Light steel profile rolling punching forming production line

A production line and profile technology, applied in the direction of feeding devices, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of complex punching process and low efficiency, reduce work intensity, improve work efficiency, and improve punching efficiency and the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

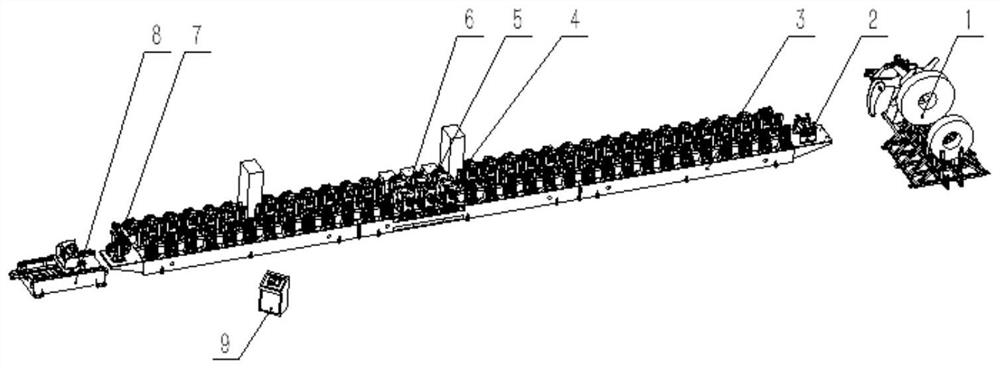

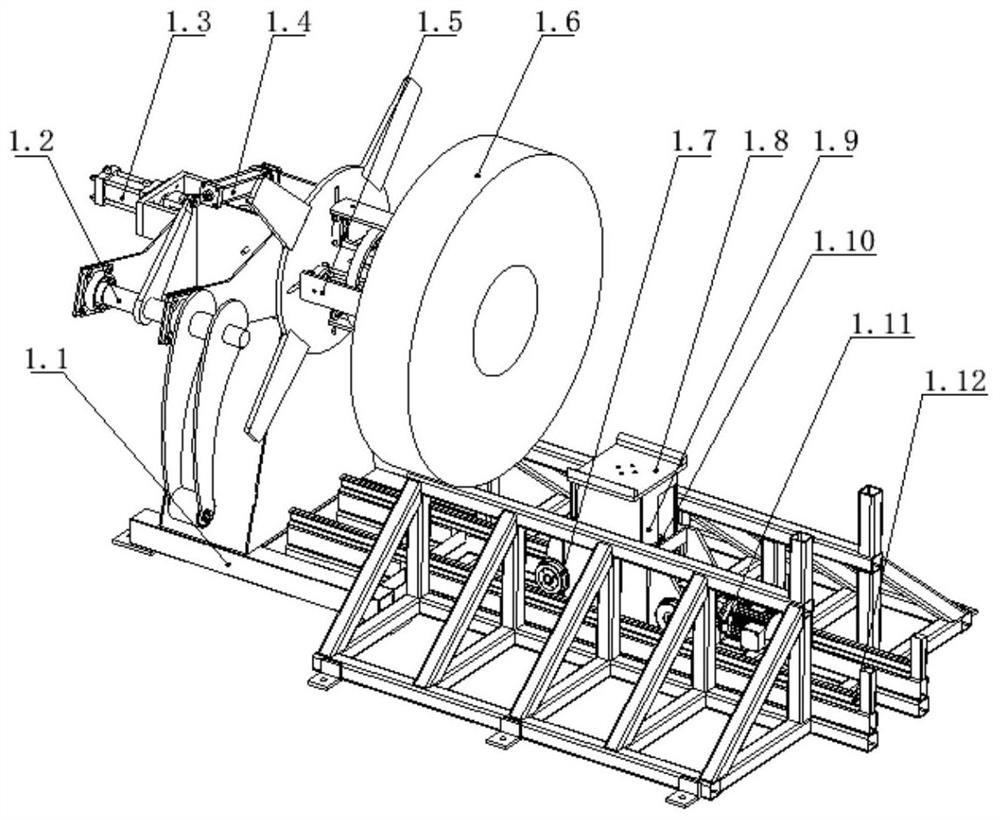

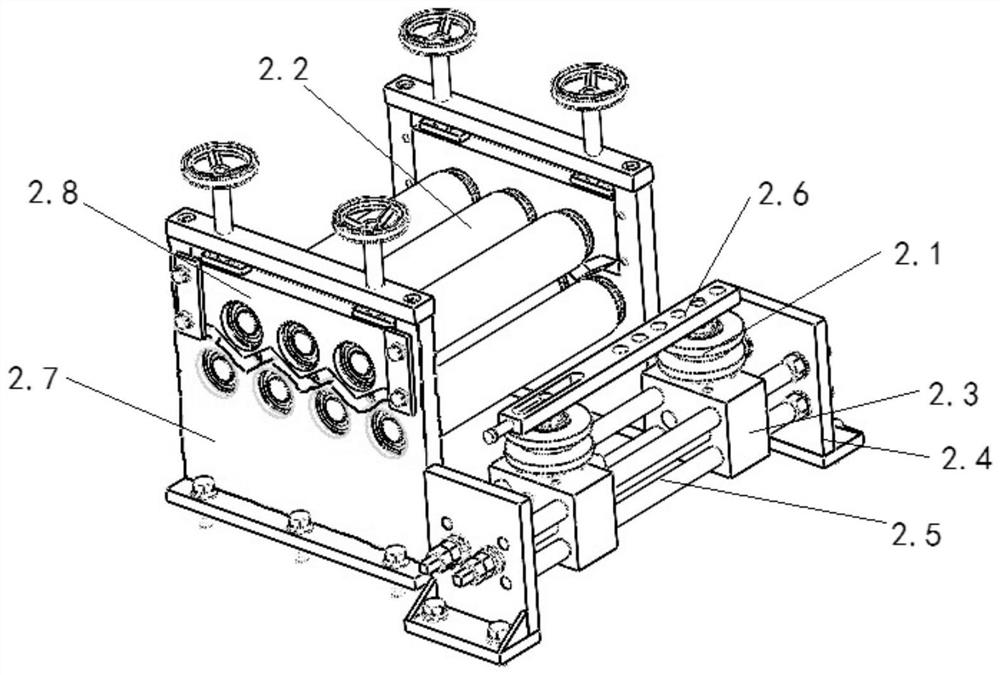

[0051] In a typical embodiment of the present invention, as Figure 1-Figure 8 As shown, a light steel profile roll forming production line is proposed, including a tensioning and uncoiling mechanism 1, a flattening mechanism 2, a forming host 3, a rolling punching unit, a correction mechanism 7, a tracking filing and cutting mechanism 8 and a control center 9. Center 9 is used to control the entire light steel profile roll forming production line.

[0052] Among them, the tensioning and unwinding mechanism 1 and the tracking filing and cutting mechanism 8 are respectively located on the loading side and the unloading side of the molding host 3; the correction mechanism 7 is movably arranged on the unloading end of the molding host 3. between the tracking and filing mechanism 8; the flattening mechanism 2 is fixedly arranged at the unloading end of the forming host 3, that is, the flattening mechanism 2 is located between the forming host 3 and the tensioning and uncoiling mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com