Patents

Literature

40results about How to "Fast reversing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

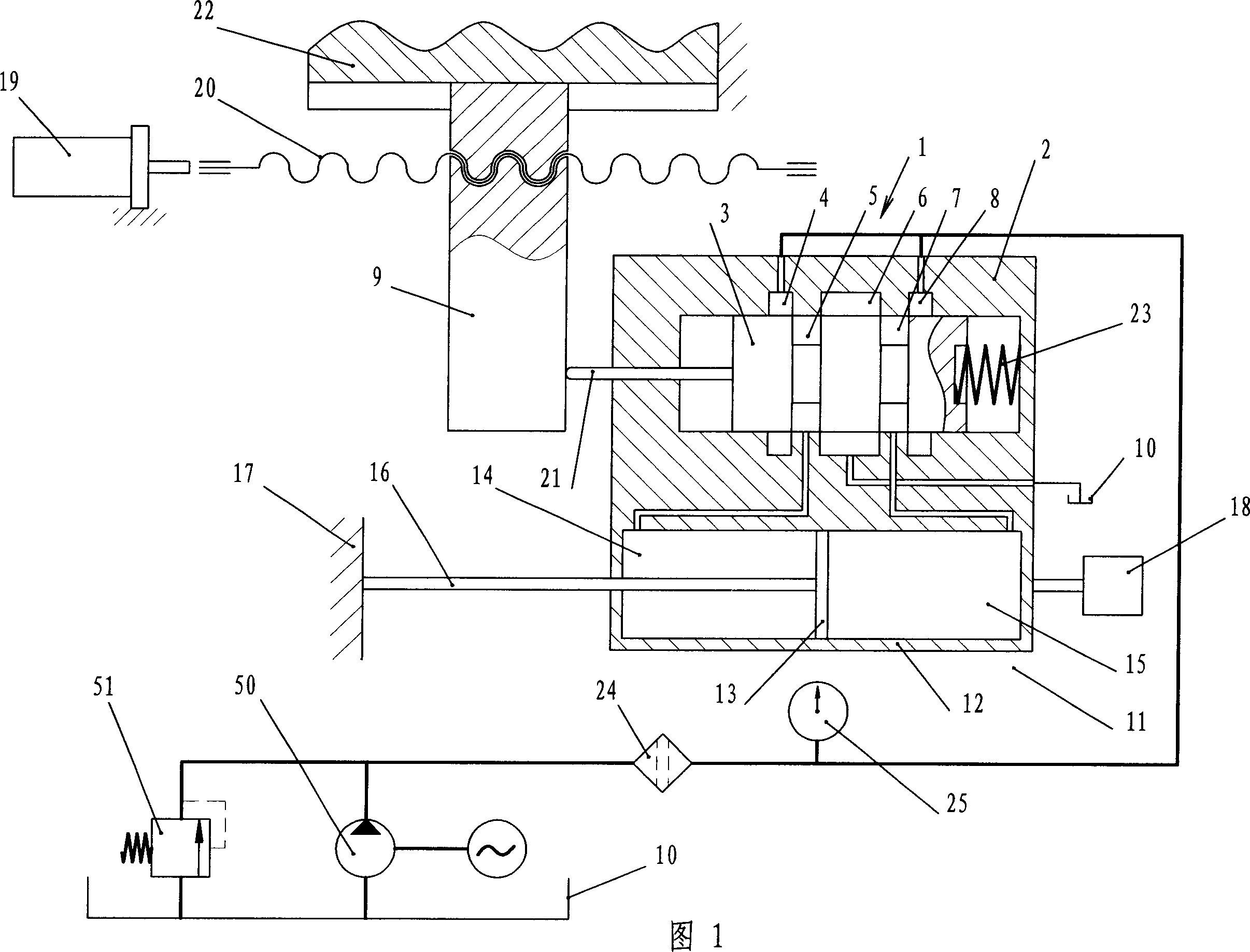

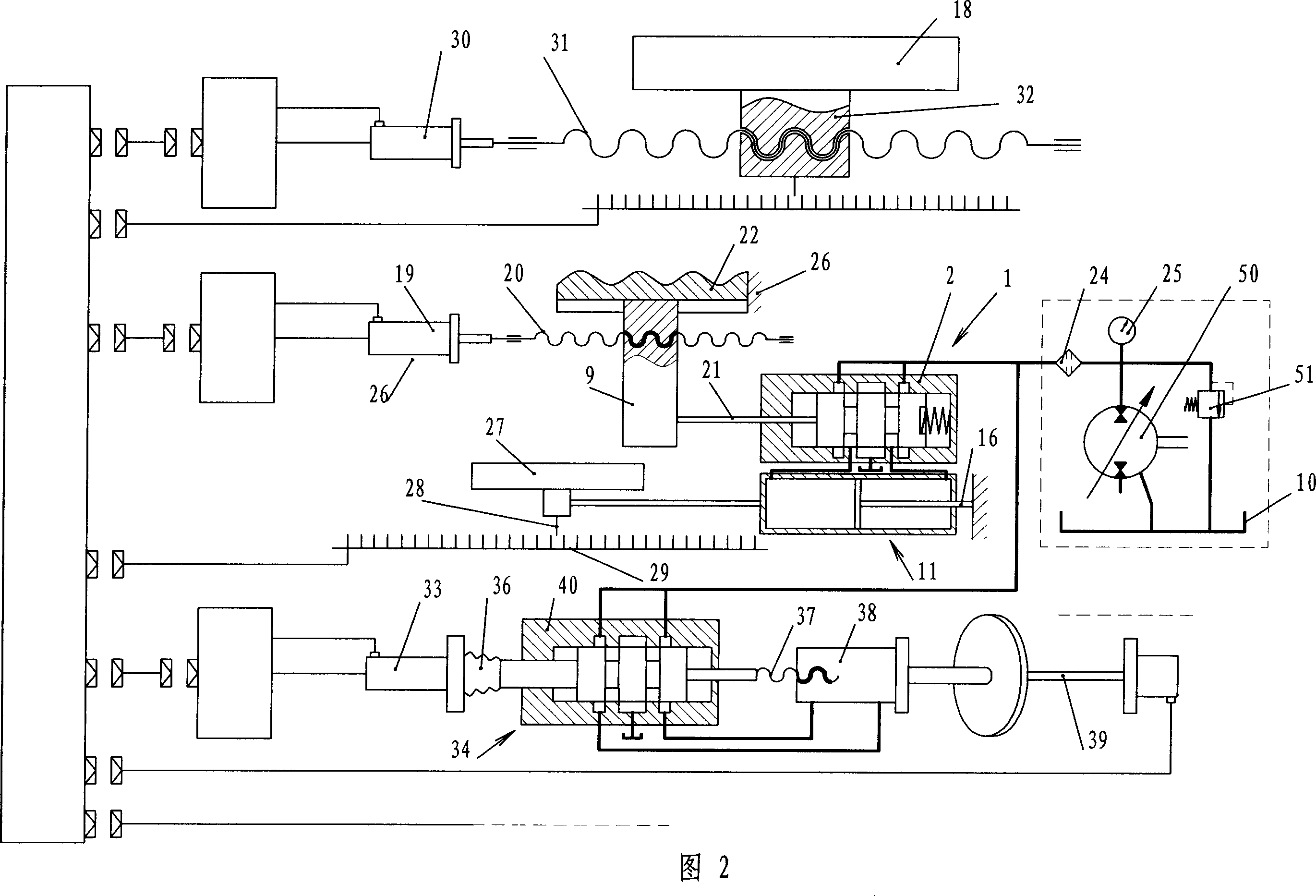

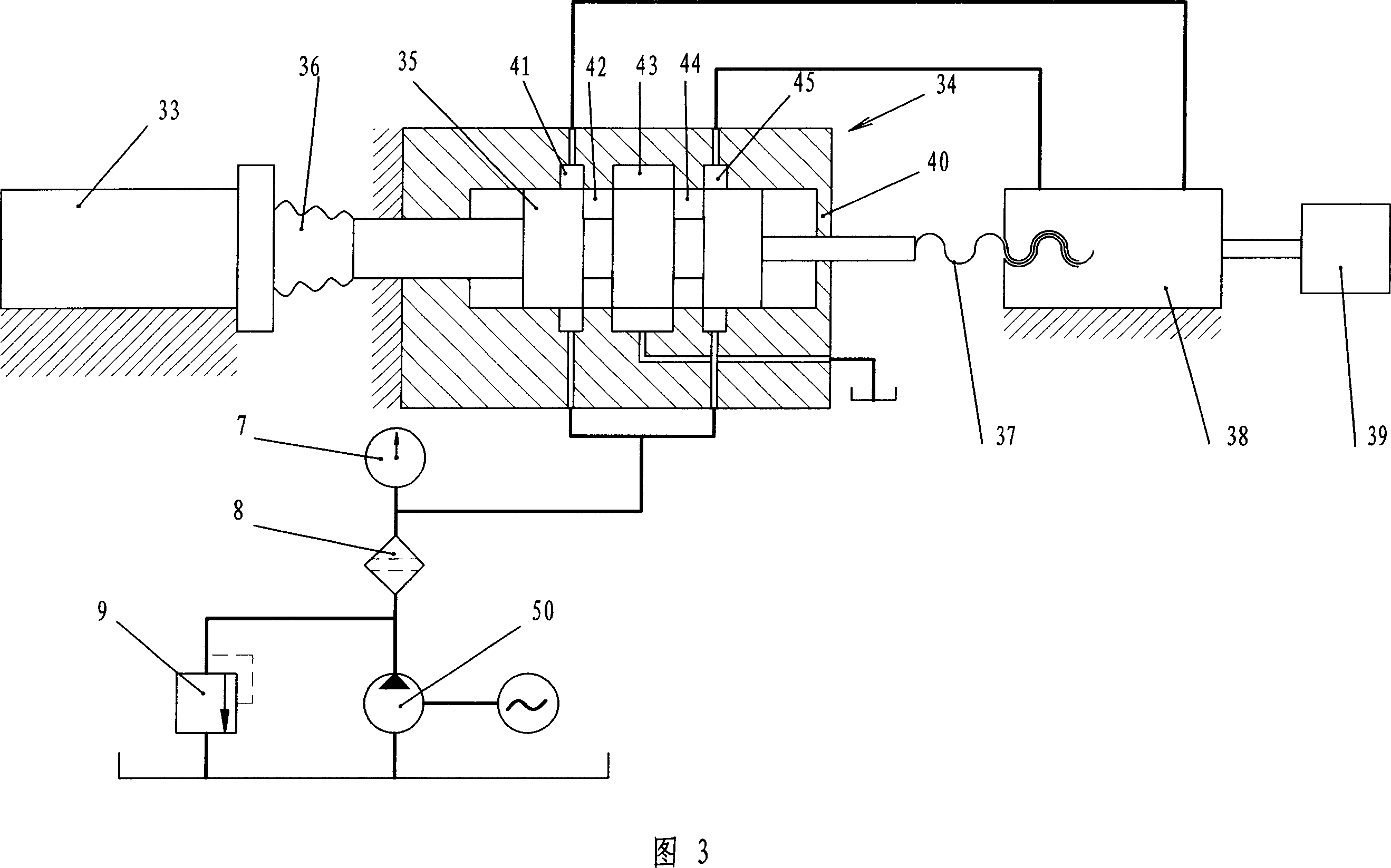

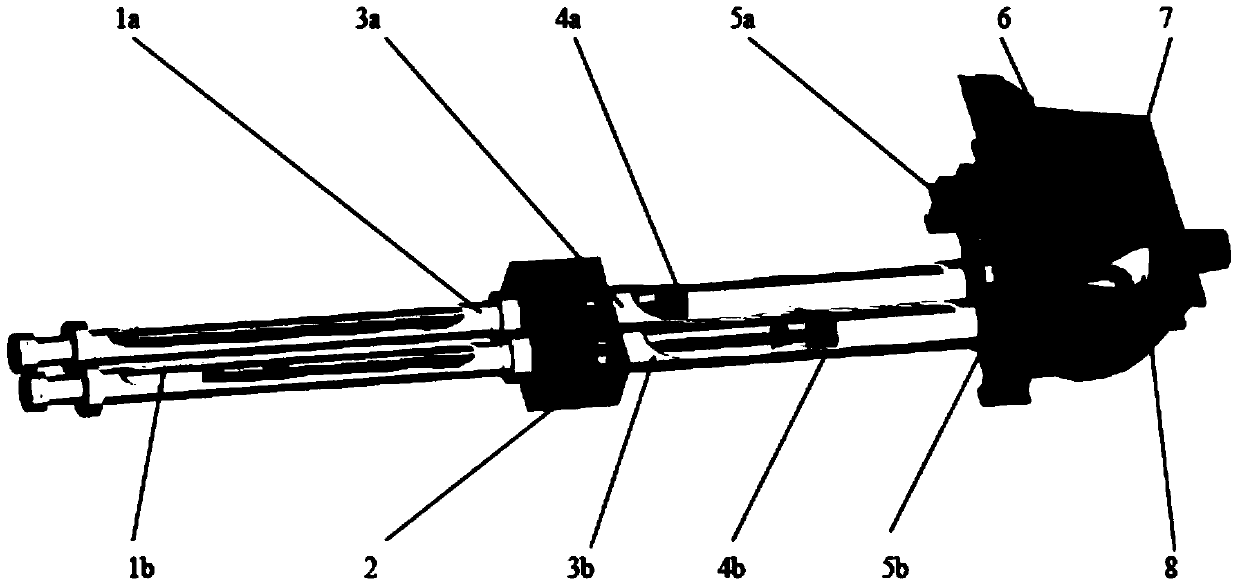

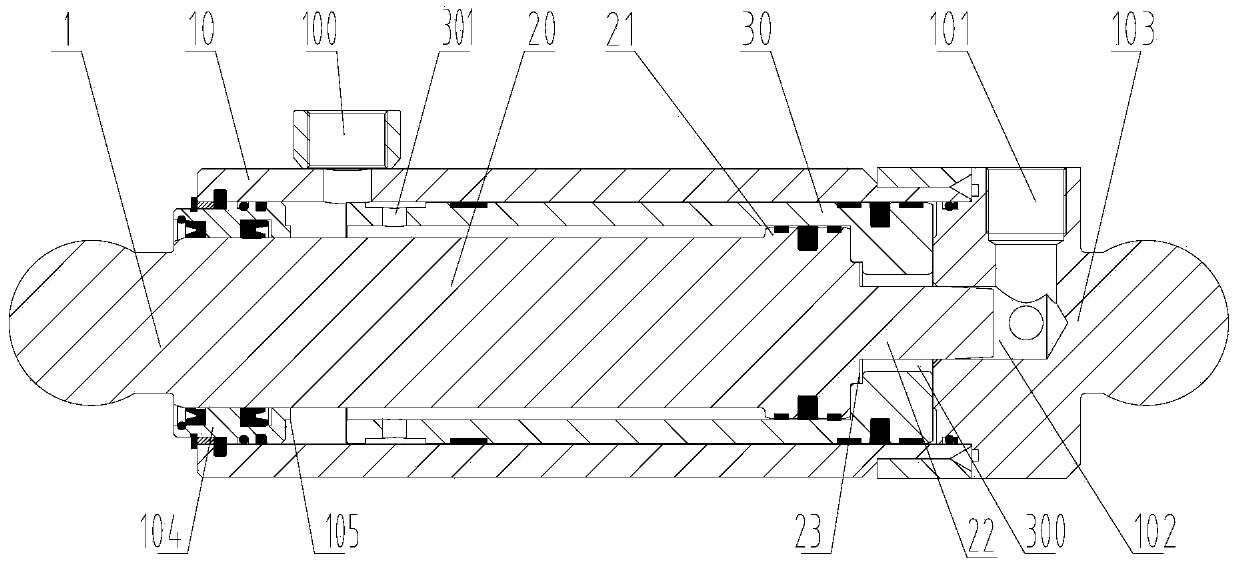

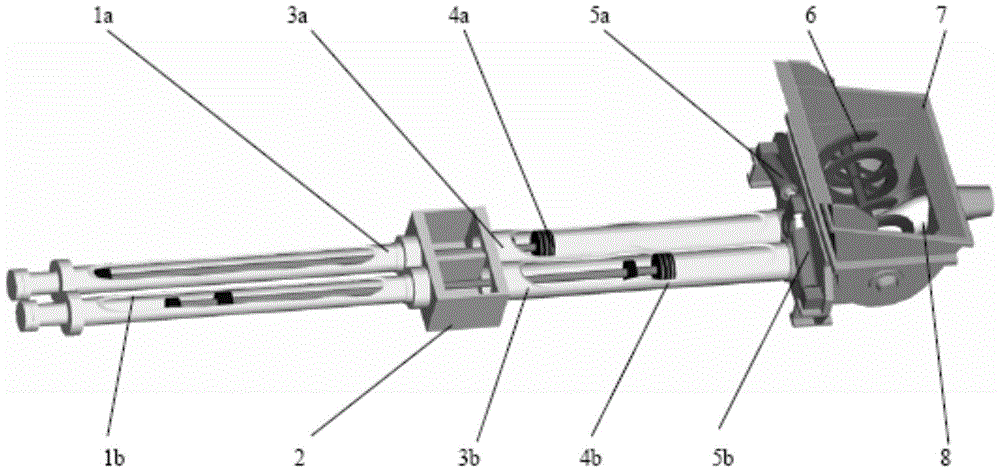

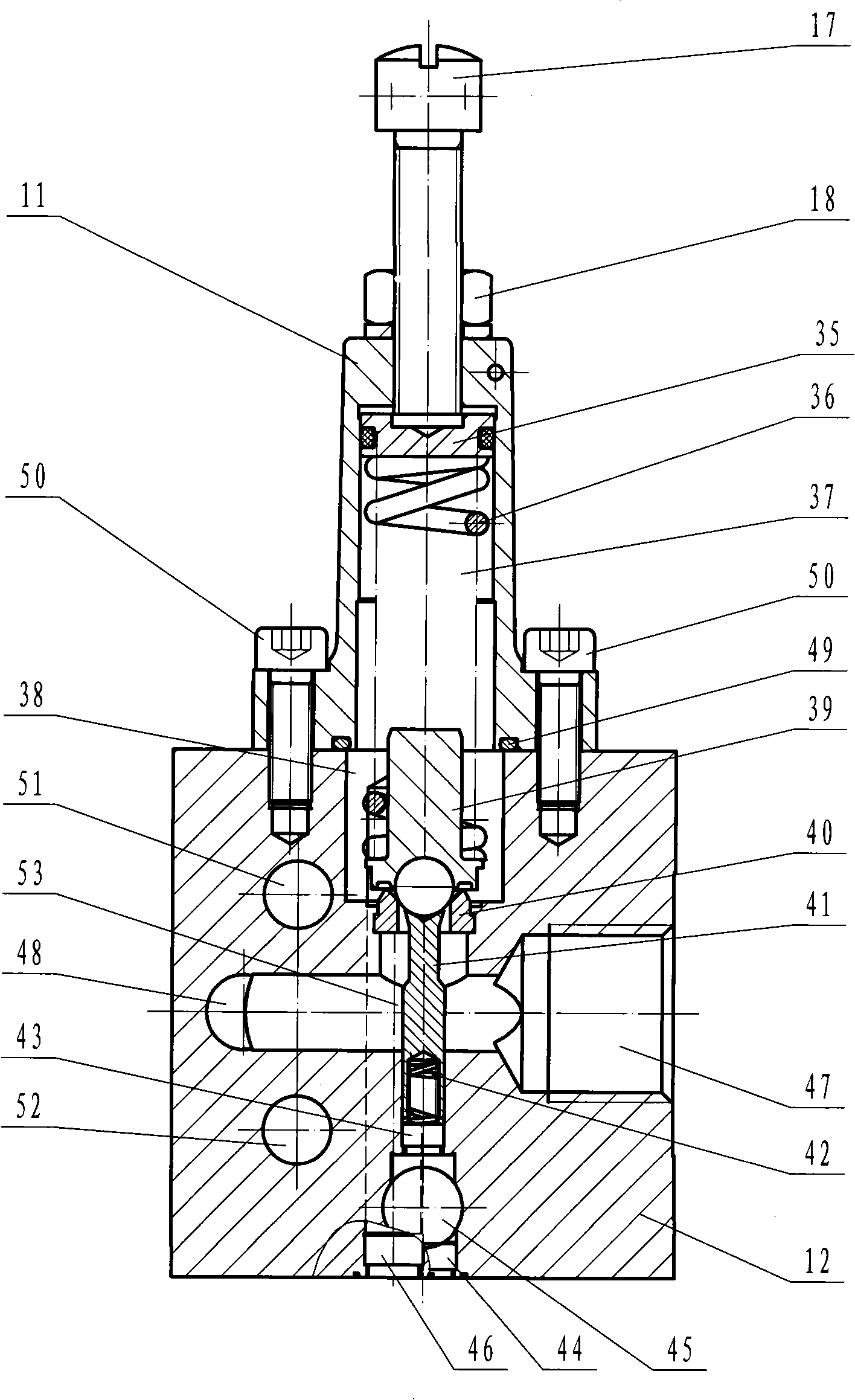

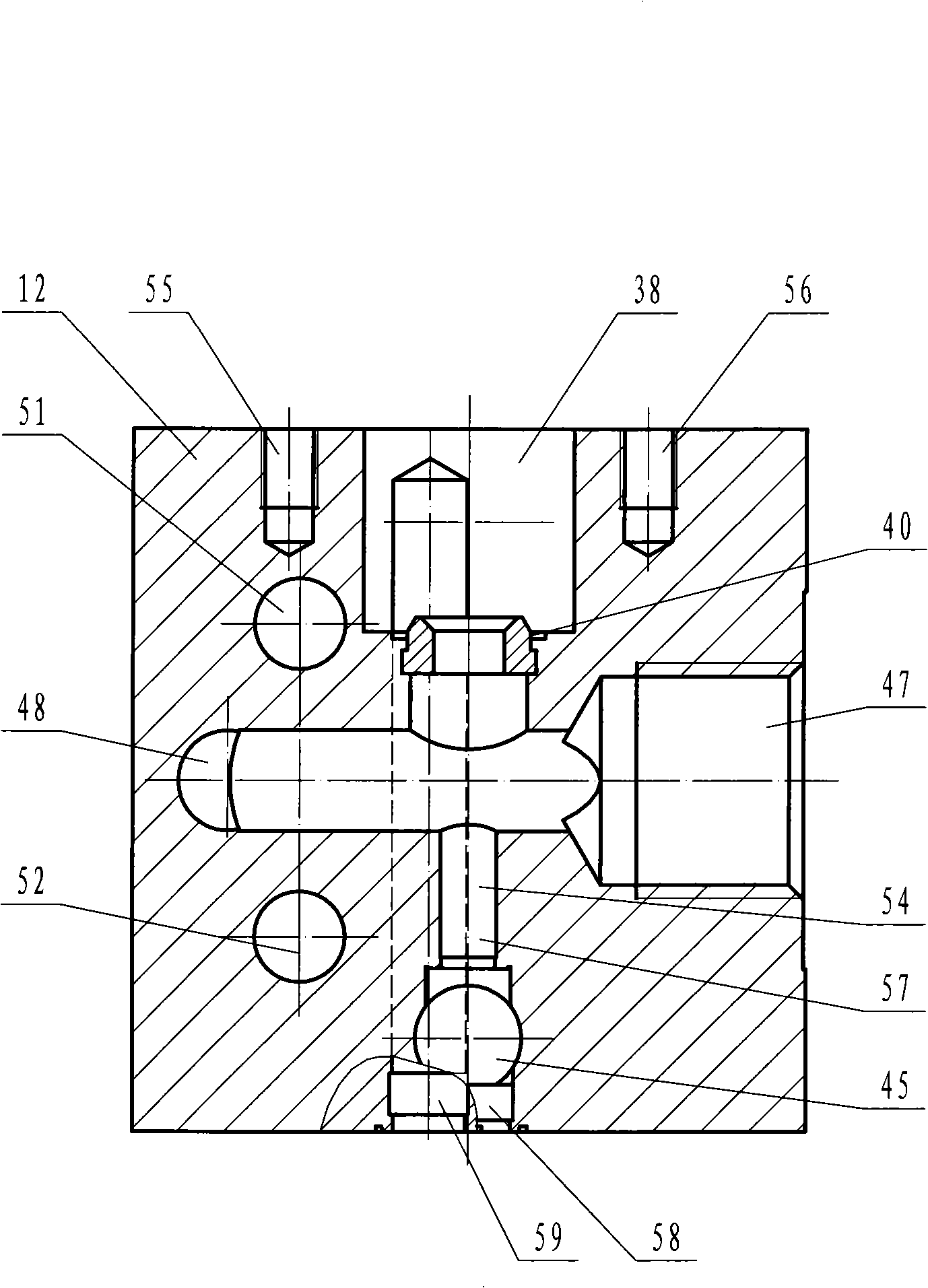

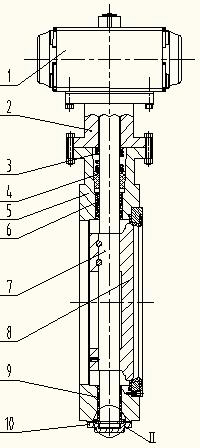

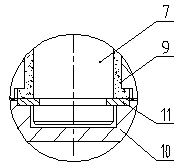

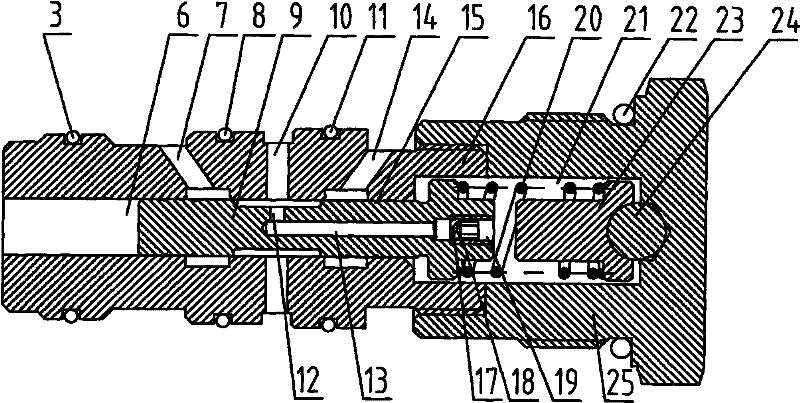

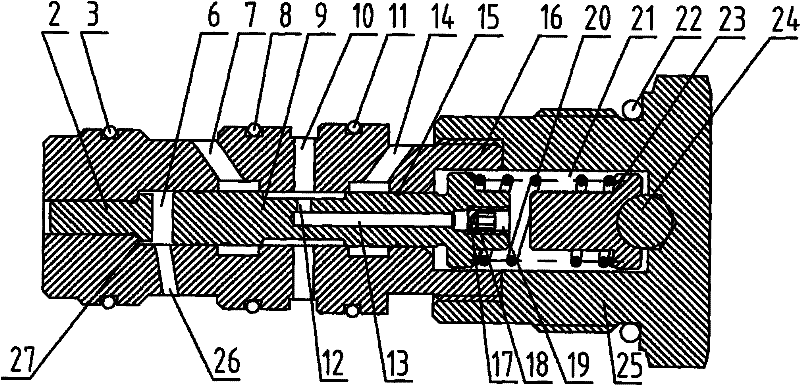

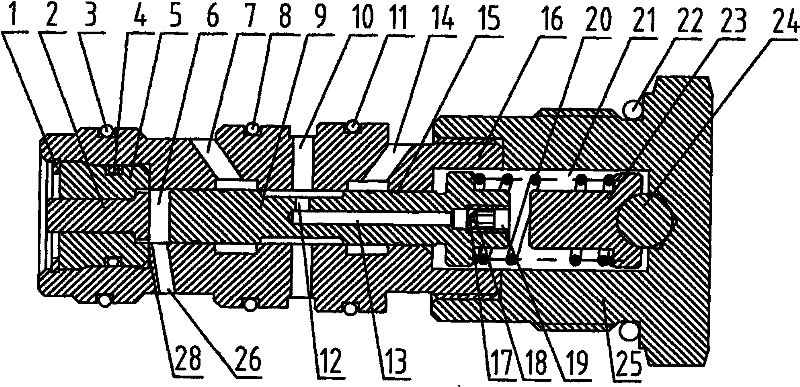

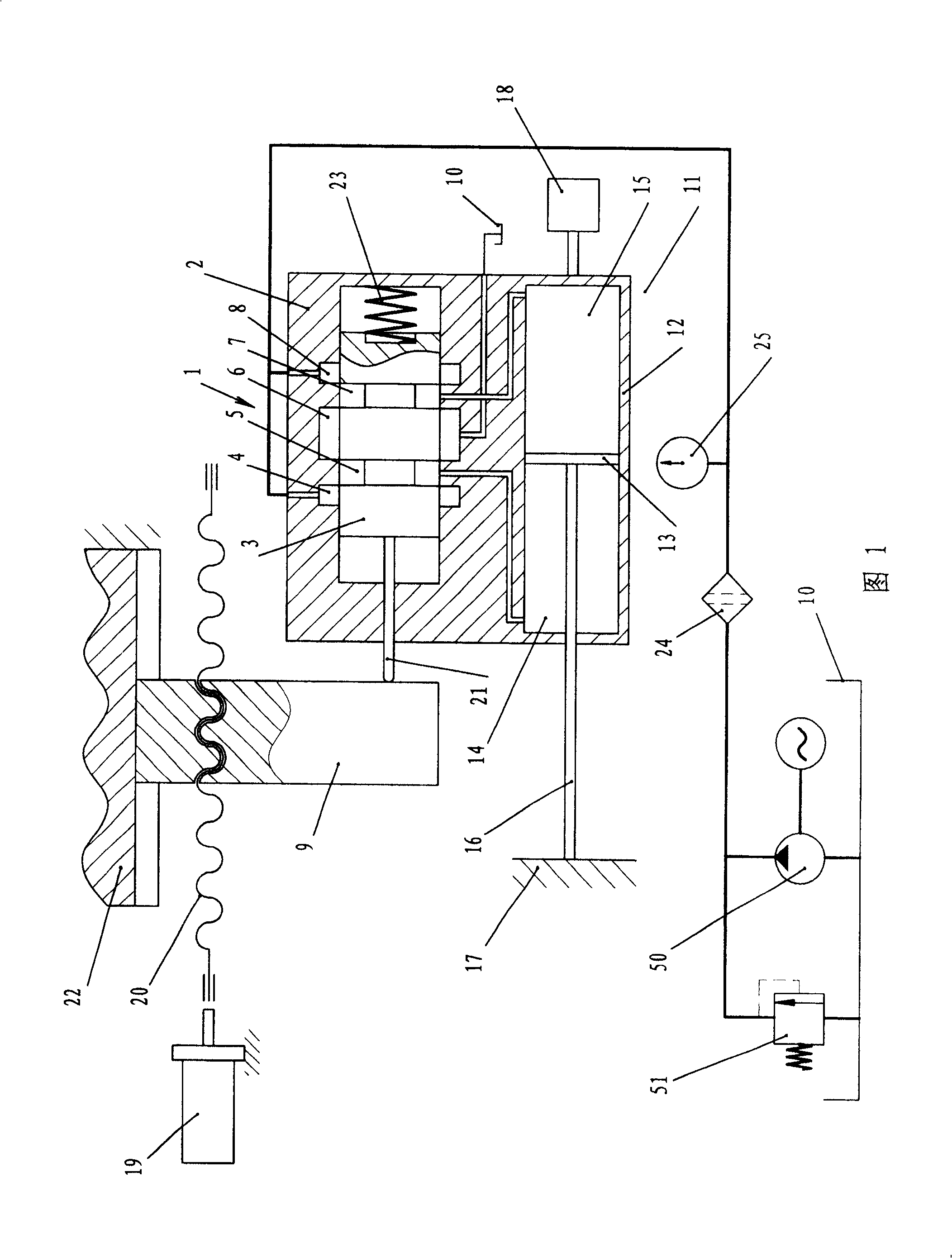

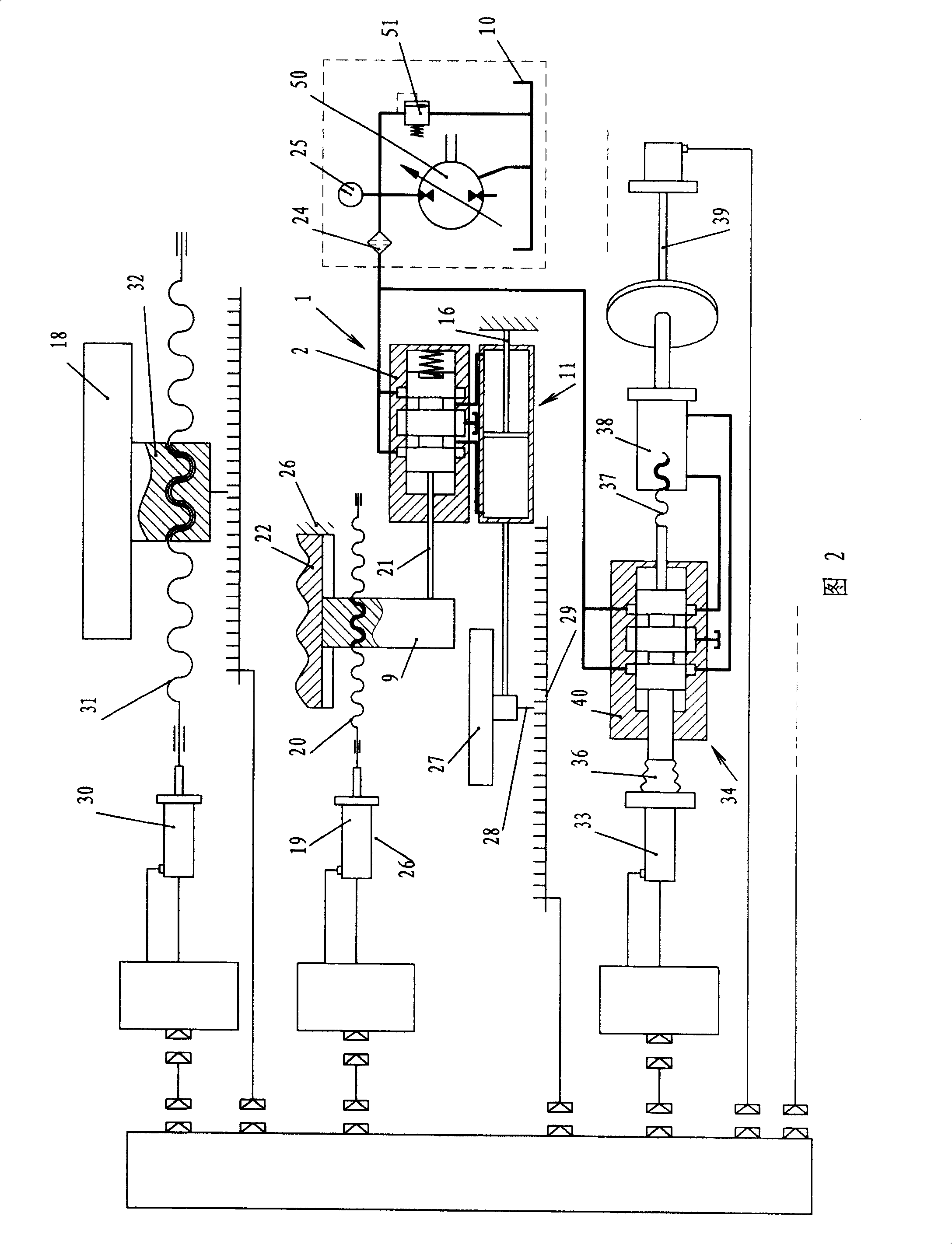

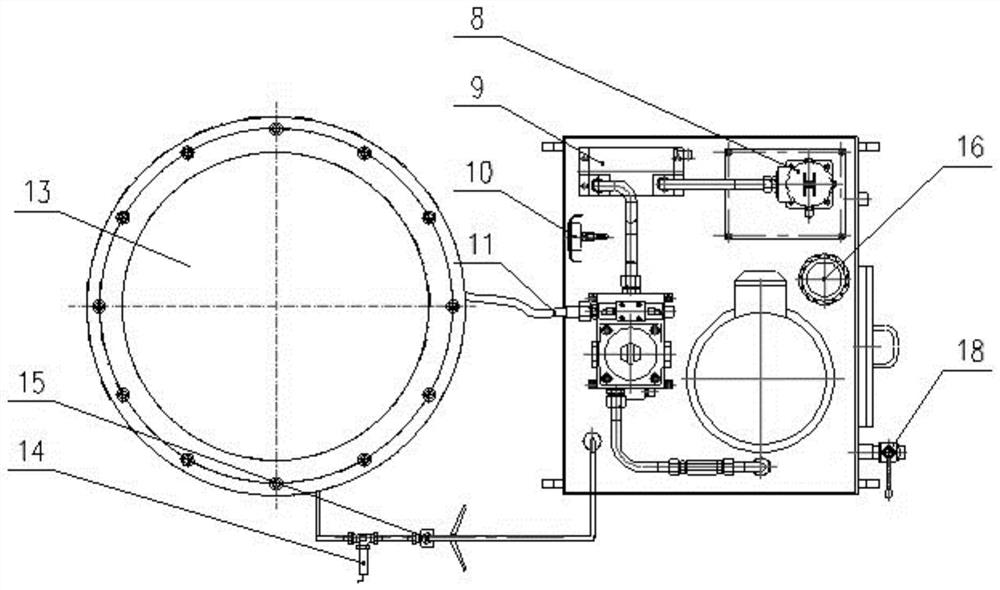

Electrohydraulic servo oil cylinder and numerical control machine tool using same

InactiveCN101008413AServo follow-up motion with high precisionHigh precisionOperating means/releasing devices for valvesServomotor componentsHydraulic cylinderControl system

The invention relates to an electro-hydraulic servo cylinder, comprising a four-edge sliding valve whose base is mounted with a valve element moving left and right. The valve base is fixed on the cylinder whose piston rod is fixed with the frame; the cylinder is connected with the load. The left driving chamber via tube is communicated with the left working chamber, while the right driving chamber via tube is communicated with the right working chamber; one end of valve element is engaged with the dial block mounted on the straight motion output element of straight motion output device. The digit-control machine with said electro-hydraulic servo cylinder comprises a first axle servo driving system, a second axle servo driving system, a third axle servo driving system and a digit-control system, wherein, the second driving system comprises a straight load axle. The invention has high accuracy, quick steering speed, and stable property, which combines the digit control technique with the electro-hydraulic servo motion, with high accuracy in large power.

Owner:路文忠

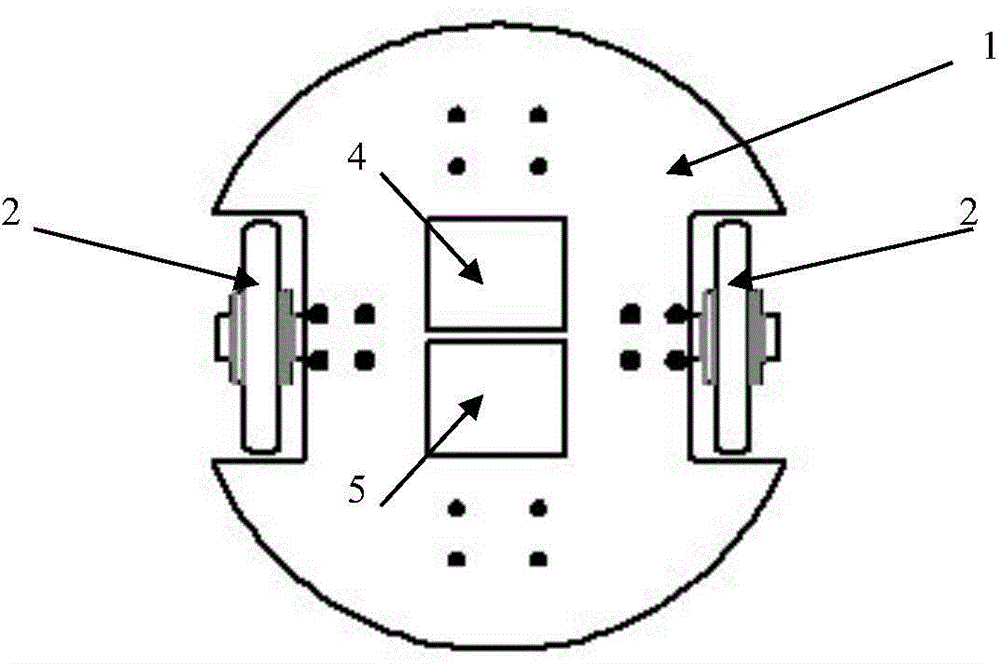

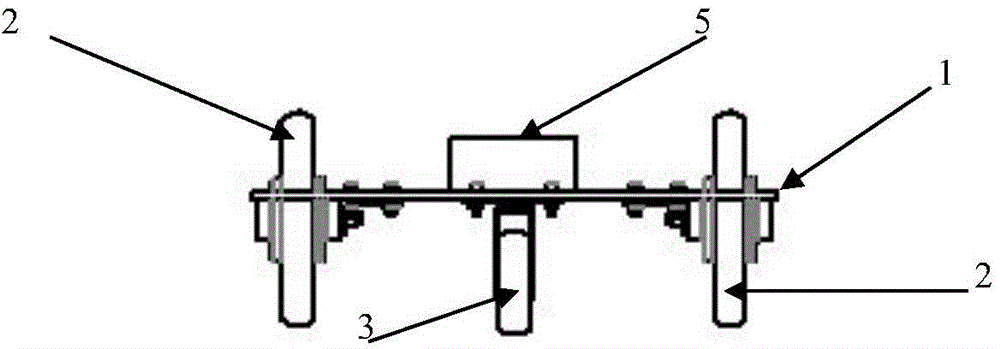

