SNCR (Selective Non-Catalytic Reduction) denitration wall jet apparatus

An injector and denitrification technology, which is applied in the field of SNCR denitrification wall injectors, can solve problems such as difficulty in meeting environmental protection requirements, and achieve the effects of meeting reversing requirements, reducing the size of the gun body, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

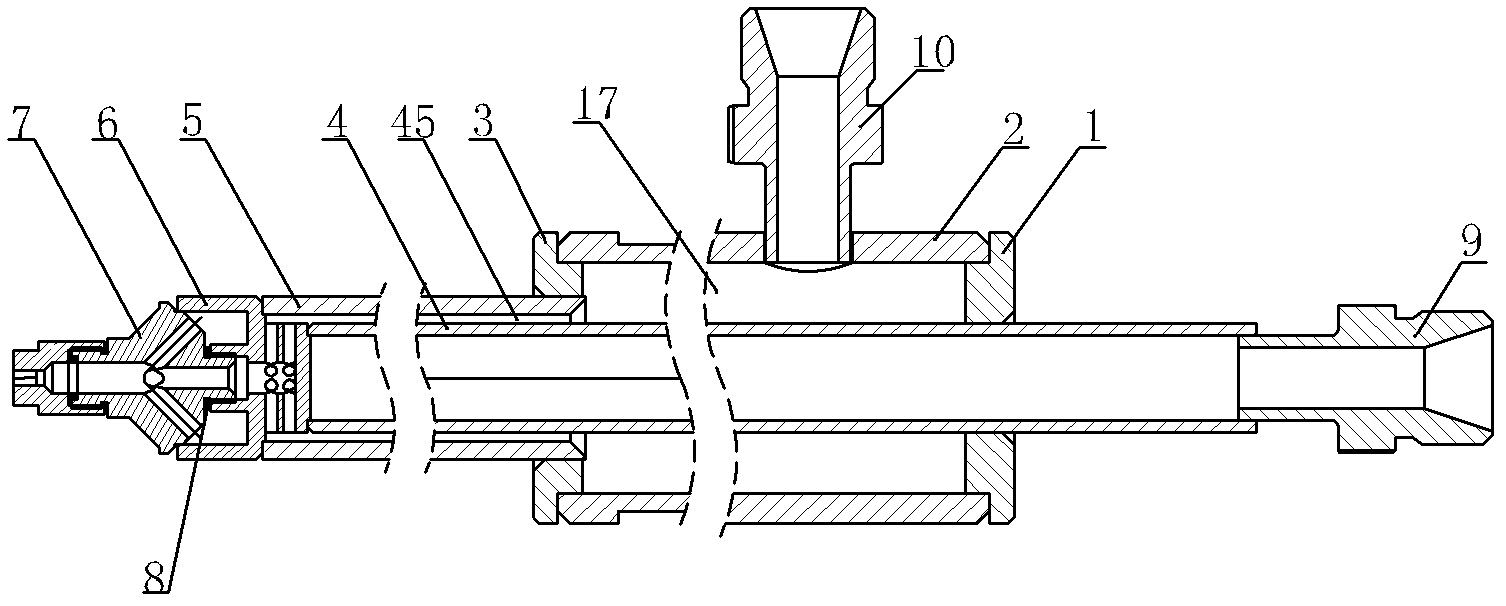

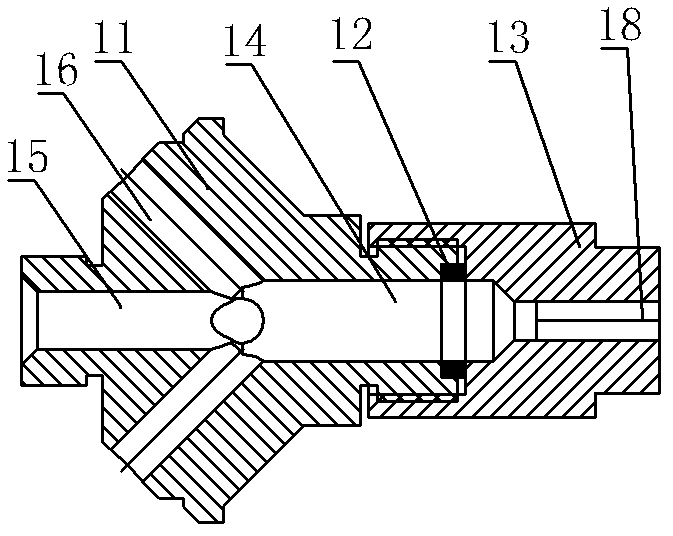

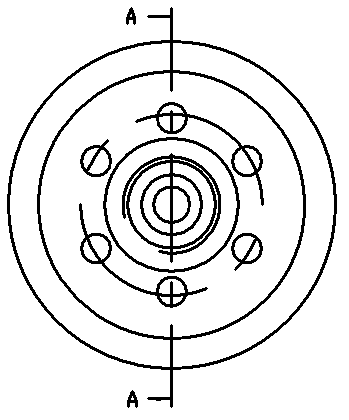

[0031] figure 1 It is a structural diagram of the SNCR denitration wall injector of the present invention, including a gun body and a nozzle. The gun body consists of an air pipe 4, a urea pipe 5, a reversing head 6, a reversing gasket 8, an air joint 9, a urea water joint 10 and The regulating tube is composed of the rear blocking plate 1, the collecting pipe 2 and the front blocking plate 3. The air tube 4 is located in the center of the gun body, and the urea water ring cavity 45 is formed between the air tube 4 and the urea tube 5. The gun body is connected to the pneumatic propeller through the manifold 2, and the manifold 2 is designed with slots at different positions, which can realize The position of the wall injector protruding into the furnace is adjustable. The nozzle assembly 7 adopts a Y-shaped pneumatic fan nozzle. The structure of the nozzle and the angle of the diversion groove can be configured according to the distribution of the flue gas flow field.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com