Asphalt mixture three-stage crushing system and method

A technology of asphalt mixture and tertiary crushing, which is applied in chemical instruments and methods, solid separation, and separation of solids from solids by air flow, etc. Long, unstable synthesis gradation and other problems, to achieve the effect of prolonging the sieving time, reducing the probability of sieving, and improving the sieving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

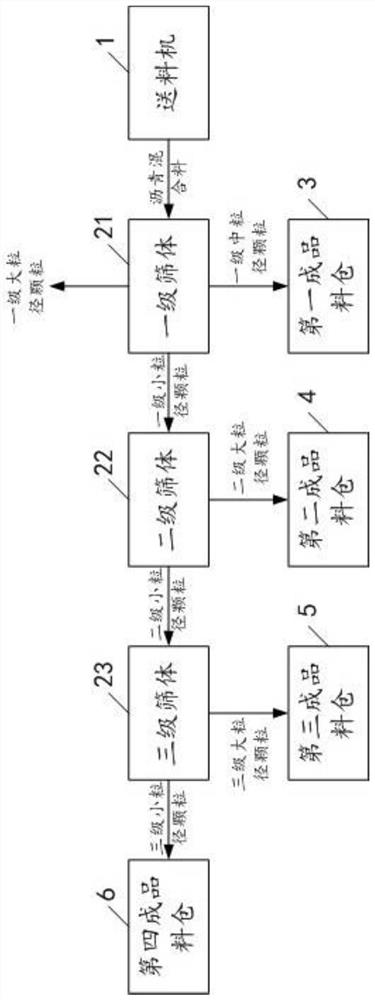

[0107] see Figure 9 , Figure 9 Shows the flow chart of the first embodiment of the asphalt mixture tertiary crushing method based on the asphalt mixture tertiary crushing system of the present invention, which includes:

[0108] S101, driving the transmission mechanism to transmit the asphalt mixture in the feeder to the primary screen body.

[0109] Furthermore, the asphalt mixture tertiary crushing system also includes an iron remover, and the transmission mechanism drives the iron remover to remove the metal body in the asphalt mixture during the process of transporting the asphalt mixture in the feeder to the primary screen body.

[0110] S102, driving the first-stage sieve body to separate the asphalt mixture into first-stage large-size particles, first-stage medium-size particles, and first-stage small-size particles.

[0111] S103, driving the transmission mechanism to transmit the primary medium-sized particles to the first finished product silo, and the primary sm...

no. 2 example

[0132] see Figure 10 , Figure 10 Shows the flow chart of the second embodiment of the asphalt mixture tertiary crushing method based on the asphalt mixture tertiary crushing system of the present invention, which includes:

[0133] S201, driving the transmission mechanism to transmit the asphalt mixture in the feeder to the primary sieve body, and driving the iron remover to remove the metal body in the asphalt mixture during the transmission process.

[0134] S202, driving the first-stage sieve body to separate the asphalt mixture into first-stage large-size particles, first-stage medium-size particles, and first-stage small-size particles.

[0135] S203, the first-stage large-diameter particles enter the flexible separation mechanism along the upper screen of the first-stage sieve body.

[0136] S204, driving the flexible separation mechanism to crush the primary large particle size particles.

[0137] S205, driving the flexible separation mechanism to output the crushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com