A sorting sand screening machine

A technology of sand screening machine and screen mesh, applied in the field of sand screening machine, can solve the problems of adding sand material, large floor space, high height, etc., and achieve high screening efficiency, increase screening time, and increase screening efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

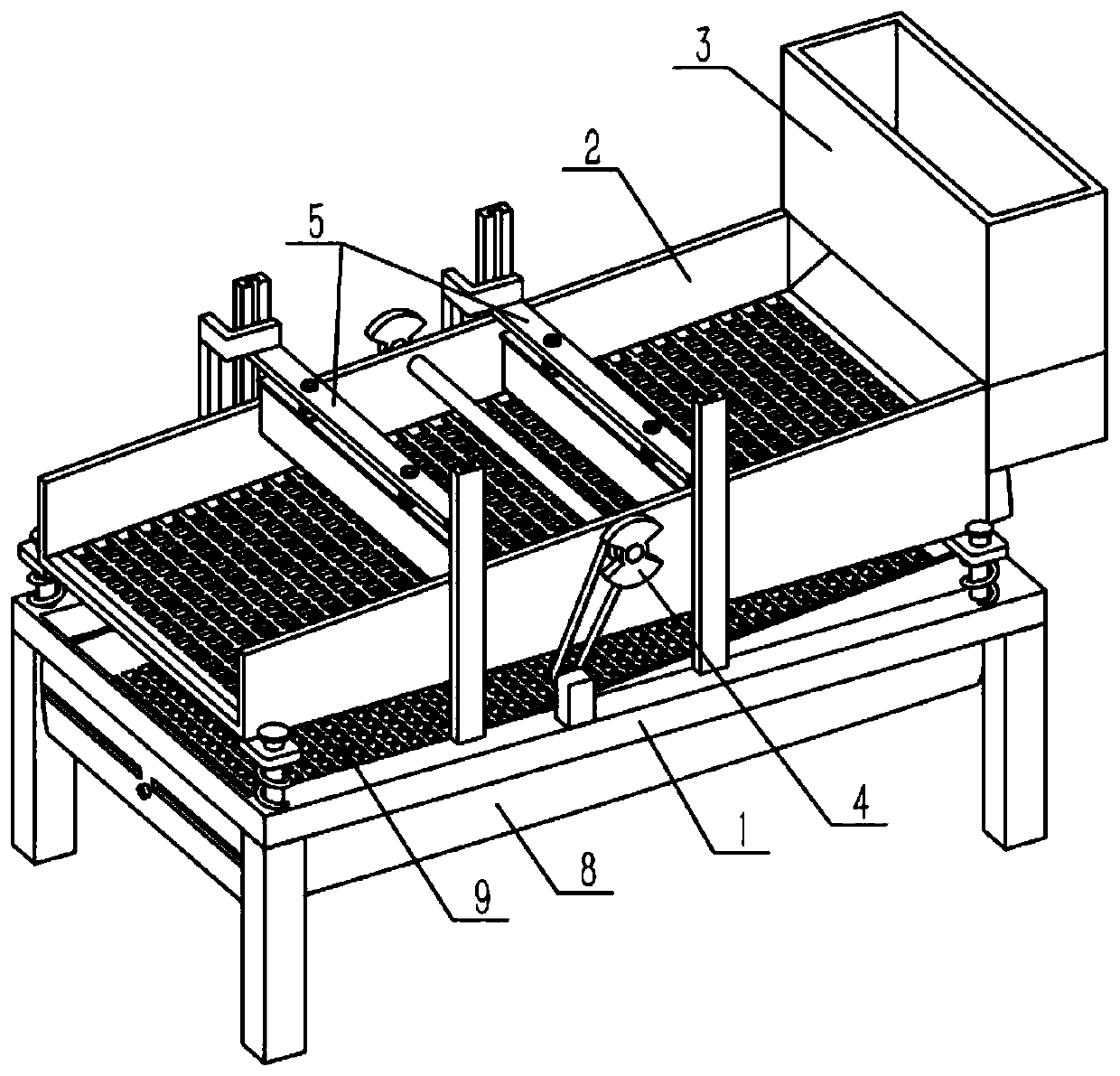

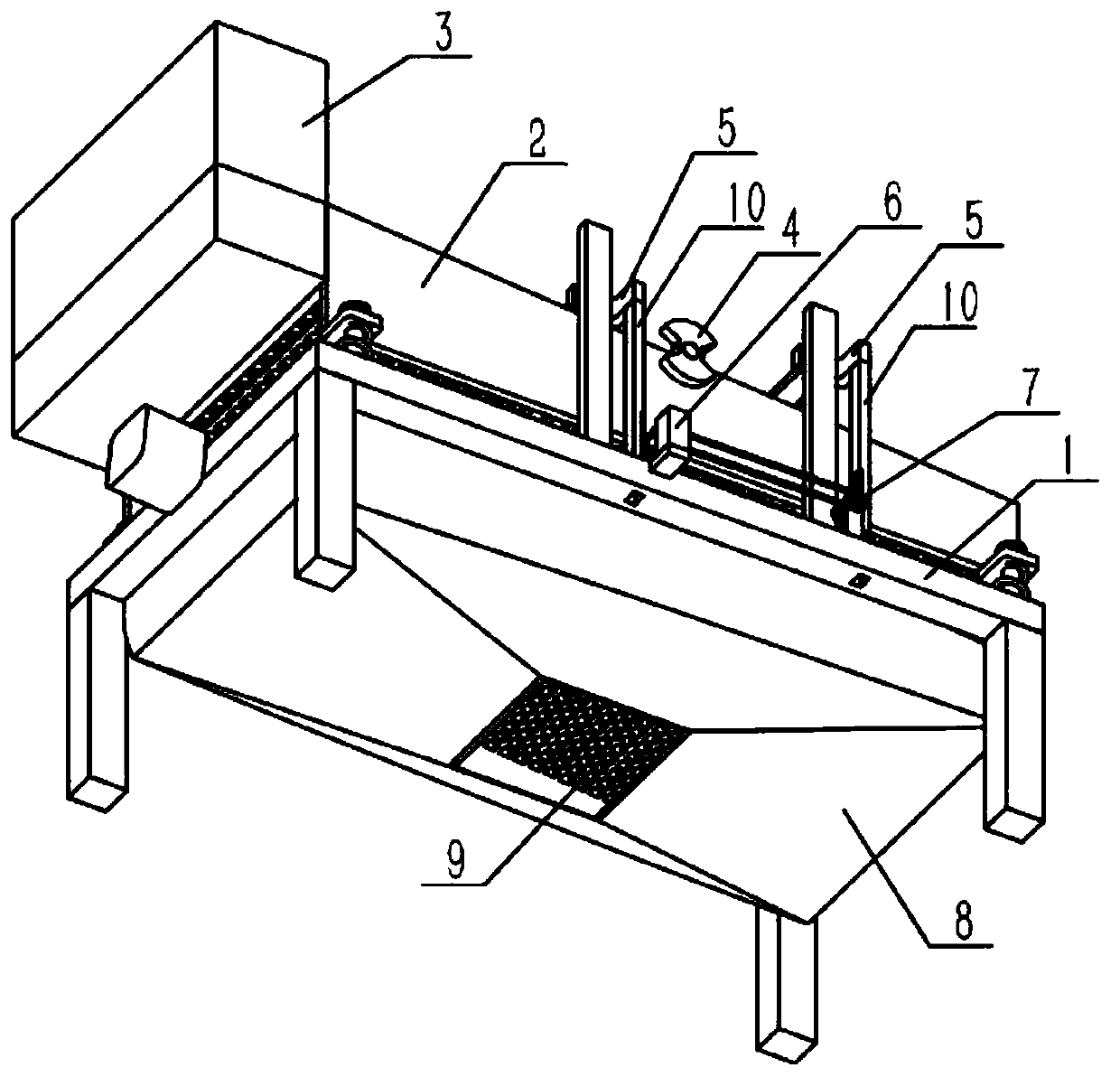

[0032] Such as Figure 1-11 As shown, a sorting sand screening machine includes a base body 1, a first screen 2, an initial collection bucket 3, an oscillation part 4, a slow-down mechanism 5, a brake part 6, a transmission part 7, a sub-bucket 8, and an increaser 9 and the rack 10, the base 1 is connected with the first screen 2, the right end of the first screen 2 is fixedly connected with the initial receiving bucket 3, and the oscillation part 4 is connected to the middle part of the upper side of the first screen 2 by rotation, and slowly falls There are two mechanisms 5, and the two slow-falling mechanisms 5 are slidingly connected to the left and right sides of the middle part of the first screen 2 respectively. Symmetrically arranged, the brake part 6 is fixed on the base body 1, the base body 1 is engaged with the left end face of the rack 10 on the right side for transmission, the transmission part 7 is fixed on the base body 1, and the brake part 6 and the transmiss...

