Bionic non-smooth sorting screen surface

A non-smooth, sieve surface technology, applied in the direction of sieving, solid separation, grid, etc., can solve the problems of clogged sieve holes, non-discovery, sieve surface adhesion, etc., and achieve increased sieving time, simple processing, and adhesion sex-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

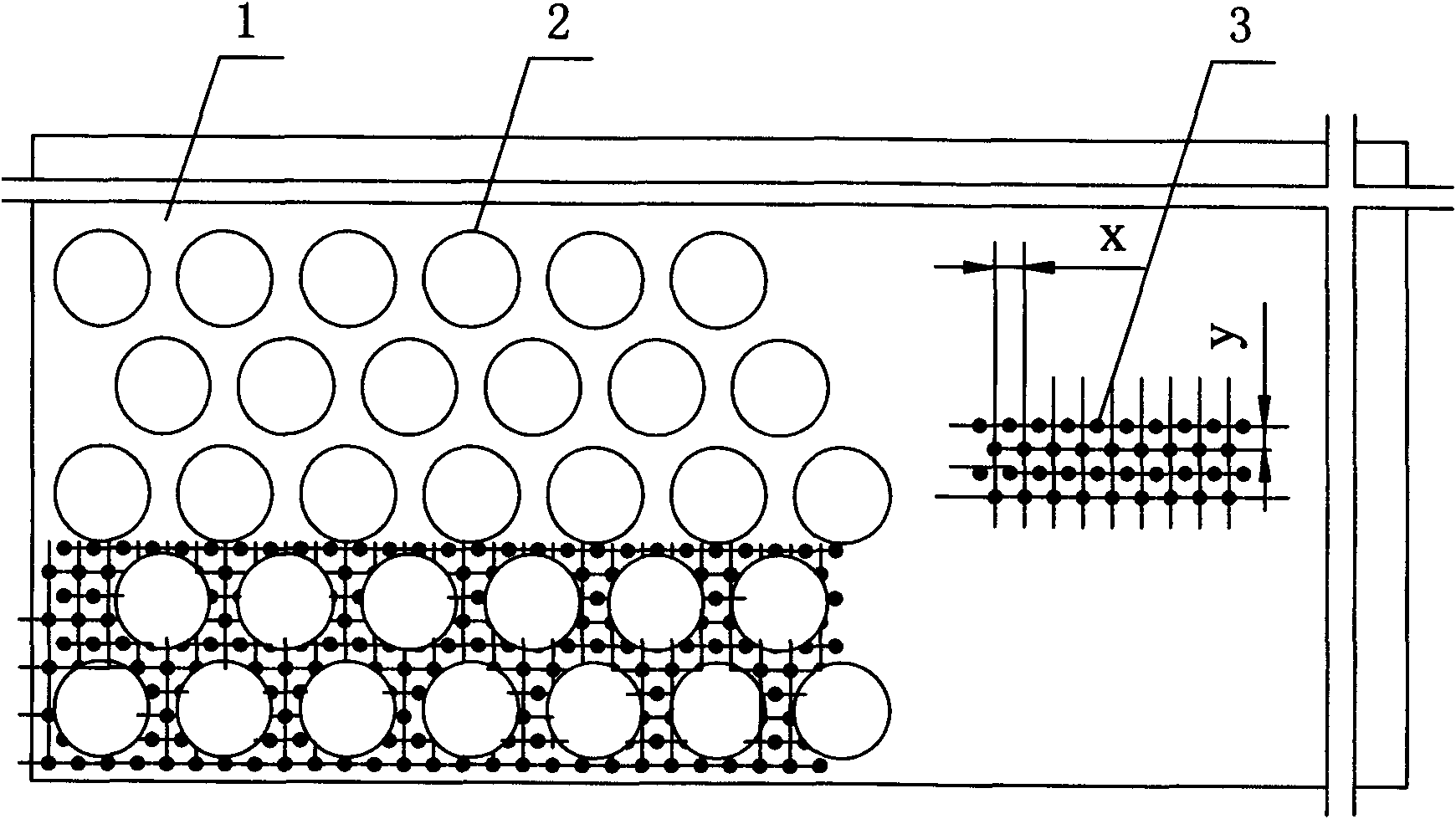

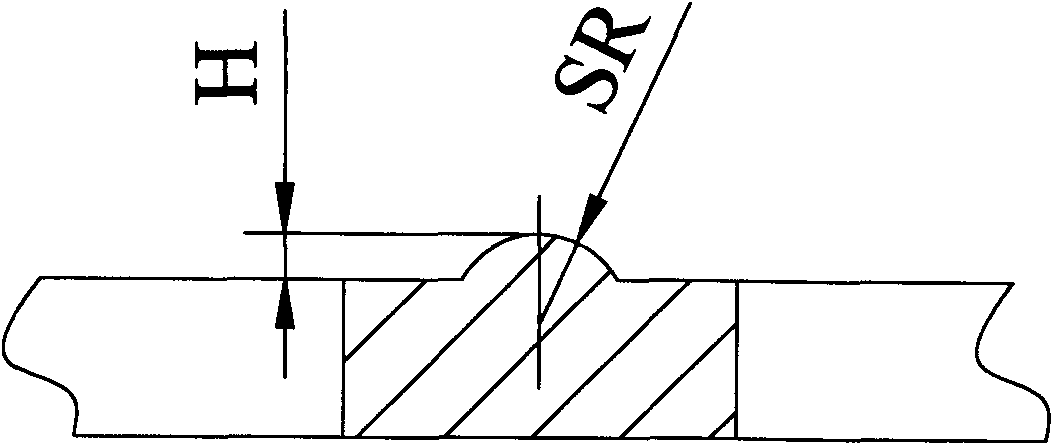

[0023] figure 1 , 2 It is a bionic non-smooth cleaning sieve surface suitable for wet rapeseed extracts. Spherical crown-shaped convex units 3 are distributed on the sieve surface substrate 1. The diameter SR of the spherical crown is 0.5mm, and the height H is 0.5mm. The raised unit bodies 3 are arranged in a staggered grid, the horizontal distance x of the unit bodies 3 is 2 mm, the longitudinal distance y of the unit bodies 3 is 1.5 mm, and the distribution density of the raised unit bodies 3 is one of the geometric projected areas on the surface of the substrate. The ratio of the sum to the surface area of the substrate is 35%, and the sieve surface substrate 1 is provided with sieve holes 2. Compared with the ordinary smooth cleaning sieve, the adhesion between the rape extract to be screened and the sieve surface is reduced by 80%, which is effective Sieving time increased by 15 times;

Embodiment 2