Four-wheel type indoor mobile robot

ActiveCN104407614AHighlight substantive featuresIncrease lossPosition/course control in two dimensionsBrushless motorsDrive wheel

The invention provides a four-wheel type indoor mobile robot, and relates to a robot. The four-wheel type indoor mobile robot comprises a chassis, two driving wheels, two universal wheels, a controller and a lithium battery. The two driving wheels are two independent driving wheels adopting a wheel hub type DC brushless motor with a Hall effect sensor to act as a driving motor. The driving wheels and the driving motors are integrated. The controller adopts a full-bridge PWMDC / DC converter working in a bipolar mode to drive the DC brushless motors so that disadvantages in the prior art that DC brush motors are slow in commutation speed and high in noise, and the motors are liable to be damaged when the motors are in a wear and tear state for a long time can be overcome.

Owner:HEBEI UNIV OF TECH

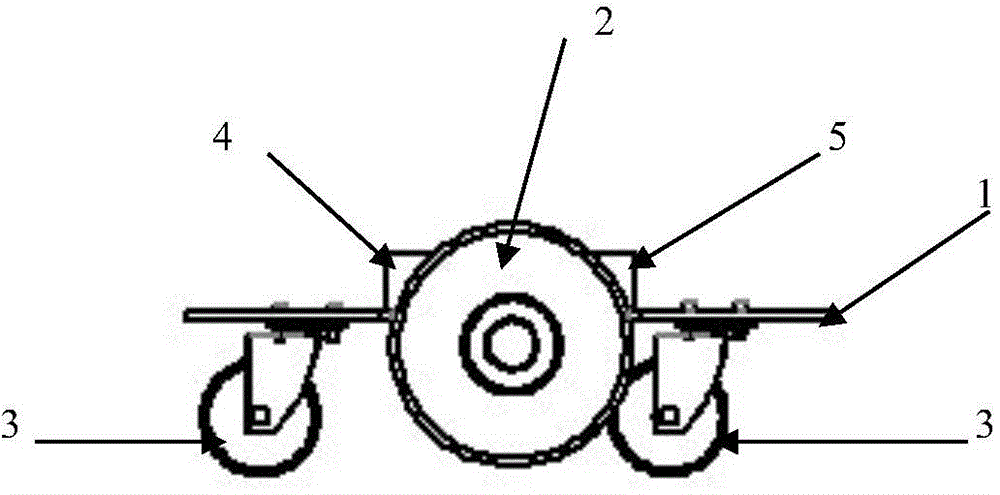

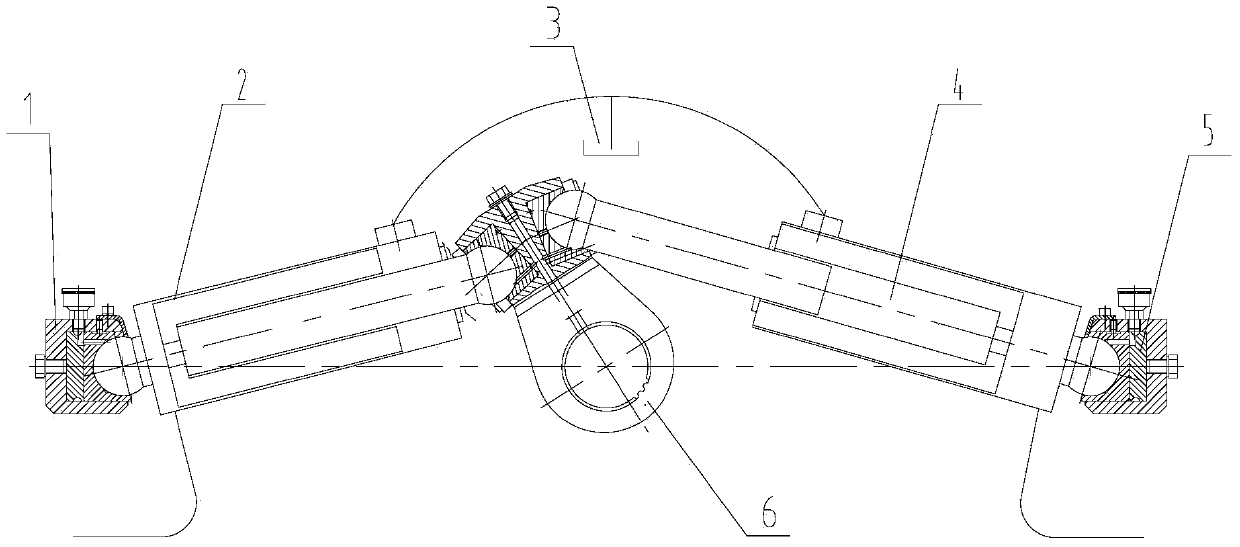

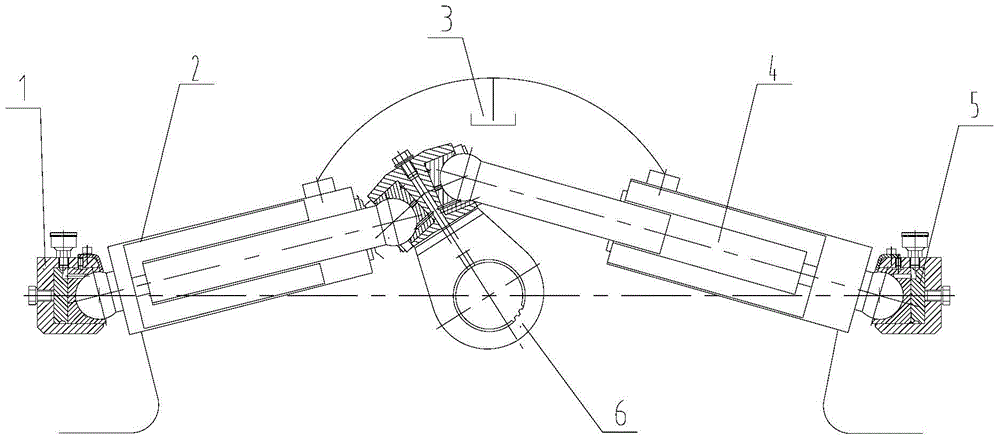

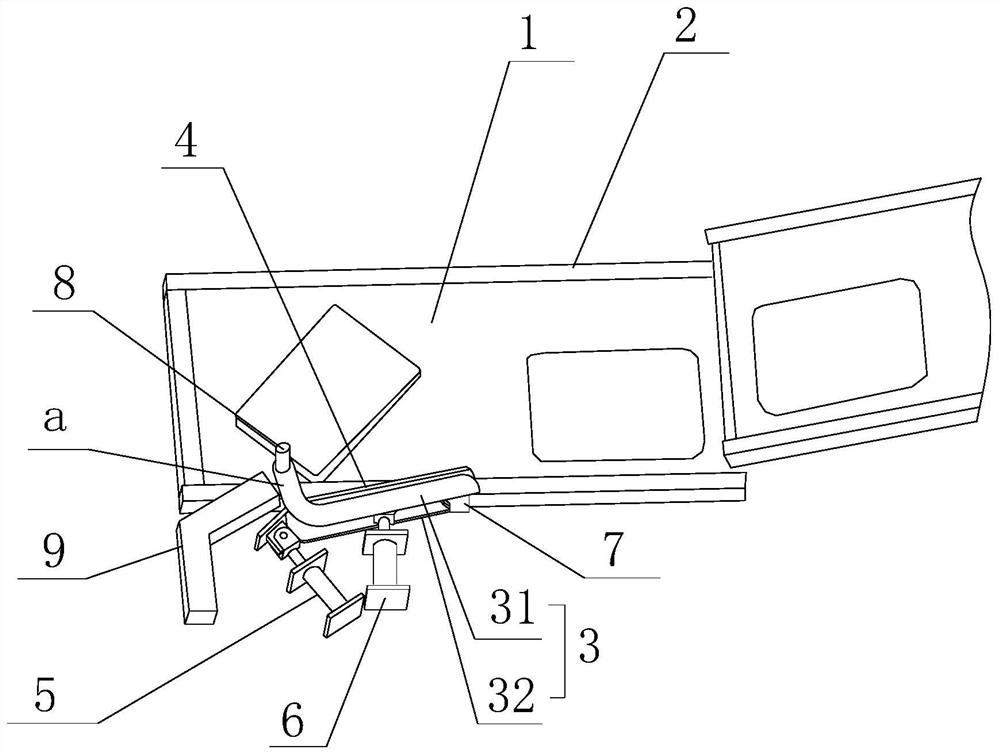

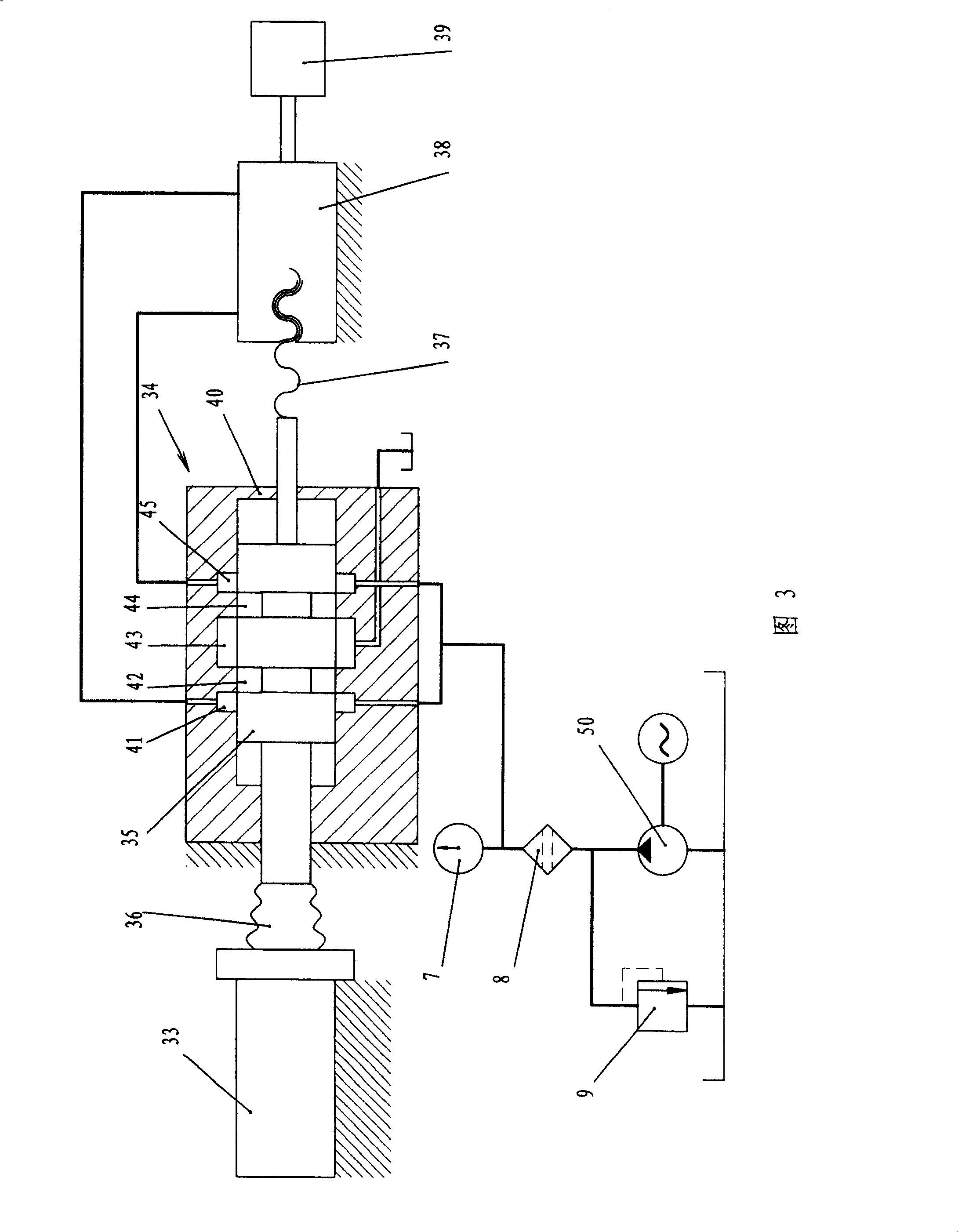

Swing mechanism and concrete pumping device

ActiveCN103470555AFast changeover timeReduce changeover timeServomotorsPumpsReverse timeMechanical engineering

The invention discloses a swing mechanism. The swing mechanism is used for driving a distributing valve of a concrete pumping device to swing and comprises a swing arm for driving the distributing valve and two hydraulic oil cylinders for driving the swing arm to swing from side to side. Ends of the two hydraulic oil cylinders are respectively connected with the left side and the right side of the swing arm, and the hydraulic oil cylinders are two-stage hydraulic oil cylinders. The invention further discloses the concrete pumping device comprising the swing mechanism. According to the swing mechanism and the concrete pumping device with the swing mechanism, the reversing speed is quick, impact is small, reversing time of the swing mechanism is close to reversing time of a main oil cylinder of the concrete pumping device, and pumping continuity is greatly improved.

