Multi-stage rotary screening and grading device for aluminum alloy powder

An aluminum alloy powder and classification device technology, which is applied in the field of alloy powder processing, can solve the problems of incomplete powder screening, poor vibrating screening effect, easy dust generation, etc., so as to improve the powder screening efficiency and promote the screening. time, and the effect of improving the quality of powder screening and classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

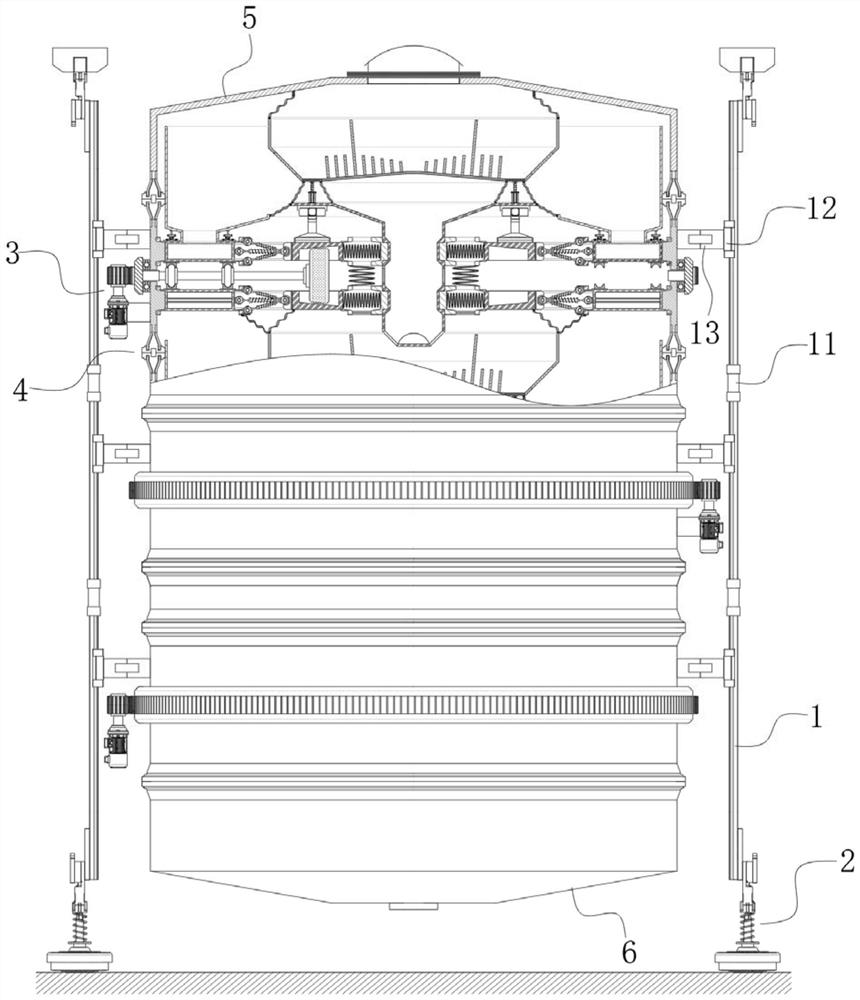

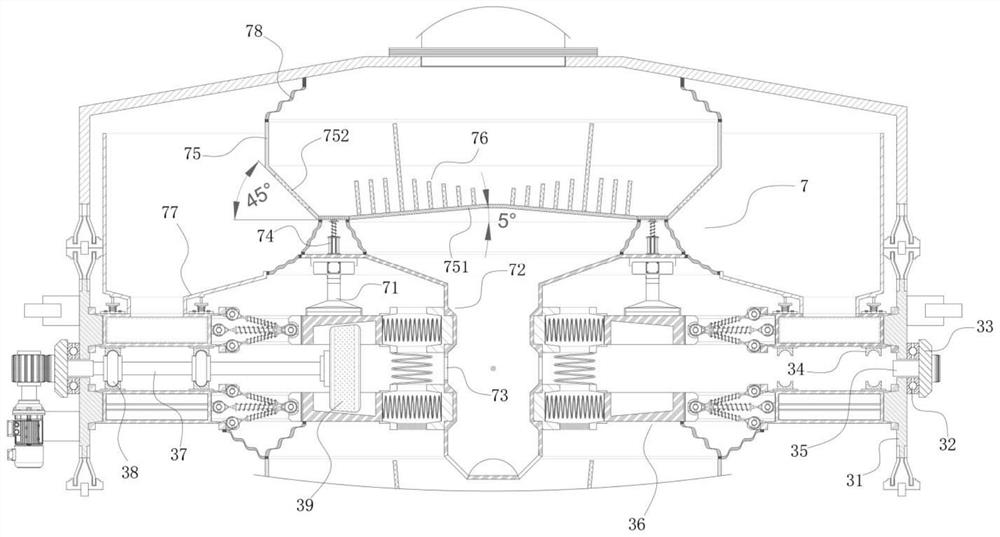

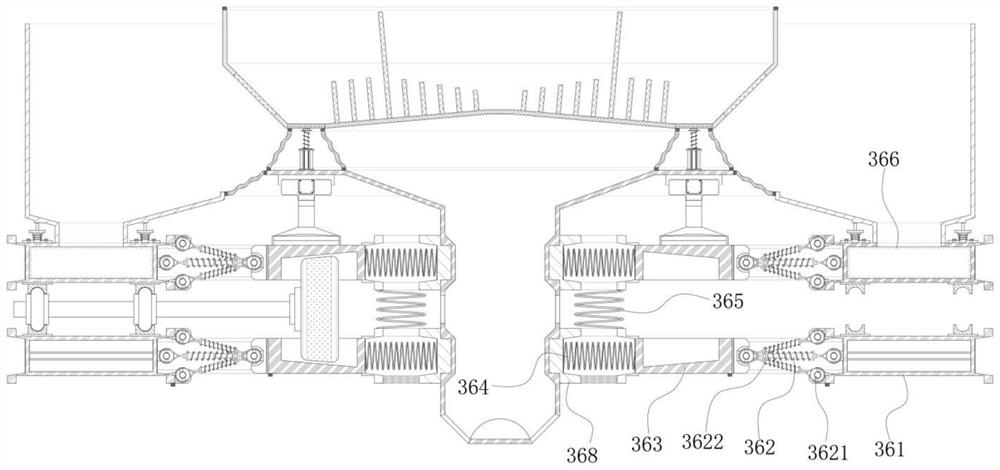

[0035] refer to Figure 1-5 , the present invention provides a technical scheme: a multi-stage rotary sieving and classifying device for aluminum alloy powder, which comprises:

[0036] At least three groups of guide rail racks 1 are arranged on a horizontal circumference. A drive seat 12 is installed on the guide rail rack 1, a clamping seat 13 is installed on the drive seat 12, and the guide rail rack 1 can pass through the splicing seat. 11. Longitudinal installation is carried out, so as to improve the stability during the vibrating screening process;

[0037] A plurality of sets of screening assemblies 3 are arranged coaxially in the longitudinal direction and are sealedly connected by the sealing joint ring member 4, and the corresponding upper and lower ends of the screening assembly 3 located at the top and bottom are respectively connected with the sealing cover 5, the lower end through the sealing joint ring member 4. The bottom collection cover 6 is sealed and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com