A conveying device for truss loading

The technology of a conveying device and a truss is applied in the field of conveying devices for truss loading to achieve the effects of improving loading efficiency, simple and compact structure, and fast reversing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the technical solution of the present invention will be described in detail through specific examples.

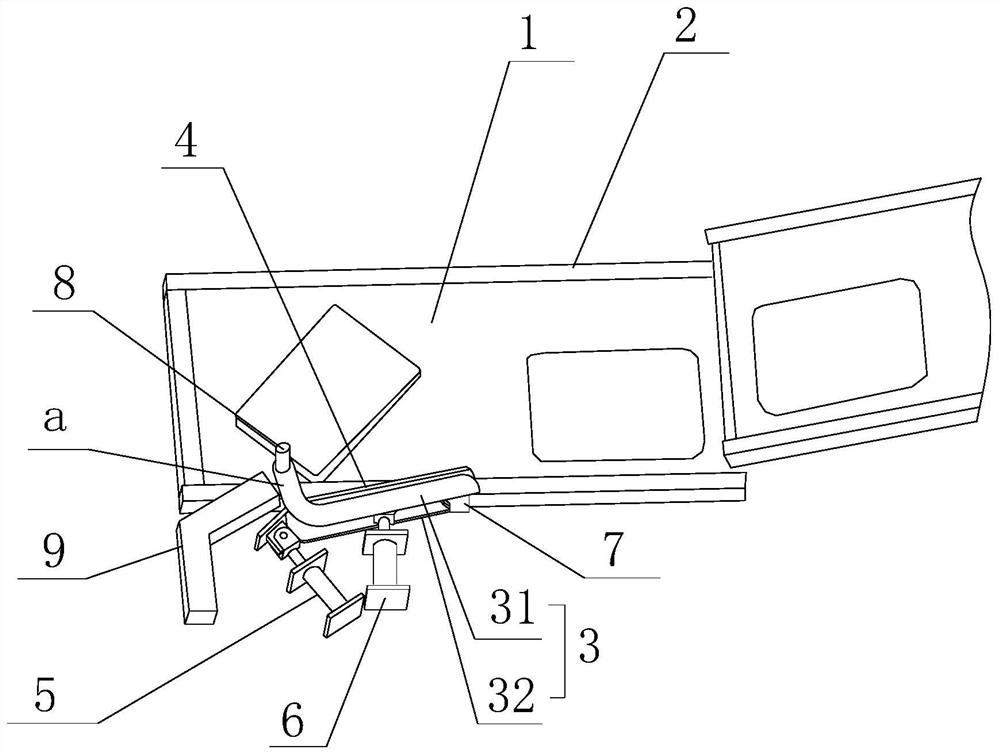

[0019] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a conveying device for truss loading proposed by the present invention.

[0020] refer to figure 1 , a conveying device for truss loading proposed by an embodiment of the present invention, comprising: a conveyor belt 1, guard plates 2 located on both sides of the conveyor belt 1, and a driving mechanism for driving the conveyor belt 1 to carry out the conveying action, wherein: one side of the conveyor belt 1 A reversing baffle plate 3, a push plate 4, a first power mechanism 5 and a second power mechanism 6 are provided.

[0021] The place face of reversing baffle 3 is positioned at the top of conveyor belt 1 conveying surface, and reversing baffle 3 comprises upper baffle 31 and lower baffle 32, and upper baffle 31 and lower baffle 32 are arranged up and down and pre-set b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com