Owner:SANY AUTOMOBILE MFG CO LTD

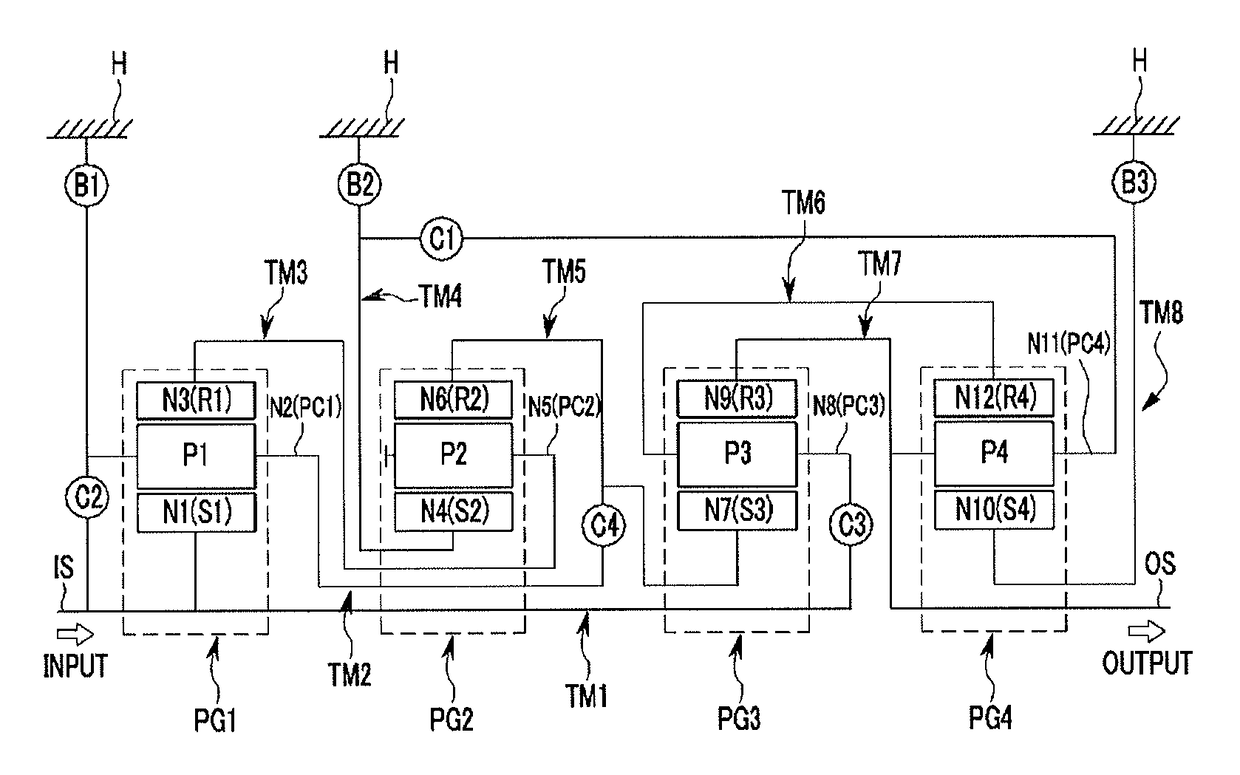

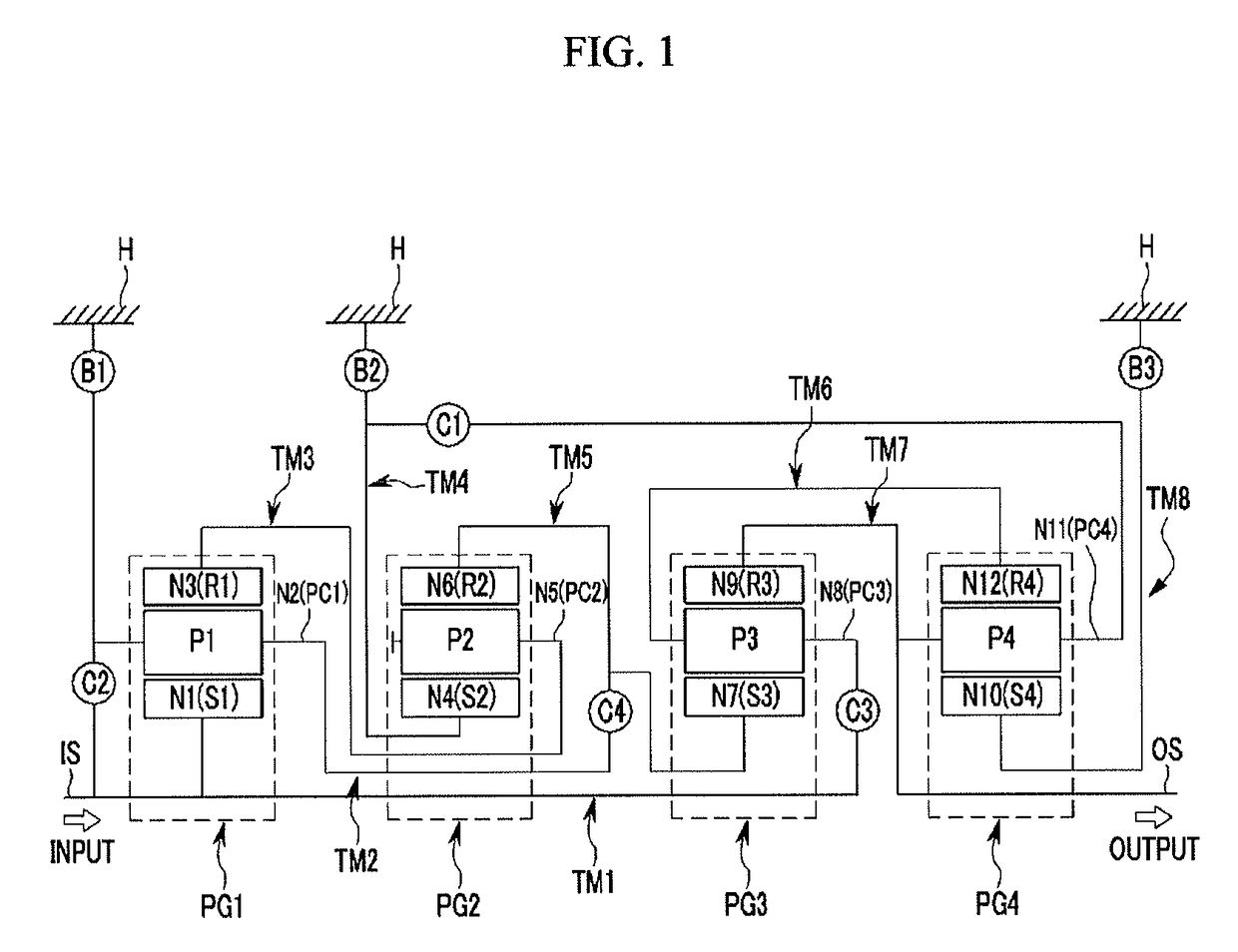

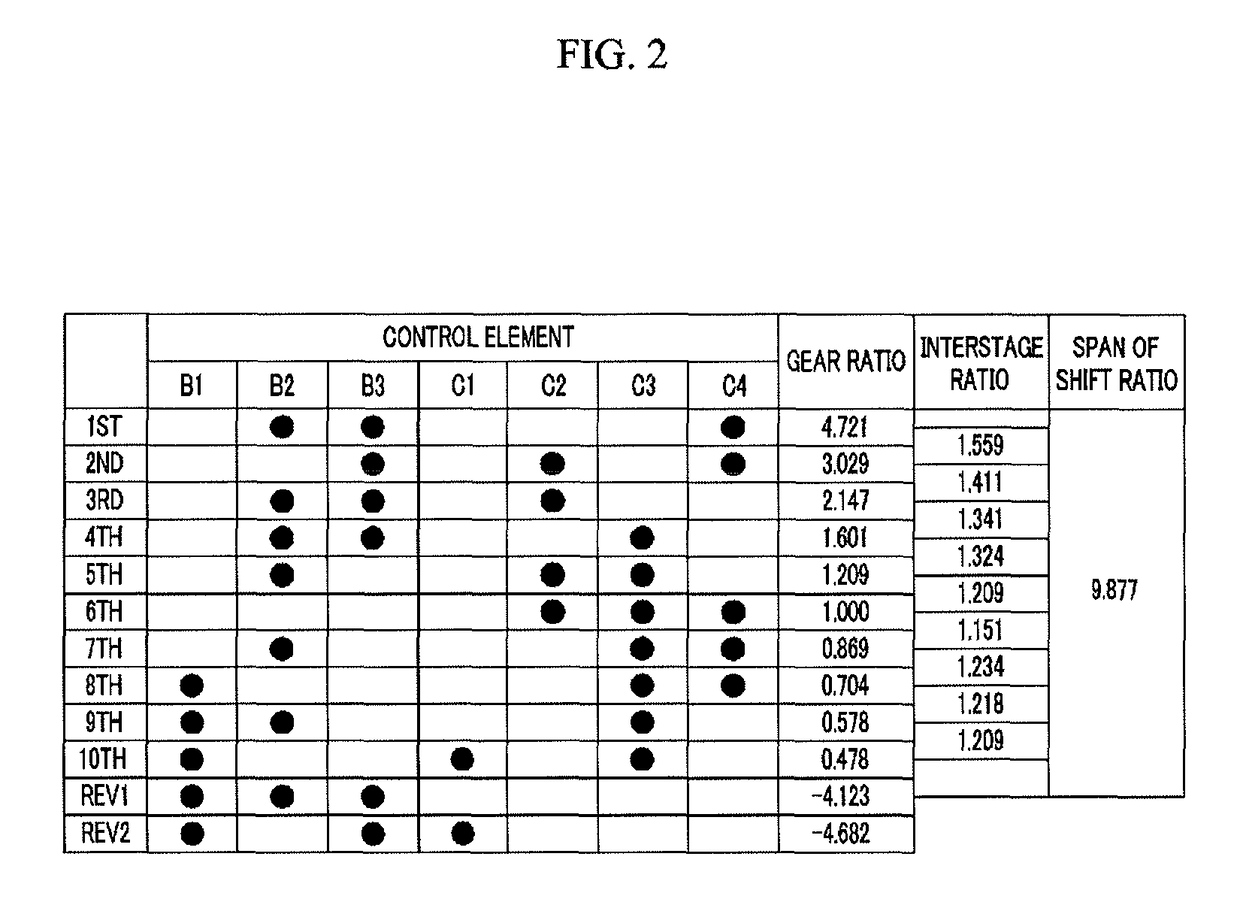

Planetary gear train of automatic transmission for vehicles

ActiveUS9651115B2Increase spanImprove efficiencyToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A planetary gear train of an automatic transmission for vehicles may include an input shaft receiving power of an engine, an output shaft outputting shifted power of the engine, a first planetary gear set including first, second, and third rotational elements, a second planetary gear set including fourth, fifth, and sixth rotational elements, a third planetary gear set including seventh, eighth, and ninth rotational elements, a fourth planetary gear set including tenth, eleventh, and twelfth rotational elements, and seven control elements disposed between the rotational elements and at positions at which the rotational elements and a transmission housing are selectively connected.

Owner:HYUNDAI MOTOR CO LTD

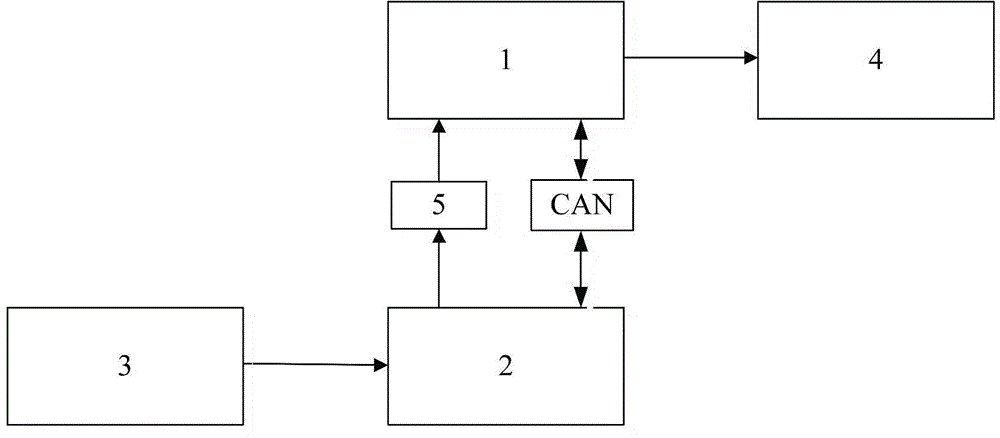

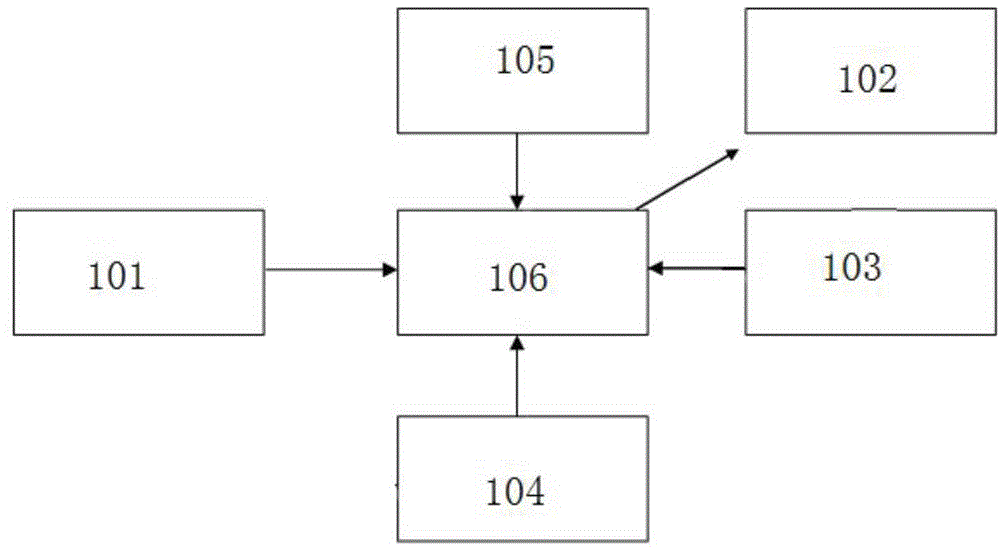

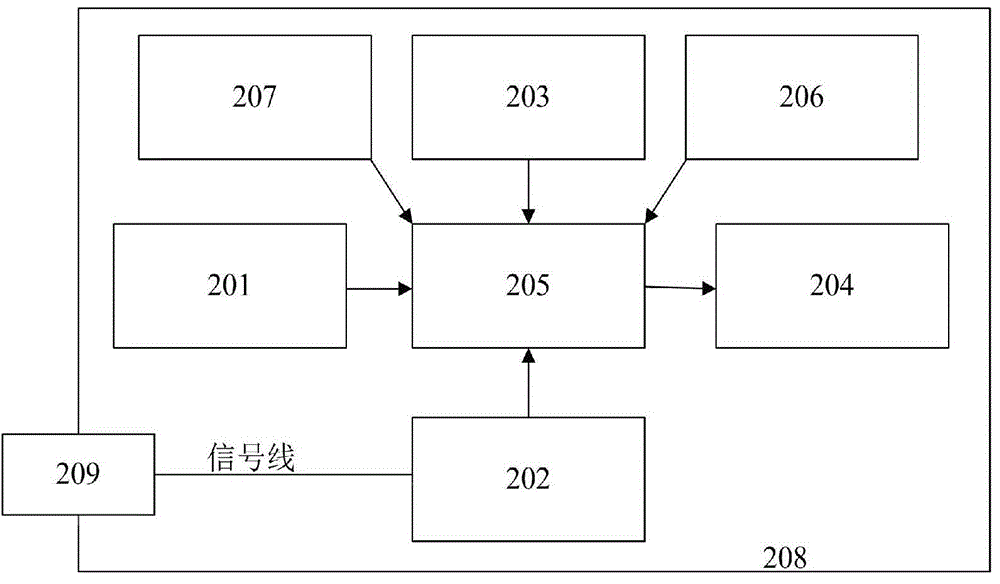

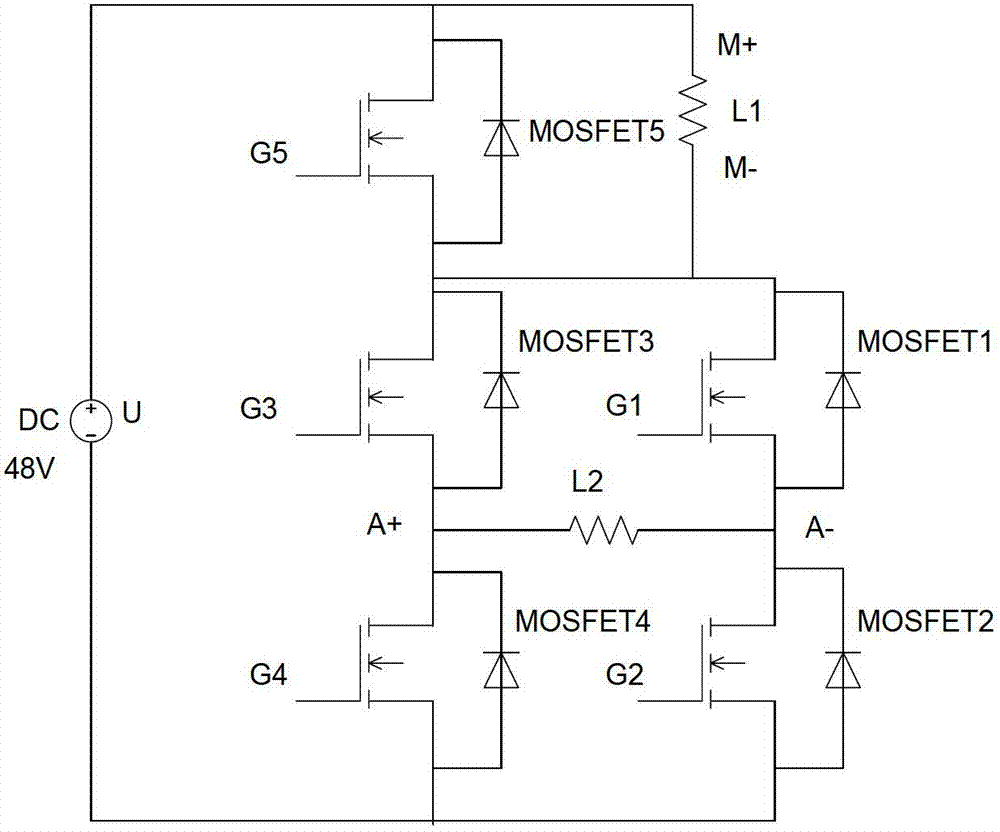

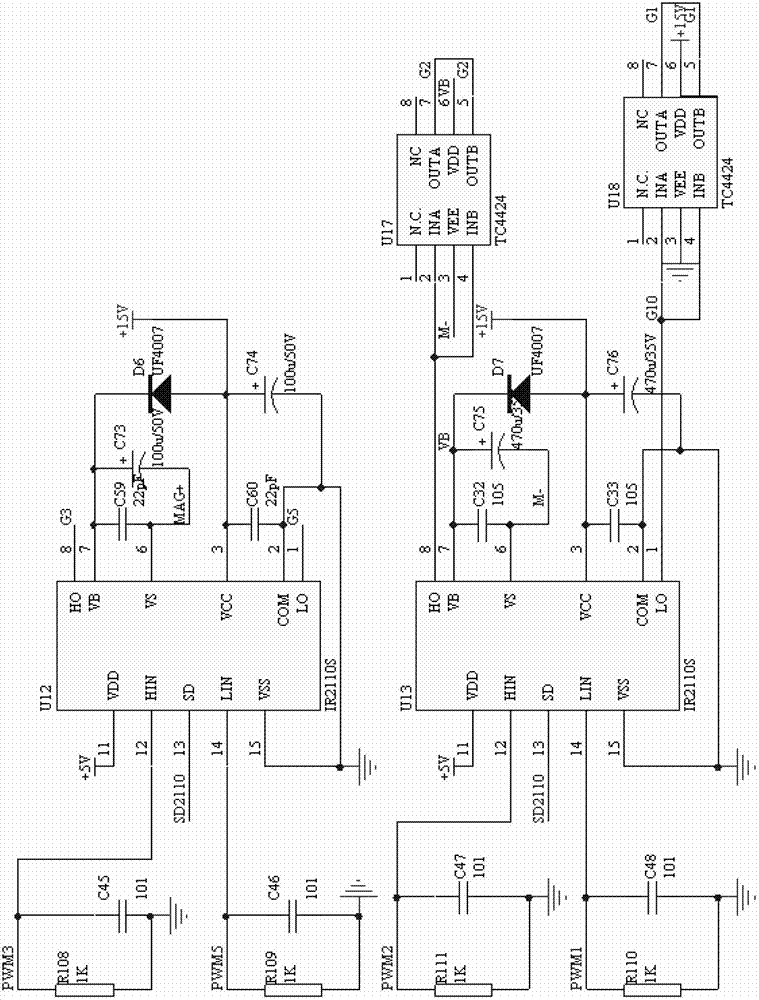

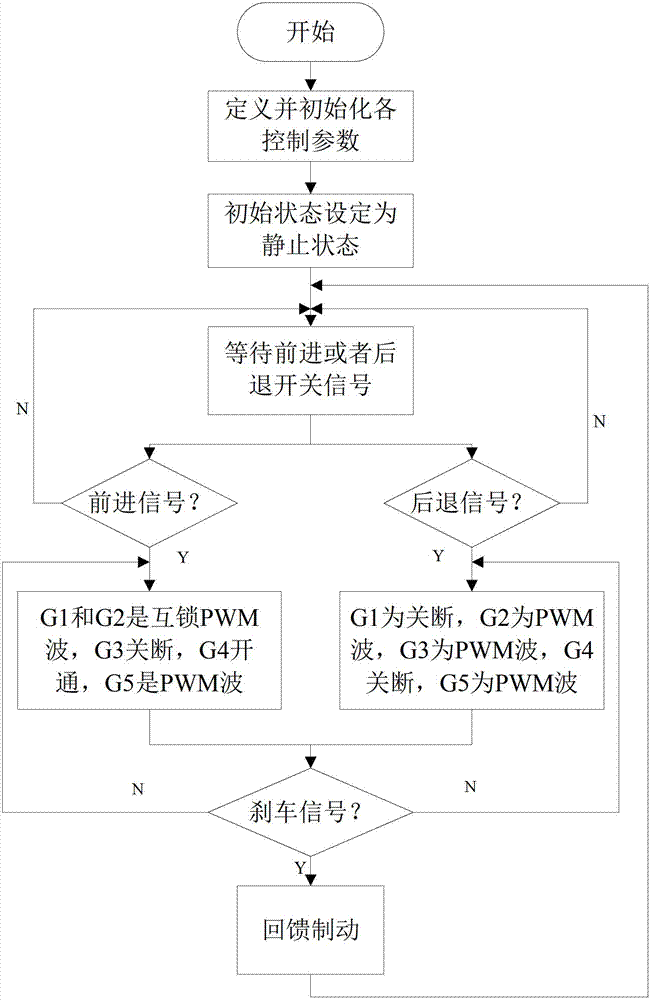

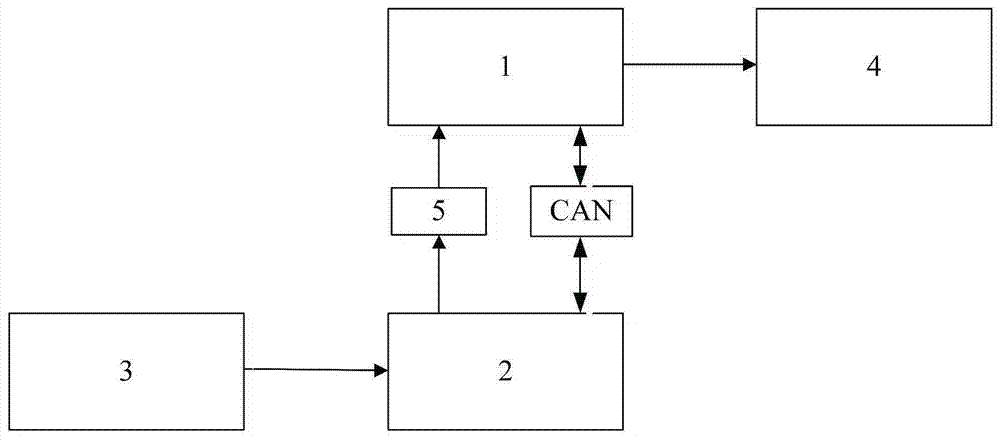

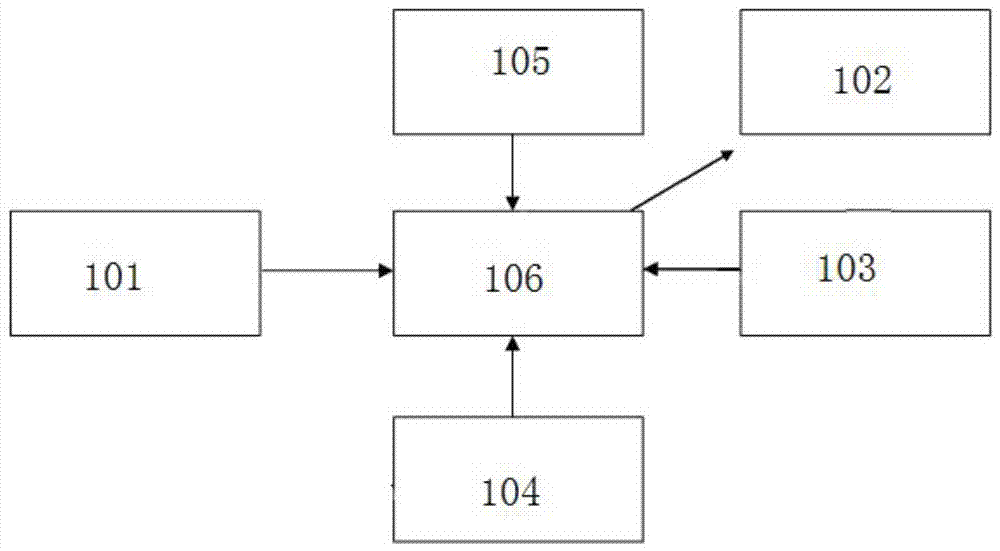

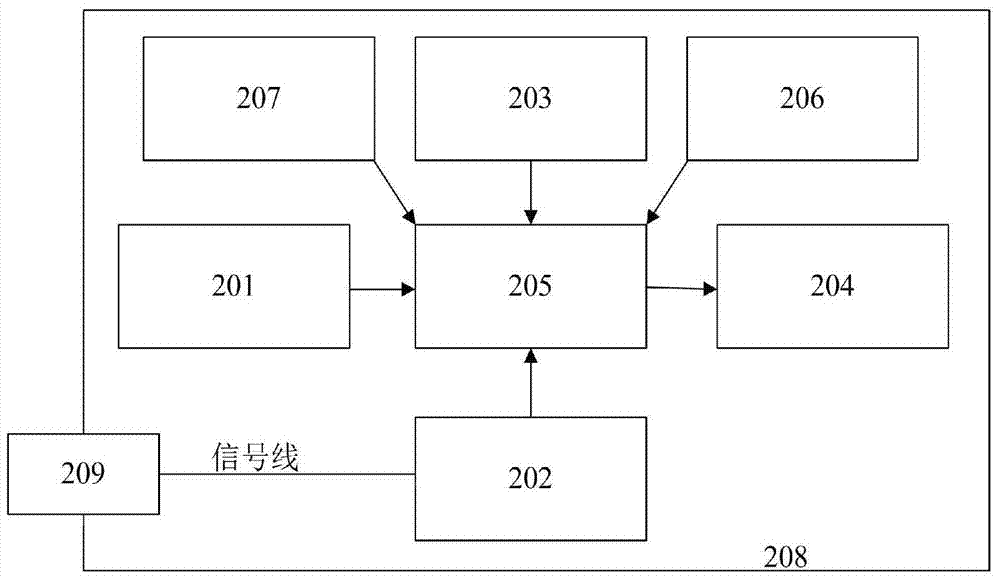

Dual-motor coordination control electric wheelchair control device

ActiveCN104881055AFast reversing speedReduce lossField or armature current controlSpeed/accelaration control using electric meansMotor driveWheelchair

The invention relates to a dual-motor coordination control electric wheelchair control device, and relates to a motor driving wheelchair; the electric wheelchair control device comprises a controller, a manual operator, a storage battery and motors; a connecting mode of the parts are that one end of the manual operator is connected with the controller through a relay, and the other end of the manual operator is connected with the storage battery; the controller and the manual operator communicate through CAN; an output end of the controller is connected with the motors; the storage battery provides power for the controller, the manual operator and the motors; the brushless DC motors are employed, a double-wheel coordination differential velocity control method is used, and a feedback compensation mode enables the wheelchair to keep left and right wheels in synchronization in operation, so the wheelchair is stable in motion, thus solving the problems in the prior art that a brush DC motor is slow in commutation speed, large in noise, and the motor is easy to be damaged in long term wearing state of the motor, and solving the disadvantages in the prior art that a conventional electric wheelchair is unstable in motion process and left and right wheel driving are not in synchronization.

Owner:HEBEI UNIV OF TECH

Controller for reversing of series motor of series electric vehicle

ActiveCN103117696AHighlight substantive featuresImprove driving abilityDC motor rotation controlElectric vehiclePower circuits

The invention discloses a controller for reversing of a series motor of a series electric vehicle, and relates to a controller for achieving reversing of a series motor. The controller controls conduction sequences of an MOS (metal oxide semiconductor) tube to substitute for a contactor to achieve reversing of the series motor, and comprises a hardware part and a software part, the hardware part is composed of a power circuit and a driving circuit, and the software part comprises a controller program, a regenerative feedback program and a flux-weakening speed regulating program. The controller overcomes the defects of low reversing speed of the contactor, loud noise and overlarge energy consumption due to long-time through large current.

