A kind of flow booster reversing valve

A technology of flow boosting and reversing valves, which is applied in the field of hydraulic devices, can solve the problems of insufficient liquid flow response and insufficient reversing effects, and achieve the requirements of reversing, simple structure, and large reversing force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

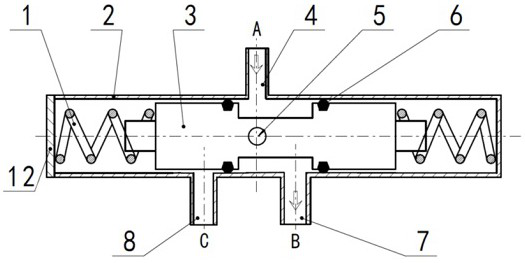

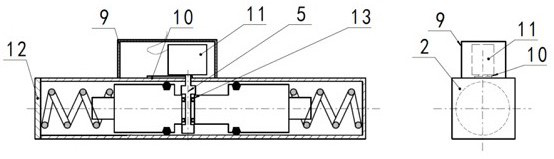

[0024] Bonded below Figure 1-5 And the embodiments are further described in detail in the present invention:

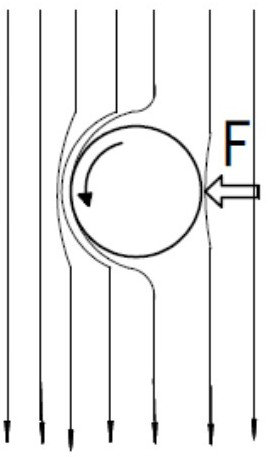

[0025] A flow boost-type commutation valve comprising a valve body 2, a valve stem 3, a hydraulic pilot lever 5, and a rotating electric machine 11; two sides of the valve body 2 having a rectangular curved valve body for cancel the current reset The reset spring 1; the side surface of the valve body 2 is also mounted for the valve body cover 12 of the valve body 2, and the valve body cover 12 and the valve body 2 are attached to the valve body 2; the valve body 2 is also attached to the motor cover 9 for closure valve body. The liquid in the 2nd there is an outlet of the power supply line in the motor cover 9, and the motor cover 9 also protects the rotary electric machine 10; the rotary electric machine 11 is connected by the power supply line, because the motor cover 9 during operation The fluid is filled with liquid, so the rotary electric machine 10 employs a motor t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com