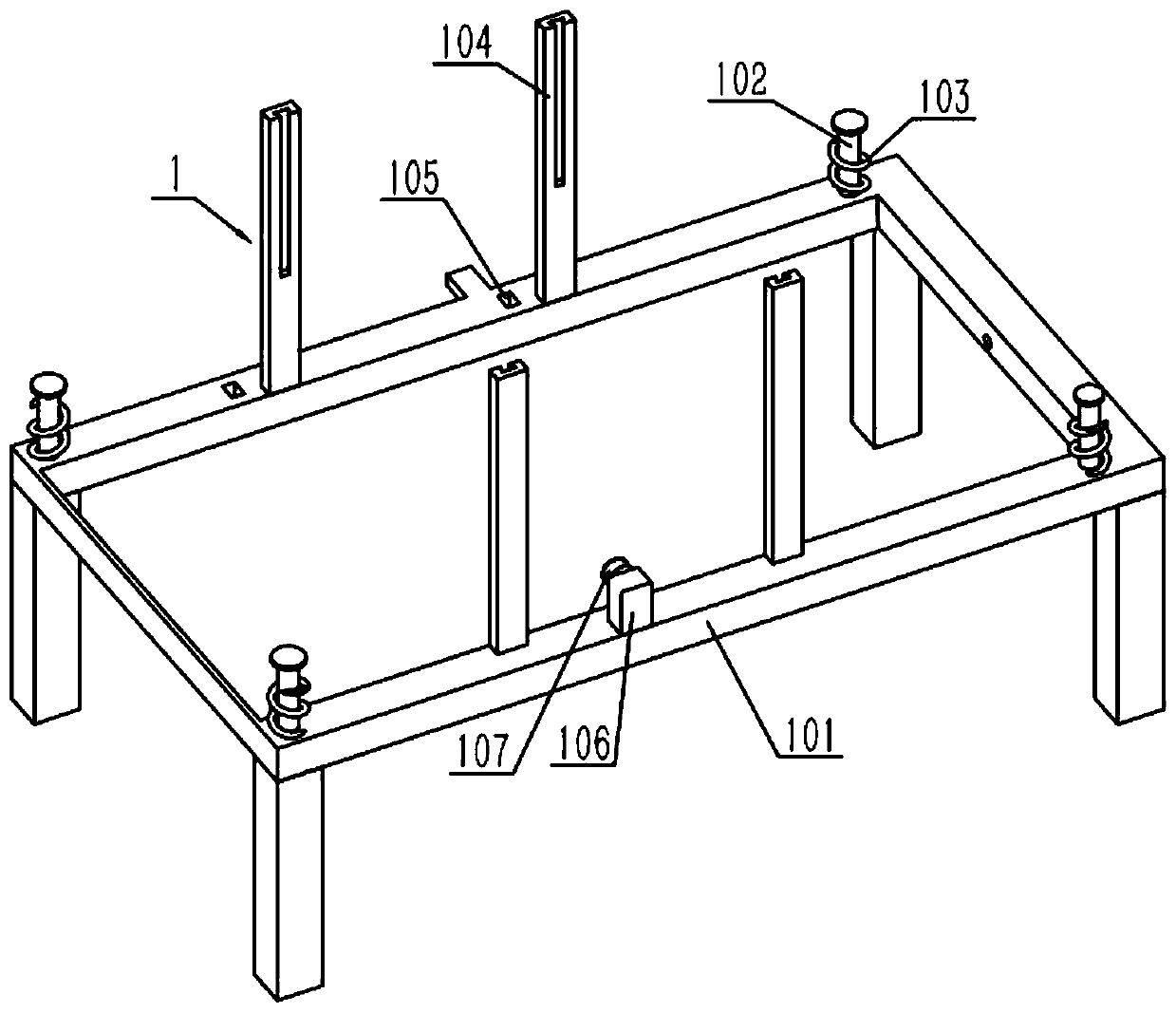

A vibrating drum screening machine

The invention discloses a vibrating drum screening machine capable of sorting for multiple times. A frame is provided with a vibrating rotating shaft; a helical blade is fixed to the vibrating rotating shaft; the outer side of the helical blade is fixedly connected with a rotary screen; one end of the vibrating rotating shaft is arranged on the frame and can rotate around the frame; the other end of the vibrating rotating shaft is provided with a vibrating translation bearing and a vibrating transmission bearing; the vibrating translation bearing is arranged in a vibrating restraining support and is used for limiting the vibrating rotating shaft to vertically move only; the frame is provided with a vibrating motor and a rotating motor; the output shaft of the vibrating motor is provided with a shaft of a cam through belt connection; the vibrating transmission bearing is arranged on the top of the cam; the vibrating rotating shaft is connected with the output shaft of the rotating motor through a universal coupling. When the vibrating drum screening machine is used for screening goods, the vibrating frequency and the rotation speed of a drum can be freely adjusted, the screening efficiency is improved, and the vibrating drum screening machine is safe, reliable and convenient to operate.