Owner:XINJI HUAYI AUTOMOBILE INSTR

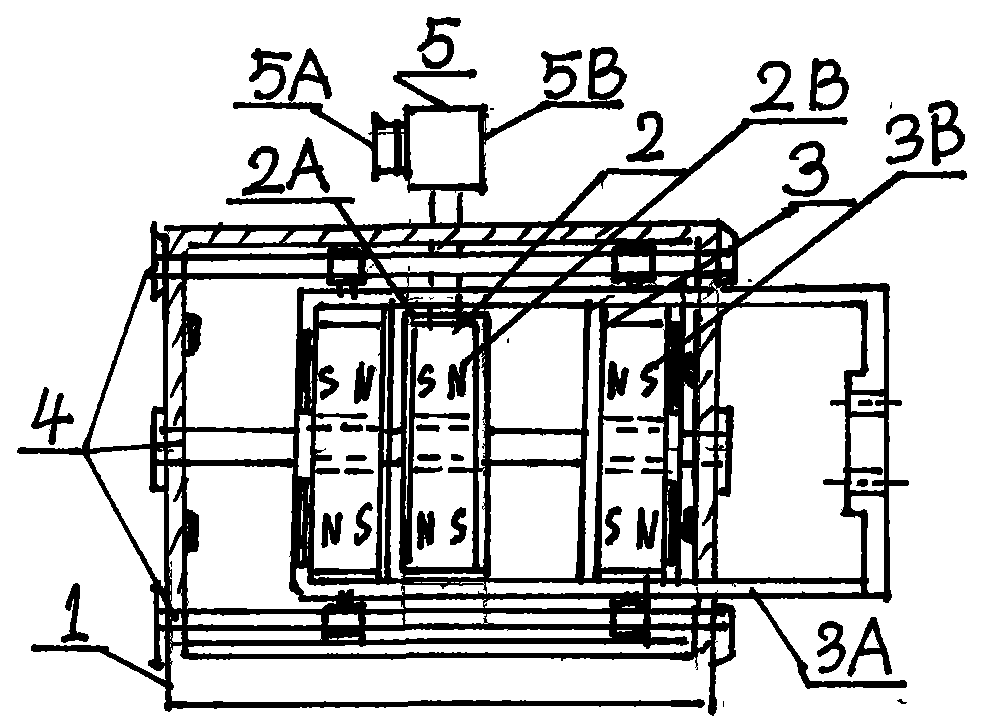

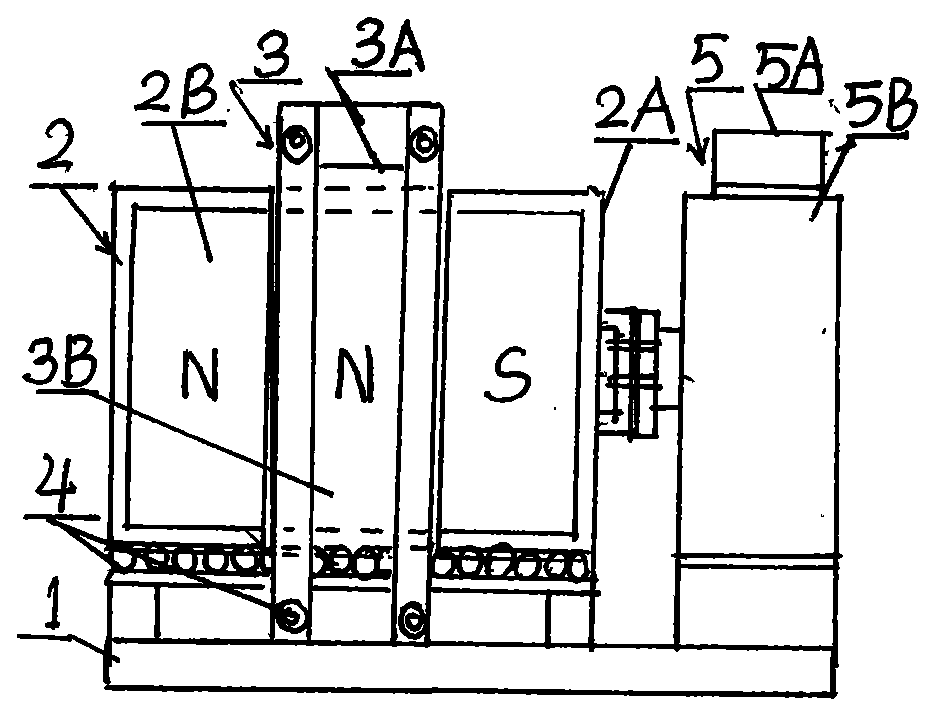

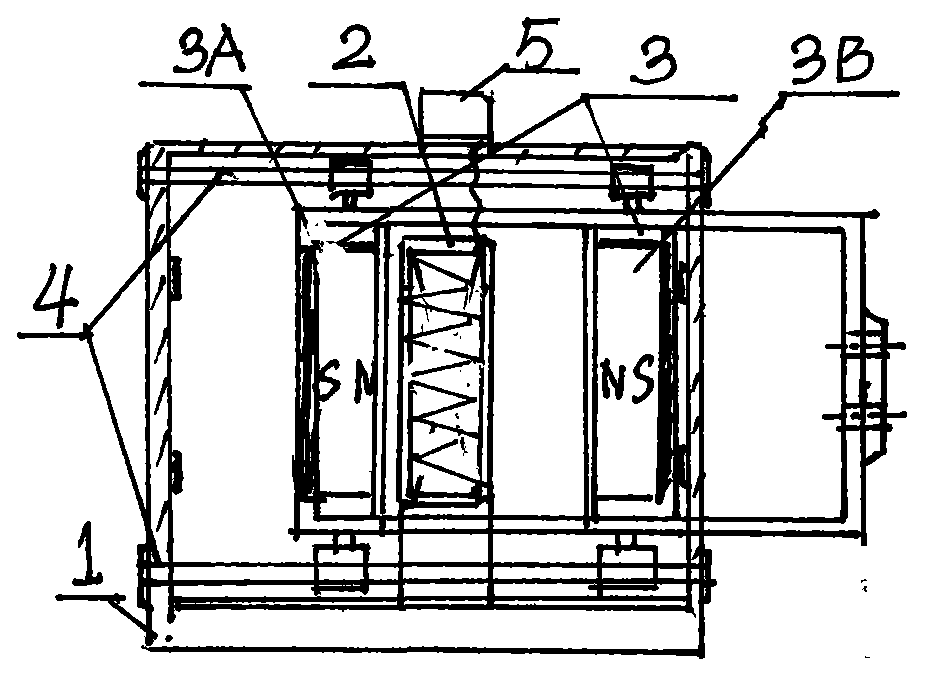

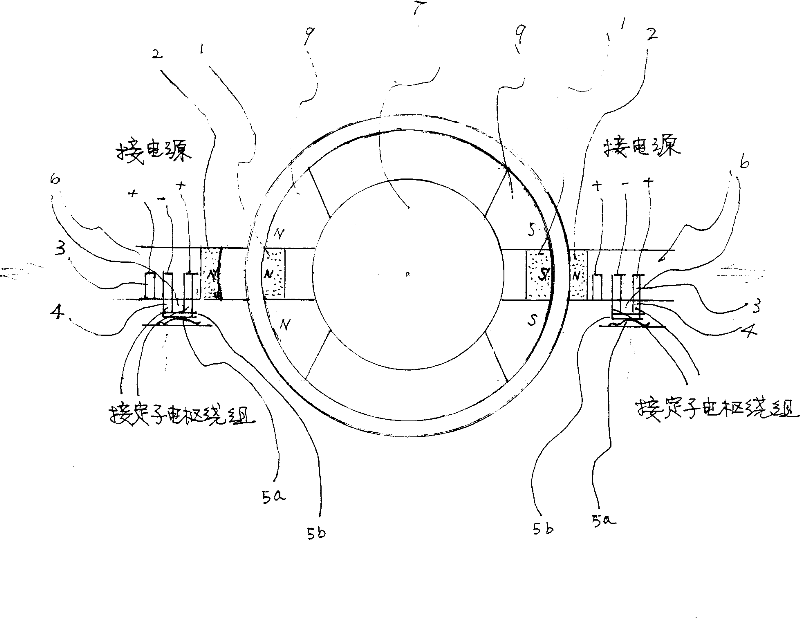

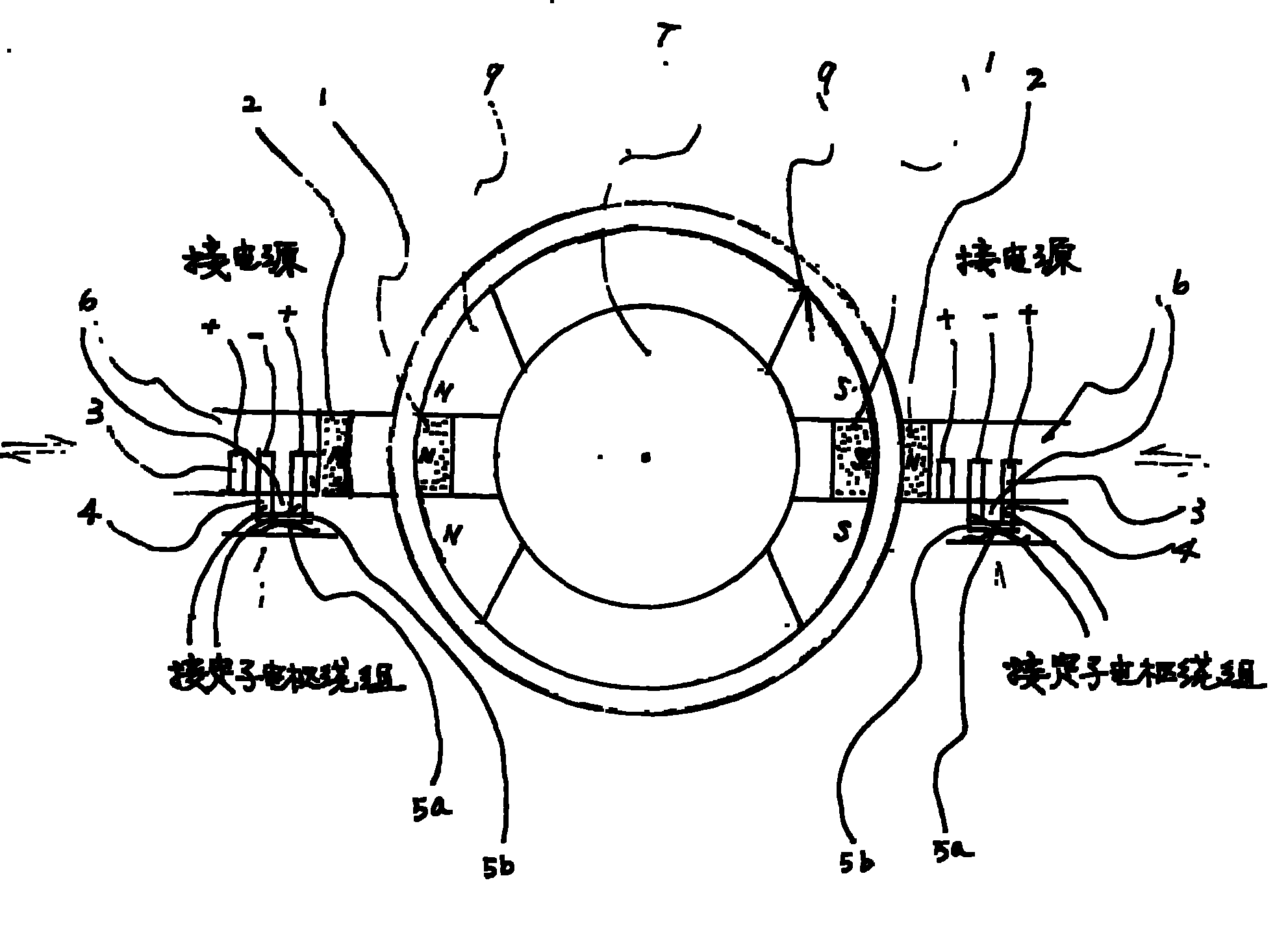

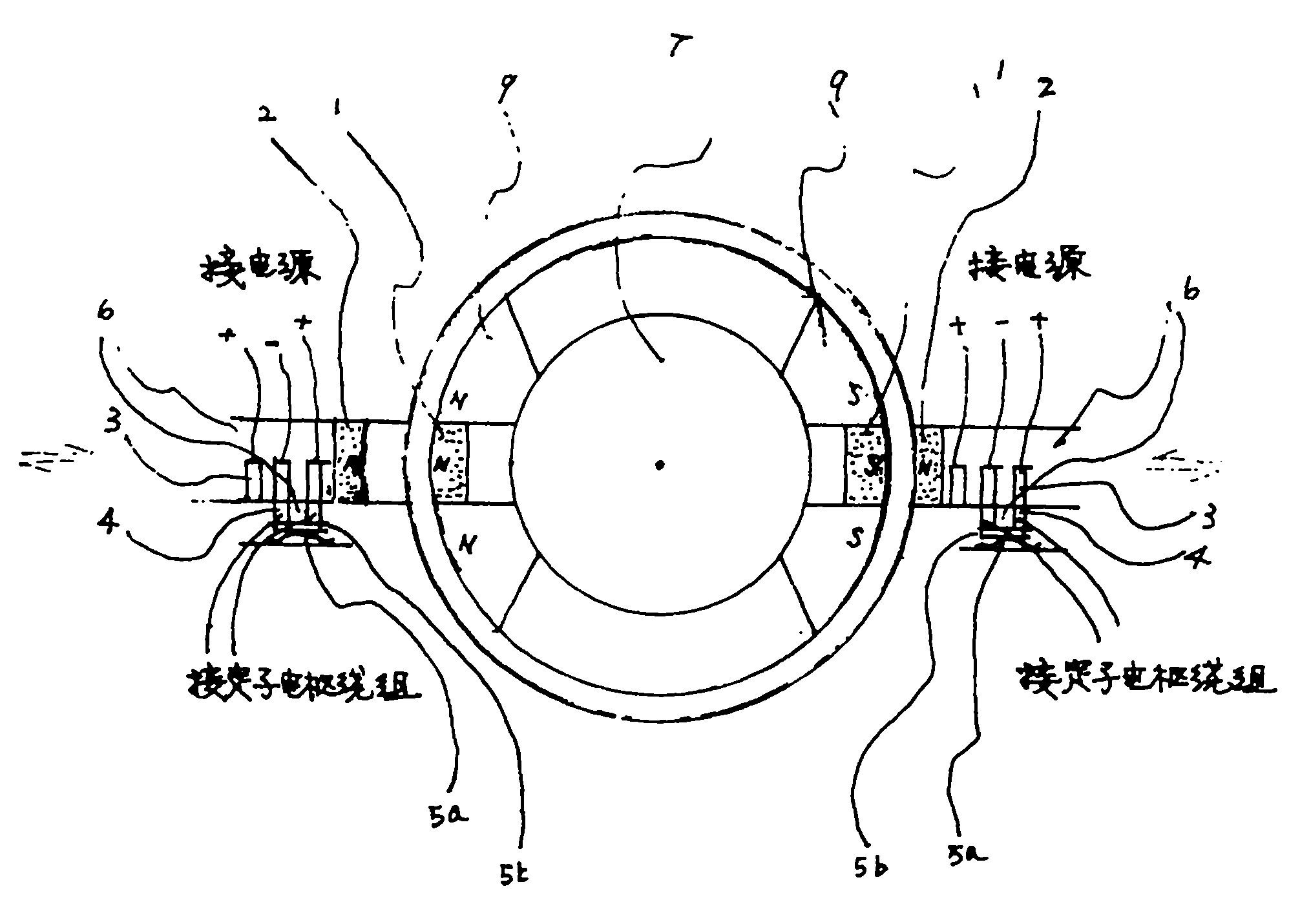

Method of acquiring magnetic field driving force and residue power, magnetic power machine and magnetic press machine

InactiveCN103066891AHigh magnetic driving forceHigh magnetic energy utilization efficiency methodDynamo-electric brakes/clutchesGenerators/motorsMagnetic energyHigh energy

The invention discloses a method of acquiring magnetic field driving force and residue power, a magnetic power machine, a magnetic press machine and the like. Magnetomotive force is used for setting the magnetic power machine and the magnetic press machine, and magnetic discs of fixed driving mechanisms and magnetic discs of motion driving mechanisms are arranged in a front parallelism mode. Polarities of one ends of magnetic fields between the center magnetic disc and the magnetic disc of two outer ends are same, and polarities of the other ends are different and corresponding. Magnetic field polarity changing servosystem is used for driving the controlled magnetic discs to conduct the above magnetic field polarity status switching, and driving the motion driving mechanisms to move repeatedly to work to produce driving force or pressure, and work is larger than energy consumption such as magnetic field polarity changing to have residue power. The driving force can be used as power source or used for changing into electrical energy and heat energy, and the problems that existing energy consumption power devices have high energy consumption cost and pollute environment are solved. Compared with the prior art, the method of acquiring the magnetic field driving force and the residue power, the magnetic power machine and the magnetic press machine have the advantages of being high in magnetic energy efficiency use ratio, stronger in driving force, high in residue power rate, low in unit energy acquiring cost, strong in application, and extensive in uses and the like.

Owner:陈凤琼

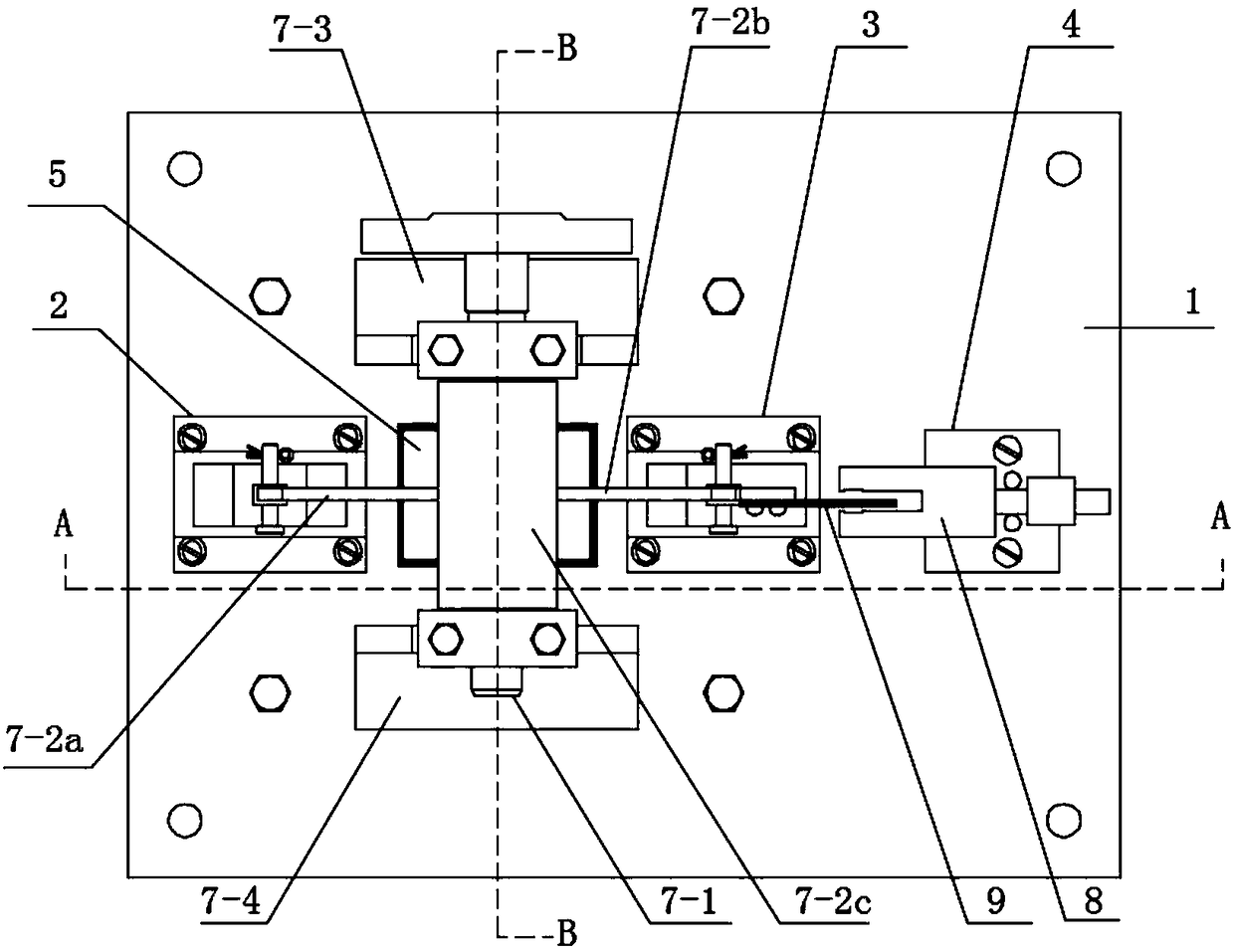

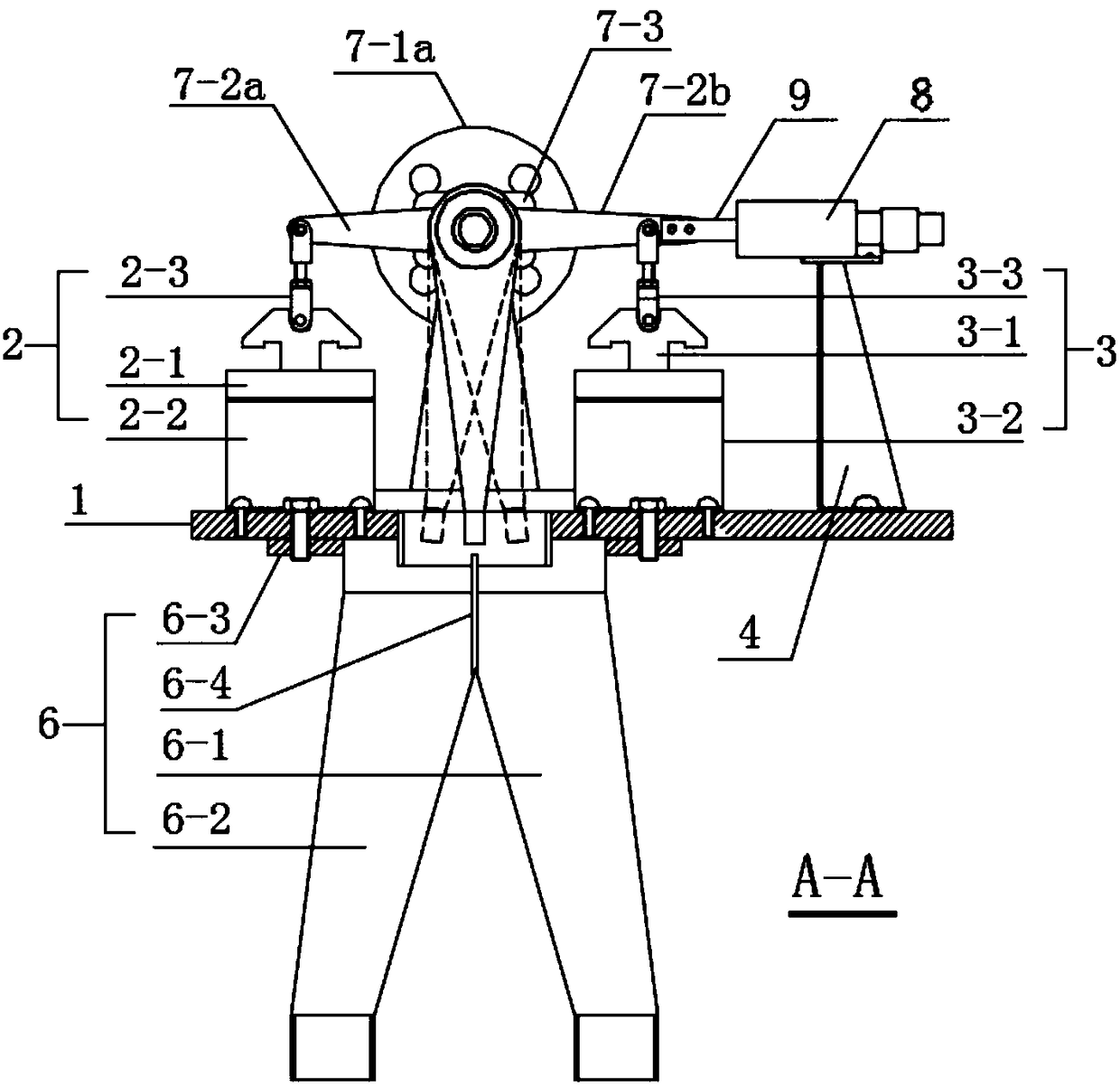

A swing mechanism and concrete pumping equipment

ActiveCN103470555BFast changeover timeReduce changeover timeServomotorsPumpsMaster cylinderEngineering

A wobbler mechanism is used for driving a distributing valve of a concrete pumping device to wobble, and comprises a wobbling arm (6) for driving the distributing valve, and two hydraulic oil cylinders (2, 4) for driving the wobbling arm (6) to wobble from side to side. One end of each of the two hydraulic oil cylinders (2, 4) is connected to left and right sides of the wobbling arm (6), and the hydraulic oil cylinders (2, 4) are two-stage hydraulic oil cylinders (2, 4). Also disclosed is a concrete pumping device having the wobbling mechanism. The wobbling mechanism and the concrete pumping device having the wobbling mechanism is fast in direction change and has a low impact, so that the direction change time of the wobbling mechanism is close to that of a master cylinder of the concrete pumping device, thereby greatly improving pumping continuity.

