Beating machine for producing prepared Chinese ink

An ink block and tray technology, applied in the field of traditional calligraphy ink production machinery, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

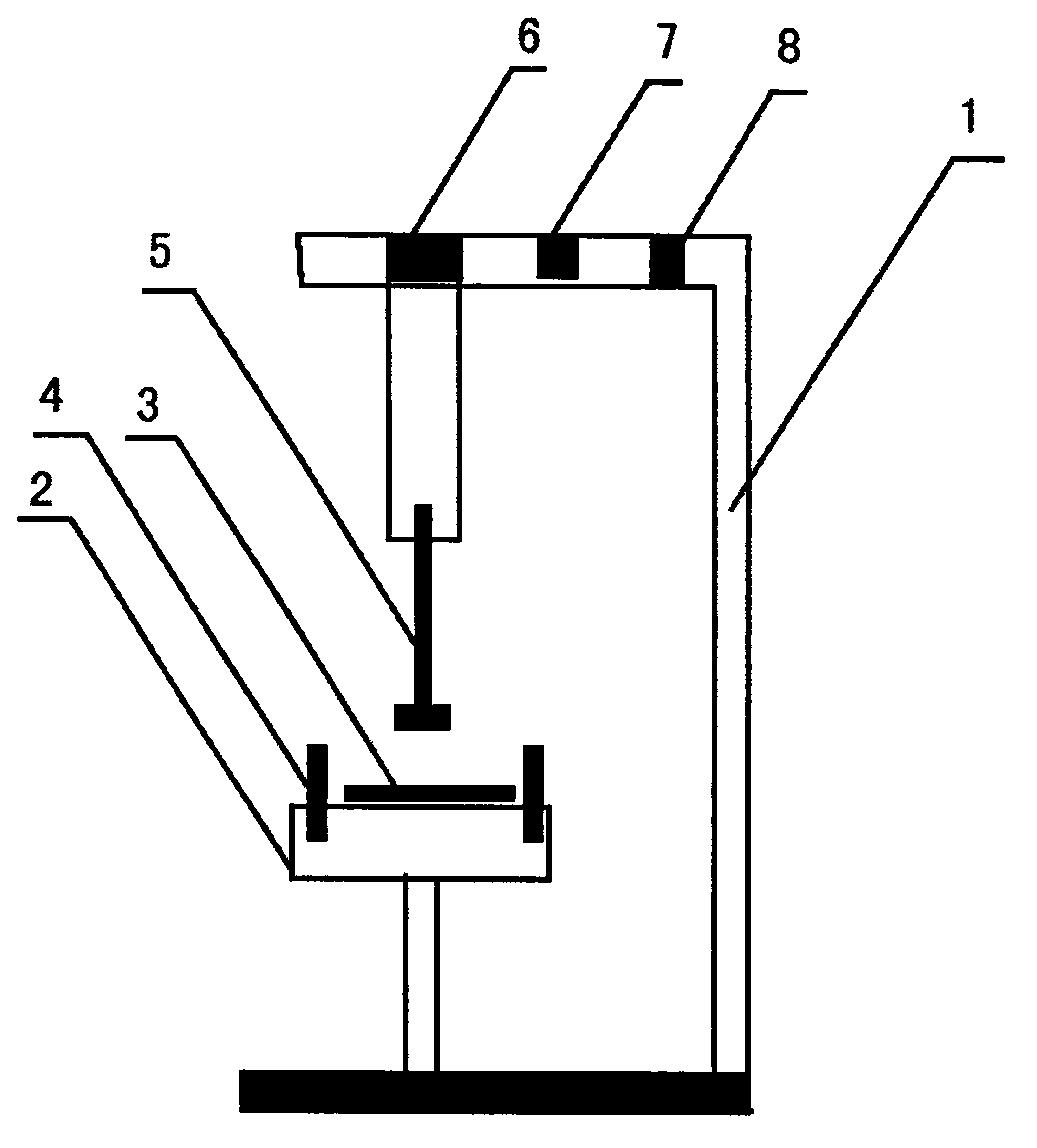

[0013] Embodiment: as shown in the accompanying drawing. Ink-making beater, a support [1], a beater tray [2] is set, an ink block [3] gathering device [4] is set on the beater tray [2], a beater bar [5] is set, a beater bar [5] Electric drive is used to adjust the corresponding speed, strength, frequency and other parameters. When in use, the ink block [3] is placed on the beating tray [2], and after the beating rod [5] has been beaten once, the gathering device [4] Automatically gather the edge-beating modules, and you can start beating again.

[0014] Ink-making hammering machine, hammering tray [2] The base layer is made of hard rubber, which is elastic and can carry out necessary hammering.

[0015] For the ink-making beating machine, a corresponding control module [6] is set to control the beat and strength of the beating.

[0016] The ink-making beating machine is equipped with a corresponding prompt module [7], and a prompt message is sent when the machine finishes se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com