Owner:GUANGXI UNIV

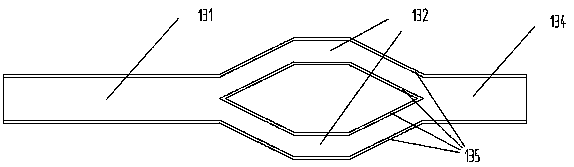

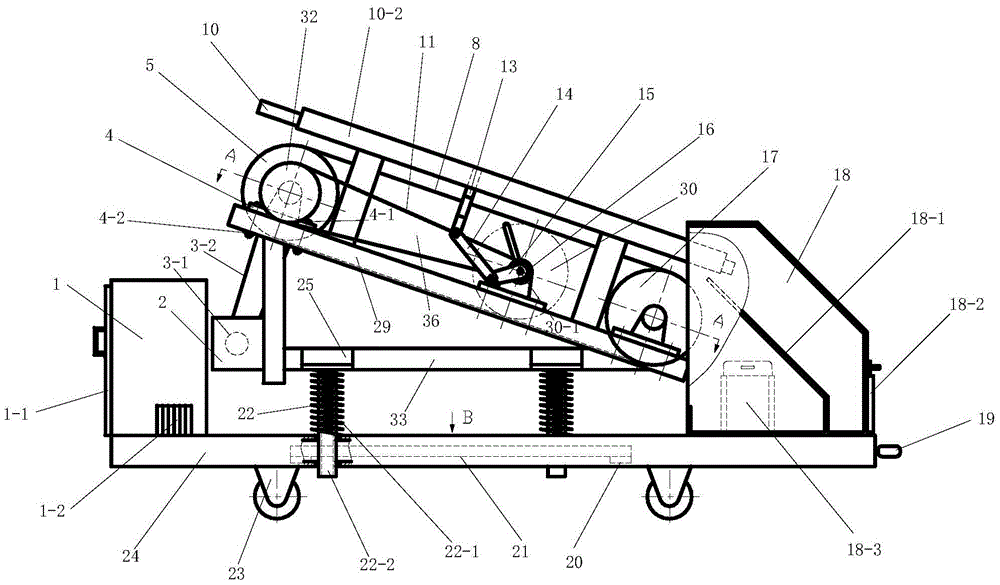

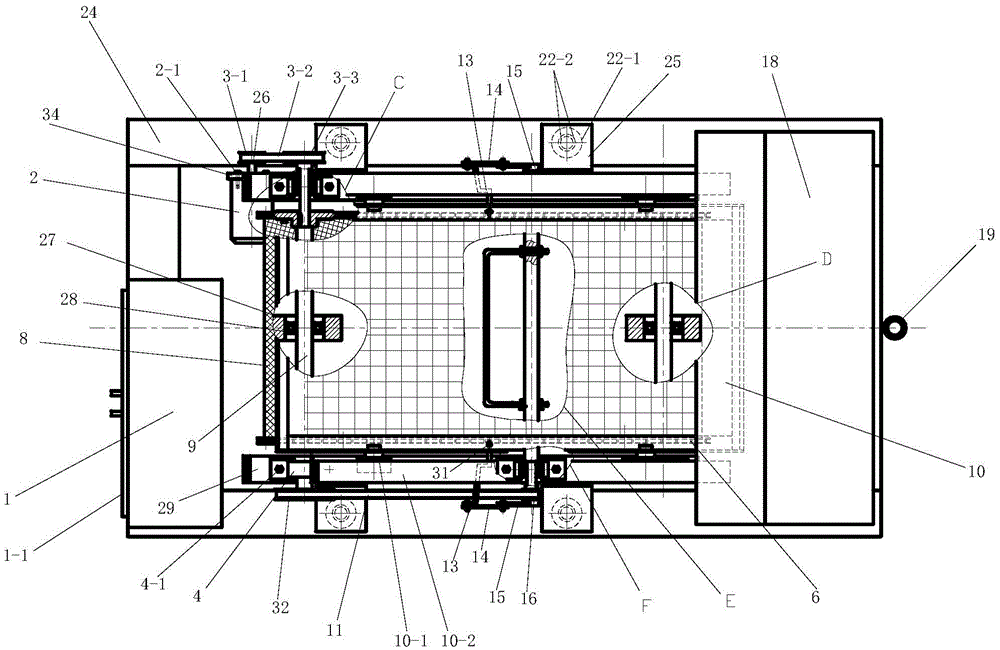

Movable screening and breaking integrated machine for underground coal mine road

PendingCN111013736ARealize broken integrationAvoid the situation of being broken againSievingScreeningCoal briquetteMining engineering

The invention provides a movable screening and breaking integrated machine for an underground coal mine road, and relates to the technical field of underground coal mine equipment. The movable screening and breaking integrated machine is arranged at the position of a reversed loader head and located on the upper portion of a conveying belt of a belt conveyor. The movable screening and breaking integrated machine comprises a road body, a screening device and a breaking device. The screening device and the breaking device are arranged in one device, coal briquettes entering the road body from the reversed loader head are screened by the screening device firstly, small coal briquettes penetrate through the screening device to fall onto the conveying belt of the belt conveyor, large coal briquettes slide to the position making contact with the breaking device along the screening device to be broken by the breaking device, sequential screening and breaking are achieved, the situation that the small coal briquettes are broken again is avoided, a part of distance is reserved at the screening position of the screening device, the screening time of the coal briquettes is prolonged, the coalbriquettes are conveniently screened, the large coal briquettes incapable of penetrating through the screening device make contact with the breaking device to be broken, screening and breaking are integrated, no procedures are added, and therefore the production efficiency is relatively improved.