Owner:SANY AUTOMOBILE MFG CO LTD

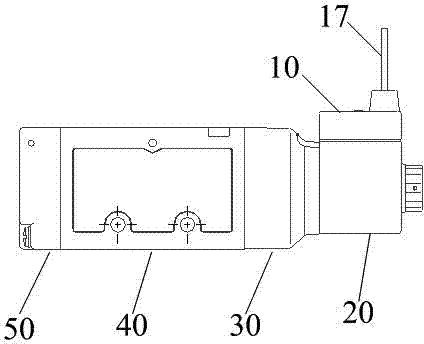

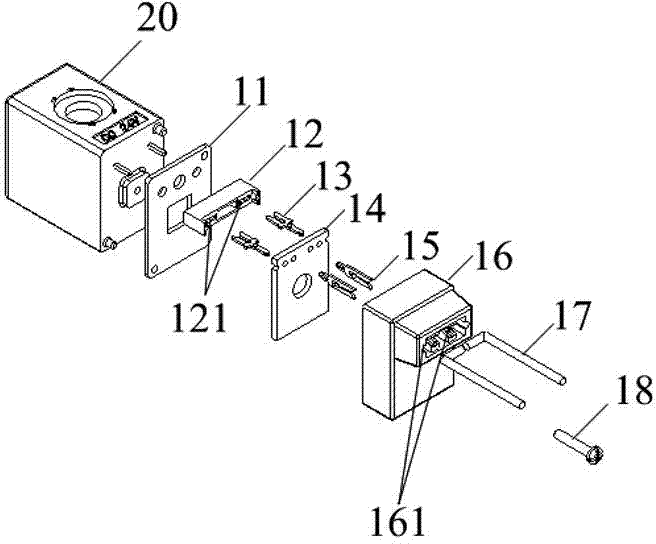

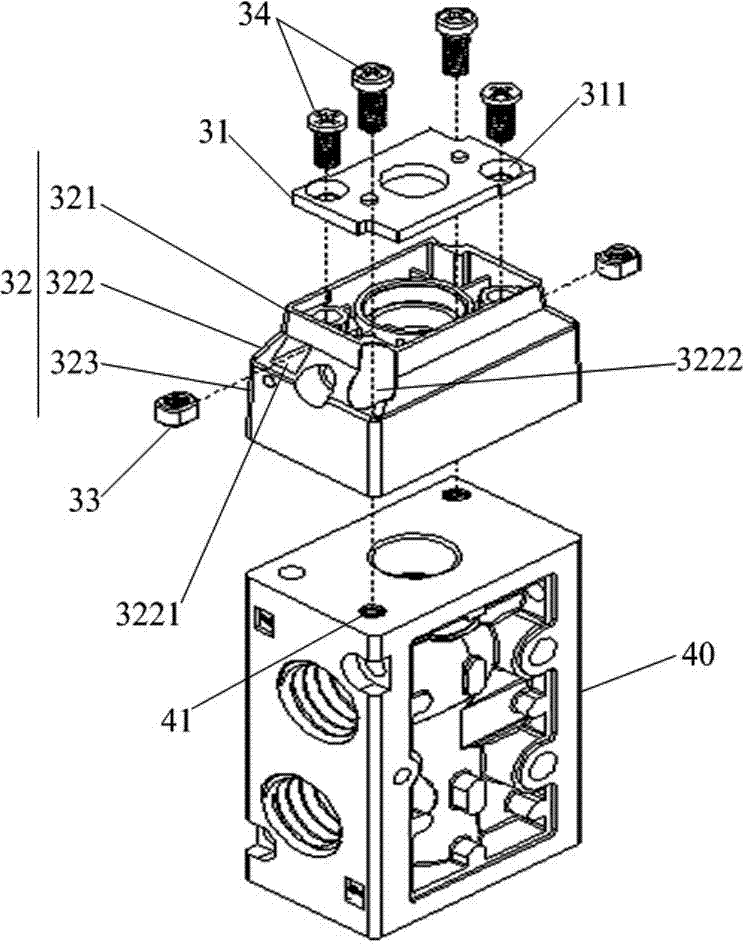

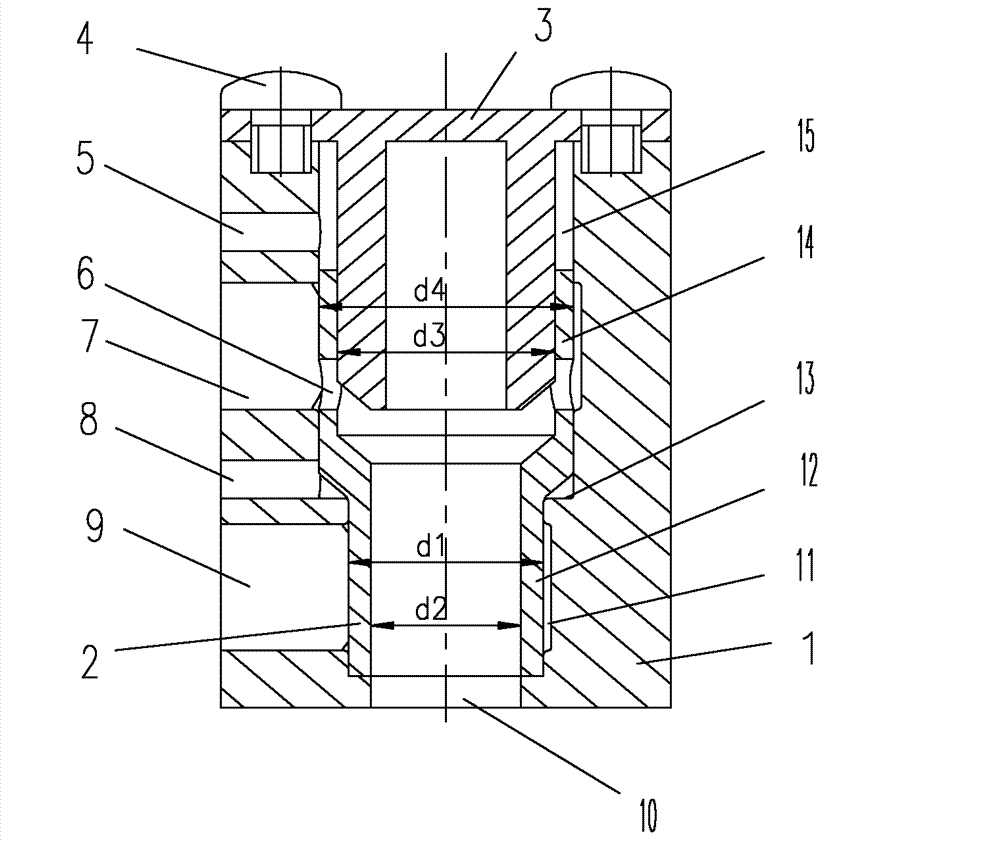

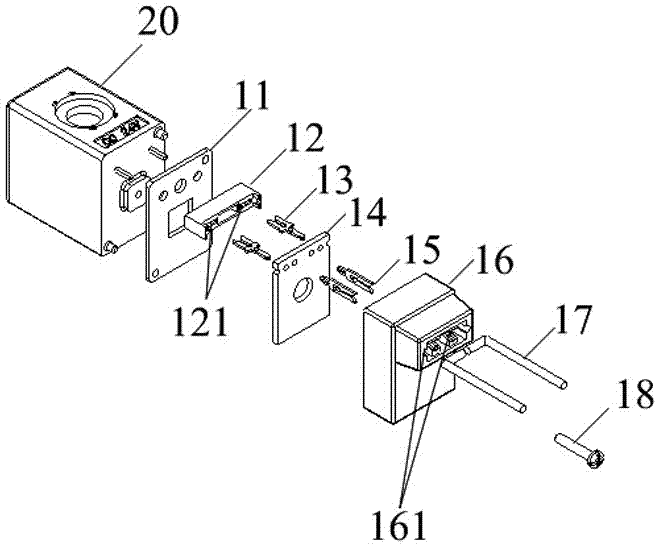

Novel solenoid valve connected by screw insert

InactiveCN104847950AReduce volumeBeautiful volumeOperating means/releasing devices for valvesValve housingsSolenoid valveEngineering

The invention relates to a novel solenoid valve connected by a screw insert. The novel solenoid valve connected by the screw insert comprises a socket, a coil, a front cover, a valve body and a rear cover connected in sequence, wherein the front cover comprises a pressing plate and a frame, the frame comprises a coil frame part and a valve body frame part, the connection part between the coil frame part and the valve body frame part is the connection inclined plane, and the pressing plate is connected with the coil frame part; grooves are formed in the connection inclined plane at two positions being corresponding to the centre point, a nut is arranged in the groove, a pressing plate through hole is formed in the pressing plate corresponding to the nut, the front cover bolt is connected with the nut through the pressing plate through hole, and a guide head component is mounted in the front cover; locking through holes are formed in the connection inclined plane at another two positions corresponding to the centre point, screw holes are formed in the valve body corresponding to the locking through holes, and the front cover bolt is used for connecting the front cover to the valve body through the locking through holes. The novel solenoid valve connected by the screw insert is smaller in product size, beautiful, and fast in reversing speed; the power consumption is low, the consumption is saved, the use cost is reduced for meeting national energy conservation and emission reduction requirements.

Owner:ZHEJIANG EASUN PNEUMATIC SCI & TECH

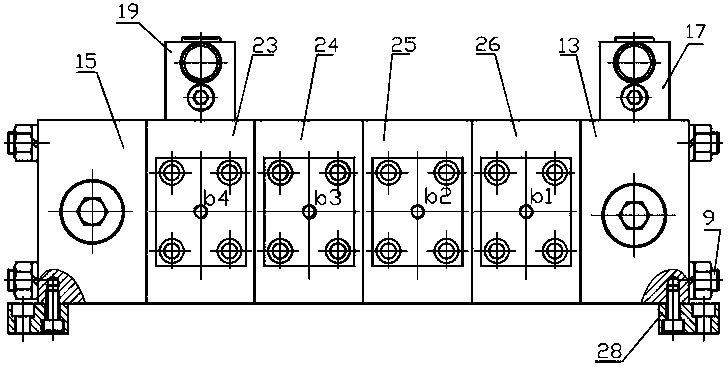

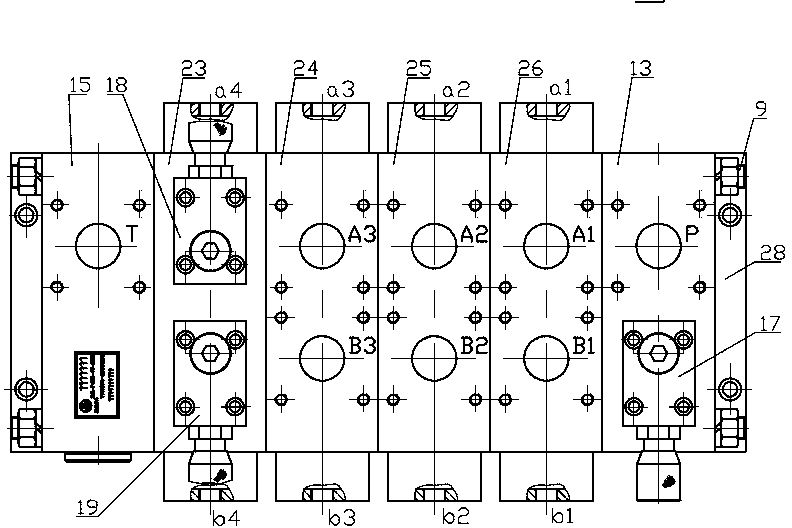

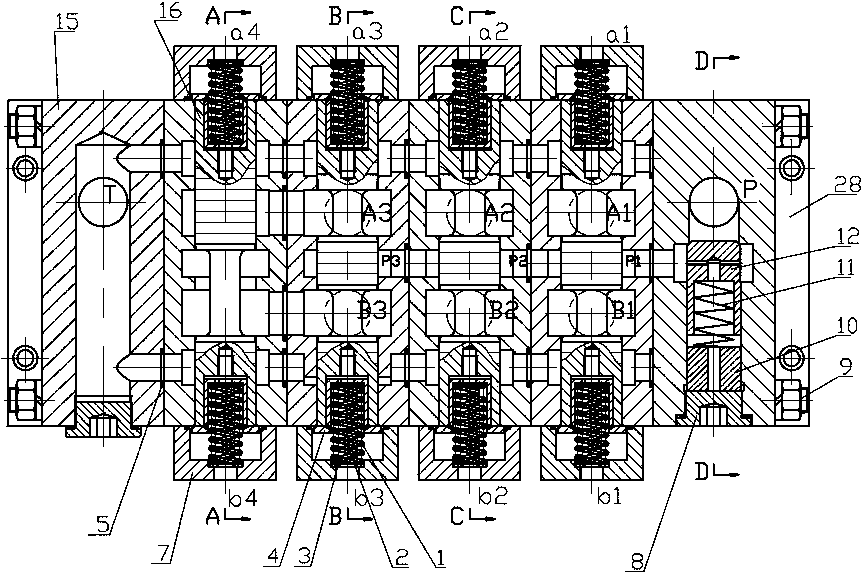

Multi-way reversing valve of hydraulic device

InactiveCN101328912AHigh strengthReduce intensityServomotor componentsValve housingsInlet valveHigh intensity

The invention relates to a multichannel reversing valve of a hydraulic device. The main structure of the multichannel reversing valve consists of a liquid inlet valve, a reversing valve, a throttle reversing valve and a liquid return valve; the liquid inlet valve uses a piston mode to control the oil hydraulic pressure; the common reversing valve and the throttle reversing valve are adopted to carry out dual control for reversing; the reversing valve is assembled by adopting an upper valve body and a lower valve body to form an integrated reversing valve chamber; the revering valve mainly uses a piston rod, a valve core, a one way valve, a liquid feed port, a dual liquid outlet to carry out liquid in and out in turns, thereby completing a reversing function; the throttle reversing valve is provided with a throttle port inside to effectively control a hydraulic oil amount; the reversing valve chamber has large path, high bearing pressure and small thickness; the valve chamber adopts a punch forming technology, the valve body has high intensity, high service time, material saving, rapid reversing speed which can be increased by 100 percent than the prior art, high efficiency and good universality; the device has a compact structure, reasonable design and a small size and is safe, stable, sensitive, rapid and reliable and is a very perfect universal multichannel reversing valve of the hydraulic device and quite suitable for underground operation in a coal mine under harsh environments.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