[0025] figure 1 , 3 It is a bionic non-smooth cleaning sieve surface suitable for wet corn cleaning. Spherical crown-shaped convex units 3 are distributed on the sieve surface substrate 1. The diameter SR of the spherical crown is 2 mm, and the height H is 2 mm. The spherical crown-shaped convex The unit bodies 3 are arranged in a staggered grid, the horizontal distance x of the unit bodies 3 is 7mm, the longitudinal distance y of the unit bodies 3 is 6mm, and the distribution density of the raised unit bodies 3 is the sum of the geometric projection area on the surface of the substrate and the sum of the matrix The surface area ratio is 42%, and the sieve surface substrate 1 is provided with sieve holes 2. Compared with ordinary smooth cleaning sieves, the adhesion between the corn extracts to be sieved and the sieve surface is reduced by 40%, and the effective sieving time increase by 6 times;

Embodiment 3

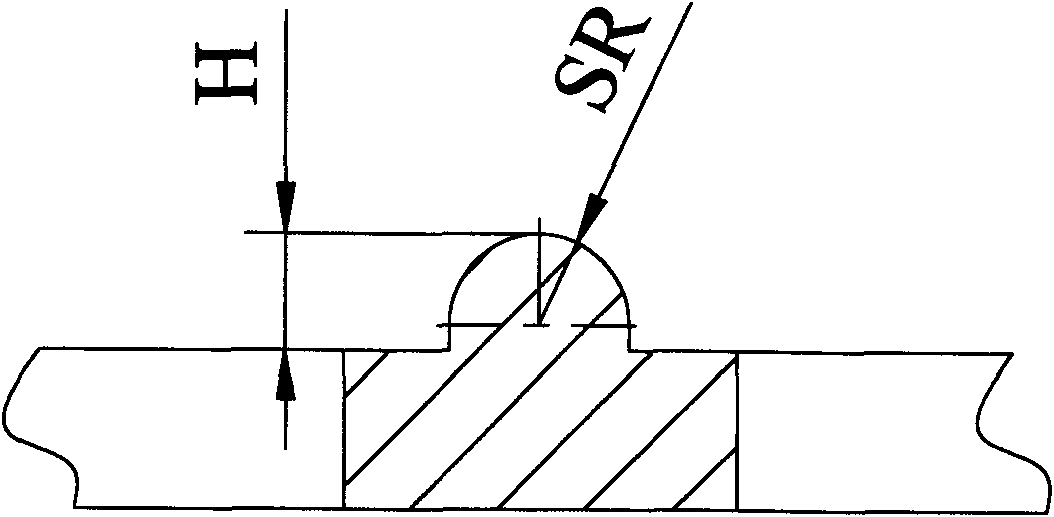

[0027] figure 1 , 4 It is a bionic non-smooth cleaning sieve surface suitable for moist rice extracts. The sieve surface substrate 1 is distributed with cylindrical convex units 3, and the diameter of the cylinder is is 1.6mm, height H is 1mm, cylindrical raised units 3 are arranged in a staggered grid, the horizontal distance x of unit 3 is 2.9mm, the longitudinal distance y of unit 3 is 3mm, and the distribution density of raised units 3 is The ratio of the sum of the geometric projected areas on the surface of the substrate to the surface area of the substrate is 30%. The sieve surface substrate 1 is provided with sieve holes 2. The adhesion of the surface is reduced by 50%, and the effective sieving time is increased by 8 times;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com