Owner:NINGXIA TIANDI BENNIU IND GRP +1

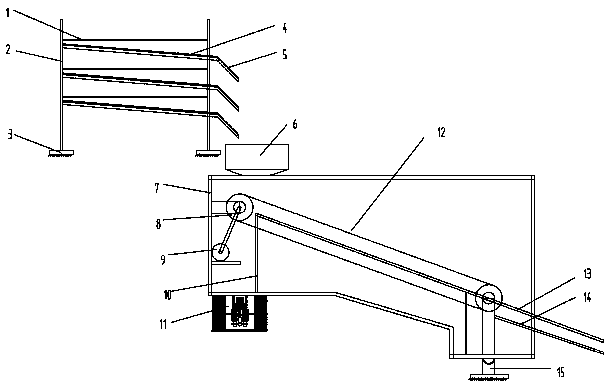

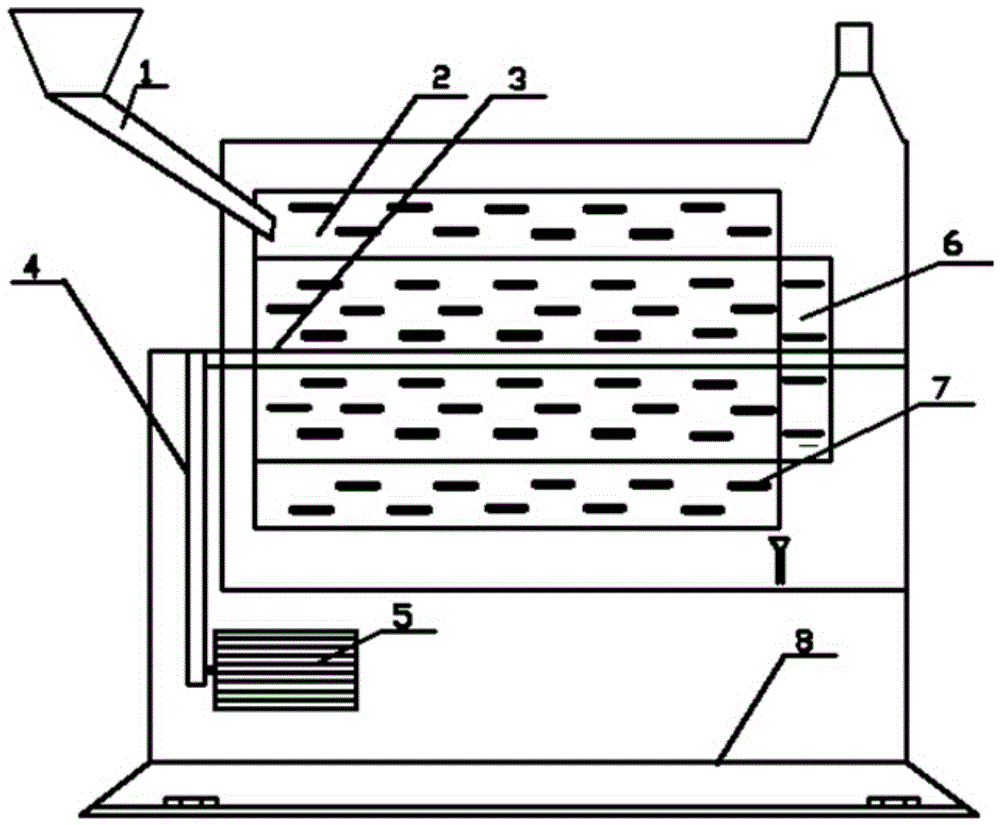

A kind of solid mixture multi-layer vibrating physical screening machine

InactiveCN104028452BSimple structureReasonable designSievingScreeningVehicle frameReciprocating motion

The invention discloses a solid mixture multilayer vibration physics screening machine. The solid mixture multilayer vibration physics screening machine comprises sliding screen nets installed on a car frame and a machine frame and a double layer circling screening device, wherein the double layer circling screening device is obliquely installed on a sliding guide rail of the machine frame and can perform straight reciprocating motion along the sliding guide rail of the machine frame, a beating mechanism is located between two layers of screen nets of the double layer circling screening device, a beating rod on a rotation shaft of the beating mechanism performs auxiliary beat on a vibrating screen net so as to achieve efficient and rapid penetration screening, the car frame is located at the bottom of the solid mixture multilayer vibration physics screening machine, the machine frame is installed on the car frame on the lower portion of the solid mixture multilayer vibration physics screening machine through a shock absorption mechanism, a material receiving disc is located below the double layer circling screening device and installed on the car frame, a material receiving box is installed and fixed on a portion of the car frame, located in front of the solid mixture multilayer vibration physics screening machine, the material receiving box is divided into storage compartments of different grain diameters of materials through material guide dummy plates, and the different storage compartments are respectively provided with different unloading doors. The solid mixture multilayer vibration physics screening machine can effectively screen solid mixture materials, achieves physics screening on the solid mixture materials according to the different grain diameters, and is high in efficiency, low in labor intensity, low in cost, and wide in application range.

Owner:CHANGAN UNIV

A capsule precision screening device

InactiveCN106111525BRealize automatic screening functionImprove screening effectSievingScreeningEngineering

The invention relates to a precise capsule screening device. The precise capsule screening device comprises a screening support plate; a screening frame is mounted at the middle part of the screening support plate; two pairs of fixed lugs are symmetrically arranged on the upper end surface of the screening frame; rotating lugs are mounted between the two pairs of fixed lugs through pin shafts; two rotating lugs between the two pairs of fixed lugs are symmetrically arranged at the middle part of the lower end surface of a screening box; the screening frame can rotate on two pairs of fixed lugs through the two rotating lugs; four limiting branch chains are respectively mounted between two sides of the screening box and two side walls of the screening frame; and when the screening box continuously rotates up and down, the four limiting branch chains symmetrically distributed on two sides of the screening box achieve an excellent limiting effect, so that the screening box is helped to quickly recover to the middle position, and the up-down rotating amplitude of the screening box is limited. The precise capsule screening device can realize an automatic screening function of unqualified capsules.

Owner:XUCHANG UNIV

Sulphuric acid cCatalyst screening method

InactiveCN101391755BReduce energy consumptionImprove efficiencySulfur-trioxide/sulfuric-acidPhysical well beingEconomic benefits