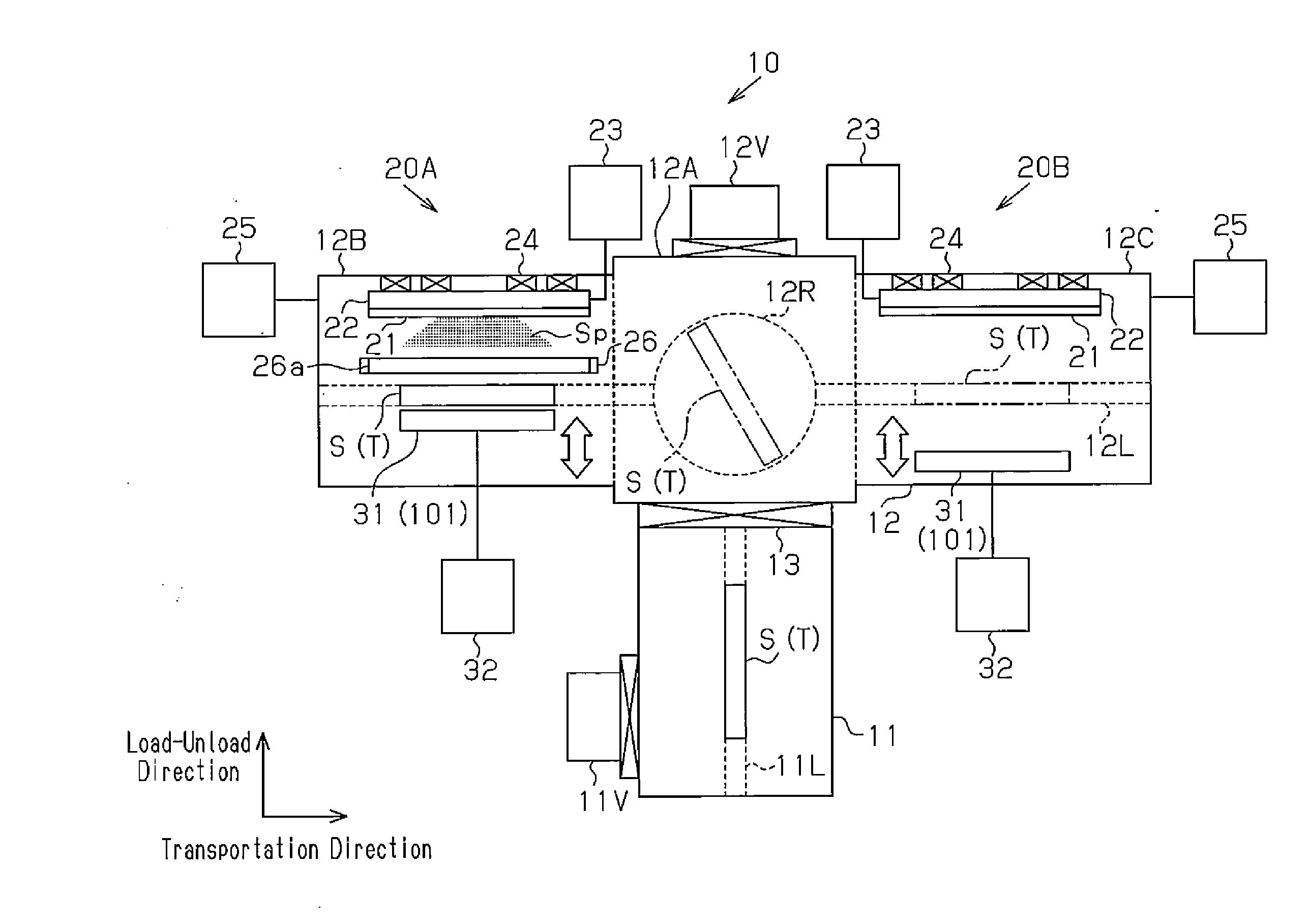

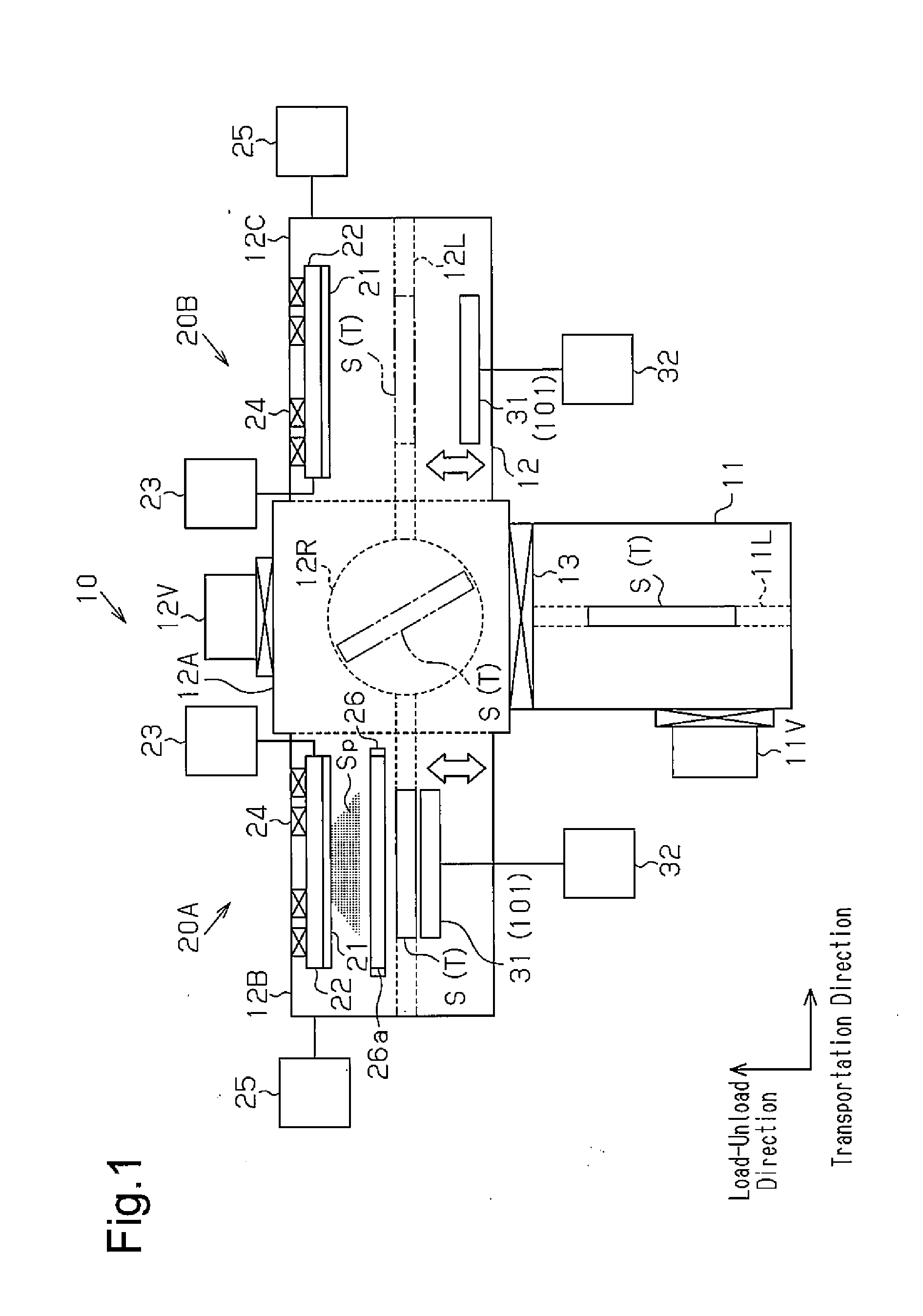

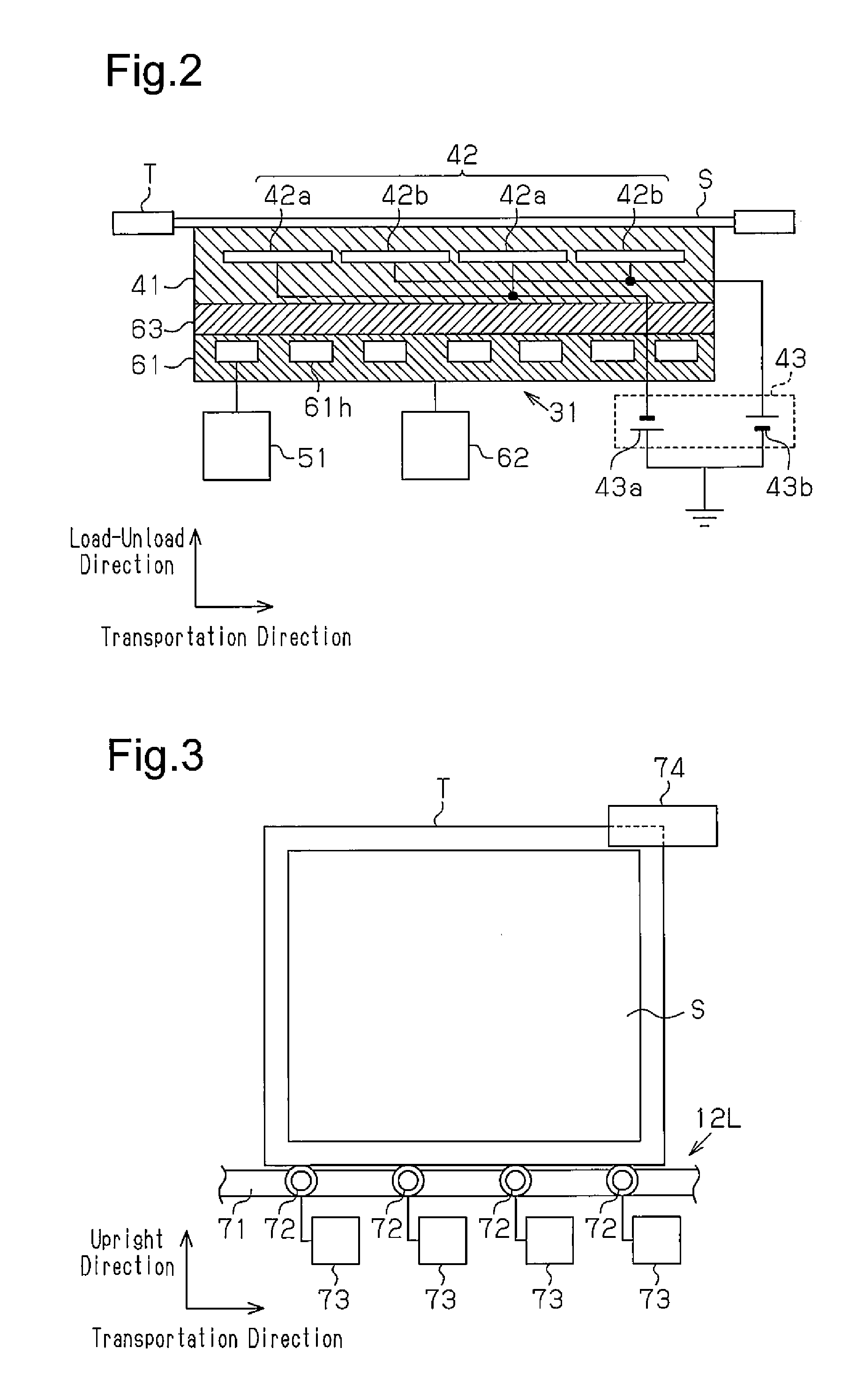

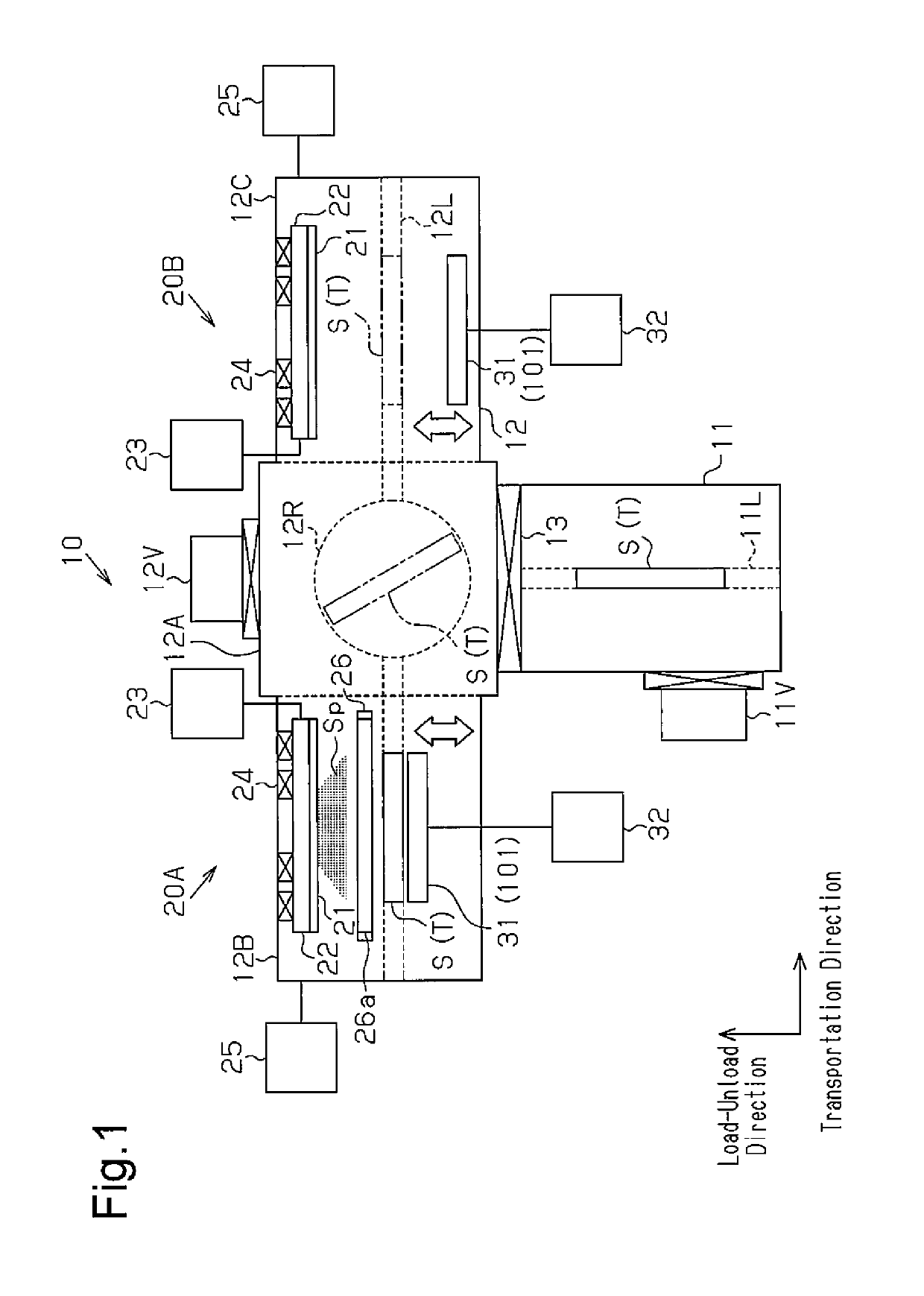

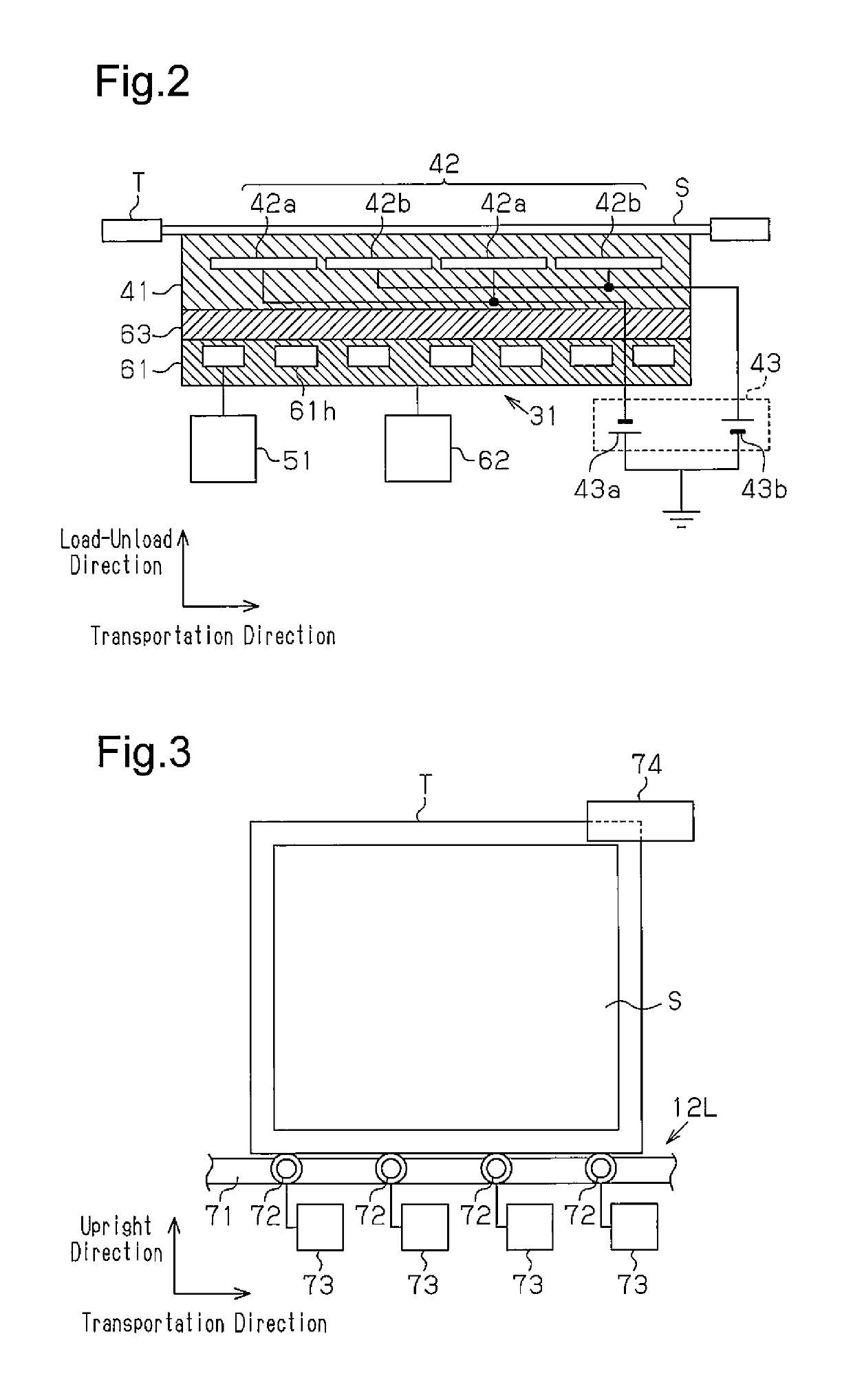

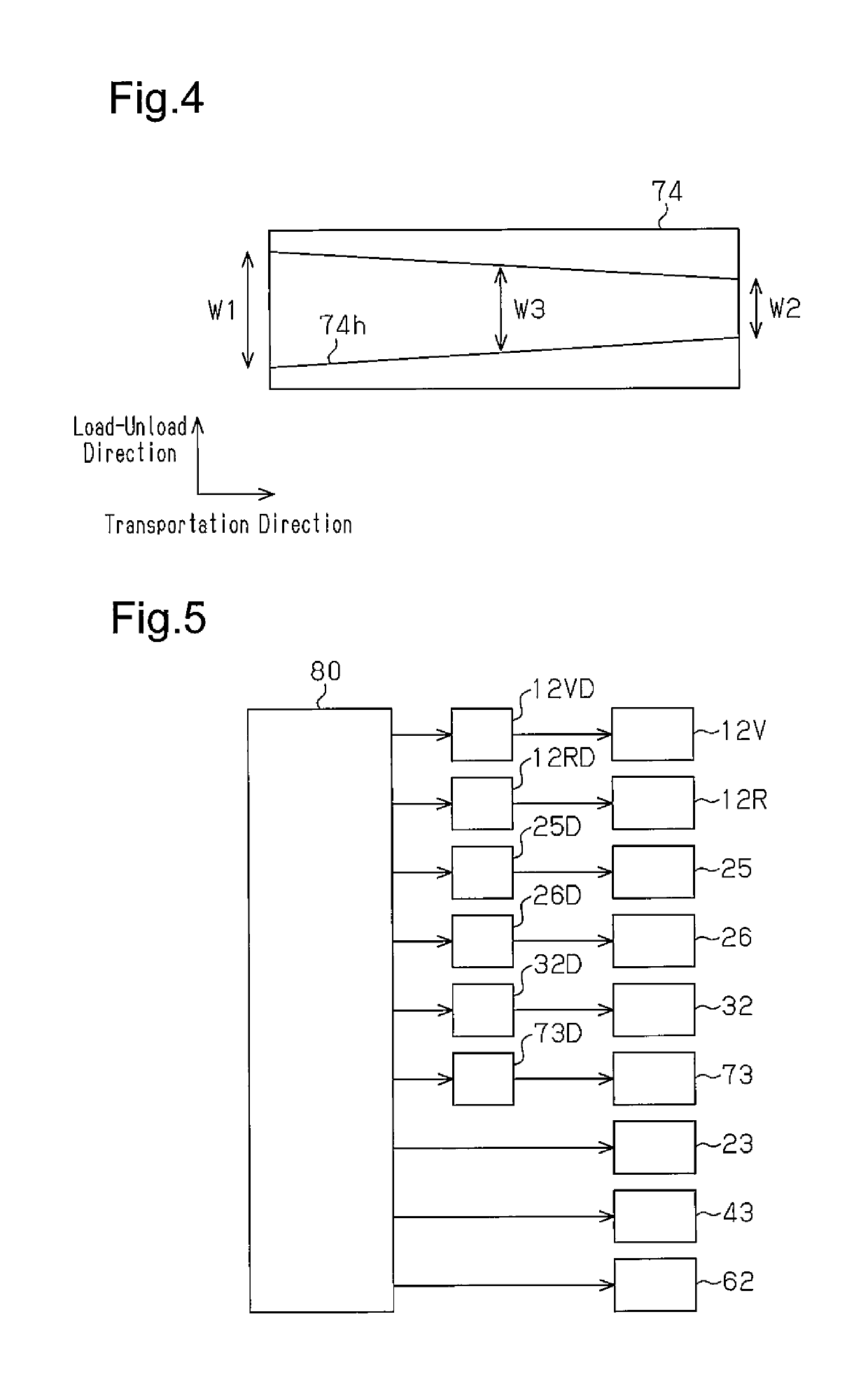

Thin substrate processing device

ActiveUS20160376697A1Improve cooling effectControl damageCellsElectric discharge tubesMaterials science

A thin substrate processing device includes a substrate processing unit configured to process a thin substrate, and a cooling unit configured to cool the thin substrate when the substrate processing unit is processing the thin substrate.

Owner:ULVAC INC

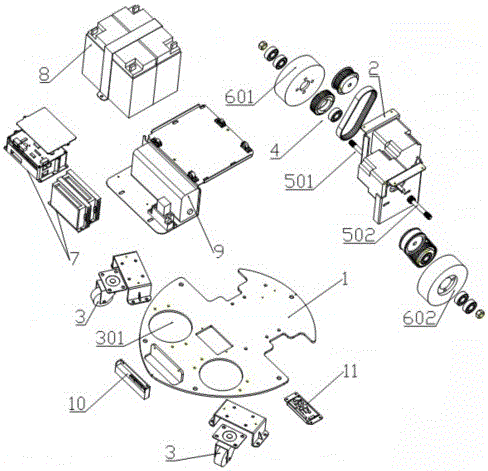

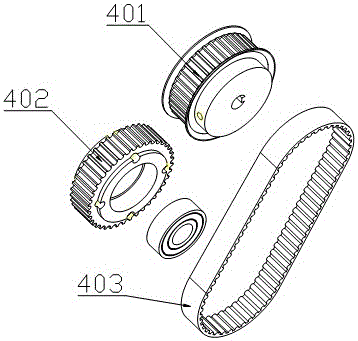

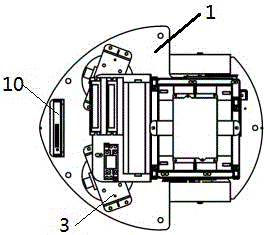

Quadricycle walking mechanism for moving robot

The invention discloses a quadricycle walking mechanism for moving a robot. The mechanism comprises a motor, driving wheels and a circle-arc tooth synchronous tyre device, wherein the driving wheels are arranged on the motor driving shaft through the circle-arc tooth synchronous tyre device. The quadricycle walking mechanism has the advantages of high reversing speed, small damping gap, precise transmission distance, low consumption, no noise or vibration hazard, good starting performance, energy conservation and economical efficiency, is relatively simple in structure, convenient to assemble, and powerful in functions, and especially can be used for reducing cost.

Owner:SHENZHEN ZHONGZHOU INTELLIGENT TECH CO LTD

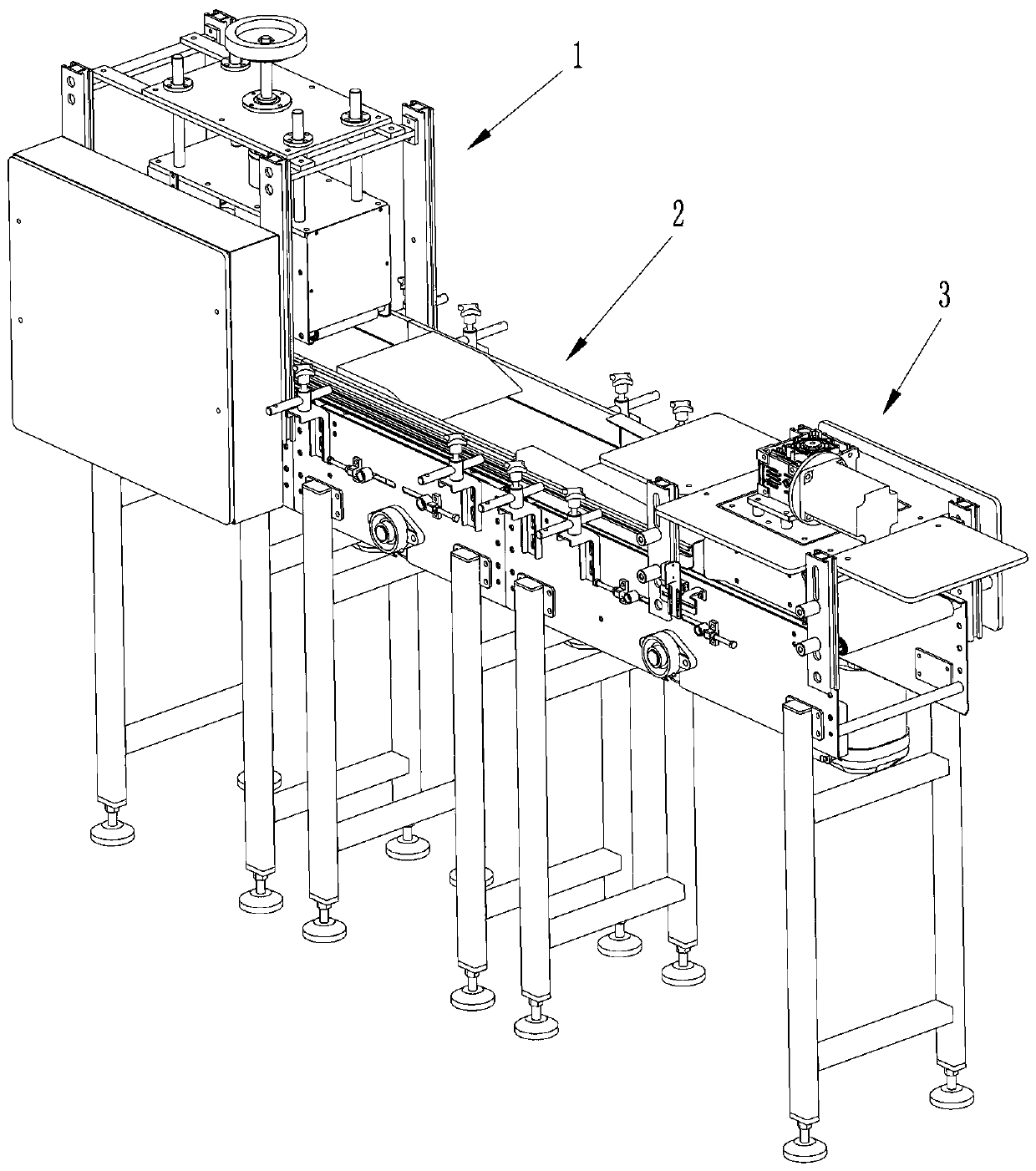

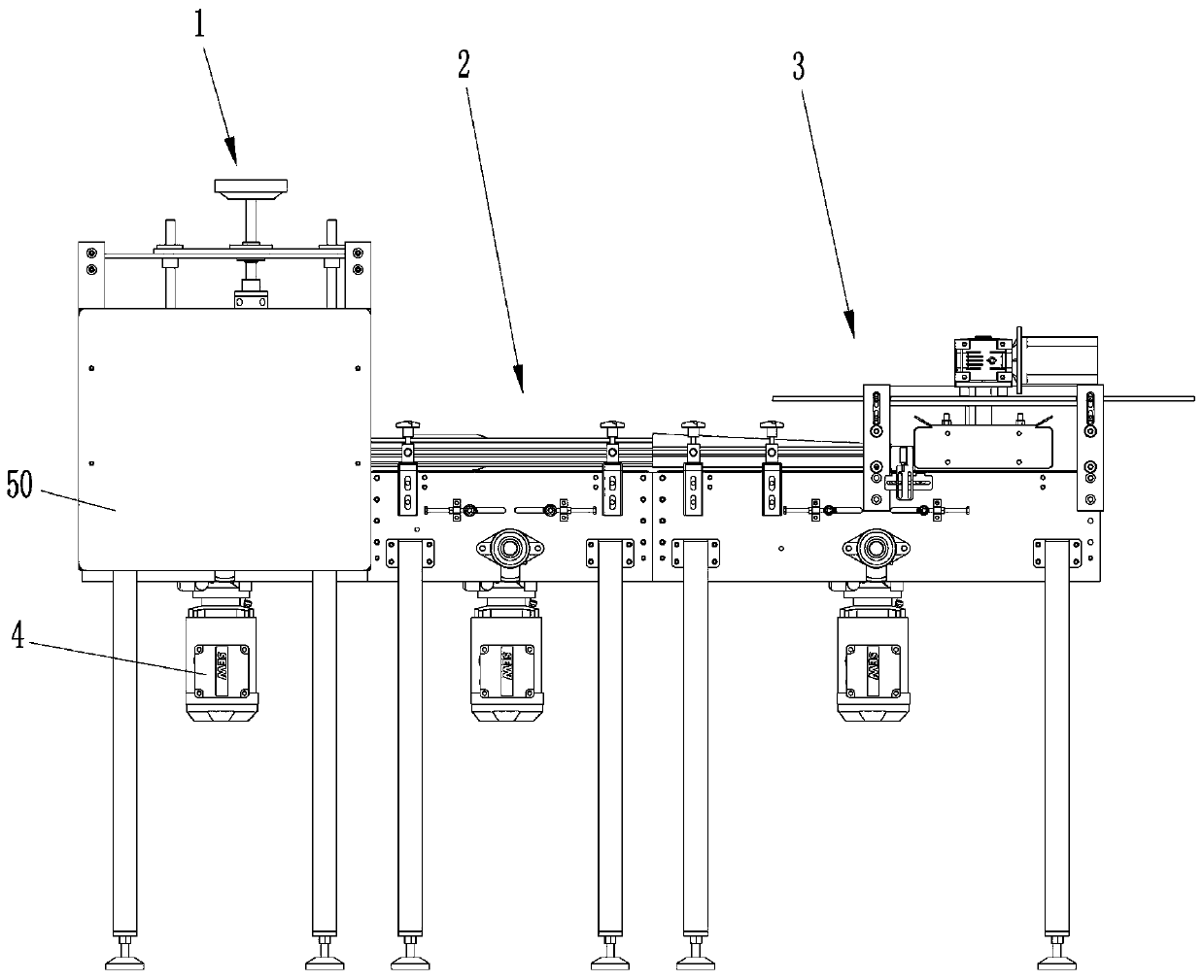

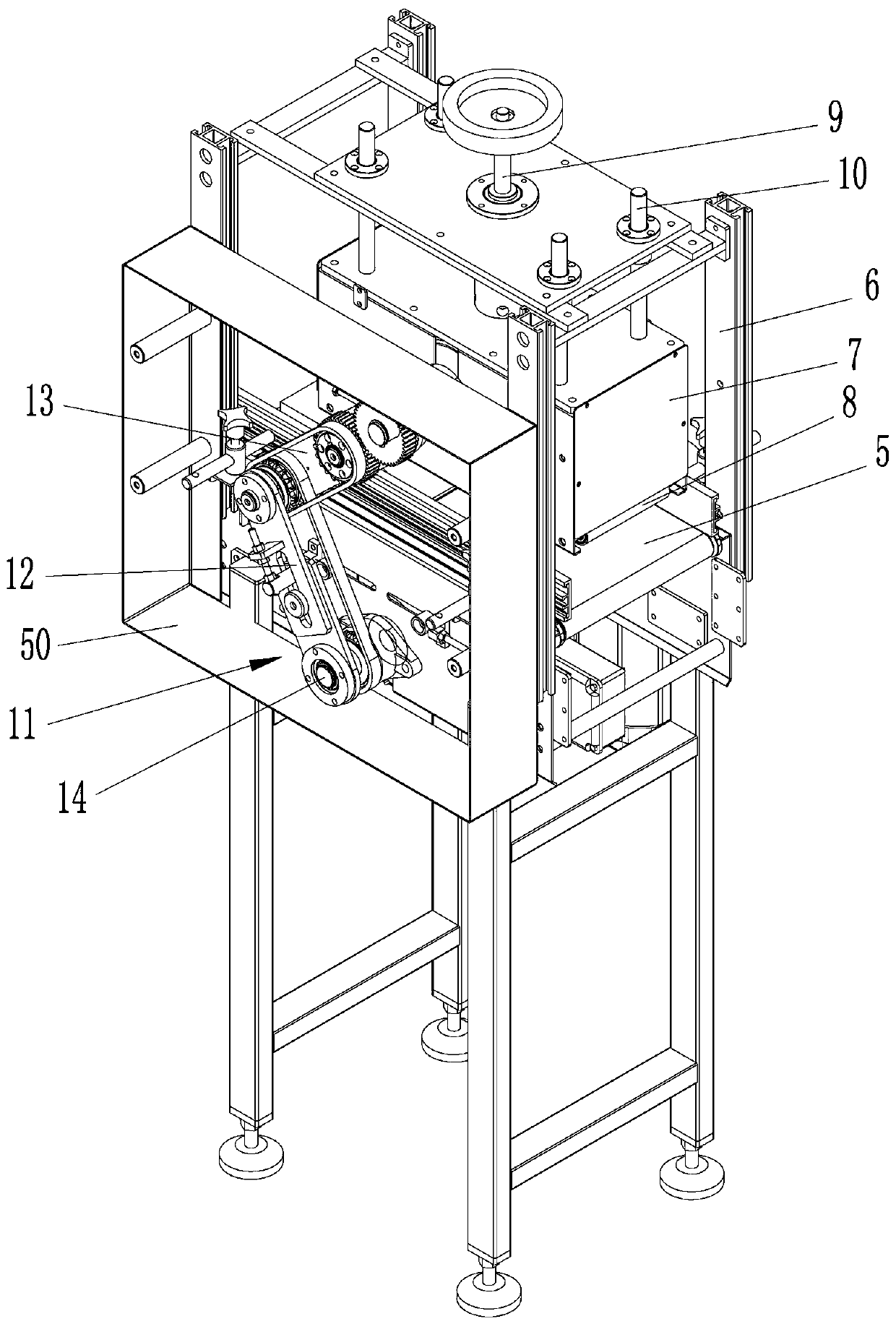

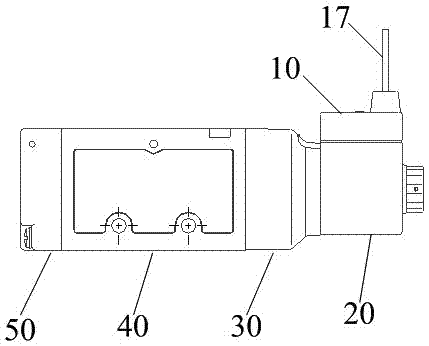

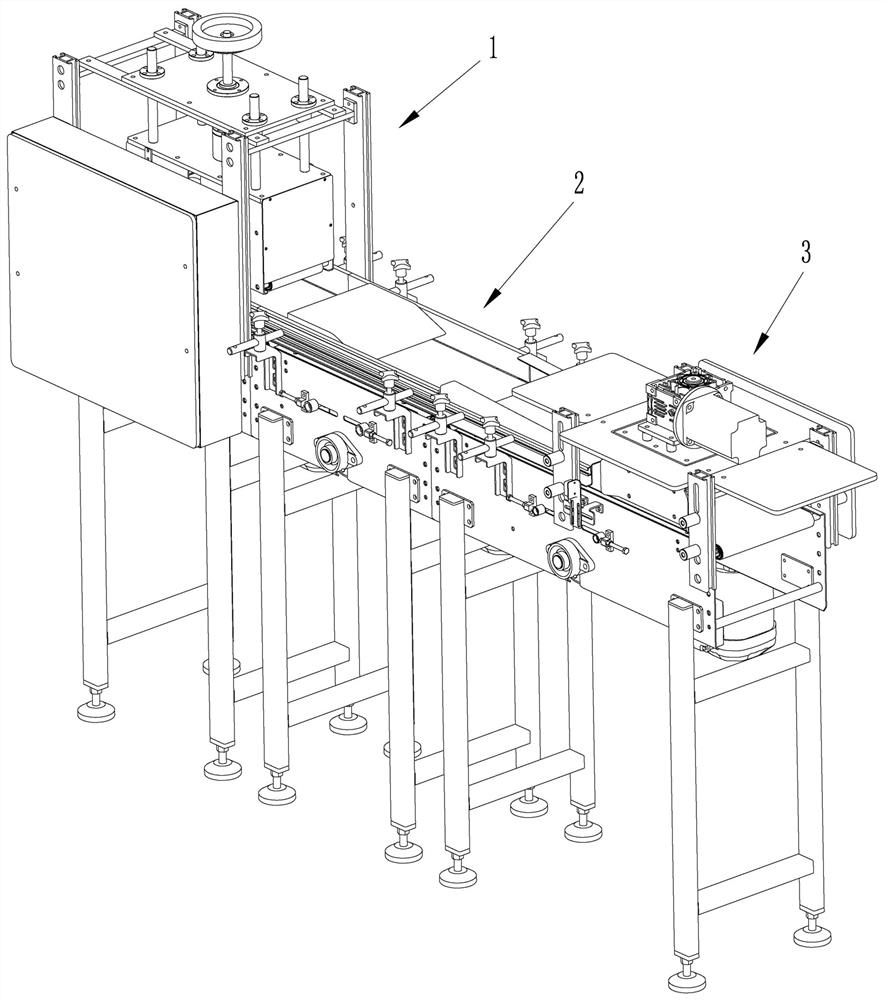

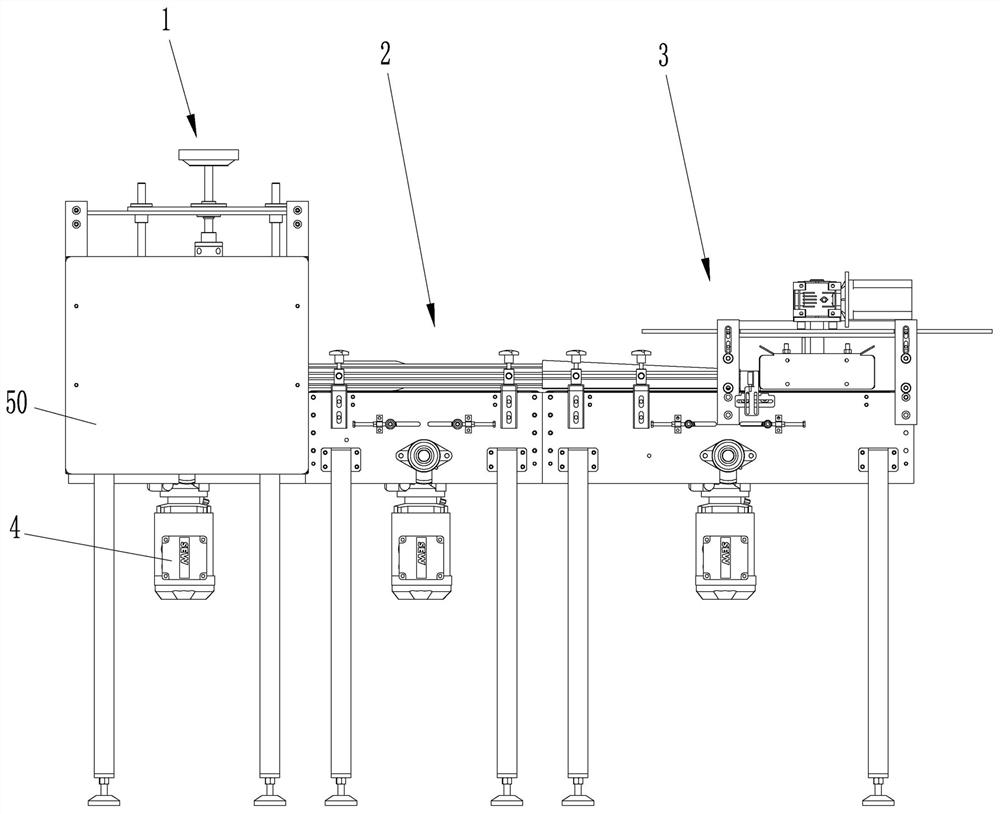

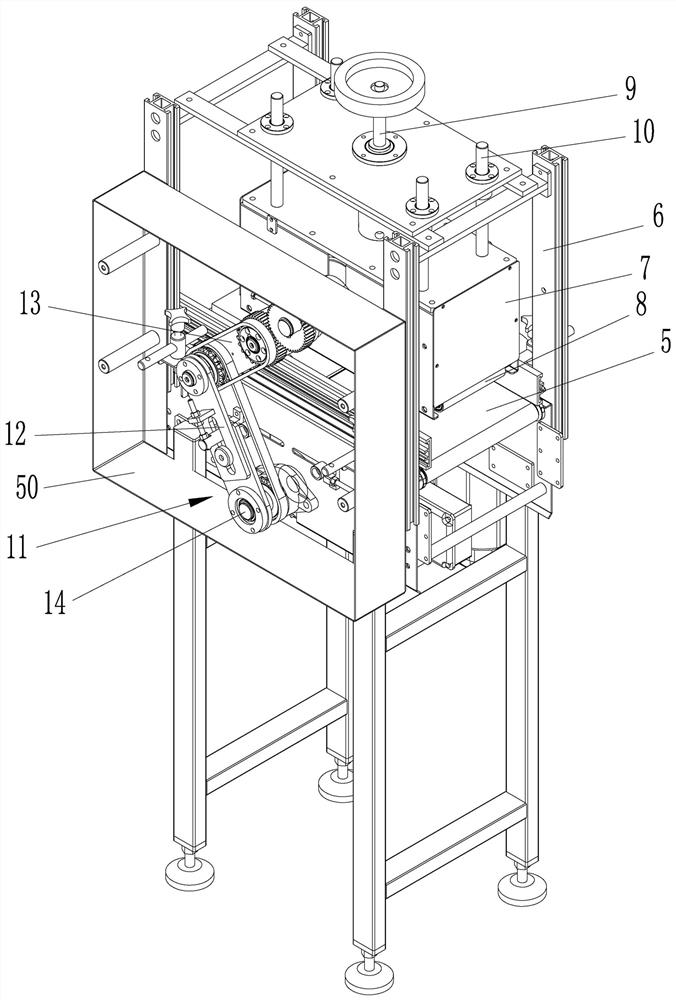

Flatten shaping and reversing equipment for soft bag packaging

ActiveCN109573213AImprove stabilityFast reversing speedConveyorsPackagingEngineeringMechanical engineering

The invention discloses flatten shaping and reversing equipment for soft bag packaging. The equipment comprises a flatten shaping conveying device, an acceleration conveying device and a reversing conveying device which are sequentially arranged according to the conveying direction of soft bags; the reversing conveying device comprises a first conveying mechanism and a reversing mechanism arrangedat the top of the first conveying mechanism; the reversing mechanism comprises a reversing mounting frame, a speed reducing servo motor, a rotating frame and an infrared sensing assembly, wherein thereversing mounting frame is fixed to the first conveying mechanism, the speed reducing servo motor is arranged at the top of the reversing mounting frame, the rotating frame is arranged at the bottomof the speed reducing servo motor and connected to the output end of the speed reducing servo motor; and the rotating frame comprises a rotating base plate and two side baffles arranged on the two sides of the rotating base plate, the two side baffles are arranged in parallel to form a channel for allowing the soft bags to enter the rotating frame and move out of the rotating frame, and the two side baffles drive the soft bags to be reversed during the rotating process of the rotating base plate. The soft bags are subjected to flattening and shaping through the flatten shaping conveying device, so that the specification is unified, and reversing is carried out through the reversing conveying device.

