Screen on ball pressing machine

A technology of ball briquetting machine and screen, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of reducing the yield of finished products, easy to sieve endless sand, reducing the quality and yield of briquetting balls, etc., to improve the quality and Yield, long sieving time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the accompanying drawings.

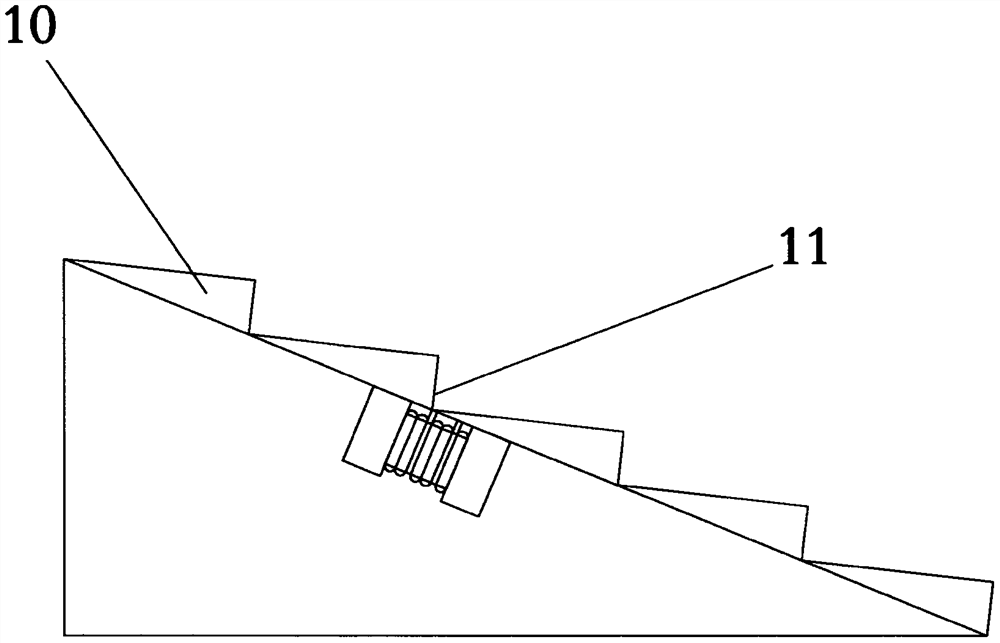

[0012] The invention provides a screen 10 on a ball pressing machine, such as figure 1 , which is set as an inclined slope, the screen 10 is set as a ladder shape, and its steps 11 are vertically set. The included angle between the screen 10 and the horizontal direction is 15° to 45°.

[0013] The above description has fully disclosed the specific implementation manners of the present invention. It should be pointed out that any changes made by those skilled in the art to the specific embodiments of the present invention will not depart from the scope of the claims of the present invention. Accordingly, the scope of the claims of the present invention is not limited only to the foregoing specific embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com