Owner:云南云天化股份有限公司三环分公司 +1

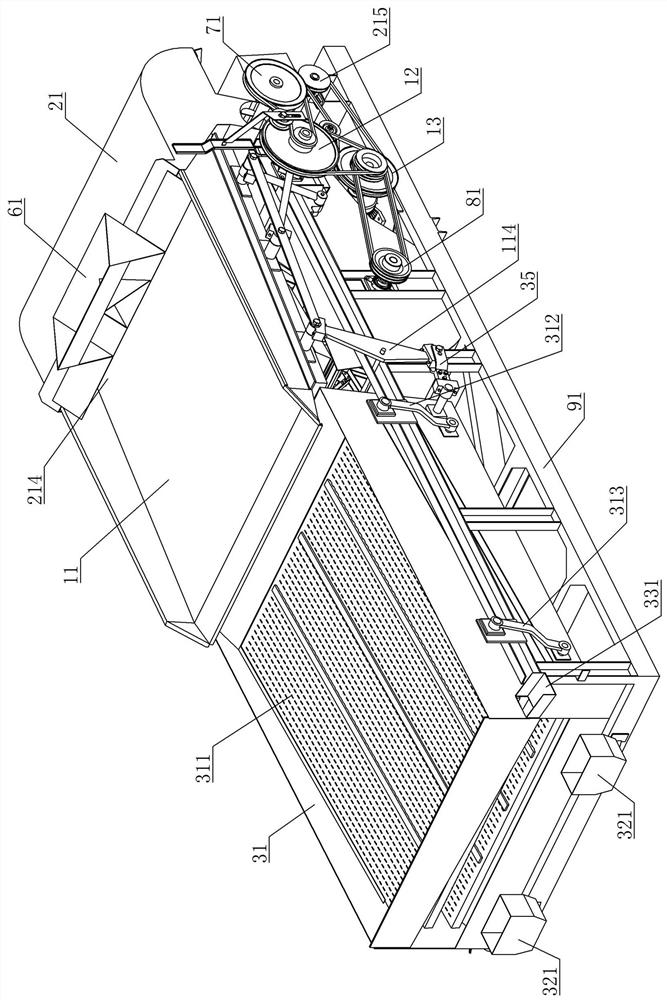

Novel sesame harvester screening device

ActiveCN112474355AImprove screening effectSieve cleanSievingGas current separationAgricultural engineeringEngineering

The invention relates to a novel sesame harvester screening device. According to the novel sesame harvester screening device, sesame seeds are primarily screened through a vibration type winnowing assembly, fan blades in a fan cover generate wind power and blow air to the tail part of a winnowing vibration hopper through an air blowing opening in the upper part, and light straw entering the winnowing vibration hopper from a conical feeding hopper is blown away; a belt wheel A drives a rotating shaft to rotate through a belt wheel B, the rotating shaft continuously pushes and pulls the winnowing vibration hopper through an eccentric wheel and a driving connecting rod, the winnowing vibration hopper shakes front and back at the front end of a rack through a connecting rods hinged to the twoends, and the screening effect of front-back shaking during winnowing is better; and the winnowing vibration hopper shakes to continuously push and pull a screening shell through the lower part of a connecting rod A, the screening shell shakes front and back at the rear end of the rack through the connecting rod, and the multiple layers of screening plates screen out straw with heavy mass step bystep. Sesame mingled with the straw is screened step by step through vibration winnowing and vibration screening, the screening process is finer, screening is through, and the overall screening efficiency is improved.

Owner:HENAN SESAME RES CENT HENAN ACADEMY OF AGRI SCI

Hydro-mechanical linkage environmental protection vehicle for beach cleaning

The invention relates to a hydraulic mechanical linkage environment-friendly vehicle for beach cleaning. The hydraulic mechanical linkage environment-friendly vehicle comprises a frame, wheels, a feeding device and a screening device, wherein the screening device comprises a vertical cylinder body; a plurality of vertically distributed screen frames are arranged on the inner side of the cylinder body; the adjacent screen frames are connected through isolation columns; a motor is arranged on the cylinder body; the plurality of screen frames are sequentially connected with the motor through eccentric shaft sleeves; gears are coaxially arranged on the screen frames; gear rings which are coaxial with the motor are arranged on the cylinder body, and the gears are engaged with the gear rings; aplurality of horizontal screen hoppers are distributed on the screen frames in the circumference direction; guide rods which are arranged in the radial direction are hinged to the screen hoppers; thescreen hoppers are hinged to the screen frames, and hinge axes are perpendicular to axes of the screen frames and the guide rods; hinge axes of the guide rods and the screen hoppers are parallel to the hinge axes of the screen hoppers and the screen frames; guide grooves corresponding to the screen frames one by one are formed in the cylinder body; the outer end portions of the guide rods are arranged in the corresponding guide grooves in a sliding mode; a part of each guide groove is in an arc sinking shape; a discharging port is formed in the cylinder body; and a collecting bag is arranged at the discharging port. According to the hydraulic mechanical linkage environment-friendly vehicle, multi-stage deep filtering and classified screening are achieved.

Owner:王鸳

Sesame harvester screening device

ActiveCN112474355BImprove screening effectSieve cleanSievingGas current separationAgricultural engineeringPrimary screening

The invention relates to a screening device for a sesame harvester. The screening device conducts primary screening of sesame seeds through a vibrating winnowing assembly, and the fan blades in the fan housing generate wind force and blow air to the tail of the winnowing vibrating bucket through the blowing port on the upper part. , the lighter straw that enters the winnowing vibrating bucket from the conical feed hopper is blown away, and the pulley A drives the rotating shaft through the pulley B, and the rotating shaft passes through the eccentric wheel and the driving connecting rod A and driving connecting rod B to continuously push and pull the winnowing vibration The air selection vibrating bucket shakes back and forth at the front end of the frame through the connecting rods hinged at both ends, and the screening effect is better when the air selection is accompanied by the front and rear shaking; body, the screening shell shakes back and forth at the rear end of the frame through the connecting rod, and the multi-layer screening plate screens out the heavier straws step by step; Step by step screening, the screening process is more refined and cleaner, which improves the overall screening efficiency.

Owner:HENAN SESAME RES CENT HENAN ACADEMY OF AGRI SCI

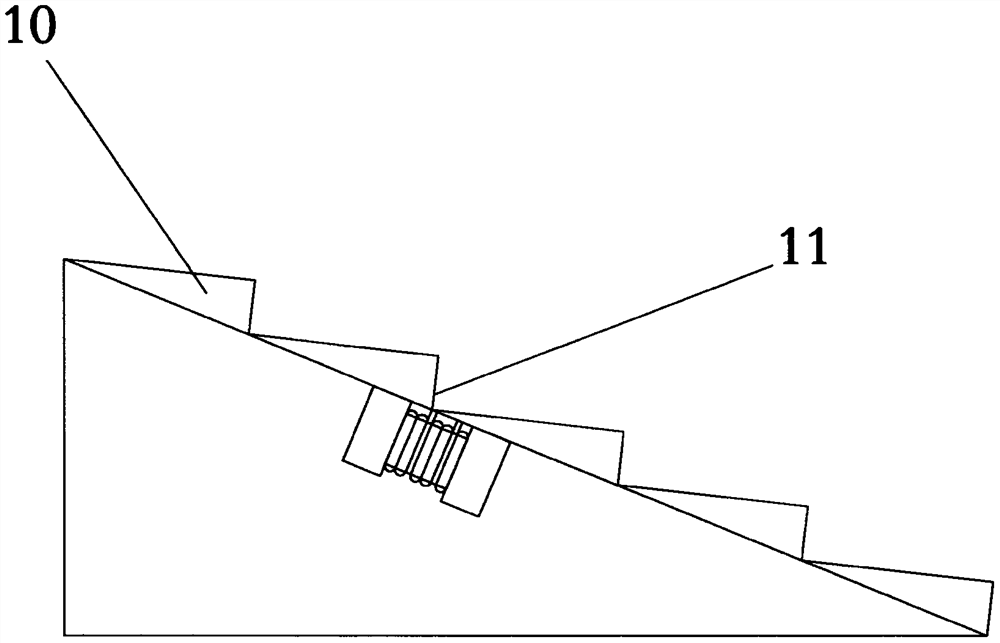

Screen on ball pressing machine

InactiveCN111974675ASimple structureEasy to implementSievingScreeningMechanical engineeringIndustrial engineering