Owner:广州市万世德智能装备科技有限公司

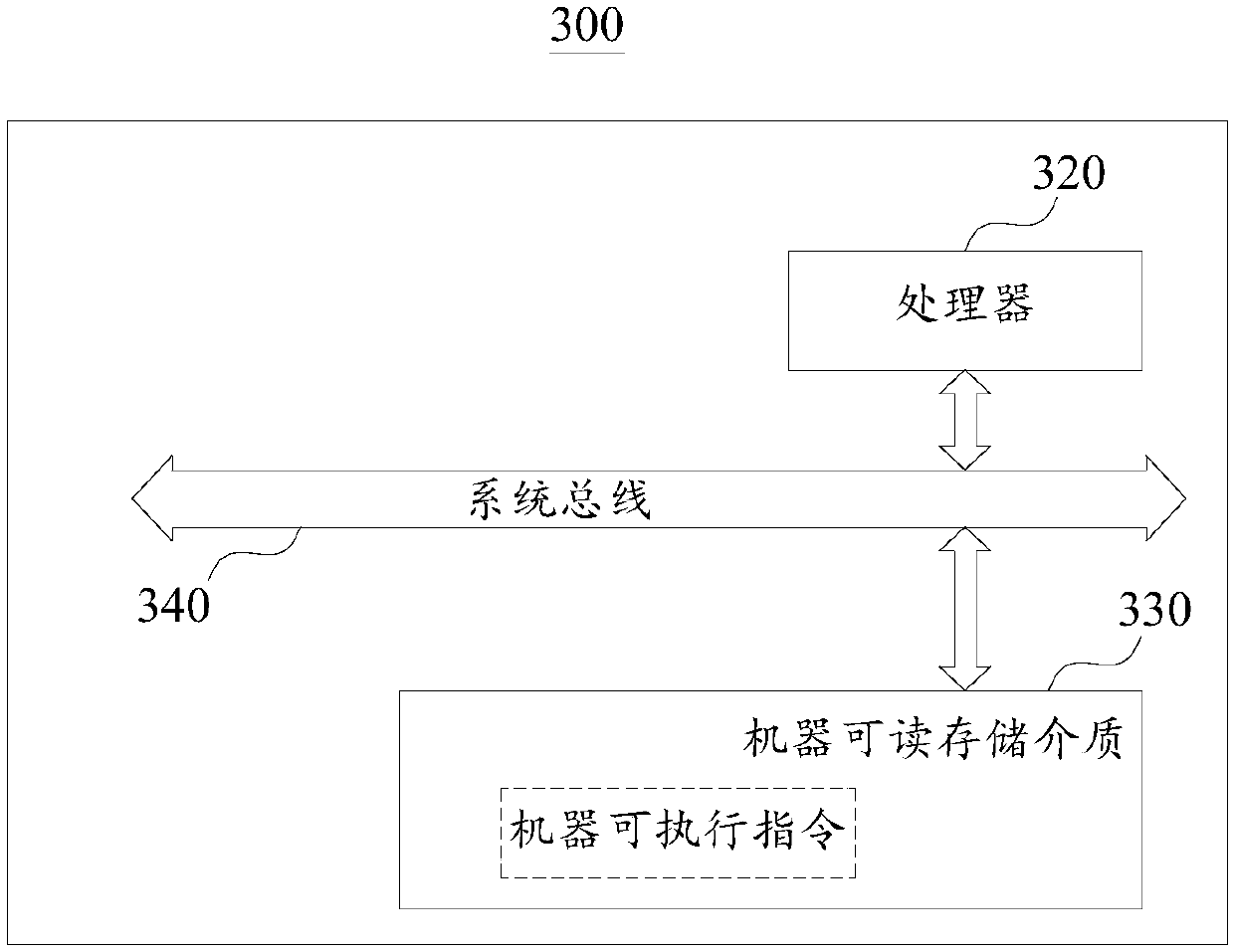

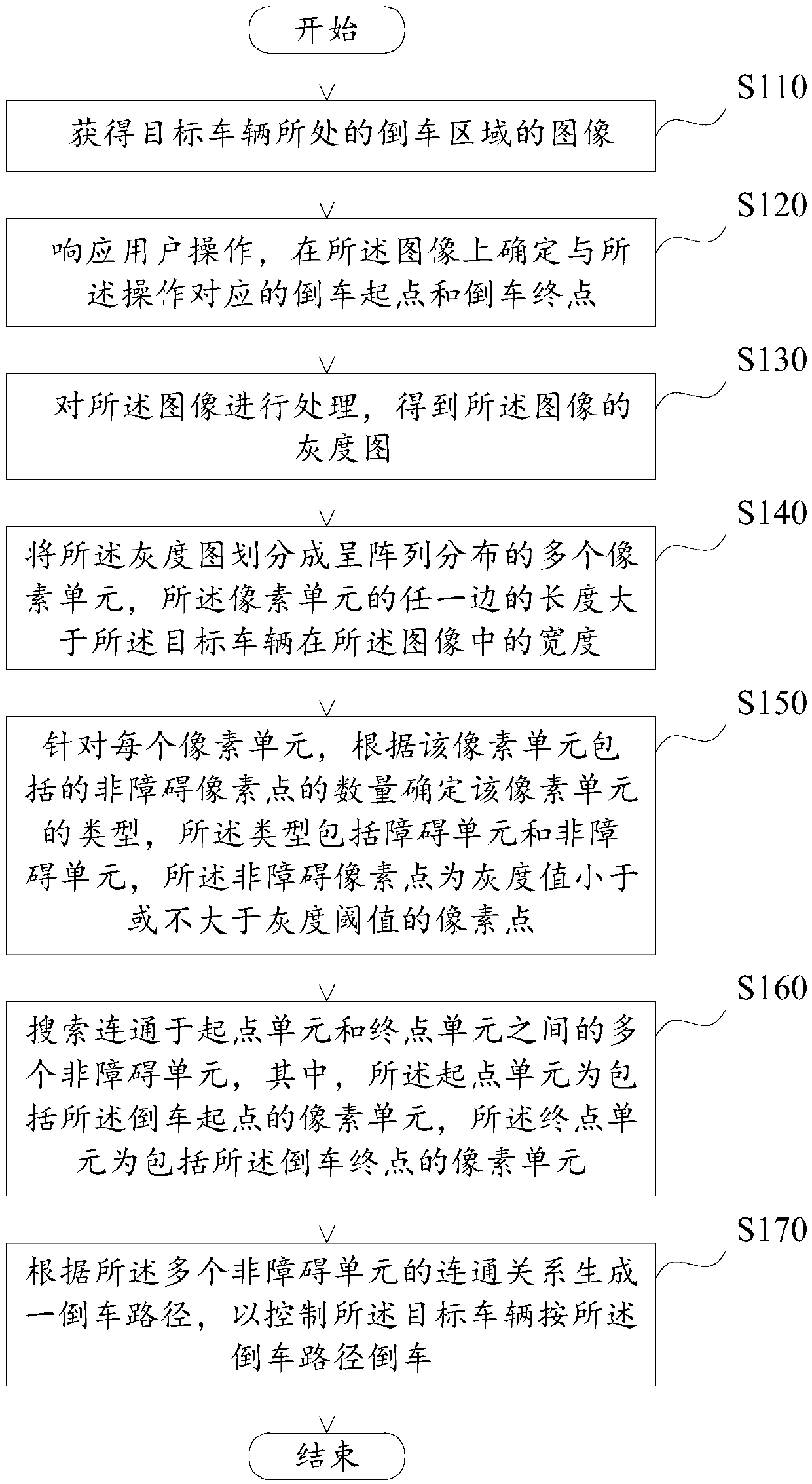

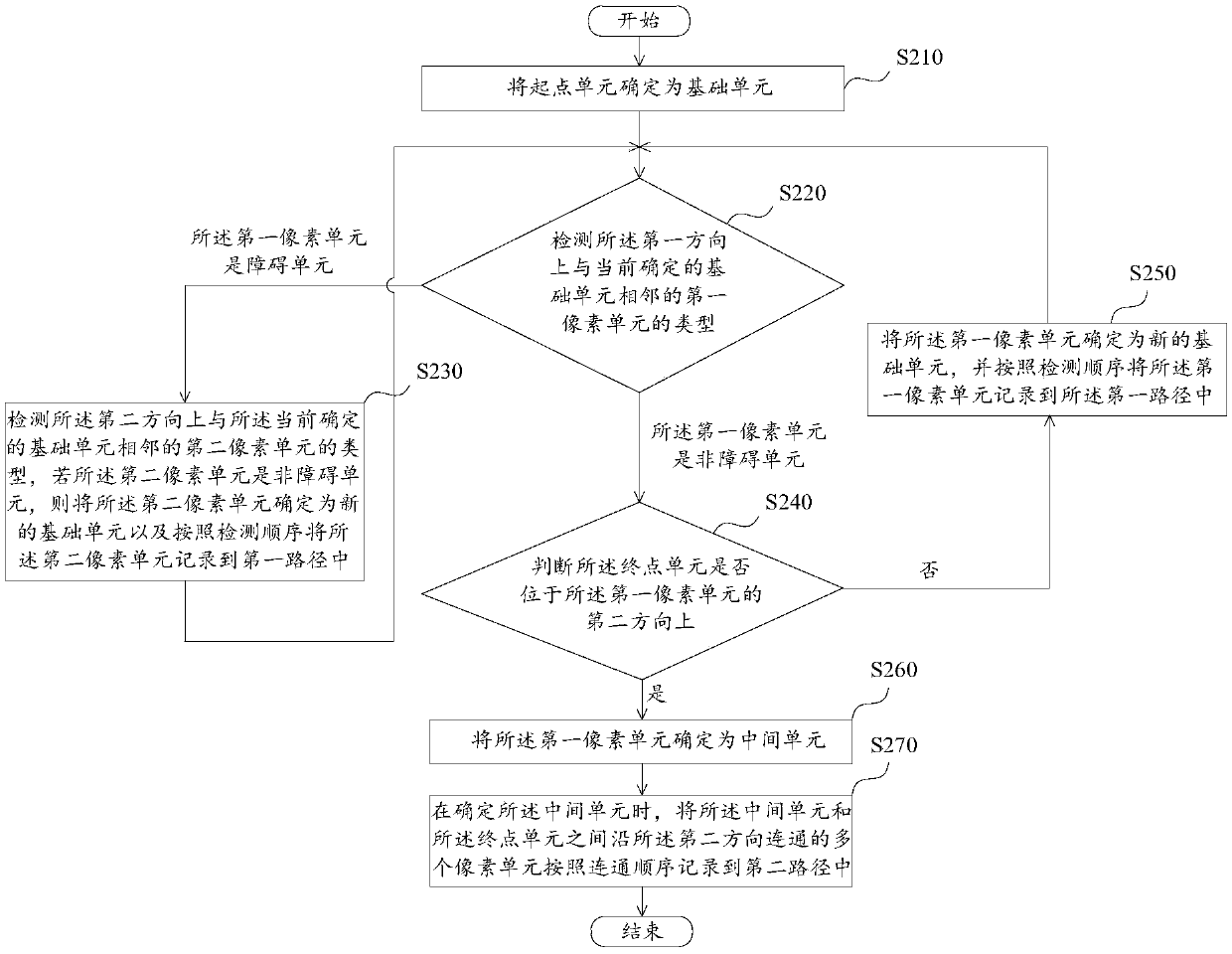

Reversing control method and device

PendingCN109657585AEasy to operateFast reversing speedCharacter and pattern recognitionPosition/course control in two dimensionsControl engineeringControl theory

The embodiment of the invention provides a reversing control method and device. The method comprises the following steps: obtaining a sample; a grayscale image of the reversing area is obtained; dividing the grey-scale map into a plurality of pixel units of which the length of any side is greater than the vehicle width; and determining a non-obstacle unit in the plurality of pixel units accordingto a gray threshold, and searching a plurality of non-obstacle units communicated between the starting point unit and the end point unit, thereby generating a reversing path according to a communication relationship of the plurality of non-obstacle units, and controlling the target vehicle to reverse according to the reversing path. Therefore, the image processing equipment can automatically generate the reversing path according to the reversing starting point and the reversing terminal point specified by the user, so that the automobile can automatically complete reversing according to the reversing path, the user operation is simplified in the whole process, and the reversing speed is increased.

Owner:BEIJING CHINA TSP

Micro-liquid-flow electromagnetic commutator

PendingCN108225500AMeet the needs of on-site commutation detectionOverall small sizeTesting/calibration for volume flowEnergy supplyShock resistance

The invention discloses a micro-liquid-flow electromagnetic commutator which comprises a bottom plate. The micro-liquid-flow electromagnetic commutator is characterized in that a left traction electromagnet, a right traction electromagnet and a communicator support are sequentially arranged on the upper portion of a base plate from left to right, the bottom plate is provided with a water inlet hole between the left and right traction electromagnets, a branched liquid distribution device and a liquid guide device are arranged above and under the water inlet hole respectively and both communicated with the water inlet hole, and a photoelectric pulse communicator is arranged on the communicator support. By coil power on-off control of the left and right traction electromagnets, commutation ofthe electromagnetic commutator is realized; in a commutation process, the photoelectric pulse communicator is triggered by a light barrier to record commutation actuation time nodes. The micro-liquid-flow electromagnetic commutator has advantages of small size, portability, convenience and quickness in mounting and demounting, structural steadiness, shock resistance, impact resistance, quicknessin commutation action, movability and low environmental requirements of places, energy supply and the like.

Owner:WUHAN INST OF MEASUREMENT & TESTING TECH

High-temperature pulse reversing valve

InactiveCN104343992AGuaranteed tightnessExtended service lifeSpindle sealingsLift valveSplit ringWear resistant

The invention discloses a high-temperature pulse reversing valve which comprises a driving cylinder, a connector, a valve rod, a valve plate, a valve body, a valve-rod upper bearing, a valve-rod lower bearing, a lower end cover and a valve-rod upper shaft sealing structure, wherein the valve-rod upper shaft sealing structure is arranged in a conical cavity which is positioned between the upper end of the valve body and the valve rod and is expanded upward, and the valve-rod upper shaft sealing structure comprises a sealing element and a spring; the sealing element is a conical element which is made of expanded graphite and mounted in the conical cavity between the upper end of the valve body and the valve rod; the spring is arranged between the upper end face of the sealing element and the lower end face of the connector and compresses the sealing element to form an elastic self-sealing structure; the valve-rod upper bearing and the valve-rod lower bearing are graphite bearings and are made of high-strength leaching and roasting graphite. The high-temperature pulse reversing valve has further improvements as follows: a ring slot is formed in the lower end of the valve rod, and a split ring made of a wear-resistant material is arranged in the ring slot; the lower end face of the split ring is supported by the lower end cover. The high-temperature pulse reversing valve has the advantages of high temperature resistance, strong self lubrication, good sealing reliability, high reversing speed and long service life.

Owner:JIANGSU TENGTIAN IND FURNACE

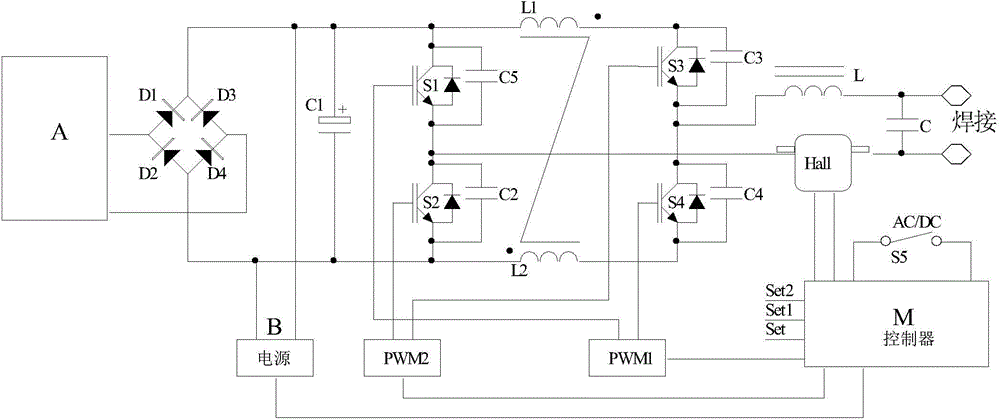

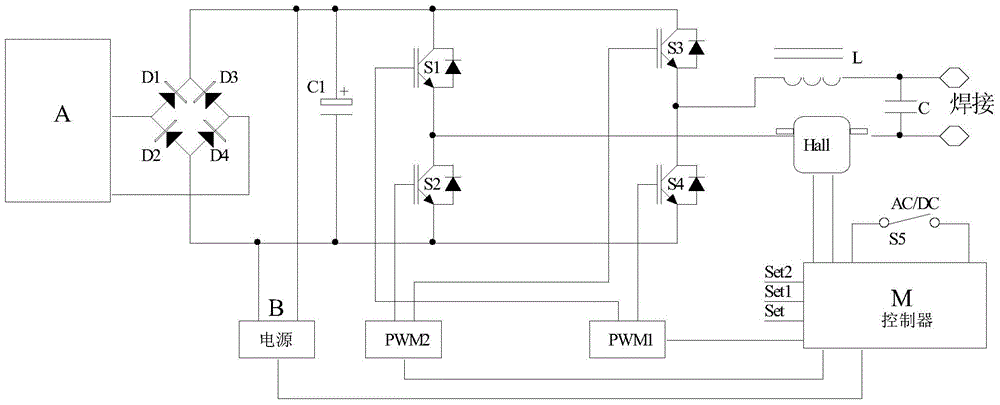

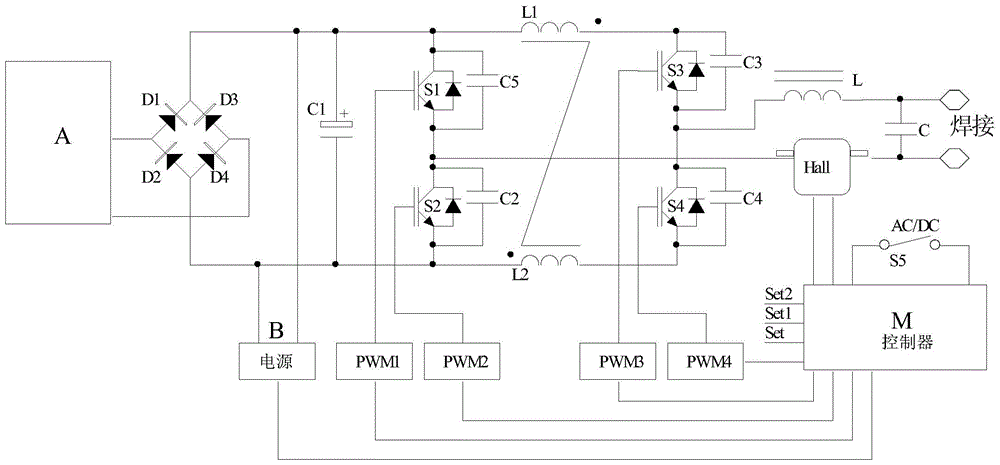

Novel DC/AC arc welding device

ActiveCN104625333AIncreased current stressSimple structureArc welding apparatusLow voltageEngineering

The invention relates to a novel DC / AC arc welding device. The DC / AC arc welding device can meet the welding technical requirements and is high in reliability and simple in structure. According to the technical scheme, the novel DC / AC arc welding device is characterized by comprising a low-voltage power supply, a bridge rectifier circuit, a bridge conversion circuit and a conversion control circuit, the output end of the low-voltage power supply is connected with the input end of the bridge rectifier circuit, the output end of the bridge rectifier circuit is connected with the input end of the bridge conversion circuit, the conversion control circuit is connected with the bridge conversion circuit and controls the bridge conversion circuit, and the output end of the conversion control circuit outputs welding current to the outside.

Owner:HANGZHOU KAIERDA ELECTRIC WELDING MACHINE

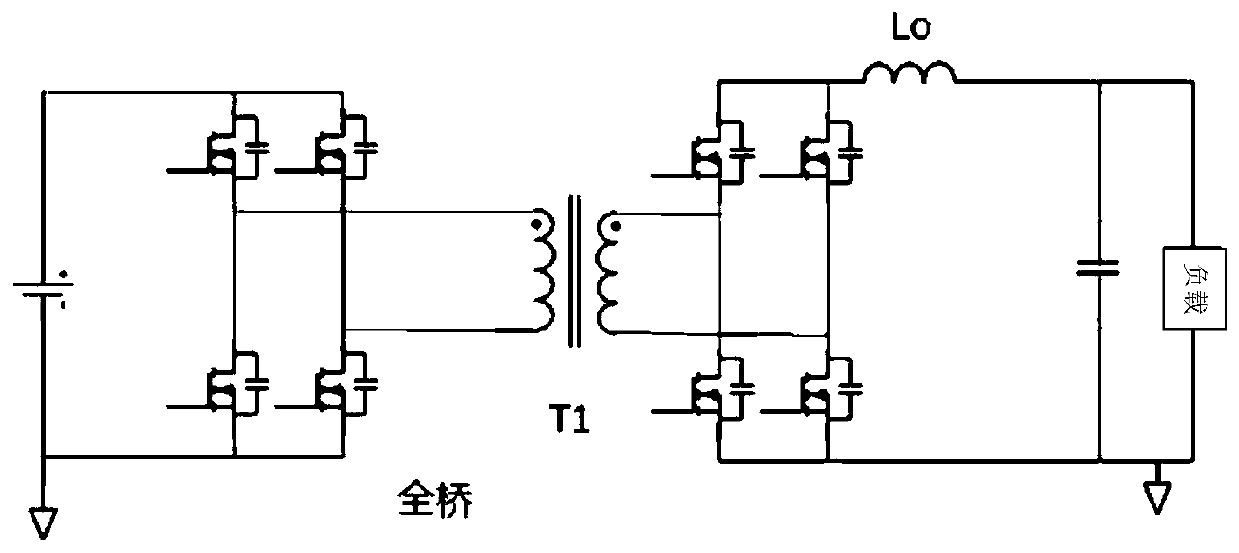

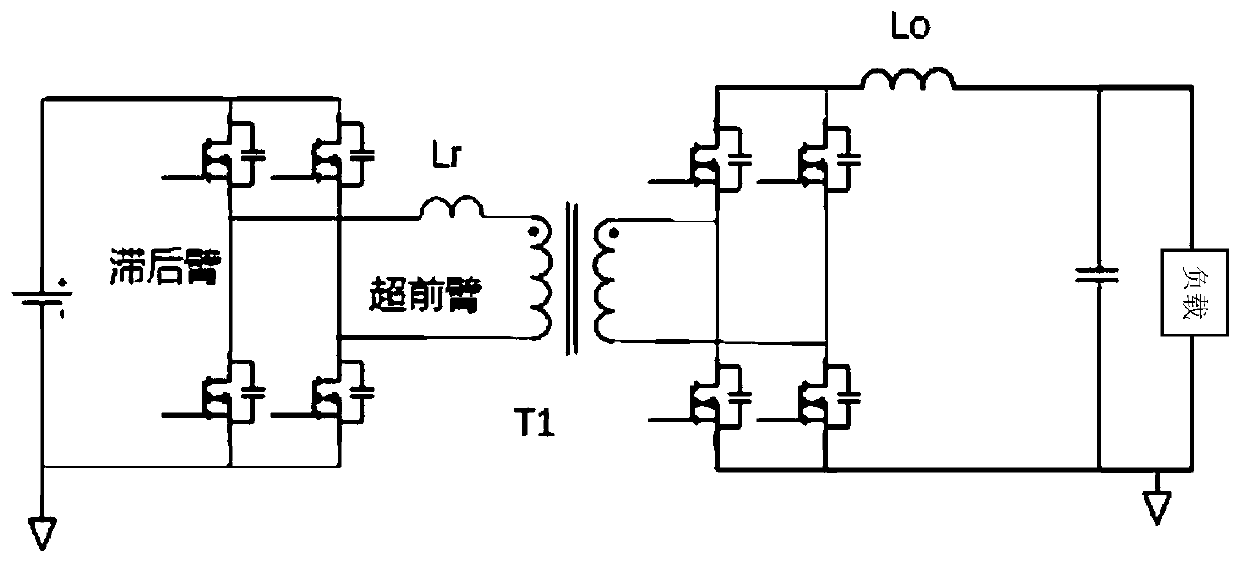

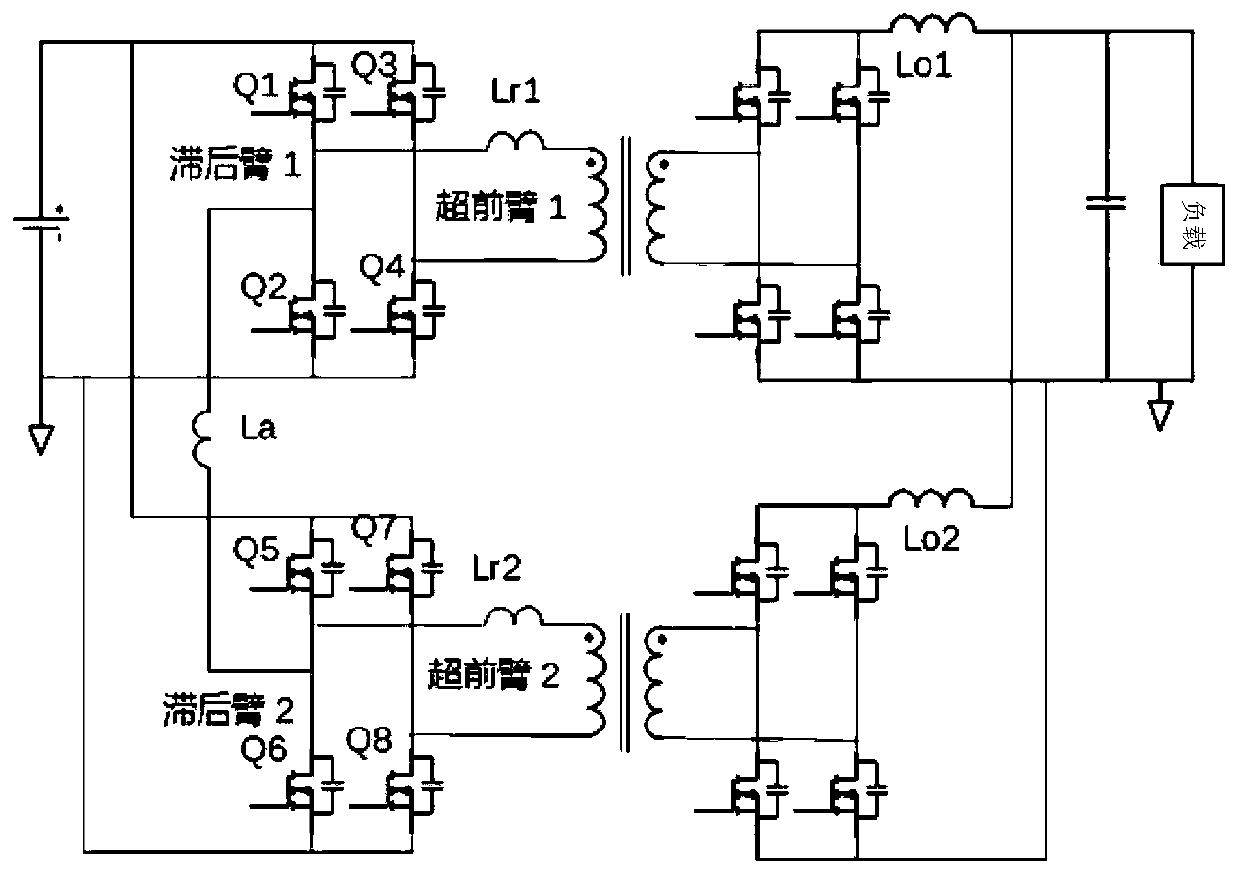

Full-bridge circuit and full-bridge converter

PendingCN111384858AFast reversing speedTroubleshooting Duty Cycle LossEfficient power electronics conversionAc-dc conversionSoft switchingFull bridge

The invention provides a full-bridge circuit and a full-bridge converter. The full-bridge circuit comprises a primary side bridge circuit, a transformer and a secondary side rectifying circuit, the primary side bridge circuit comprises a first primary side bridge circuit and a second primary side bridge circuit which are connected in parallel, and an auxiliary inductor is connected between a lagging arm of the first primary side bridge circuit and a lagging arm of the second primary side bridge circuit. According to the invention, the auxiliary inductor of which the current is not influenced by the load is connected between the two full-bridge circuits connected in parallel, so that soft switching of the lag arm can be realized under the condition of smaller inductance, and the current reversing speed is increased by reducing the inductance so as to solve the problem of duty ratio loss.

