Up-down vibration flattening device

A flattening device, vibrating roller technology, applied in textile and papermaking, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of small vibration amplitude, carbon fiber breakage, vibration frequency limitation, etc., to achieve guaranteed effect, Novel structure, the effect of ensuring vibration stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

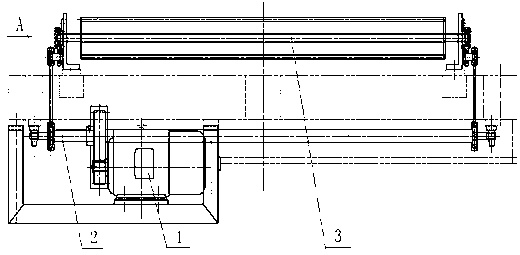

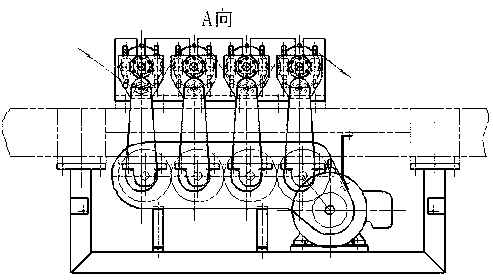

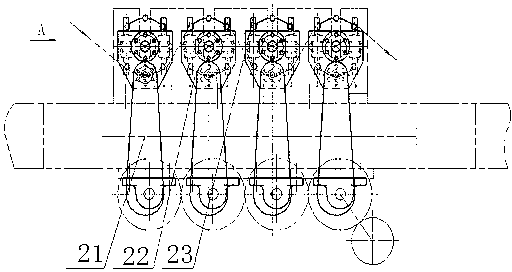

[0017] Such as Figure 1-Figure 6 As shown, the up and down vibrating flattening device is mainly composed of transmission part 1, moving part 2 and vibrating roller part 3. 3. Set on the upper part of the frame body and connect with the moving part 2. The transmission part 1 adopts frequency conversion motor to drive through gears. The moving part 2 includes arm plate 21, moving plate 22, linear guide rail 23, bearing 24, bearing 27, rotating shaft 25 and eccentric wheel 26 , the bearing 24 and the bearing 27 are respectively arranged in the holes at both ends of the arm plate 21, one end of the arm plate 21 cooperates with the outer ring of the eccentric wheel 26, and the other end cooperates with the rotating shaft 25, the eccentric wheel 26 is arranged on the rotating shaft 25, and the linear guide rail 23 and rotating shaft 25 are installed on the moving plate 22 respectively. The vibrating roller part 3 is composed of four groups of vibrating rollers. Each adjacent group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com