Fast hydraulic change-over valve

A reversing valve and hydraulic technology, applied in the field of hydraulic control, can solve the problems of slowing down the opening speed of the hydraulic reversing valve, increasing the spring force of the hydraulic reversing valve, and long reset time, so as to save installation space and reduce The effect of spring force and fast return speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

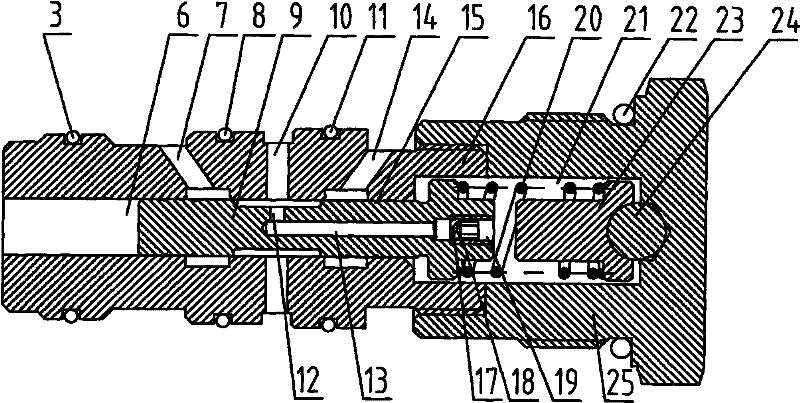

[0021] Such as figure 1 , Figure 4 , Figure 5 As shown, the quick hydraulic reversing valve of the present invention mainly includes a valve body 16 and a sleeve 25 . One end of valve body 16 is shaped on external thread (in Figure 1 to Figure 3 Among them, the external thread is at the right end of the valve body 16), the inside of the sleeve 25 is correspondingly processed with a groove and an internal thread is formed in the groove, so that the valve body 16 and the sleeve 25 are threadedly connected, and the valve body 16 The end face that is shaped on one end of external thread is close to the groove face of sleeve 25. A through hole is set inside the valve body 16 as the valve hole 6, and the valve core 9 is installed in the valve hole 6. The inner diameter of the valve hole 6 is matched with the outer diameter of the valve core 9. When the hydraulic control reversing valve is working, the valve The core 9 reciprocates left and right in the valve hole 6 to realize...

Embodiment 2

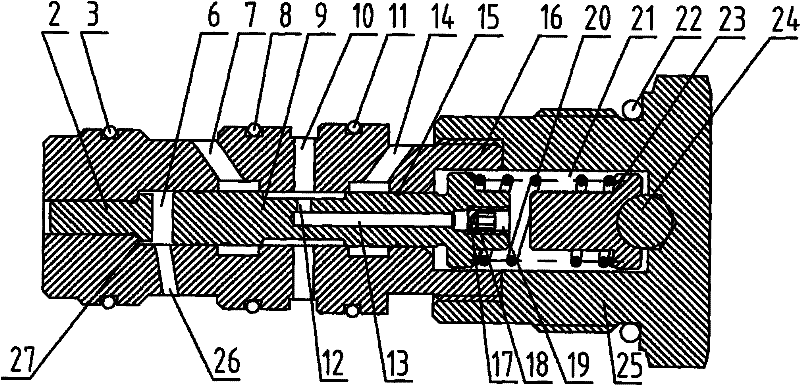

[0024] Such as figure 2 As shown, the end of the valve hole 6 away from the external thread (in figure 2 , that is, the left end of the valve hole 6) is stepped, and the stepped surface 27 of the valve hole 6 divides the end valve hole 6 into two parts. Among them, such as figure 2 As shown, the inner diameter of the valve hole on the left side of the stepped surface 27 is smaller than the inner diameter of the valve hole on the right side of the stepped surface 27, and a control push rod 2 is built in the valve hole on the left side of the stepped surface 27. The control push rod 2 is in clearance fit with this part of the valve hole 6; the inner diameter of the valve hole on the right side of the stepped surface 27 is larger, and a valve core 9 is built in it. As a preferred embodiment of the present invention, the control push rod 2 is also provided with a shoulder, which is located in the valve hole on the right side of the stepped surface 27, and the shoulder portion...

Embodiment 3

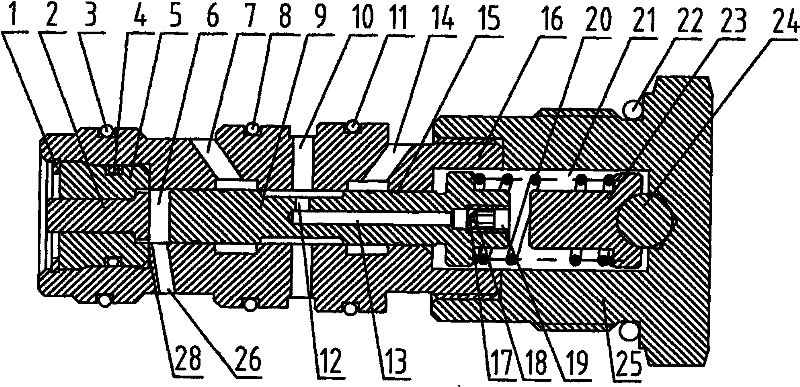

[0026] Such as image 3 As shown, further, at the end of the valve body 16 away from the external thread (in image 3 , which is the left end of the valve hole 6) is provided with a counterbore, and a support guide sleeve 5 is sealed and fixed on the inner wall of the counterbore. The center hole of the support guide sleeve 5 communicates with the valve hole 6 and is coaxial, and the support guide sleeve The center hole of 5 has a built-in control push rod 2, and the control push rod 2 is matched with the center hole of the support guide sleeve 5. When installing, the control push rod 2 is put into the center hole of the support guide sleeve 5 and integrated into the valve body. In the counterbore of 16, circlip 1 is installed on the outside of support guide sleeve 5, is used for fixing support guide sleeve 5, prevents loosening, and O type ring 4 is housed on the support guide sleeve, is used for sealing oil. On the wall of the valve body 16, there is also an oil drain cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com