The invention provides a screen on a ball pressing machine. The ball pressing machine is arranged in a sloped manner; the screen is step-shaped; and steps of the screen are vertically arranged. The screen on the ball pressing machine has the advantaged of simple structure, convenience for operation, completeness in screening, improved product quality and yield and the like.

Owner:JIANGSU DAFENG PORT HESHUN TECH CO LTD

A method of raw coal transportation

ActiveCN107555195BEasy to installExtend sieving timeLoading/unloadingJigging conveyorsEnvironmental engineeringConveyor belt

Sundry screens are arranged through supports, holes are formed in the sundry screens, slide way grooves are formed under the holes, raw coal is conveniently collected, the raw coal which is separatedout can be further subjected to washing processing to be used as fuel, the pollution degree of the environment is decreased, the effect of the fuel is better brought into play, and waste utilization for shaft backfilling and the like can also be achieved for sundries. By means of the arrangement, the structure is simple and efficient. By means of the invention, reverse operation is achieved whilescreening is conducted through a conveyor belt so that the screening time can be prolonged; separation processing can be effectively conducted for the raw coal, the raw coal which is separated out canbe collected after being conveyed, and therefore the separation and utilization efficiency of the raw coal is effectively improved, pollution and waste caused by the raw coal are reduced, the whole device is convenient to use and high in utilization rate, and the labor intensity is lowered.

Owner:准格尔旗昶旭煤炭有限责任公司

A raw coal conveying device

ActiveCN107352283BEasy to installExtend sieving timeConveyorsSupporting framesProcess engineeringCoal

Owner:JIANGSU MEIKE ELECTROMECHANICAL EQUIP MFG

All-in-one filter and screening unit for beach cleaning

ActiveCN110170450BEasy to handleFully filteredGas current separationWaste processingVehicle frameGear wheel

