Double-channel air channel reversing device

A reversing device and dual-channel technology, applied in the direction of fluid pressure actuators, servo motor components, fluid pressure actuation system components, etc., can solve the problems of multiple pipelines, scattered and complex structures, and complicated control methods, and achieve improved Sound-absorbing effect, improving performance stability and reliability, and facilitating layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

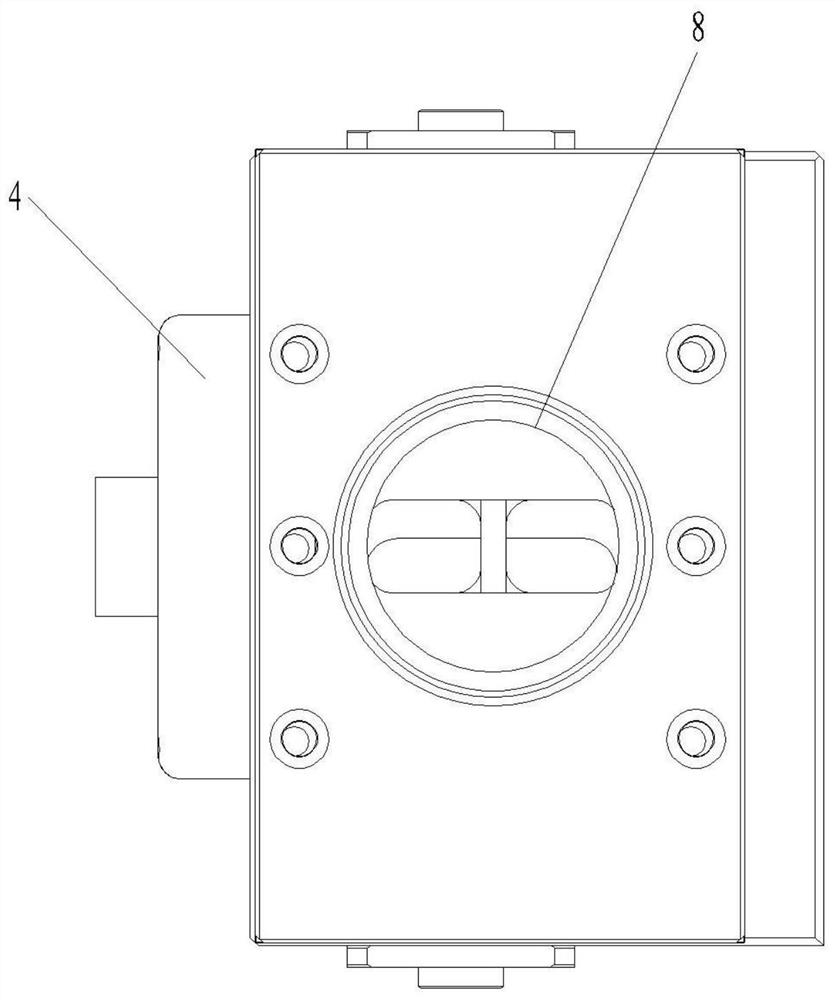

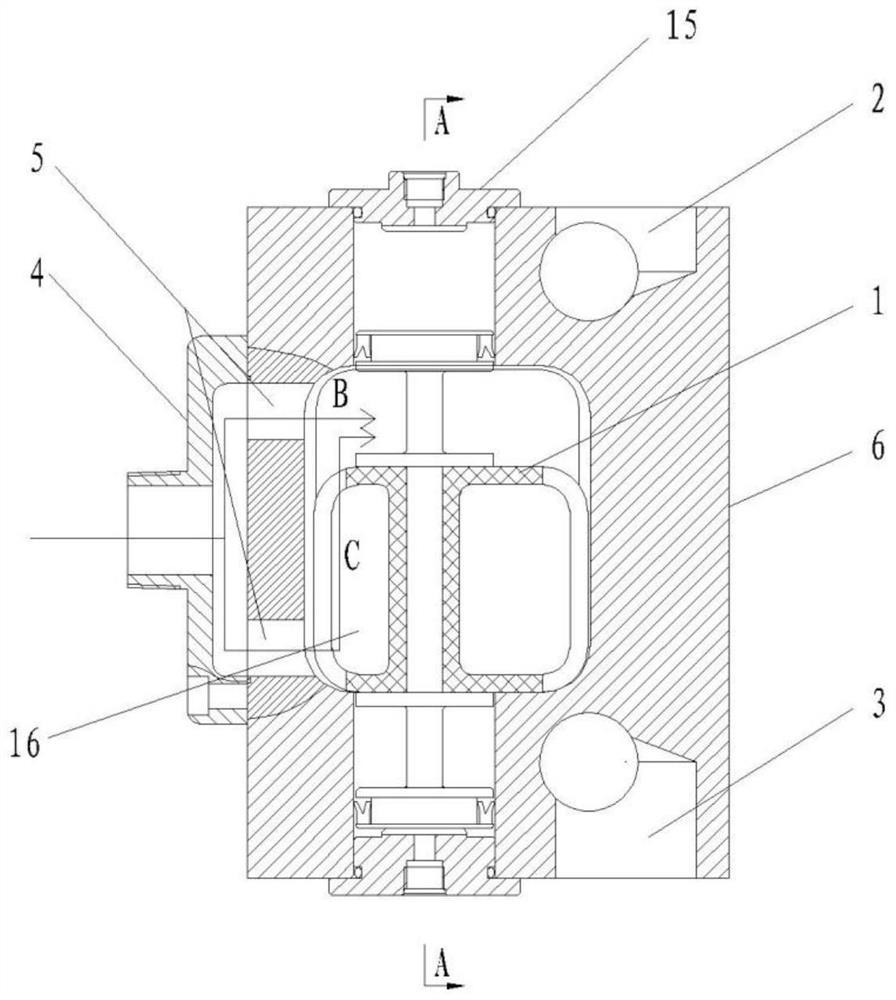

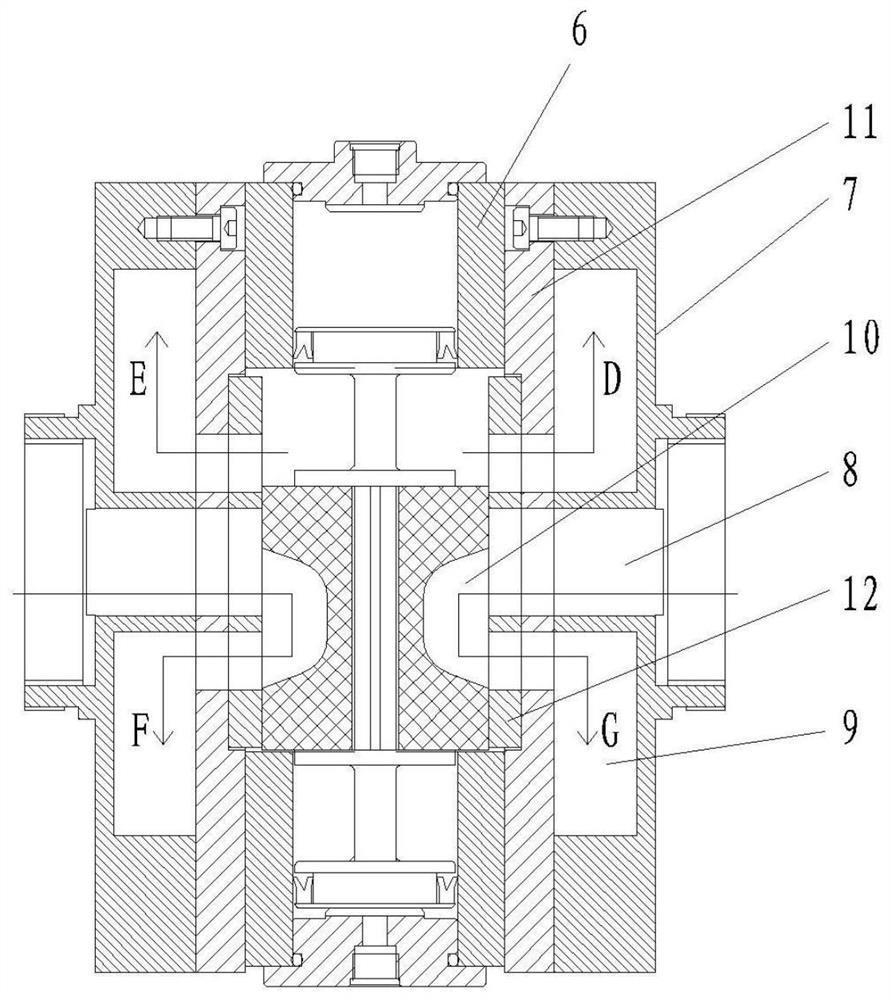

[0027]As shown, the present embodiment provides a dual-channel airway commutation device including a commutation assembly and a commutating piston 1, which is slidably mounted in the inner cavity of the commutation assembly, the commutation The assembly is opened with a carrying airway I2, a gas passage II3, a gas passage, and an air passage that communicates with its inner cavity. The air channel I2 and the air passage II3 are respectively used to communicate with the cylinder chamber and the lower chamber. The switching piston has at least two sliding positions and forms two air path states; state one: connect the air passage and the input air channel I2, and connect the air passage II3 and the air passage; state 2: The gas absorbing channel is connected to the air channel II3 and the air passage I2 is in communication with the air passage. CombineFigure 1 to 3 As shown, the commutation assembly has a vertically opened up and down channel, and the upper and lower end cover of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com