Method for flattening original film base belt for magnetron sputtering coating

A magnetron sputtering coating and film-based technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve problems affecting product quality and photoelectric performance indicators of deposited films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, this technology is further described:

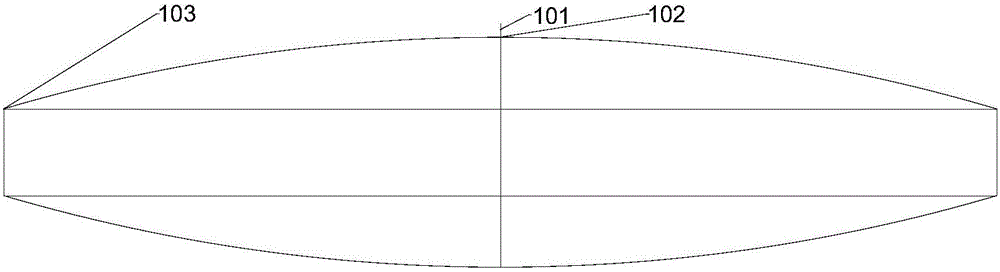

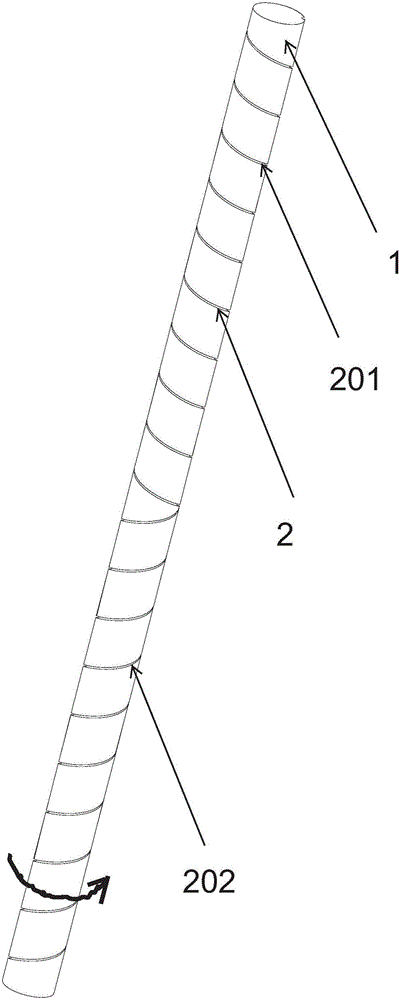

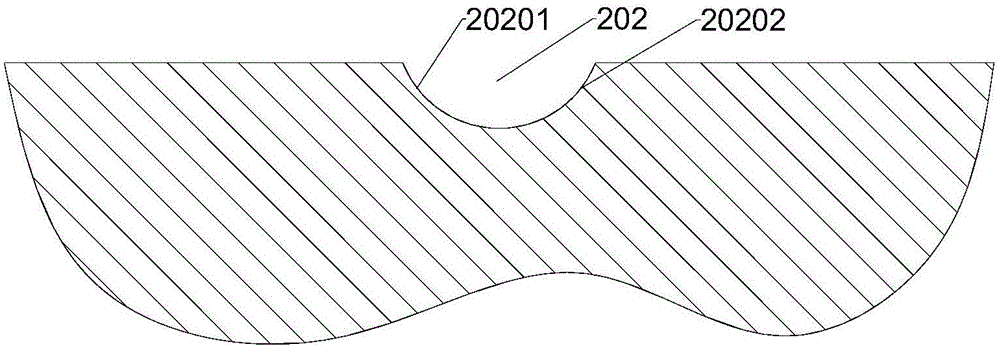

[0018] see figure 1 , figure 2 A kind of flattening roller shown, comprises roller shaft 1, and roller shaft 1 is made of hard material; The generatrix that the middle part of outer surface of roller shaft 1 protrudes is circular arc; The diameter of the section circle in the outer surface of roller shaft 1 is greater than The diameter of the end face circle on the outer surface of the roller shaft 1; on the outer surface of the roller shaft 1, there is also a spiral groove 2 symmetrical to the middle section of the roller shaft, and the spiral groove on the left side of the middle section of the roller shaft 1 is left-handed, and is located on the roller shaft 1 The spiral groove on the right side of the middle section is right-handed; the rotation direction of the roller shaft 1 is right-handed.

[0019] In order to ensure the sufficient strength of the roller shaft 1, avoid the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com