Numerical control vertical hot ring rolling mill and control method

A numerically controlled vertical and roll technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of uneven quality of forming rings, large consumption of raw materials, low precision of forgings, etc., to save manpower, waste products The effect of low rate and high forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

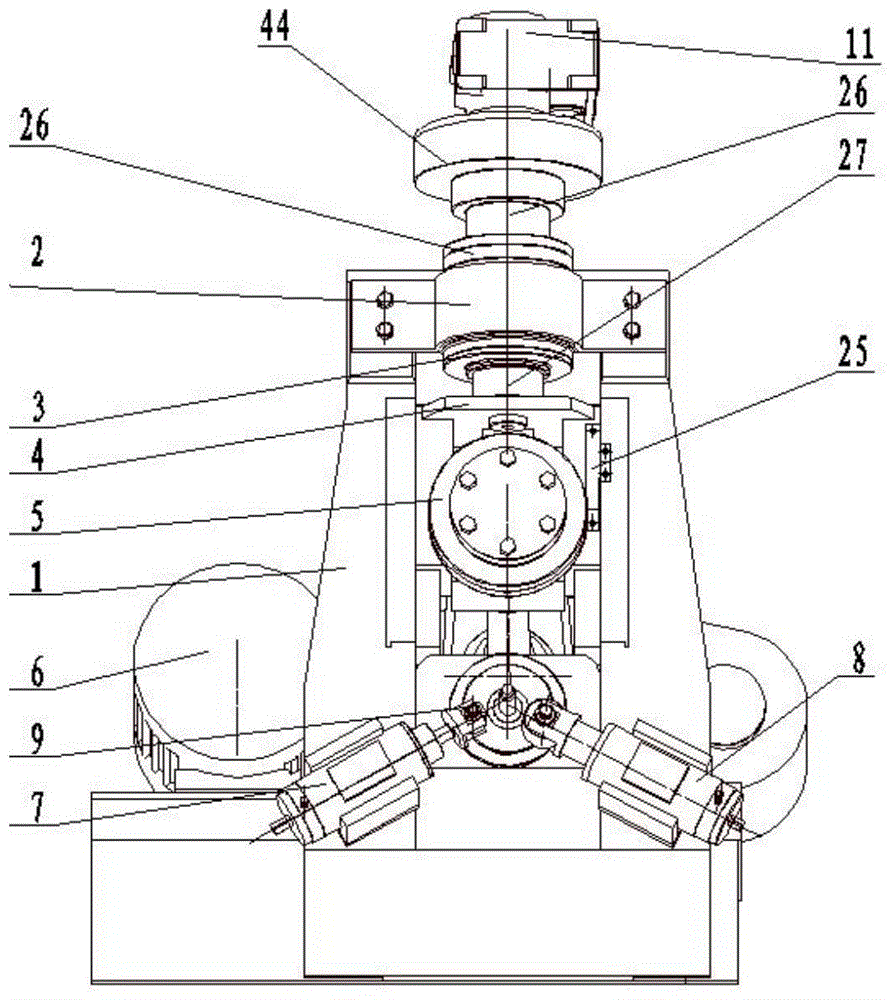

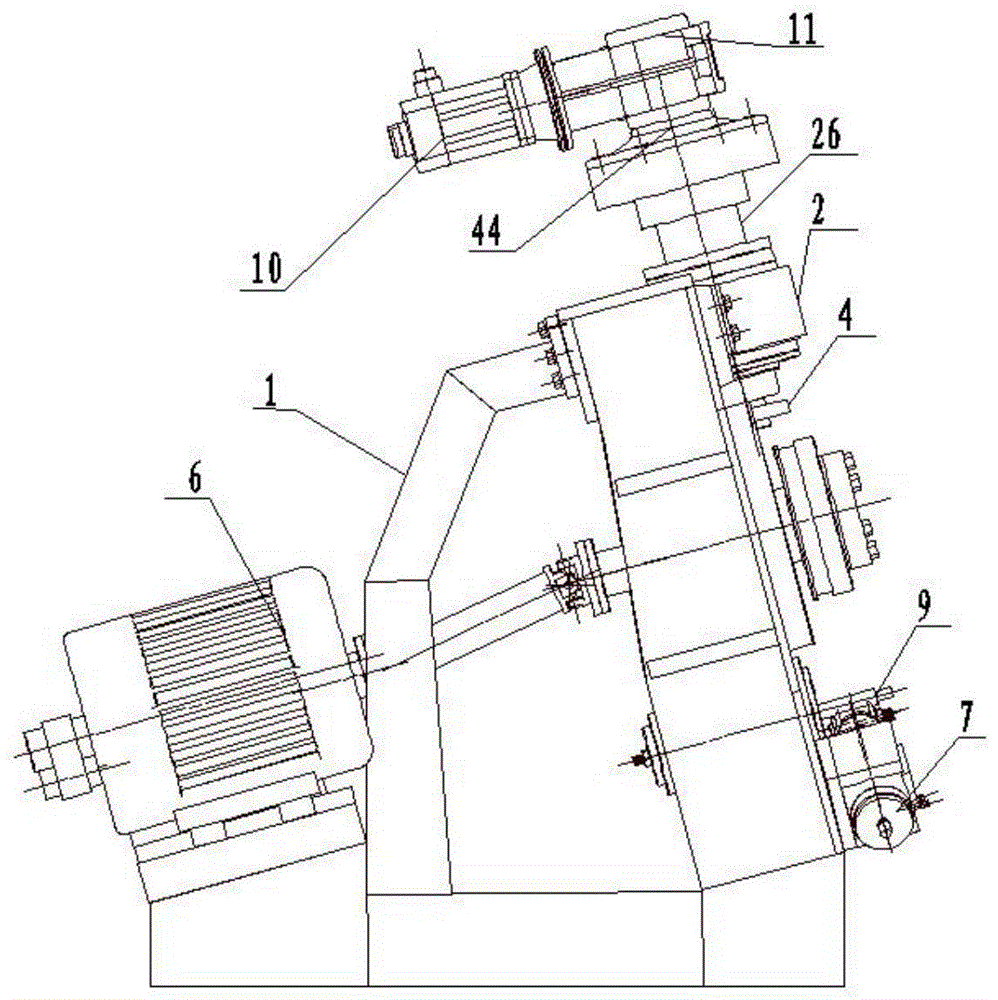

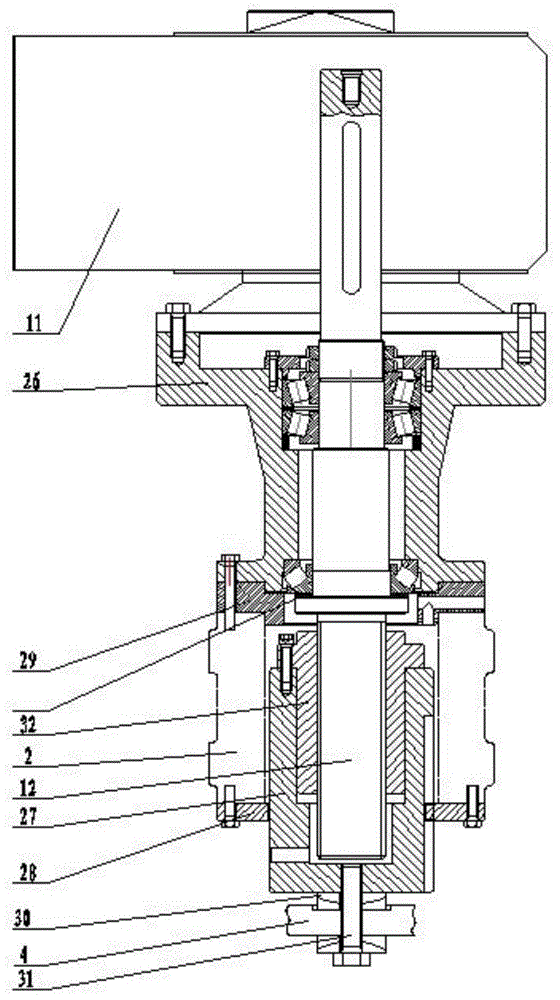

[0022] Such as Figure 1-4As shown, a numerically controlled vertical hot rolling ring machine includes a frame 1, a roll mechanism 3, a measuring roll mechanism 7, a guide roll mechanism 8, a core roll mechanism 9, a feed mechanism 44, and a control device. The roll mechanism 3 includes rolling The pressure wheel 5, the slider 4 and the roll motor 6, the radial centerline of the measuring roller mechanism 7 and the vertical centerline of the frame 1 form an angle of 50° to 60°, the radial centerline of the guide roller mechanism 8 and the machine The vertical centerline of the frame 1 is at an angle of 60° to 70°, the axial centerline of the core roller mechanism 9 is perpendicular to the vertical centerline of the frame 1, and the rolling wheel 5 is arranged on the core roller of the core roller mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com