Owner:无锡英倍思机械有限公司

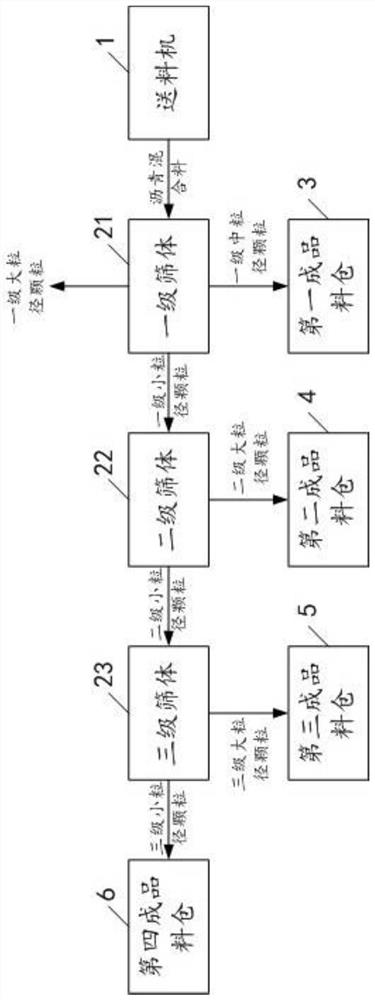

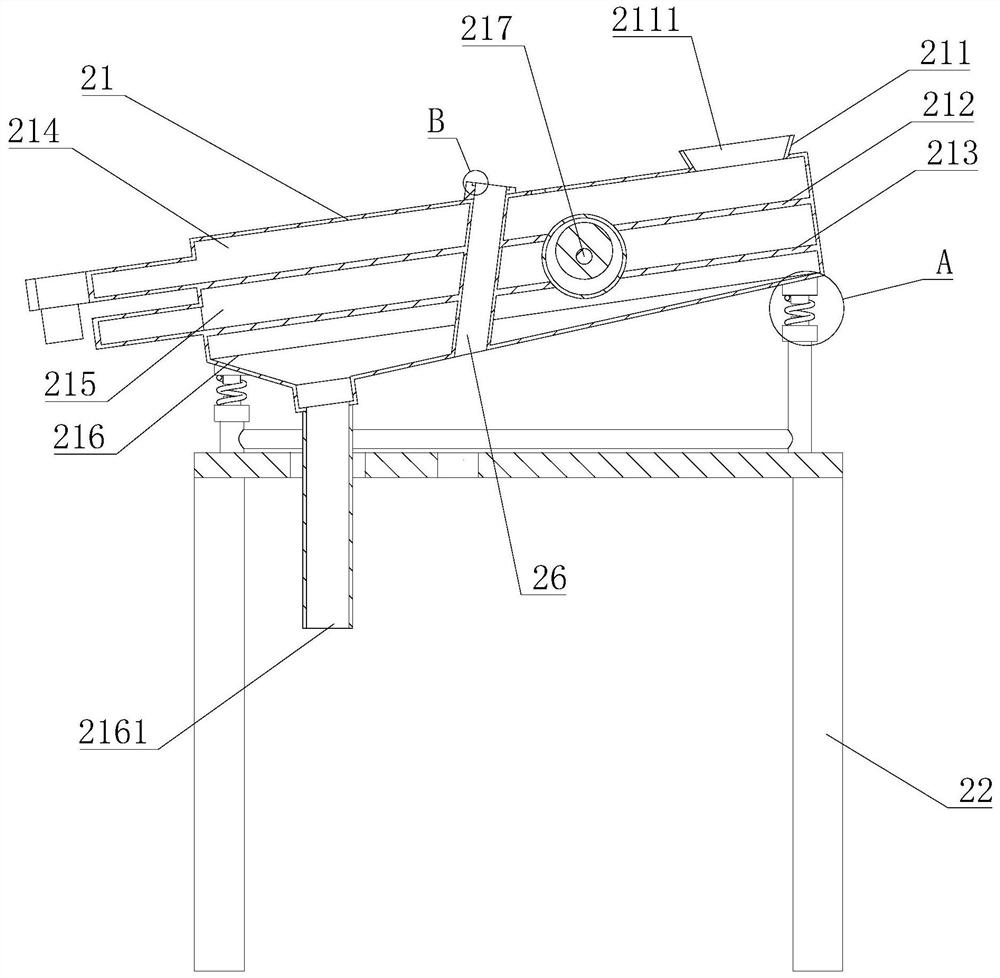

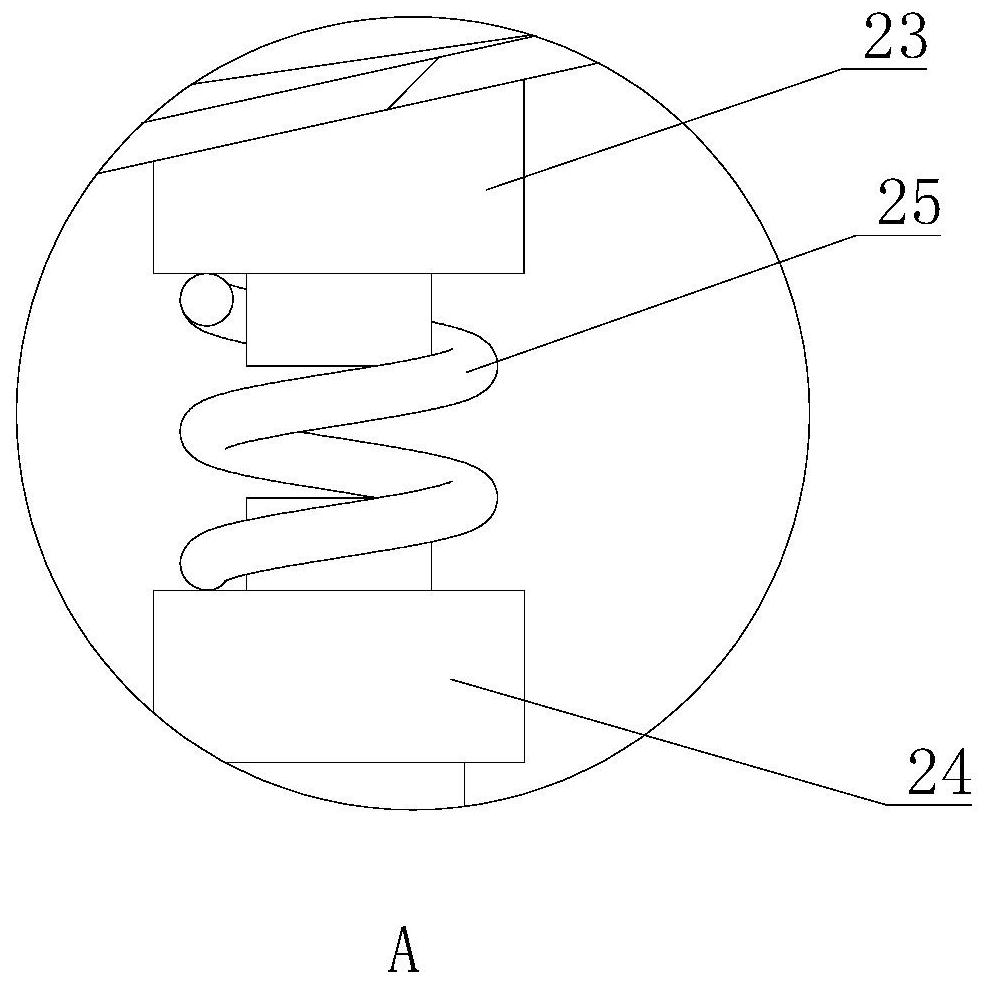

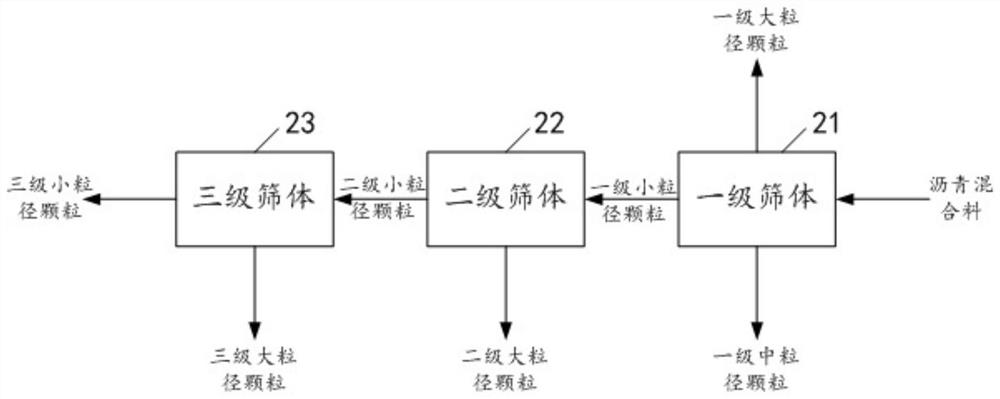

Asphalt mixture three-stage crushing system and method

PendingCN114226043ASmall particle size rangeGuaranteed performanceSievingGas current separationProcess engineeringAsphalt

The three-stage crushing system comprises a conveying mechanism, a feeding machine, a screening device, a first finished product bin, a second finished product bin, a third finished product bin and a fourth finished product bin. The screening device comprises a first-stage screen body, a second-stage screen body and a third-stage screen body which are of a double-layer screen structure, the first-stage screen body is used for separating the asphalt mixture into first-stage large-particle-size particles, first-stage medium-particle-size particles and first-stage small-particle-size particles, and the second-stage screen body is used for separating the first-stage small-particle-size particles into second-stage large-particle-size particles and second-stage small-particle-size particles; the third-stage screen body is used for separating the second-stage small-particle-size particles into third-stage large-particle-size particles and third-stage small-particle-size particles. The invention further discloses an asphalt mixture three-stage crushing method based on the asphalt mixture three-stage crushing system. According to the invention, the asphalt mixture can be subdivided into four grades, the particle size range of the single-grade finished product material is small, the mixing rate is low, the adulterability in the standard synthesis grading range is high, and the grading control is more stable.