specific Embodiment approach 2

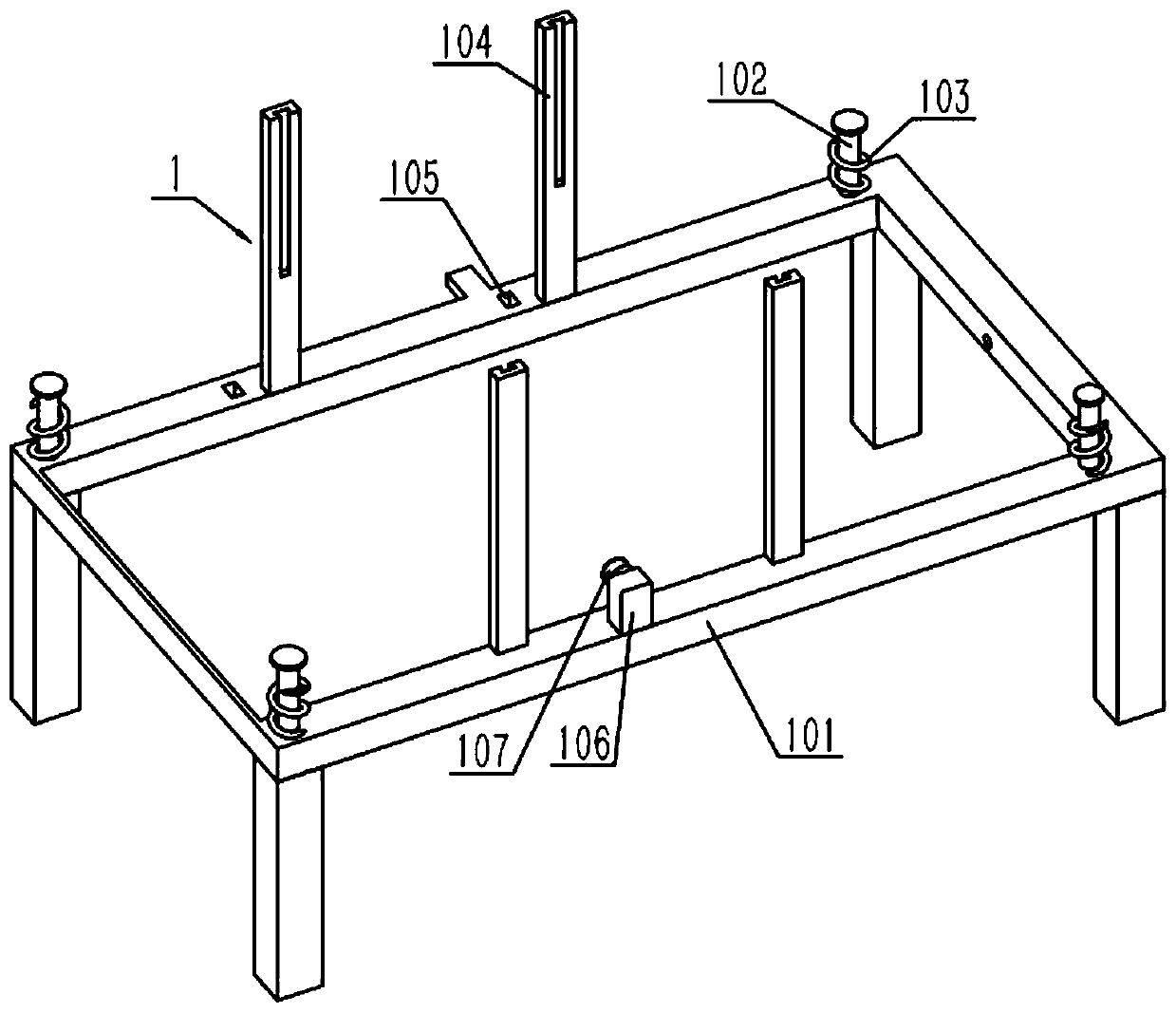

[0034] Such as Figure 1-11 As shown, the base 1 includes a base body 101, a stopper body 102, a compression spring I103, a guide rail seat 104, an opening 105, a motor I106 and a pulley I107, and four corners of the upper end of the base body 101 are respectively fixed with a stopper. Positioning bolt body 102, four limiting bolt bodies 102 are respectively covered with a compression spring I 103, the upper ends of the four limiting bolt bodies 102 are respectively fixed with a limiting block I, and the front and rear ends of the middle part of the base body 101 are fixed respectively The two guide rail seats 104, the motor I106 are fixedly connected to the base body 101, and the pulley I107 is fixedly connected to the output shaft of the motor I106. Start the motor I106, the output shaft of the motor I106 drives the pulley I107 to rotate, and the pulley I107 drives the pulley II403 to rotate through the transmission belt.

specific Embodiment approach 3

[0036] Such as Figure 1-11As shown, the first screen 2 includes a retaining frame 201, a first screen body 202 and a solid seat 203, the first screen body 202 is affixed to the retaining frame 201, and the four corners of the lower end of the retaining frame 201 are respectively One anchoring seat 203 is fixedly connected; the four anchoring seats 203 are respectively slidably connected to the four limit bolt bodies 102 , and the upper ends of the four compression springs I 103 are respectively in contact with the lower ends of the four anchoring seats 203 . Vibration promotes the sand and stones that slowly flow to the first screen body 202 to move to the left on the first screen body 202 in a layer to increase the screening efficiency. The first screen body 202 is used to separate the sand and stones, and the stones continue to the left Rolling, the sand falls through the first screen body 202 onto the second screen 901 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com