Owner:ZTE CORP

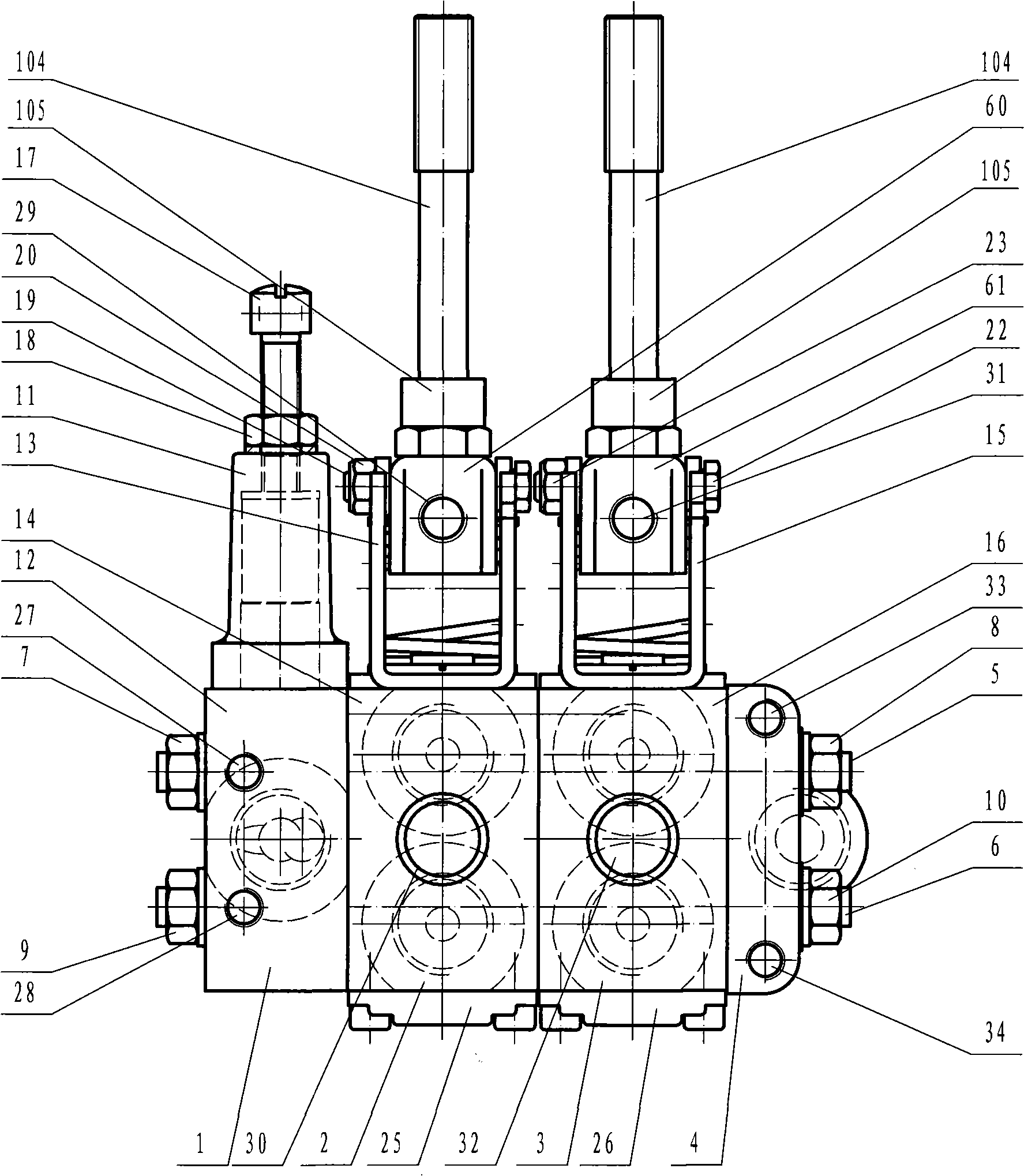

Liquid controlled multi-way valve

ActiveCN102536938BLarge outputHigh control precisionServomotor componentsEngineeringMechanical engineering

The invention relates to a liquid controlled multi-way valve which pushes a large-path multi-way valve by using oil liquid, solving the defects that manual operation is high in labor intensity and low in efficiency in the prior art. Each valve block of a valve body is correspondingly connected with respective pilot control valves; the valve blocks are connected with control ports of a hydraulic device at different working states respectively, wherein one valve block is in differential connection with a differential valve block which can increase the flow. A plurality of valve blocks are connected to form the valve body, the valve body is connected with a pilot control valve, the pilot control valve can provide a larger output force to drive the multi-way valve to change the direction, thereby reducing the labor intensity of workers; the pilot control valve is high in control precision and rapid in direction change speed, and the differential valve block is arranged in the valve body so as to increase hydraulic oil input into equipment, thereby increasing the working speed of the equipment.

Owner:梅张龙

Method for preparation of DC motor brushless commutator

InactiveCN101043115ALow costImprove reliabilityRotary current collectorDynamo-electric machinesDirect currentDC motor

The invention discloses a manufacturing method of direct current motor brushless commutator which comprises position sensing unit which provides right commutating information and switch unit which processes commutating information, the position sensing unit uses magnetic force effect and the switch unit uses mechanical contacting. The brushless commutator produced by this method possesses advantages that cost is low, reliability is high, and it is can be used in direct current motor with high rotate speed.

Owner:严密 +1

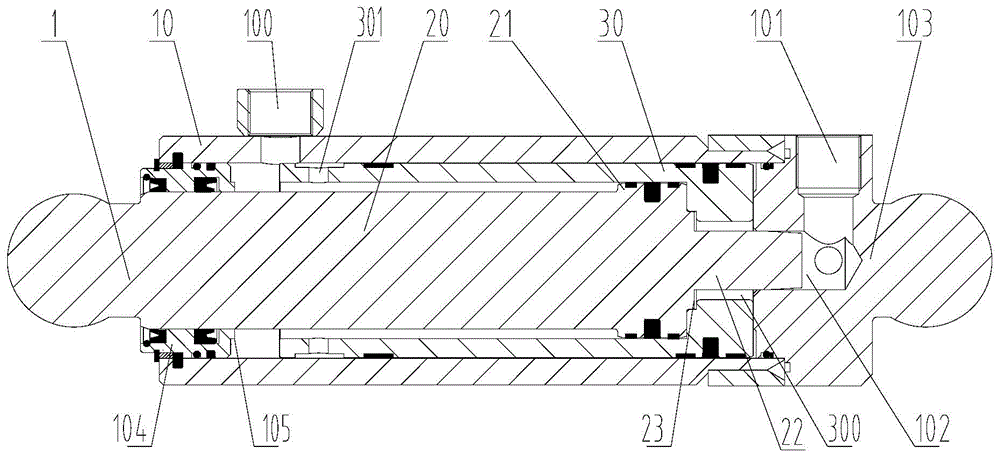

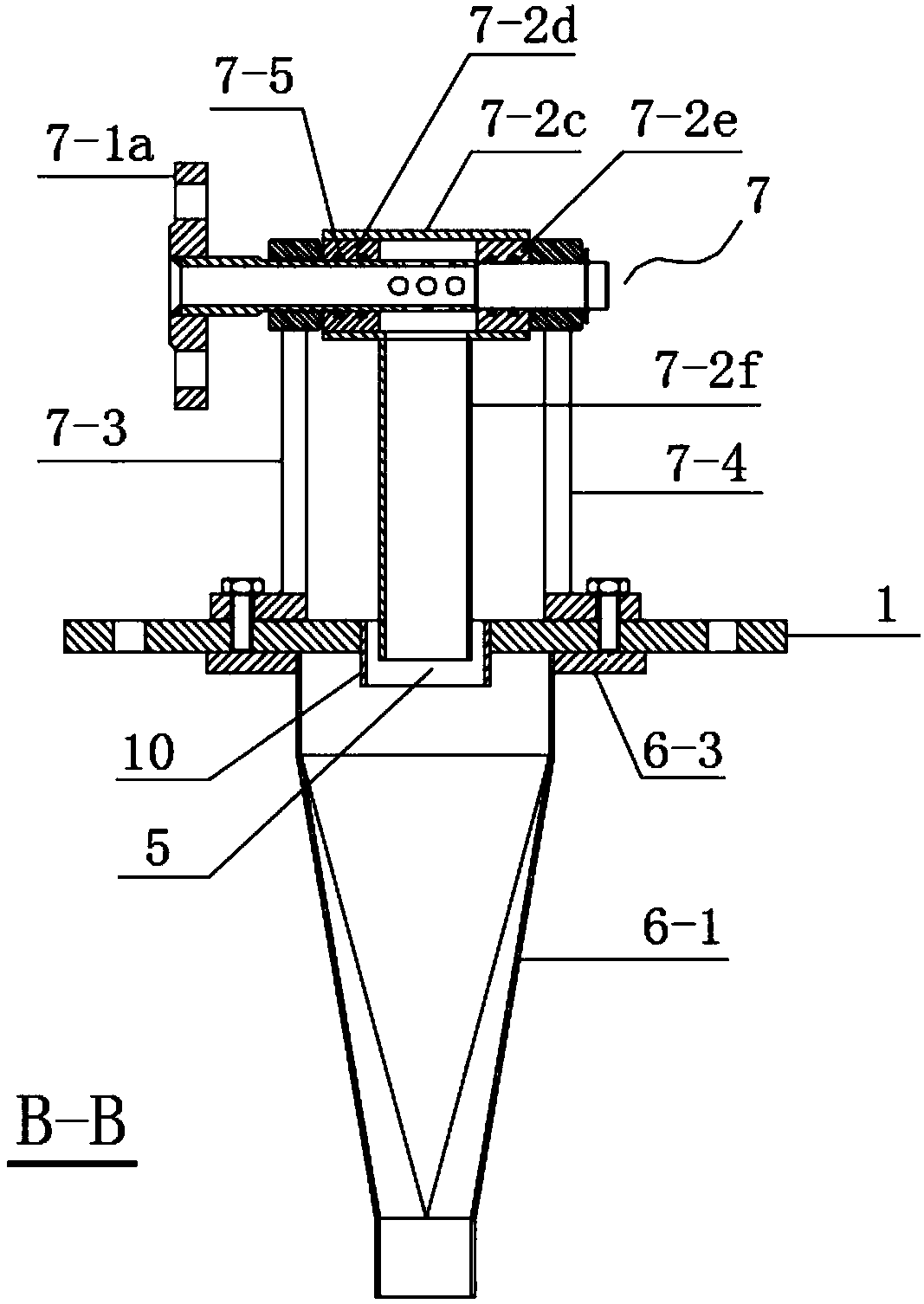

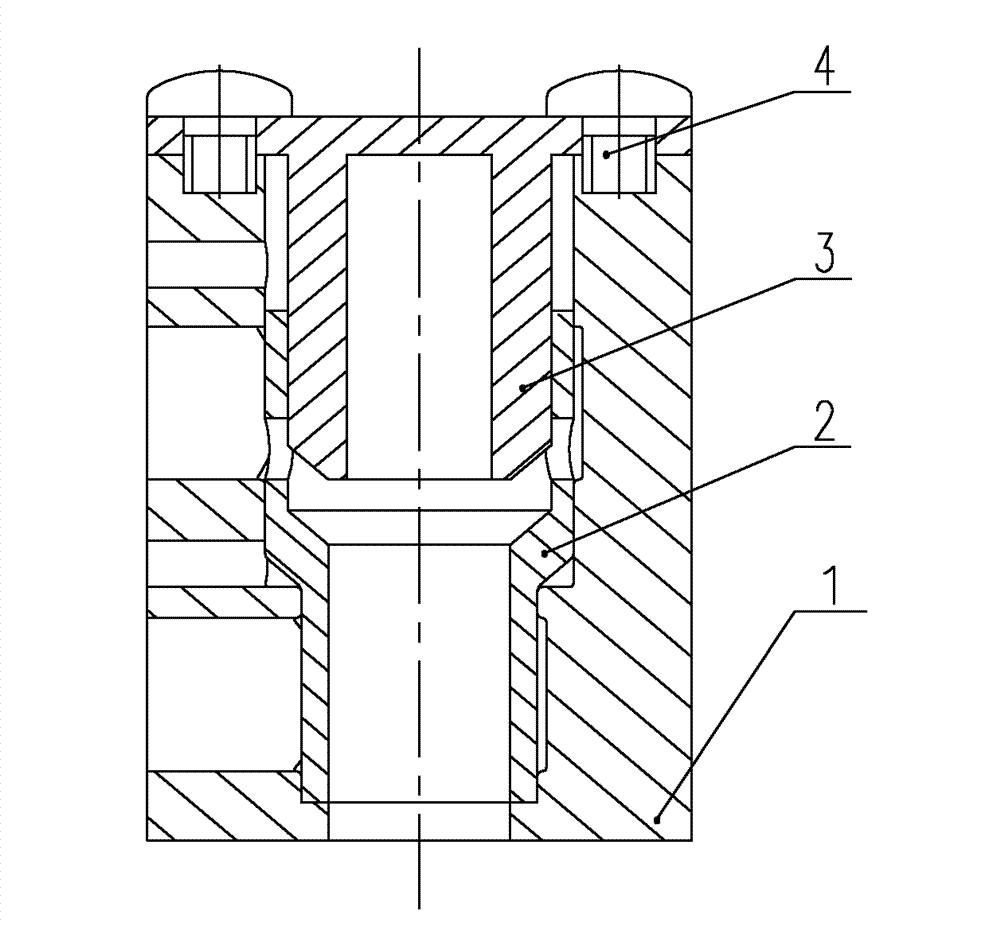

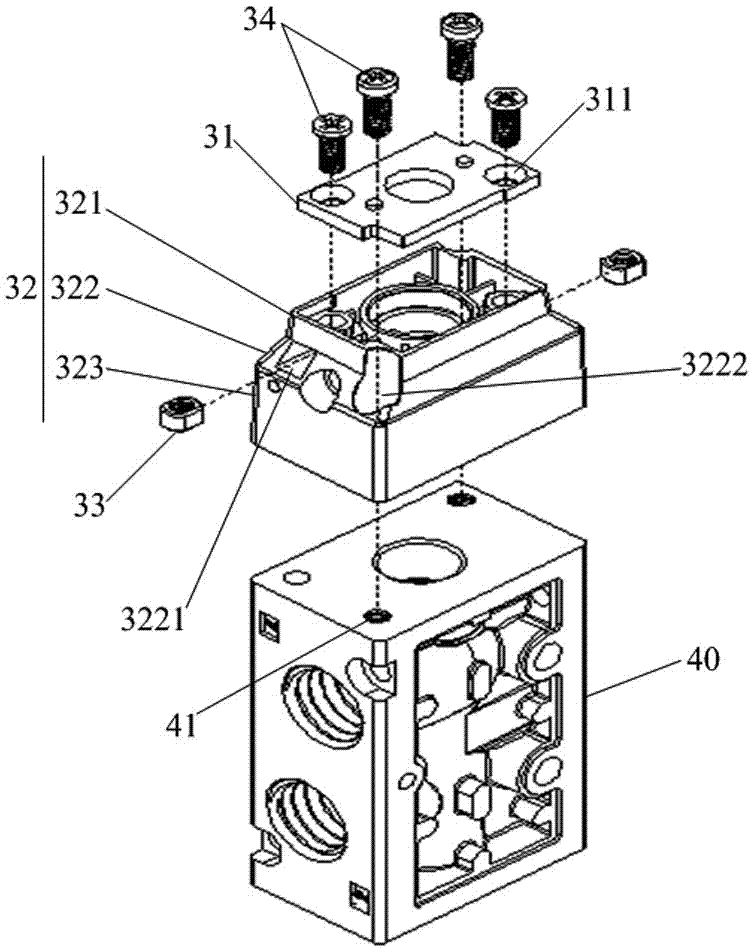

Oil distributing valve of hydraulic impactor

ActiveCN102108985BOverall small sizeEasy to manufactureServomotor componentsEngineeringHigh pressure

The invention discloses an oil distributing valve of a hydraulic impactor. A valve cavity of a valve body (1) consists of a back cavity (15) with a larger diameter and a front cavity (11) with a smaller diameter; a valve core (2) capable of sliding axially is arranged in the valve cavity of the valve body (1); the valve body (1) is provided with a first high-pressure oil opening (5), an oil return opening (7), a feedback oil opening (8), a second high-pressure oil opening (9) and a cylinder body back cavity interface (10); when the valve core (2) is far away from the cylinder body back cavityinterface (10), the oil return opening (7) and the cylinder body back cavity interface (10) are cut off by the valve core (2), and the second high-pressure oil opening (9) is communicated with the cylinder body back cavity interface (10) by the valve core (2); and when the valve core (2) is abutted on the cylinder body back cavity interface (10), the oil return opening (7) is communicated with the cylinder body back cavity interface (10) by the valve core (2), and the second high-pressure oil opening (9) and the cylinder body back cavity interface (10) are cut off by the valve core (2). The oil distributing valve of the hydraulic impactor is easy to manufacture, and is compact in structure, small in valve core volume and mass, high in reversing speed, and low in energy consumption.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

New Solenoid Valve with Screw Insert Connection

InactiveCN104847950BReduce volumeBeautiful volumeOperating means/releasing devices for valvesValve housingsSolenoid valveEngineering

The invention relates to a novel solenoid valve connected by a screw insert. The novel solenoid valve connected by the screw insert comprises a socket, a coil, a front cover, a valve body and a rear cover connected in sequence, wherein the front cover comprises a pressing plate and a frame, the frame comprises a coil frame part and a valve body frame part, the connection part between the coil frame part and the valve body frame part is the connection inclined plane, and the pressing plate is connected with the coil frame part; grooves are formed in the connection inclined plane at two positions being corresponding to the centre point, a nut is arranged in the groove, a pressing plate through hole is formed in the pressing plate corresponding to the nut, the front cover bolt is connected with the nut through the pressing plate through hole, and a guide head component is mounted in the front cover; locking through holes are formed in the connection inclined plane at another two positions corresponding to the centre point, screw holes are formed in the valve body corresponding to the locking through holes, and the front cover bolt is used for connecting the front cover to the valve body through the locking through holes. The novel solenoid valve connected by the screw insert is smaller in product size, beautiful, and fast in reversing speed; the power consumption is low, the consumption is saved, the use cost is reduced for meeting national energy conservation and emission reduction requirements.

Owner:ZHEJIANG EASUN PNEUMATIC SCI & TECH

Thin substrate processing device

ActiveUS10370757B2Control damageLimited adhesionElectric discharge tubesVacuum evaporation coatingOptoelectronics

A thin substrate processing device include a substrate processing unit configured to process a thin substrate, and a cooling unit configured to cool the thin substrate when the substrate processing unit is processing the thin substrate.

Owner:ULVAC INC

Fast hydraulic change-over valve

ActiveCN101737370BFast resetReduce movement distanceOperating means/releasing devices for valvesServomotor componentsEngineeringThrottle

The invention discloses a fast hydraulic change-over valve which comprises a valve body, a sleeve and a valve core; the valve core is arranged in the valve hole of the valve body; one end of the valve body is provided with an external thread and connected with the thread of the sleeve; the sleeve is provided with a spring cavity, the spring cavity is internally provided with a spring, and the spring is also arranged in the valve hole and contacted with the valve core; the wall of the valve body is provided with an oil inlet cavity, a working oil cavity and an returning cavity which are all communicated with the valve hole and arranged in sequence along the direction from the end provided with the external thread to the other end far away from the external thread; the valve core is provided with blind holes along the central axis of the valve core beginning from the end face opposite to the spring cavity; the shaft neck of the valve core is provided with radial holes communicated with the blind holes, the entrances of the blind holes are in thread connection with damping thread plugs, and the damping thread plugs are internally provided with throttle holes. The invention has the advantages that the valve core can be fast reset, and has short motion distance during resetting; the requirement on rigidity of the spring is low, and the valve core opening speed is accelerated; the volume of the control cavity is reduced, and the valve core has fast change-over speed; the structure is simple, the assembly and disassembly are convenient, and the assembly space is saved efficiently.

Owner:ZHEJIANG UNIV

A conveying device for truss loading

ActiveCN109051695BMeet the commutation requirementsCompact structureConveyor partsStructural engineeringConveyor belt

Owner:芜湖固高自动化技术有限公司

Method for preparation of DC motor brushless commutator

InactiveCN101043115BLow costImprove reliabilityRotary current collectorDynamo-electric machinesDirect currentDC motor

The invention discloses a manufacturing method of direct current motor brushless commutator which comprises position sensing unit which provides right commutating information and switch unit which processes commutating information, the position sensing unit uses magnetic force effect and the switch unit uses mechanical contacting. The brushless commutator produced by this method possesses advantages that cost is low, reliability is high, and it is can be used in direct current motor with high rotate speed.

Owner:严密 +1

Electrohydraulic servo oil cylinder and numerical control machine tool using same

InactiveCN100451355CServo follow-up motion with high precisionHigh precisionOperating means/releasing devices for valvesServomotor componentsSpool valveControl system

The invention relates to an electro-hydraulic servo cylinder, comprising a four-edge sliding valve whose base is mounted with a valve element moving left and right. The valve base is fixed on the cylinder whose piston rod is fixed with the frame; the cylinder is connected with the load. The left driving chamber via tube is communicated with the left working chamber, while the right driving chamber via tube is communicated with the right working chamber; one end of valve element is engaged with the dial block mounted on the straight motion output element of straight motion output device. The digit-control machine with said electro-hydraulic servo cylinder comprises a first axle servo driving system, a second axle servo driving system, a third axle servo driving system and a digit-control system, wherein, the second driving system comprises a straight load axle. The invention has high accuracy, quick steering speed, and stable property, which combines the digit control technique with the electro-hydraulic servo motion, with high accuracy in large power.

Owner:路文忠

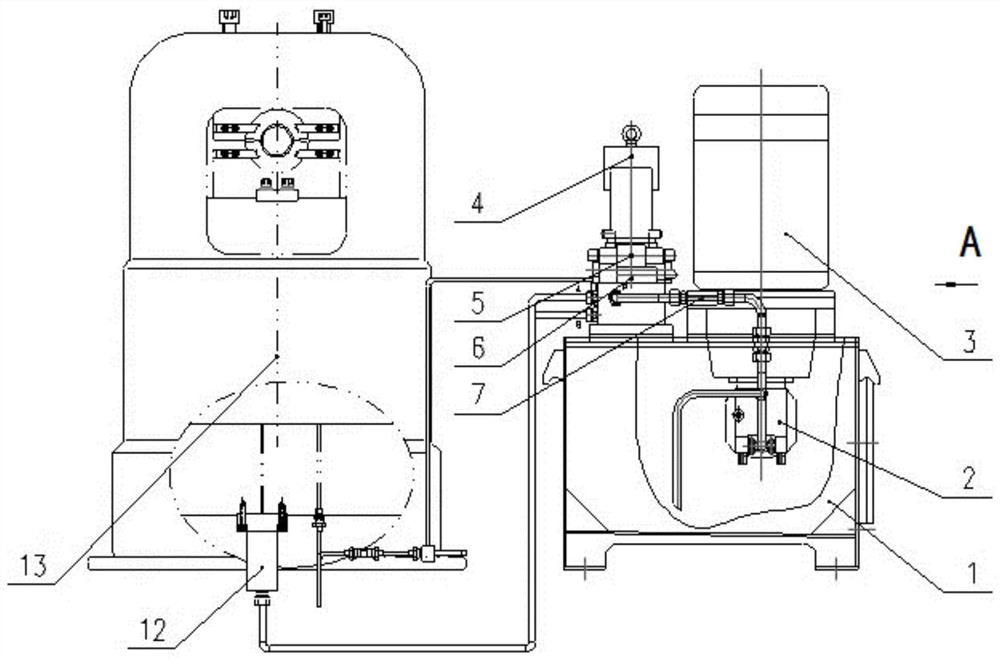

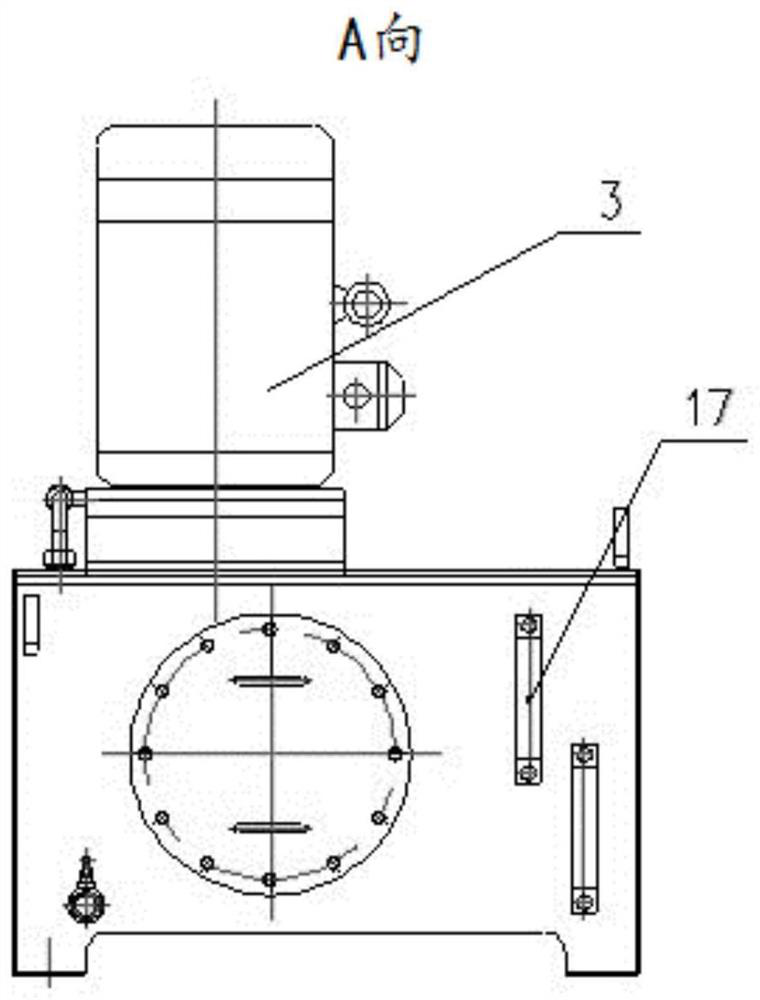

An ultra-high pressure small hydraulic press system

ActiveCN112140613BSmall form factorReduce weightFluid-pressure actuatorsPress ramUltra high pressureHydraulic pump

The invention provides an ultra-high pressure small hydraulic press system, which mainly includes an oil tank (1), a hydraulic pump (2), a motor (3), a pressure filter (4), an electromagnetic reversing valve (5), a relief valve ( 6), a one-way valve (7), a hose (11), a booster (12) and an oil cylinder (13), characterized in that the oil suction port of the hydraulic pump (2) is connected to the oil tank (1). ) connection, the oil cylinder (13) includes a cylinder barrel (1301), a plunger (1306), a cylinder head plate (1307), an inner snap ring (1308) and a base (1309), the supercharger (12) The oil outlet HP of ) is connected to the cylinder head plate (1307) of the oil cylinder (13) through a flange, and is connected to the rodless cavity of the oil cylinder (13) through the pressure hole of the cylinder head plate (1307). The ultra-high pressure small hydraulic press system of the present invention can provide continuous ultra-high hydraulic pressure and realize functions such as stepless pressurization, pressure maintenance at any time, and safe pressure relief. The oil cylinder is small in size, light in weight and easy to carry, and provides a pressing force for the pressing joint of the wire rope rigging.

Owner:SHANGHAI MARINE EQUIP RES INST

Control device for electric wheelchair with dual motor coordinated control

InactiveCN104881055BHighlight substantive featuresWith CAN communication functionDC motor speed/torque controlSpeed/accelaration control using electric meansMotor driveWheelchair

The invention relates to a dual-motor coordination control electric wheelchair control device, and relates to a motor driving wheelchair; the electric wheelchair control device comprises a controller, a manual operator, a storage battery and motors; a connecting mode of the parts are that one end of the manual operator is connected with the controller through a relay, and the other end of the manual operator is connected with the storage battery; the controller and the manual operator communicate through CAN; an output end of the controller is connected with the motors; the storage battery provides power for the controller, the manual operator and the motors; the brushless DC motors are employed, a double-wheel coordination differential velocity control method is used, and a feedback compensation mode enables the wheelchair to keep left and right wheels in synchronization in operation, so the wheelchair is stable in motion, thus solving the problems in the prior art that a brush DC motor is slow in commutation speed, large in noise, and the motor is easy to be damaged in long term wearing state of the motor, and solving the disadvantages in the prior art that a conventional electric wheelchair is unstable in motion process and left and right wheel driving are not in synchronization.

Owner:HEBEI UNIV OF TECH

A pressing and reversing equipment for soft bag packaging

Owner:广州市万世德智能装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com