Owner:FOSHAN TRANSPORTATION SCI & TECH CO LTD +1

A construction waste gravel production line

ActiveCN110947492BSmall footprintHighly compact structureSievingScreeningArchitectural engineeringCrushed stone

The invention discloses a construction waste gravel production line, which solves the problem that the current construction waste gravel production line occupies a large area. The main point of the technical solution is a construction waste crushing production line, including a main crusher, a screening machine, a secondary crushing machine, and a construction waste crushing production line. By setting an installation channel in the screening machine, the secondary crushing machine Including the crushing device and the lifting device, compared with the traditional construction waste crushing production line, the belt hoist between the secondary crusher and the screening machine is canceled, and the secondary crusher includes the crushing device and the lifting device, The crushing device is located under the semi-finished product opening of the vibrating screen box, the conical hopper in the lifting device is located under the vibrating screen box, and the lifting pipe runs through the vibrating screen box through the installation channel, so that the combined structure of the secondary crusher and the screening machine The compactness is high, which reduces the floor area of the whole construction waste gravel production line.

Owner:上海翊兆市政工程材料有限公司

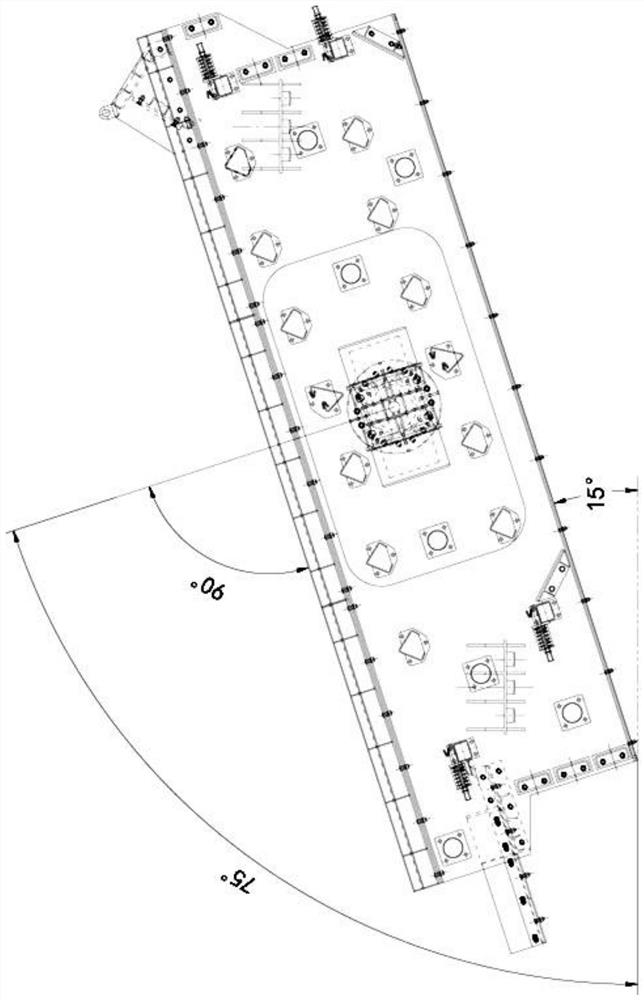

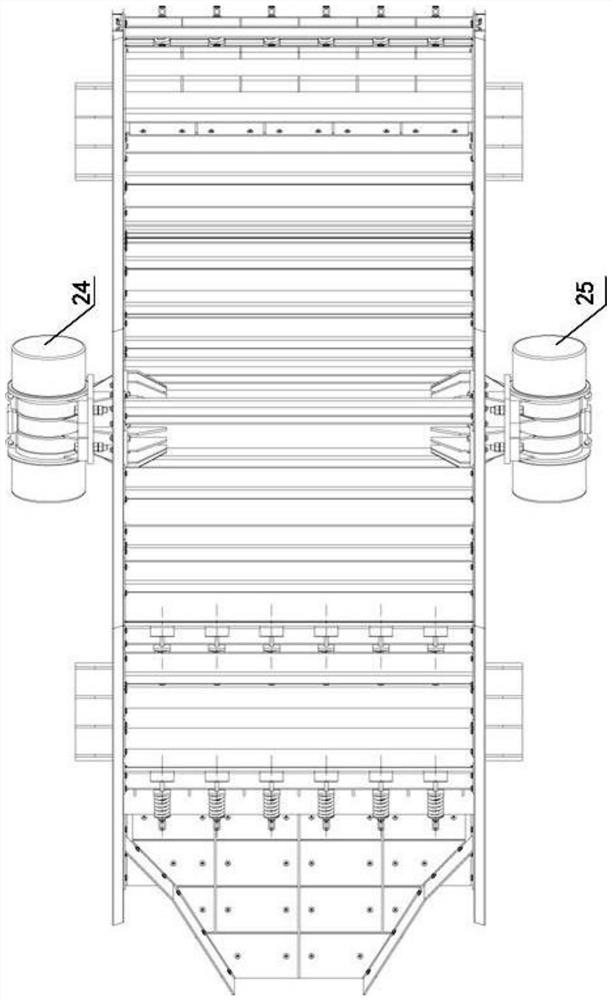

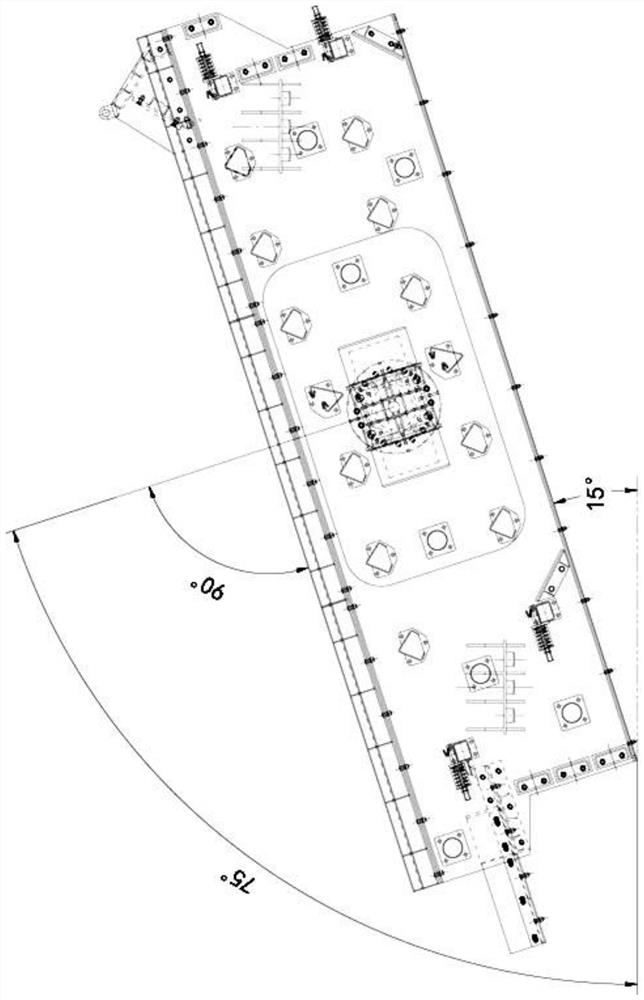

Asphalt mixture screening device

InactiveCN114226223ASmall particle size rangeGuaranteed performanceSievingGas current separationEngineeringMechanical engineering

The asphalt mixture screening device comprises at least three screen bodies and at least three excitation motor sets used for driving the screen bodies, the screen bodies correspond to the excitation motor sets in a one-to-one mode, and each screen body is of a double-layer screen structure; the screen surfaces of the screen bodies are perpendicular to the excitation force directions of the corresponding excitation motor sets, so that the excitation force directions of the excitation motor sets and the gravity centers of the corresponding screen bodies are located on the same straight line, and the screen surfaces of the screen bodies do linear motion in the corresponding excitation force directions. According to the invention, the asphalt mixture can be subdivided into multiple grades, and small particle size range, low mixing rate, high adulterability in a standard synthesis grading range and more stable grading control of a single-grade finished product material are ensured.

Owner:FOSHAN TRANSPORTATION SCI & TECH CO LTD +1

Multi-stage rotary screening and grading device for aluminum alloy powder

ActiveCN114798414AImprove screening efficiencyImprove grading qualitySievingTransportation and packagingStructural engineeringMechanical engineering

The invention discloses a multistage rotary screening and grading device for aluminum alloy powder. The multistage rotary screening and grading device comprises at least three groups of guide rail plate frames which are horizontally and circumferentially arranged, driving seats are mounted on the guide rail plate frames, clamping seats are mounted on the driving seats, and the guide rail plate frames can be longitudinally mounted through splicing seats; a plurality of groups of screening assemblies are longitudinally and coaxially arranged and are in sealing connection through sealing connecting ring pieces, the corresponding upper ends and the corresponding lower ends of the screening assemblies located at the top and the bottom are in sealing connection with the sealing cover and the bottom collecting cover through the sealing connecting ring pieces correspondingly, and each layer of screening assembly is clamped and fixed to the corresponding clamping base.

Owner:HENAN YUANYANG POWDER TECH CO LTD

A sorting sand screening machine

ActiveCN110252644BExtended service lifeShorten the lengthSievingScreeningStructural engineeringSmall footprint

The invention relates to a sand screen, in particular to a classifying sand screen. The classifying sand screen comprises a base body, a first screen mesh, an initial collecting hopper, an oscillating part, a slow falling mechanism, a braking part, a transmission part, a dividing hopper, a shifter and a rack, wherein single-layer sand stone is conveyed to the first screen mesh through buffering and dividing the added sand stone through the initial collecting hopper in combination with vibration, so that the noise is lowered, the service life of the first screen mesh is prolonged, and the screening efficiency is increased; through the alternate lifting of two baffle plates, the single-layer sand stone is blocked in sections, the screening time is prolonged, the length of the first screen mesh is reduced, and the screening efficiency can also be increased; an arc frame and an second screen mesh swinging back and forth obliquely can increase the stroke of sand screening movement, the length of the second screen mesh is reduced, and the screening efficiency of coarse sand and fine sand can be improved; according to the classifying sand screen, the screening of stones, coarse sand and fine sand can be completed through the short screening nets and the two-layer screening structure, filling is easy due to the fact that the height is low, the occupied area of the classifying sand screen is small, and the screening efficiency is high.

Owner:HARBIN UNIV

A double-layer rotary screen

The invention discloses a double-layer rotary sieve. The double-layer rotary sieve is fixed on a supporting seat and comprises a shell, an outer sieve and an inner sieve, wherein the inner sieve is arranged at the inner layer of the outer sieve; the shell is arranged at the outer part of the outer sieve; sieving holes are arranged on sieve plates of the outer sieve and the inner sieve; a plurality of arc-shaped lining plates are arranged in the inner sieve and are close to the inner sieve; the heads and the tails of the two adjacent lining plates are attached to enclose into a cylindrical shape same as the inner sieve; one end of each arc-shaped lining plate is connected with a rib frame of the inner wall of the inner sieve by a hinge and the other end of each arc-shaped lining plate is movable; in the cylinder rotating process of the inner sieve, the arc-shaped lining plates rotate in a following manner, the tail ends of the arc-shaped lining plates fall gradually and fall vertically when reaching the high point, and then sieved materials fall again by means of the gravity action, so that secondary sieving is realized, the locking of the sieving holes is avoided and the sieving effect is better.

Owner:LUOYANG INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com